1. Introduction

Whether in traditional collector stations or new power stations, issues such as equipment aging and electromagnetic interference can arise, potentially leading to the failure of existing relay protection systems. Through potential fault monitoring, potential issues in the collector lines can be identified in a timely manner, preventing equipment damage and improving operational reliability.

The development of potential fault monitoring technology has progressed from manual processes to digital intelligence. In the early stages, collector stations mainly relied on manual inspections and periodic maintenance, using simple instrument measurements and visual observations to identify potential faults. This approach often led to delays and incomplete problem detection, resulting in economic losses. With technological advancements, some single-point monitoring technologies, such as temperature sensors and current transformers, were gradually introduced, significantly improving the monitoring level for specific components. However, they still had limitations in providing a comprehensive view. Subsequently, multi-parameter comprehensive monitoring technologies emerged, capable of simultaneously detecting parameters such as current, voltage, and power. These technologies further branched into infrared thermal imaging for quickly identifying overheating, acoustic detection technology for monitoring mechanical components, and chemical analysis and oil quality detection for assessing internal chemical changes and the quality of lubricants. The three aforementioned methods are currently the mainstream approaches for potential fault detection. This paper will discuss each method's principles, advantages, disadvantages, and development trends in detail, providing a comparative analysis in table form. Additionally, due to the widespread application of wind energy, diagnosing potential faults in doubly-fed generators has become crucial. This paper will also provide an in-depth discussion of mainstream methods for diagnosing sensor faults in converters, with a comparative analysis in table form.

2. Infrared Thermal Imaging Technology

Infrared thermal imaging technology holds significant value in detecting potential faults in collector stations. Emmanuel Resendiz-Ochoa suggests that infrared thermal imaging is a supplementary technology for monitoring motor conditions in recent years, characterized by its non-invasive and non-destructive nature. Different types of faults can induce varying thermal effects on system components, resulting in distinct heat distributions[1]. This technology operates by detecting infrared energy emitted from objects and converting it into visible thermal images.

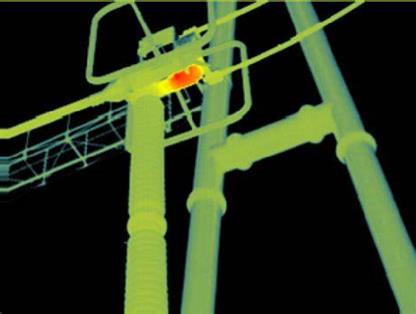

Infrared thermal imaging technology generates thermal images, and potential faults can be identified by observing abnormalities in the images. The focus is on temperature distribution, changes in temperature gradients, and critical equipment components such as joints, contacts, and transformer windings. If there is an abnormally high or low localized temperature, differing significantly from the normal temperature distribution, or if there is an unusual gradient change on the surface or between components, it can be inferred that there may be a fault. As illustrated in Figure 1, if a sudden high-temperature point appears in an otherwise uniformly heated circuit, the fault and its location can be identified.

Figure 1. A localized high-temperature point in a substation

In collector stations, infrared thermal imaging not only detects thermal anomalies in equipment but can also detect insulation failures. P. Rajamani states that power transformers are critical components of power systems, and insulation failure has long been considered one of the primary causes of transformer faults[2]. The temperature distribution of insulation material should be relatively uniform during normal operation. When insulation faults occur, such as partial discharge or mechanical stress, they can cause current leakage and increased resistance, leading to localized overheating and abnormal temperature readings. For instance, insulation faults inside power transformers can result in localized overheating. Infrared thermal imaging can detect abnormal temperature areas on the transformer's surface, which may indicate internal insulation issues.

