1. Introduction

People have realized the bright future of thermal engines and made various efforts for many years. Between 1678 to 1679, Dutch inventor Christiaan Huygens built a prototype of a single-cylinder gunpowder engine. In 1698, Thomas Savery designed the first commercial steam engine. In 1791, a gas turbine was patented by John Barber. In 1794, Thomas Mead built a reciprocating piston engine. This engine is filled with gas vapor, using the intake stroke of the piston to draw in outside air, which is then ignited by an external flame [1]. In 1798, John Stevens, who is an American engineer, built the first internal combustion engine in the U.S. After 100 years, Mercedes-Benz established in 1886 by Karl Benz, who invented the first car. In1889, the first V engine is built by German engineer Wilhelm Maybach [2]. Contemporarily, Hyundai which is one of the most famous brands of private car stops internal combustion engine development in 2022 [3]. From development to stagnation, it took human 300 years and became an integral part of human society. Nowadays, more and more companies focus on electric motors, but there are still many fresh researches about thermal engines.

Zhao’s team from Tsinghua University improved the thermal efficiency of internal combustion engines by exploring jet ignition technology. They proposed a three-stage combustion process with uniform distribution of jet ignition and optimized this through simulation. Under various conditions, the engine achieved a highest thermal efficiency of 50.3% [4]. The study of Jun-ling Liu syncretizes the heat current method with artificial neural networks (ANNs) to improve the Aero-Engine Thermal Management System (ATMS). Experiment using a water-based intermediate cycle shows that the maximum heat transfer rate increased by 8.6%, from 7740 W to 8402 W. Thermal conductivity was reduced by 36.6%, from 1628 W/K to 1032 W/K. Under controlled fuel oil conditions, thermal conductivity decreased by 32.3%, which enhance the heat dissipation and reduces aircraft weight [5]. In addition to improving the efficiency of the heat engine, scientists also try to use new energy to displace the fossil fuel in order to decrease pollutants. In the article of Kislay, they suppose ammonia could be an alternative fuel for internal combustion engines due to its carbon-free nature and high hydrogen energy density. This study explores ammonia-diesel dual fuel systems, through experimental and computational methods. They test varied ammonia proportions (0–47% by energy) at 24 Nm load and 1800 rpm. The experiment revealed engine performance is reduced (BTE dropped from 25.5% to 23.3%) and the peak of pressure is cylinder gets lower when ammonia use increases. However, combustion duration decreased, and CFD simulations showed higher hydrogen consumption and OH formation with 47% ammonia. These findings support further optimization of ammonia dual fuel systems [6]. The study from Wang investigates the combustion optimization of a hydrogen free-piston engine using high-energy ignition techniques. The research focuses on improving engine performance by enhancing combustion efficiency and stability. Through experiments and analyzing data, the study evaluates how high-energy ignition affect various engine parameters and overall efficiency. The findings aim to advance the development of hydrogen-powered engines, and offer insights into better energy utilization and emission reductions, and therefore contribute to more sustainable technologies [7].

In this study, three kinds of thermal engines are compared to help individuals and organizations discover different usage scenarios and new directions to optimize thermal engines. Through this article, people can understand the comparative performance of engines and find highlight areas for improvement and innovation. For companies, it can facilitate better decision-making in engine design and deployment for diverse industrial including automotive sectors.

