1. Introduction

The history of train engines spans back to the early 19th century with the introduction of steam locomotives. These early engines operated using high-pressure steam to drive pistons that turned the wheels, though their efficiency and performance were initially limited due to the technology of the time. As advancements were made, improved steam locomotives emerged. Significant progress in steam technology led to the Stockton & Darlington Railway, which opened in 1825, and was followed by the Liverpool and Manchester Railway in 1830. This latter railway marked the first fully scheduled service with both freight and passenger traffic powered entirely by steam locomotives. Designed by George Stephenson and built by him and his son Robert, the first locomotive on this line was the renowned Rocket, which won a competition at Rainhill, near Liverpool, in 1829 [1].

The railways began using electric power systems from the start of the 20th century. Electric motors power the train's wheels, while electric transmission lines provide the necessary energy for electric locomotives to operate. In addition to increasing productivity and protecting the environment, this approach generates more power than steam locomotives. The first electric passenger train, designed by Werner von Siemens and consisting of a locomotive and three coaches, made its debut in Berlin in 1879. The train could go only a little over eight miles per hour (13 km/h). It carried 90,000 passengers on a 984-foot (300-meter) round track over a period of four months. The train's insulated third rail provided 150 volts of direct electricity [2].

Diesel locomotives were created in the middle of the twentieth century. This diesel locomotive is ideal for a range of routes and conditions, and it runs on an internal combustion engine, which enables the train to operate in areas without electrified lines. Furthermore, diesel engines have very cheap running costs and require less maintenance. After Dr. Rudolf Diesel received his first patent in 1892 for his compression ignition engine, also known as a diesel engine, conjecture about the potential applications of this novel internal combustion technology for railroad propulsion soon arose. Although the full advantages of diesel engines in rail locomotives took several decades to materialize, diesel technology was on course to nearly replace steam locomotion by the end of World War II in 1945. By the late 1960s, steam locomotives had become extremely rare in developed countries. This shift was driven by the ongoing advancement of diesel engines, which featured improved power-to-weight ratios and greater efficiency. Many of these advancements originated from the Swiss engineering firm Suller, where Rudolph Diesel had worked for several years [3].

In the 21st century, the technology has become more developed, and some modern locomotives use hybrid power systems. Use both electricity and diesel to improve fuel efficiency and reduce emissions. At the same time, fuel cell technology is also gradually applied to the field of trains, further reducing the dependence on fossil fuels. In the future, the technology of maglev trains will gradually mature, which can achieve higher travel speeds and a safer and smoother ride experience. In addition, more environmentally friendly technologies will gradually be applied to trains.

2. Descriptions

A steam engine is a machine that burns coal to release heat. This coal is mainly used to burn water, to produce a large amount of water vapor, and then the pressure of this water vapor is used to do work. To understand the fuel for steam engines, consider coal, an organic chemical primarily composed of carbon. Coal forms over millions of years from the remains of dead plants that get buried under rocks, compressed by pressure, and heated by the Earth's internal warmth, earning it the name "fossil fuel." Essentially, lumps of coal represent stored energy. The carbon in coal is bonded with hydrogen and oxygen atoms, and burning coal breaks these bonds, releasing energy as heat. Coal delivers about half the energy per kilogram compared to cleaner fossil fuels like gasoline, diesel, and kerosene, which is why steam engines require large quantities of it [4].