Infrared thermal imaging enables non-contact, rapid, large-area scanning of equipment, promptly identifying abnormal temperature zones. Compared to traditional detection methods, it offers the advantages of speed, efficiency, and visual clarity. However, challenges remain in applying infrared thermal imaging in collector stations. Environmental factors such as temperature, humidity, and wind speed can interfere with the results. Therefore, improving accuracy is essential. In addition to regular equipment calibration and maintenance, efforts should be made to control environmental influences during detection. For unavoidable environmental factors, compensation algorithms should be applied to correct the measurements. Additionally, inspections should be conducted from multiple angles and positions to obtain comprehensive thermal distribution information, reducing detection blind spots and misjudgments. Combining this data with other electrical parameters can significantly improve fault diagnosis accuracy.

In the future, infrared thermal imaging technology will become more intelligent and automated. By integrating image analysis algorithms and deep learning, it will be possible to automatically identify and extract key features from thermal images. With the help of extensive training data, potential fault patterns can be recognized, and even new types of faults can be discovered. This will reduce reliance on human experience and enhance the safety and stability of collector stations.

3. Vibration Analysis and Acoustic Detection Technology

Electrical equipment in collector stations consists of various components, and during operation, both external conditions and internal factors can cause slight repetitive movements, which fall under mechanical motion[3-4]. Liao Jing proposed a live detection method using beamforming for potential fault monitoring of high-voltage AC-DC hybrid network cables. This method is based on acoustic detection technology, aiming to quickly locate fault sound sources by processing the acoustic signals received by the array[5]. In collector stations, vibration analysis and acoustic detection can be employed to monitor and diagnose the state of electrical equipment, allowing for the identification of potential faults. Vibration analysis technology involves installing vibration sensors on equipment to measure signals such as vibration frequency, amplitude, and phase. Time-domain analysis, frequency-domain analysis, and time-frequency-domain analysis are conducted to understand the equipment's motion state and structural characteristics. When a specific component malfunctions, its vibration characteristics often show significant changes at a certain frequency. By comparing these changes with normal conditions, the type and severity of the fault can be determined. Additionally, when abnormalities occur within electrical equipment, they produce sound waves. Acoustic sensors can capture these sound waves, and different types of faults produce distinct acoustic signatures. Through spectrum analysis and time-domain waveform analysis of the received sound signals, the type and location of the fault can also be determined. If multiple acoustic sensors are arranged in an array, the time differences of sound waves arriving at different sensors can be used for sound source localization, allowing for more accurate identification of the specific location of the fault.

The presence of various operational noises from equipment in collector stations may mask or interfere with the vibration and sound wave signals generated by faults, leading to misjudgments or difficulty in accurately identifying faults. Moreover, vibration and sound waves attenuate during propagation, especially in large collector stations, where signals can weaken over long distances, affecting measurement accuracy. Additionally, the complexity of equipment in collector stations may result in multiple simultaneous sources of vibration and sound waves, making the analysis of a single fault source challenging. To improve the accuracy of vibration analysis and acoustic detection, certain measures are necessary. Xiao Yi et al. adopted a wavelet transform method to convert recorded speech signals into speech feature sequences and used filters for noise suppression, which enhanced the accuracy of automatic speech recognition[6]. Similarly, signal processing techniques such as wavelet transform and digital filtering can be applied to suppress noise in collector station equipment operation. Considering the attenuation of vibration signals during propagation, sensor networks should be reasonably arranged, and signal amplifiers should be used to reduce the impact of signal propagation attenuation, enhancing the ability to detect weak signals. The Institute of Acoustics at the Chinese Academy of Sciences proposed a method for separating aliased bird sounds using spatial matrix filtering based on an acoustic sensor array[7]. Similarly, in collector stations, this separation technology can be used to separate multi-source signals into individual source signals, making accurate analysis easier.

Building on the current foundation, vibration analysis and acoustic detection technology are expected to evolve towards miniaturization, integration, and intelligence. Miniaturized and integrated sensors are easier to install at key positions within electrical equipment, reducing the impact on normal equipment operation. Additionally, selecting deep learning models such as convolutional neural networks (CNNs) and using pre-built datasets for model training, along with adjusting model parameters, can enhance accuracy and achieve intelligent detection of potential faults in collector stations.