2. Descriptions of thermal engines

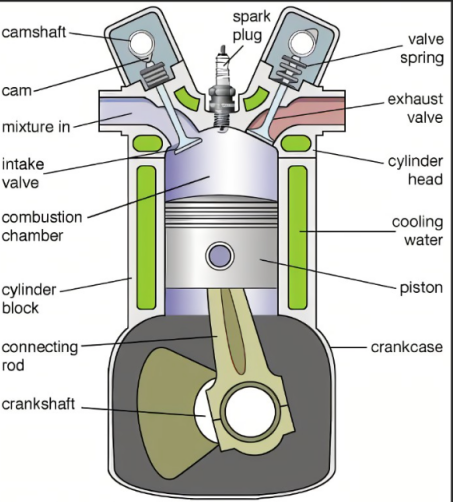

A thermal engine is a machine which can utilize the heat supplied to output work with other forms. Four-stroke engines with gasoline or diesel are the most popular ICE (internal combustion engine, seen from Fig. 1 [8]) designs used in motorized land transportation. The mechanics of four-stroke engines are not complex and separated into four parts which form a cycle. This cycle transforms internal energy of fuel into mechanical energy. For diesel and gasoline, they are similar, but there are still some differences. In the intake stroke, the intake valve opens, and then the air-fuel mixture enters the cylinder when the piston moves downward in gasoline engines while only the air enters diesel engines. For the nest step, the piston moves upward, and compress a kind of mixture formed by gasoline and air, and then the temperature as well as pressure get higher in the compression stroke. For power stroke, the spark will ignite the air-fuel in gasoline engines while injector ejects diesel into cylinder. Whether the air-fuel or diesel, they release energy during combustion, and then it forces the piston downward in order to generate power. The final step, the exhaust valve opens, and the piston moves upward, and then the exhaust gas is discharged [8]. Turbines are versatile machines used for various high-power applications like power generation, aerospace and marine propulsion. A turbine works on the principle of converting energy from fluid flow into mechanical energy. High-pressure fluid (such as steam, gas, or water) flows over the turbine blades, causing them to spin. This rotational motion is then transferred to a shaft connected to a generator or other machinery. The fluid’s energy is transformed into mechanical energy through a process involving the expansion and acceleration of the fluid flow, which drives the turbine blades and produces work [9].

Figure 1. A sketch of ICE [9].

3. State-of-art facilities

In 2022, the Lamborghini Urus, the brand's high-performance luxury SUV, be installed with the most advanced engine which is Lamborghini's V8 engine. This engine is a 4.0-liter twin-turbocharged V8, producing around 650 horsepower (485 kW), and combines powerful performance with advanced technology and luxury features. This V8 engine represents Lamborghini's commitment to merging high power with sophisticated engineering, which ensures both thrilling driving dynamics and a refined driving experience [10]. In 2016, Mercedes-benz unveils its latest 2.0T diesel engine. Mercedes-benz diesel engines were introduced in 1927, after nearly 80 years of development, after the OM654 engine stopped new development. The new 143 kW variant of Mercedes-Benz's all-aluminum four-cylinder diesel engine is 35.4 kg lighter than its 125-kW predecessor, setting a new standard in its class. It is designed to meet future emissions regulations, including RDE and WLTP, with all critical emissions control components integrated directly into the engine. This setup minimizes heat loss, improves fuel efficiency, and eliminates the need for engine temperature management during cold starts and low loads, making it more efficient, especially for short journeys [11]. For aviation, Boeing has completed the detailed design for the 787-10 Dreamliner with Trent 1000, ahead of schedule in 2018 [12]. The 787-10 features 95% commonality with the 787-9, enhancing efficiency and reducing production complexity. The Trent 1000 engine, which designed for the Boeing 787 Dreamliner, is a milestone for a significant advancement in aviation technology. It features a 10:1 bypass ratio, the highest of any Trent engine, which enhances fuel efficiency and reduces noise. The Trent 1000 incorporates a heated Engine Section Stator (ESS) for advanced ice protection, and it is crucial for operations in a harsh environments like cold or high-moisture. Its adaptive HP cooling system lowers fuel consumption and maintains performance, while the new high-pressure turbine offers increased thrust and efficiency. The Trent 1000 engine is 20% more efficient than the Boeing 767's engines, which contributes to a more stable and efficient operating cycle for the Boeing Dreamliner [13]. The sketches of engines are shown in Fig. 2. At present, researchers have tried in various ways to improve the efficiency of the heat engine. In the research from University of Windsor, it investigates how replacing gasoline with natural gas in medium- and heavy-duty spark-ignition engines can enhance energy efficiency and reduce CO2 emissions. Detailed experiments on a multi-cylinder engine reveal that natural gas contains lower carbon content. It also reduces pumping losses, improves idle stability, and offers better resistance to knock. Therefore, natural gas provides 4% higher peak power and 22.5% lower CO2 emissions compared to gasoline. [14] According to the research of Avinash Agarwal, M85(85% methanol and 15% gasoline) improves combustion characteristics, increasing brake thermal efficiency by 23% at lower loads and reducing carbon monoxide emissions significantly. [15] In addition to the new energy research, Gandolfo’s team invents a novel low thermal inertia coating for spark ignition engines, aiming to enhance performance and efficiency and mitigate knock issues. Tested in a low compression ratio engine, the coating demonstrated 0.8% improvement in thermal efficiency with a thin layer, but thicker coatings led to performance degradation due to increased knock propensity. Cold-start tests revealed that charge heating from the coating reduced unburned hydrocarbons and particulate emissions, which highlights its potential benefits for engine emissions and efficiency. [16] An engine research laboratory from India focused on developing specialized fuel injection equipment (FIE) for a three-cylinder engine running on 100% dimethyl ether (DME). The modifications of FIE included custom storage tanks, supply lines, a pneumatic feed pump, a high-pressure pump, and larger nozzle injectors. Testing showed that the DME-fueled engine achieved approximately 4.7% higher brake thermal efficiency (BTE) under full load and 8.32% under non-road conditions compared to diesel. [17]

Figure 2. The sketch of the engines for Mercedes-benz (left) and Boeing 787 (right) [11, 13].

4. Comparison

Table 1 lists the comparison for 3 engines. Gasoline engines contain several advantages. They are generally lighter and more compact than diesel engines, resulting in better handling and higher acceleration. For vehicles, gasoline engines bring smooth operation and quiet performance, which enhances driving comfort. They also produce fewer nitrogen oxides than diesel engine which could damage the environment. Diesel engines are known for their high fuel efficiency around 30-40% due to their higher compression ratios. This results in lower fuel cost and longer driving range. They provide greater torque and pulling power, which makes them ideal for heavy applications like trucks, buses, and industrial machinery. Diesel engines also have a longer lifespan and are more durable under tough conditions. Furthermore, they produce less carbon dioxide compared to gasoline engines, contributing to lower greenhouse effect. Turbine engines perform excellently in high power output and efficiency, especially in continuous operations. They are ideal for aircraft and power generation due to their high power-to-weight ratio. Turbines contain advantages in aviation and large-scale energy production, because they can work smoothly and consistently at high speeds. Compared to piston engines, they have fewer parts, which reduces mechanical wear and maintenance needs as well as cost. Additionally, modern turbines can achieve high thermal efficiencies, especially in combined-cycle power plants, leading to effective energy use. In the analysis from Erdem, a combined cycle power plant with new heat recovery and gas turbine units can achieve energy and exergy efficiencies as 56% and 50.04% calculated by energy and exergy efficiencies as 56% and 50.04% [18].

Table 1. Comparison of 3 engines.

Engine Type | Thermal Efficiency | Design Characteristics | Common Applications |

Gasoline Engine | 25-30% | Spark-ignition, lighter | Private cars, motorcycles, small machinery with low power |

Diesel Engine | 30-40% | Compression-ignition, more robust, higher compression ratio | Trucks, buses, industrial machines with high power |

Turbine Engine | Variable, 30-40% in jets | Complex, high-speed rotating components | Aircraft, power generation, mega-vessel |

5. Limitations and prospects

The thermodynamic limits of maximizing the efficiency of internal combustion engines are important considerations for future engine design and development. The study from Jerald investigates the thermodynamic limits of internal combustion engines using the first and second laws of thermodynamics. It explores maximum efficiencies which achieve 66.9% under ideal conditions like no heat losses, friction, lean operation, short burn time and high compression ratios [19]. The study relaxes these ideal conditions to a certain extent in order to simulate the real engine’s condition. It reveals that combustion irreversibility and heat transfer significantly impact efficiency. High compression ratios are crucial for enhancing efficiency, but reducing heat transfer is really challenging. It also points the one of the future development directions of heat engines. The thermal engines can increase the compression ratio through optimizing fuel quality, improving engine design and ignition systems. In addition, incomplete combustion of fuel results emissions like carbon dioxide (CO2), nitrogen oxides (NOx), and hydrocarbons (HC). CO2, which is a kind of greenhouse gas, is the main factor of global warming due to its ability of trapping heat in the atmosphere. NOx gases lead to smog formation, acid rain, and respiratory issues. They play a role in the formation of ground-level ozone, which can impair people’s lung and harm ecosystems. Hydrocarbons react with nitrogen oxides (NOx) in sunlight, contributing to the formation of ground-level ozone, because it is the key ingredient in smoke. This smog can cause various health problems, including asthma and chronic bronchitis. Therefore, regulations from the government require engines to minimize these emissions, leading to the development of technologies for example catalytic converters can promote chemical reactions that convert harmful gases into less harmful substances.