4. Chemical Analysis and Oil Quality Detection Technology

Chemical analysis and oil quality detection are crucial techniques for identifying potential faults in collector stations. Chemical analysis primarily focuses on analyzing the composition and properties of materials like insulating media and coolants used in collector stations. If signs of aging, decomposition, or contamination are detected in the insulating materials, it may indicate a decline in insulating performance and predict potential insulation failures. Oil quality detection, on the other hand, evaluates the condition of insulating oils and lubricants used in electrical equipment such as transformers and circuit breakers, examining parameters like oil acidity, water content, and dielectric strength. An increase in oil acidity may indicate overheating or partial discharge within the equipment, leading to oil oxidation and degradation. Excessive water content in the oil may suggest poor equipment sealing, allowing moisture to penetrate and reduce the oil's insulating properties[8]. A decrease in dielectric strength also weakens the oil’s insulation capacity.

Qian Yihua et al. argue that infrared spectroscopy is a fast, non-destructive, and highly sensitive method for oil quality detection. By using infrared spectroscopy, the aging condition of transformer oil can be quickly assessed, allowing for the detection of internal faults in oil-filled electrical equipment[9]. This infrared detection technology is a modern analytical method within oil quality detection. The basic principle involves measuring the absorption of infrared light at different wavelengths by the sample to obtain molecular structure and chemical composition information. Its high sensitivity, fast detection speed, and ease of operation are among its advantages. This technology can monitor the quality of the oil by detecting trace information from the oil's infrared spectrum[10]. For instance, in a transformer, the winding is affected by water, high temperatures, discharge, and oxidation, causing the transformer oil to degrade and its quality to decline, which reduces the transformer’s safety and increases its failure rate[11-12]. Transformer oil degradation produces oxidation products such as carboxylic acids, aldehydes, and ketones, which can be detected through Fourier-transform infrared spectroscopy (FTIR) by identifying the corresponding absorption peaks, indicating the oil’s oxidation level. Aside from oxidation products, FTIR spectra of transformer oil should also focus on the absorption peaks of water, aromatics, saturated hydrocarbons, and antioxidants. By comparing the measured FTIR spectrum with standard spectra of normal and aged oil, and considering changes in multiple characteristic peaks, the aging degree and potential faults of the oil can be accurately assessed.

Infrared thermography, vibration analysis and acoustic detection, and chemical analysis and oil quality detection are the mainstream methods for detecting potential faults in traditional collector stations. Each method is applied in different scenarios, including temperature anomaly detection, mechanical fault detection, and chemical composition analysis. The advantages and disadvantages of the three methods can be briefly compared in a tabular form.

Table 1. Comparison of Potential Fault Detection Methods for Traditional Collector Stations

Monitoring Method |

Advantages |

Disadvantages |

Infrared Thermography |

Non-contact detection, fast, large-scale scanning, intuitive temperature distribution display |

Susceptible to environmental interference, may be less accurate for small or deep-seated faults |

Vibration and Acoustic Detection |

Detects mechanical balance and looseness issues, good real-time performance |

Requires precise sensor placement, complex data analysis, susceptible to noisy environments |

Chemical Analysis and Oil Quality Detection |

Reflects internal chemical changes in equipment, good diagnostic ability for insulation and lubrication systems |

Complex detection process, time-consuming, requires specialized equipment and personnel |

In response to China's "dual carbon goals," modern power stations, such as solar and wind power plants, are being rapidly developed. Compared to traditional collector stations, these modern stations offer significant advantages such as environmental friendliness and sustainability. Although modern power stations have higher technical requirements, technological advancements and supportive national energy policies are elevating their importance in the energy sector. However, traditional fault detection methods for collector stations may fall short when applied to modern power plants. Traditional techniques often focus on specific equipment or components, while modern stations involve more complex systems and technologies or integrate multiple energy sources. As a result, traditional methods may need further adaptation and expansion to improve fault detection accuracy and efficiency.

Wind energy has a vast potential, is renewable, and produces no pollution, making it ideal for large-scale development. Wind power systems based on doubly-fed induction generators (DFIG) have become more effective in recent years. Compared to permanent magnet synchronous generators, DFIG systems offer better control over cost, size, and weight[13]. DFIGs adjust rotor speed in response to wind speed changes, maintaining stable output power. This design allows DFIGs to operate efficiently across a broad range of wind speeds, providing advantages such as high efficiency, stability, and reliability, and better adaptability to grid fluctuations[14]. Converters are critical interfaces and power control devices between wind turbines and the grid, playing a key role in ensuring the safe and stable operation of wind turbines. Therefore, detecting potential faults in wind turbine converters is of great importance[15]. Common converter faults can be categorized into sensor faults, semiconductor faults, and passive component faults. In wind power systems, accurately measuring signals such as voltage and current is crucial, as any drift can lead to control errors. This paper will analyze and diagnose sensor faults, as they are critical in ensuring accurate system measurements and control.

4.1. Hardware Redundancy Method

The hardware redundancy method for converter sensors can improve the reliability and fault diagnosis accuracy of wind power systems. The basic principle of this method is to install multiple sensors of the same type at key measurement points to measure the same physical quantity. When one sensor fails, the other functioning sensors can still provide accurate measurement data, reducing errors caused by single sensor faults and increasing measurement reliability. Since multiple sensors are measuring the same physical quantity, any anomalies can be quickly detected by comparing the values from all sensors. If there is a significant difference in the values measured by different sensors, it is likely that one of the sensors has malfunctioned, or there may be an abnormal change in the measured physical quantity. This approach enhances overall fault diagnosis capabilities. In the event of a sensor failure that requires maintenance or replacement, the remaining sensors ensure that the system continues to operate without needing to shut down due to a single component failure, thus improving system availability. However, there are some limitations to the hardware redundancy method. It requires additional sensors, increasing hardware costs[16-17]. The installation and wiring of multiple sensors are more complex compared to using just one, requiring more space and resources. Additionally, the data from multiple sensors need to be fused and compared, making data processing more challenging. Therefore, the decision to implement hardware redundancy must balance system reliability requirements, cost constraints, and technical feasibility.

4.2. Analytical Redundancy Method

The analytical redundancy method for converter sensors relies on the redundant information of the sensors, which is independent of the measured object. This means that the sensor’s output contains information about both the measured object and the sensor itself. Based on this, a mathematical model is constructed to establish an analytical relationship between the sensor's output and the measured signal [18]. This method detects and diagnoses faults through mathematical analysis and processing. For the circuit portion of the converter, a mathematical relationship between different measured quantities can be established based on the circuit model and working principles. If the actual measurement data do not align with the expected relationships, it may indicate a sensor fault. The analytical redundancy method does not require additional hardware sensors, relying solely on the analysis of existing measurement data, making it a cost-effective solution. Moreover, it is highly flexible, allowing for the creation of customized analytical models tailored to specific system characteristics and fault modes. However, the accuracy of the analytical redundancy method depends heavily on the precision of the established models. The models must accurately reflect the practical characteristics of the system; otherwise, there may be misjudgments. Additionally, this method faces the challenge of high computational complexity. Particularly for complex systems, data analysis and processing may demand significant computational resources.

4.3. Temporal Redundancy Method

The temporal redundancy method for converter sensors is a fault detection and diagnosis technique that leverages the characteristics of sensor measurement data over time. The basic principle is to analyze and compare the sensor's data collected at different time points. Under normal conditions, the sensor data should exhibit certain regularity and continuity over time. If there is a sudden abnormal change at a particular time point or over a specific period, it could indicate a sensor fault. One of the main advantages of the temporal redundancy method is that it does not require additional sensors or hardware, which reduces costs. Moreover, it can detect intermittent faults by analyzing long sequences of data, making it useful for identifying faults that occur sporadically. However, this method has some limitations, such as high requirements for data storage and processing, as it needs to store large amounts of historical data and perform complex analysis. When the system's operating conditions change significantly, the normal data patterns may be disrupted, potentially leading to misjudgments. Therefore, in practical applications, the temporal redundancy method is often combined with other fault diagnosis techniques to improve the accuracy and reliability of fault detection.