In addition, the hybrid vehicles improve fuel efficiency, reducing overall emissions. Internal combustion engines and electric motors powered by batteries are combined to build a hybrid electric vehicle (HEVs), which are recharged through regenerative braking and the engine itself. Unlike plug-in hybrids, HEVs cannot be charged externally. The electric motor assists the engine, potentially allowing for a less-fuel-consume engine, because electric motors powered by batteries helps power systems and reduces engine idling. Hydrogen is perfect one to use as an energy source for vehicles, because it contains the most energy per unit weight. Hydrogen, which burns and only produce water, is cleaner than gasoline or methane but face significant challenges, such as complex storage and transportation due to hydrogen's instability and high brisance. In 2021, hydrogen cars like the Toyota Mirai and Hyundai Nexo have been available but in limited numbers. Compared with the traditional IC engines, fuel cell vehicles improve fuel economy and power performance. They are classified into fuel cell-internal combustion engine hybrid vehicles and fuel cell-battery hybrid vehicles. Proton Exchange Membrane Fuel Cells (PEMFCs), commonly used in these vehicles, rely on different flow field designs such as straight parallel, serpentine, pin-type, and interdigitated types to efficiently manage reactants and water within the fuel cell stack. Improving total energy management and PEMFC system operations are important for enhancing fuel cell-internal combustion engine’s performance. Current research focuses on improving power management for various PEMFC applications. PEMFCs are known for their efficiency around 65%, and their environmental benefit which is producing only pure water as a byproduct [20]. Therefore, it becomes an outstanding technology in automotive fuel cells and the research focus in the future.

6. Conclusion

To sum up, although optimizing internal combustion engine efficiency remains a complex challenge, internal combustion engine still has future. Whether it's a sports car, a truck or a passenger plane, they are all equipped with the most advanced internal combustion engine. Manufacturers and companies choose the proper type with different advantages of internal combustion engine according to the function of the product and the needs of the customer. On the way to improving the internal combustion engine, researchers focus on increasing compression ratios by improving fuel quality, engine design and ignition systems and using new kinds of fuel like hydrogen. In the near future, the internal combustion engine will achieve a higher efficiency and lower emissions as well as more environmental benefit. Through this article, individuals and organizations can get a clear understanding of advantages and limitations of internal combustion engine. For companies and researcher, particularly those in the automotive sectors, this paper hopes to help them make strategic decision in engine design and deployment.

References

[1]. Grover F 1909 Modern Gas and Oil Engines technical Publishing Company

[2]. Larson L 2008 Dreams to automobiles Xlibris Corporation

[3]. Del Río F and Máximo L 1987 Cosas de la ciencia SEP

[4]. Zhao Z, Qi Y and Wang Z 2024 Thermal efficiency optimization of a single cylinder gasoline engine based on active jet ignition International Journal of Engine Research p 255

[5]. Liu J, Li M, Zhang T, et al 2024 Optimization of the aero-engine thermal management system with intermediate cycle based on heat current method Applied Thermal Engineering vol 237 p 121793

[6]. Kishore K, Kurien C and Mittal M 2024 Experimental and numerical analysis of engine characteristics of an ammonia-substituted dual-fuel CRDI diesel engine Fuel vol 366 p 131354

[7]. Wang Y Xu Z Zhang C and Liu L 2024 Combustion optimization of a hydrogen free-piston engine with high-energy ignition International Journal of Hydrogen Energy vol 49B pp 483-494

[8]. Heywood J B 1988 Internal combustion engine fundamentals McGraw-Hill

[9]. Dixon S L and Hall C A 2014 Fluid mechanics and thermodynamics of turbomachinery 7th ed Elsevier

[10]. Lamborghini Lamborghini LMDh prototype car will fit a V8 twin-turbo hybrid engine Retrieved from https://wwwlamborghinicom

[11]. Mercedes-Benz Group and New diesel engine OM 654 Mercedes-Benz https://groupmercedes-benzcom/innovation/diesel/new-diesel-engine-om-654html

[12]. Boeing Boeing 787-10 Dreamliner begins major assembly Retrieved from: https://wwwprnewswirecom/news-releases/boeing-787-10-dreamliner-begins-major-assembly-300238528html

[13]. Rolls-Royce Trent 1000 Rolls-Royce Retrieved from: https://wwwrolls-roycecom/products-and-services/civil-aerospace/widebody/trent-1000aspx

[14]. Divekar, P., Han, X., Zhang, X., Zheng, M., & Tjong, J. (2023). Energy efficiency improvements and CO2 emission reduction by CNG use in medium- and heavy-duty spark-ignition engines. Energy, 263(B), 125769.

[15]. Agarwal, A., Yadav, O., & Valera, H. (2024). Methanol (M85) port fuel-injected spark ignition motorcycle engine development—Part 1: Combustion optimization for efficiency improvement and emission reduction. SAE International Journal of Engines, 17(3), 321-340.

[16]. Gandolfo, J., Gainey, B., & Lawler, B. (2024). Low thermal inertia thermal barrier coatings for spark ignition engines: An experimental study. Journal of Thermal Spray Technology, 24(7).