The hardware redundancy method, analytical redundancy method, and temporal redundancy method approach sensor fault diagnosis from three different perspectives: quantity, mathematical modeling, and time characteristics. Depending on the needs of the wind power station, different methods can be selected. Below is a comparison of the advantages, disadvantages, and applicable scenarios for the three methods:

Table 2. Comparison of Sensor Fault Analysis Methods

Method |

Advantages |

Disadvantages |

Applicable Scenarios |

Hardware Redundancy |

Increases measurement reliability; enhances fault diagnosis capability; improves system availability |

Increases costs; complex installation and wiring; difficult data processing |

Critical wind power systems requiring high reliability and can afford higher costs |

Analytical Redundancy |

Relatively low cost; high flexibility |

High model accuracy requirements; high computational complexity |

Wind power systems where the system model is relatively clear and an accurate analytical model can be established |

Temporal Redundancy |

No additional hardware required; can detect intermittent faults |

High requirements for data storage and processing; limited adaptability to dynamic system changes |

Wind power systems with relatively stable operations and data patterns |

5. Conclusion

For traditional substations, potential fault detection is crucial to ensure reliable operation. Infrared thermal imaging technology enables non-contact detection of equipment temperature, providing early warnings for potential electrical faults and insulation issues. Vibration analysis and acoustic detection technologies monitor the vibrations and sound signals of equipment during operation, helping prevent major accidents such as sudden equipment shutdowns. Chemical analysis and oil quality detection techniques assess the chemical composition and performance of transformer oil and other key components, reflecting the insulation performance and operational condition of equipment, thus ensuring the normal operation and extending the service life of electrical equipment. As technology continues to advance, potential fault detection methods in substations are becoming more integrated, digital, and intelligent. In the future, the use of multi-sensor fusion technology and big data analysis will make fault detection more precise and efficient, providing stronger support for the safe and stable operation of substations. In wind power plants, the converter sensors in doubly-fed induction generators play a critical role. Hardware redundancy, analytical redundancy, and temporal redundancy methods can diagnose sensor faults under different scenarios, thereby ensuring the safe and stable operation of wind power stations. With the development of technology, these three methods are likely to evolve further, relying on more advanced sensor technologies, deep learning, artificial intelligence, and high-precision time synchronization technologies. This will improve detection accuracy, reliability, and adaptability, leading to more intelligent and efficient fault detection and diagnostic systems.

References

[1]. Reséndiz-Ochoa, E., Morales-Hernández, L. A., Cruz-Albarran, I. A., & Álvarez-Junco, S. (2022). Fault analysis of induction motors using machine learning and infrared thermography. 2022 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 1–6. DOI: 10.1109/ROPEC55836.2022.10018653.

[2]. Rajamani, P., Dey, D., & Chakravorti, S. (2011). Wavelet network aided classification of dynamic insulation faults of transformer windings during impulse tests. IEEE Transactions on Dielectrics and Electrical Insulation, 18(2), 521–532. DOI:10.1109/TDEI.2011.5739458。

[3]. Huang, J., & Yang, B. (2015). Mechanical condition monitoring system based on vibration signals and its application in GIS. Guangxi Electric Power, 38(5), 55–59.

[4]. Yang, Z., Xing, J., Gao, Y., et al. (2015). Research on vibration signal characteristics and detection system for abnormal sounds in GIS equipment. Shandong Industrial Technology, (21), 216–218.

[5]. Lio, J., Li, W., Li, W., Cai, Y., Ye, T., & Lei, X. (2020). Key technologies for acoustic detection of AC and DC cables based on beamforming. 2020 5th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 495–500. Doi:10.1109/ICPRE51194.2020.9233179.

[6]. Xiao, Y., Ge, L., Hu, K., et al. (2024). Automatic speech recognition method based on PNCC features for recorded speech. Automation Technology & Application, 43(5), 163–167. DOI: 10.20033/j.1003-7241.(2024)05-0163-05.

[7]. Chinese Academy of Sciences, Institute of Acoustics. (2024). A method for separating aliased bird sounds using a sound sensor array spatial matrix filter. CN202211201141.0[P]. 2024-04-05.

[8]. Ou, K., Miyagi, K., & Hanaoka, R. (2023). Study on AC breakdown voltage characteristics of dissolved water in insulating oil under JIS C 2101. 2023 International Symposium on Electrical Insulating Materials (ISEIM), Shimane, Japan, 123–128. DOI: 10.23919/ISEIM60444.2023.10329246。

[9]. Qian, Y., Wang, Y., Zhao, Y., Fan, S., Fu, Q., & Wang, H. (2020). Applied infrared spectroscopy in oil quality detection. 2020 IEEE International Conference on High Voltage Engineering and Applications (ICHVE), Beijing, China, 1–4. DOI:10.1109/ICHVE49031.2020.9279670。

[10]. Qian, Y., Zhao, Y., & Wang, Q. (2022). Application of infrared spectroscopy in monitoring the aging process of transformer oil. 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Hangzhou, China, 844–848. DOI: 10.1109/ACPEE53904.2022.9784028。

[11]. Gayathri, R., & Sundari, P. D. (2019). Overview of electrical and thermal analysis of insulation performance of different transformer oils. Journal of Electrical Engineering, 19(4), 9.

[12]. Zhou, Z., Jiang, X., & Yang, J. (2015). Study on the change of acid value during the thermal aging process of transformer oil. Insulating Materials, 48(12), 46–48+54.

[13]. Hassan, M., Stone, O., Monaco, S., & El-Amary, N. (2019). Stability analysis and control of grid-connected wind turbines based on doubly fed induction generators. 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), Genoa, Italy, 1–6. DOI: 10.1109/EEEIC.2019.8783923。

[14]. Chen, C., Qian, L., & Su, J. (2024). Research on control of doubly-fed variable speed constant frequency wind power system. Times Automobile, (04), 13–15+44.

[15]. Xue, Z. (2020). Research on converter fault diagnosis of doubly-fed wind power generation system based on data-driven algorithms [Doctoral dissertation, South China University of Technology].

[16]. Che, L., Zhou, X., & Cheng, Y. (1999). Multi-sensor weighted data fusion algorithm considering sensor failure. Journal of Engineering Design, (1), 38–40.

[17]. Zhao, Z., Zhao, W., Zhaozhi-Gang, et al. (2006). Sensor failure detection method for multi-sensor systems based on dynamic uncertainty theory. Journal of Sensing Technology, 19(6), 2723–2726.

[18]. Su, S. X. P., Yang, H. S., & Agogino, A. M. (2005). A resonant accelerometer with two-stage microleverage mechanisms fabricated by SOI-MEMS technology. IEEE Sensors Journal, 5(6), 1214–1223.

Cite this article

Chen,S. (2024). A review of potential fault detection methods for traditional collector stations and sensor fault diagnosis in wind farm doubly-fed generator converters. Applied and Computational Engineering,92,75-82.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 6th International Conference on Computing and Data Science

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Reséndiz-Ochoa, E., Morales-Hernández, L. A., Cruz-Albarran, I. A., & Álvarez-Junco, S. (2022). Fault analysis of induction motors using machine learning and infrared thermography. 2022 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 1–6. DOI: 10.1109/ROPEC55836.2022.10018653.