[17]. Agarwal, A. K., Mehra, S., Valera, H., Mukherjee, N. K., Kumar, V., & Nene, D. (2023). Dimethyl ether fuel injection system development for a compression ignition engine for increasing the thermal efficiency and reducing emissions. Energy Conversion and Management, 287, 117067.

[18]. Ersayin E and Ozgener L 2015 Performance analysis of combined cycle power plants: A case study Renewable and Sustainable Energy Reviews vol 43 pp 832-842

[19]. Caton J A 2017 Maximum efficiencies for internal combustion engines: Thermodynamic limitations International Journal of Engine Research p 1910

[20]. Aminudin M A, Kamarudin S K, Lim B H, Majilan E H, Masdar M S and Shaari N 2023 An overview: Current progress on hydrogen fuel cell vehicles International Journal of Hydrogen Energy vol 4811 pp 4371-4388

Cite this article

Li,H. (2024). Analysis and Comparison of the Performances and Applications for the State-of-art Thermal Engines. Applied and Computational Engineering,98,29-34.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Grover F 1909 Modern Gas and Oil Engines technical Publishing Company

[2]. Larson L 2008 Dreams to automobiles Xlibris Corporation

[3]. Del Río F and Máximo L 1987 Cosas de la ciencia SEP

[4]. Zhao Z, Qi Y and Wang Z 2024 Thermal efficiency optimization of a single cylinder gasoline engine based on active jet ignition International Journal of Engine Research p 255

[5]. Liu J, Li M, Zhang T, et al 2024 Optimization of the aero-engine thermal management system with intermediate cycle based on heat current method Applied Thermal Engineering vol 237 p 121793

[6]. Kishore K, Kurien C and Mittal M 2024 Experimental and numerical analysis of engine characteristics of an ammonia-substituted dual-fuel CRDI diesel engine Fuel vol 366 p 131354

[7]. Wang Y Xu Z Zhang C and Liu L 2024 Combustion optimization of a hydrogen free-piston engine with high-energy ignition International Journal of Hydrogen Energy vol 49B pp 483-494

[8]. Heywood J B 1988 Internal combustion engine fundamentals McGraw-Hill

[9]. Dixon S L and Hall C A 2014 Fluid mechanics and thermodynamics of turbomachinery 7th ed Elsevier

[10]. Lamborghini Lamborghini LMDh prototype car will fit a V8 twin-turbo hybrid engine Retrieved from https://wwwlamborghinicom

[11]. Mercedes-Benz Group and New diesel engine OM 654 Mercedes-Benz https://groupmercedes-benzcom/innovation/diesel/new-diesel-engine-om-654html

[12]. Boeing Boeing 787-10 Dreamliner begins major assembly Retrieved from: https://wwwprnewswirecom/news-releases/boeing-787-10-dreamliner-begins-major-assembly-300238528html

[13]. Rolls-Royce Trent 1000 Rolls-Royce Retrieved from: https://wwwrolls-roycecom/products-and-services/civil-aerospace/widebody/trent-1000aspx

[14]. Divekar, P., Han, X., Zhang, X., Zheng, M., & Tjong, J. (2023). Energy efficiency improvements and CO2 emission reduction by CNG use in medium- and heavy-duty spark-ignition engines. Energy, 263(B), 125769.

[15]. Agarwal, A., Yadav, O., & Valera, H. (2024). Methanol (M85) port fuel-injected spark ignition motorcycle engine development—Part 1: Combustion optimization for efficiency improvement and emission reduction. SAE International Journal of Engines, 17(3), 321-340.

[16]. Gandolfo, J., Gainey, B., & Lawler, B. (2024). Low thermal inertia thermal barrier coatings for spark ignition engines: An experimental study. Journal of Thermal Spray Technology, 24(7).

[17]. Agarwal, A. K., Mehra, S., Valera, H., Mukherjee, N. K., Kumar, V., & Nene, D. (2023). Dimethyl ether fuel injection system development for a compression ignition engine for increasing the thermal efficiency and reducing emissions. Energy Conversion and Management, 287, 117067.

[18]. Ersayin E and Ozgener L 2015 Performance analysis of combined cycle power plants: A case study Renewable and Sustainable Energy Reviews vol 43 pp 832-842

[19]. Caton J A 2017 Maximum efficiencies for internal combustion engines: Thermodynamic limitations International Journal of Engine Research p 1910

[20]. Aminudin M A, Kamarudin S K, Lim B H, Majilan E H, Masdar M S and Shaari N 2023 An overview: Current progress on hydrogen fuel cell vehicles International Journal of Hydrogen Energy vol 4811 pp 4371-4388