[2]. Rajamani, P., Dey, D., & Chakravorti, S. (2011). Wavelet network aided classification of dynamic insulation faults of transformer windings during impulse tests. IEEE Transactions on Dielectrics and Electrical Insulation, 18(2), 521–532. DOI:10.1109/TDEI.2011.5739458。

[3]. Huang, J., & Yang, B. (2015). Mechanical condition monitoring system based on vibration signals and its application in GIS. Guangxi Electric Power, 38(5), 55–59.

[4]. Yang, Z., Xing, J., Gao, Y., et al. (2015). Research on vibration signal characteristics and detection system for abnormal sounds in GIS equipment. Shandong Industrial Technology, (21), 216–218.

[5]. Lio, J., Li, W., Li, W., Cai, Y., Ye, T., & Lei, X. (2020). Key technologies for acoustic detection of AC and DC cables based on beamforming. 2020 5th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 495–500. Doi:10.1109/ICPRE51194.2020.9233179.

[6]. Xiao, Y., Ge, L., Hu, K., et al. (2024). Automatic speech recognition method based on PNCC features for recorded speech. Automation Technology & Application, 43(5), 163–167. DOI: 10.20033/j.1003-7241.(2024)05-0163-05.

[7]. Chinese Academy of Sciences, Institute of Acoustics. (2024). A method for separating aliased bird sounds using a sound sensor array spatial matrix filter. CN202211201141.0[P]. 2024-04-05.

[8]. Ou, K., Miyagi, K., & Hanaoka, R. (2023). Study on AC breakdown voltage characteristics of dissolved water in insulating oil under JIS C 2101. 2023 International Symposium on Electrical Insulating Materials (ISEIM), Shimane, Japan, 123–128. DOI: 10.23919/ISEIM60444.2023.10329246。

[9]. Qian, Y., Wang, Y., Zhao, Y., Fan, S., Fu, Q., & Wang, H. (2020). Applied infrared spectroscopy in oil quality detection. 2020 IEEE International Conference on High Voltage Engineering and Applications (ICHVE), Beijing, China, 1–4. DOI:10.1109/ICHVE49031.2020.9279670。

[10]. Qian, Y., Zhao, Y., & Wang, Q. (2022). Application of infrared spectroscopy in monitoring the aging process of transformer oil. 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Hangzhou, China, 844–848. DOI: 10.1109/ACPEE53904.2022.9784028。

[11]. Gayathri, R., & Sundari, P. D. (2019). Overview of electrical and thermal analysis of insulation performance of different transformer oils. Journal of Electrical Engineering, 19(4), 9.

[12]. Zhou, Z., Jiang, X., & Yang, J. (2015). Study on the change of acid value during the thermal aging process of transformer oil. Insulating Materials, 48(12), 46–48+54.

[13]. Hassan, M., Stone, O., Monaco, S., & El-Amary, N. (2019). Stability analysis and control of grid-connected wind turbines based on doubly fed induction generators. 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), Genoa, Italy, 1–6. DOI: 10.1109/EEEIC.2019.8783923。

[14]. Chen, C., Qian, L., & Su, J. (2024). Research on control of doubly-fed variable speed constant frequency wind power system. Times Automobile, (04), 13–15+44.

[15]. Xue, Z. (2020). Research on converter fault diagnosis of doubly-fed wind power generation system based on data-driven algorithms [Doctoral dissertation, South China University of Technology].

[16]. Che, L., Zhou, X., & Cheng, Y. (1999). Multi-sensor weighted data fusion algorithm considering sensor failure. Journal of Engineering Design, (1), 38–40.

[17]. Zhao, Z., Zhao, W., Zhaozhi-Gang, et al. (2006). Sensor failure detection method for multi-sensor systems based on dynamic uncertainty theory. Journal of Sensing Technology, 19(6), 2723–2726.

[18]. Su, S. X. P., Yang, H. S., & Agogino, A. M. (2005). A resonant accelerometer with two-stage microleverage mechanisms fabricated by SOI-MEMS technology. IEEE Sensors Journal, 5(6), 1214–1223.