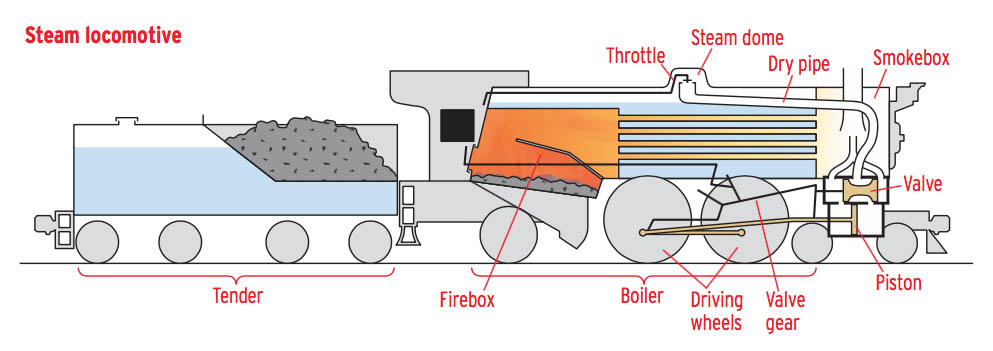

The working flow for steam train is as follows. First, the driver puts coal and other fuel into the combustion chamber of the boiler to ignite it. The energy from burning the fuel boils the water above the boiler and produces steam. This steam goes into the cylinders of the train, and the piston is pushed by high pressure to reciprocate. The pistons are transmitted to the wheels through the movement of the connecting rod and the crankshaft, causing them to rotate to move the truck forward. In addition, one can control the speed of the train by adjusting the amount of steam. In terms of exhaust gas treatment, at the upper end of the locomotive, there is a chimney to discharge the smoke and steam after combustion.

Figure 1. A sketch of the working flow for train engines [5].

As shown in Fig. 1, the advantage of the steam train is that it promotes the economic development of the previous society, and its transportation capacity and stability are very good. However, its disadvantages are also very obvious, the first is that its efficiency is very low, because it is limited by fuel and heat loss. Second, the problem of environmental pollution. The large amount of smoke and carbon dioxide released by steam trains burning coal will cause air pollution and destroy the ecological balance. The third is that the operation of steam trains is more complicated, it takes a long time to heat the boiler, and the noise will be larger. Finally, steam trains have high requirements for maintenance personnel and drivers, requiring professional training and technical support.

For working process of diesel engine, first, diesel engines use diesel as fuel. The diesel is transported to the engine's injection system through the fuel pump. At the same time, the engine sucks in air from the outside for compression. In the process of compression, the temperature and pressure of the air increase. When the piston is compressed into a fixed position, the fuel injection system injected diesel fuel into the high-temperature and high-pressure cylinder, and burned with the air to produce a higher-pressure gas. These high-pressure gases continue to push the piston downward to produce mechanical energy. After the work is done, the exhaust valve is opened and the exhaust gas is discharged from the cylinder. It is worth mentioning that diesel engines require oil pumps to lubricate the various moving parts of the engine, thereby reducing friction and wear.

In a two-stroke diesel engine, the entire cycle occurs with a single up-and-down movement of the piston, the work flow is as follows [6]:

• Exhaust and Intake: Fresh air enters the cylinder from the side, pushing out the exhaust through valves at the top.

• Compression: With the inlet and exhaust valves closed, the piston moves upward to compress and heat the air. Fuel is injected at the top of the stroke, igniting spontaneously.

• Power: The ignition of the air-fuel mixture forces the piston downward, turning the crankshaft and producing power for the wheels.

Diesel trucks have many advantages and disadvantages. The advantage is that it does not depend on the power supply and is suitable for various railway conditions. The second is that its efficiency is very high, while the energy conversion is relatively high, it also has a large output power. And diesel trains are easier to maintain than steam trains. Diesel trucks also have lower operating costs. For its disadvantages, first of all, diesel locomotive also has a bad impact on the environment, diesel engine emissions include carbon dioxide, nitrogen oxides and other harmful gases. In addition, the market volatility of fuel prices is relatively large, which may cause uncertainty in operating costs. In the process of operation, wear will cause greater economic losses, there will be additional costs.

Diesel engines offer significant advantages for trains, primarily due to their efficiency. Compared to steam engines, diesel engines can generate more power with less fuel, leading to reduced operating costs and lower emissions for train companies. They are also more reliable and require less maintenance, resulting in reduced downtime and fewer delays for passengers. Additionally, diesel engines deliver high levels of torque, essential for hauling heavy loads up steep gradients. Their flexibility allows for various configurations, making them adaptable to different types of trains and operational needs [7].

Higher Upfront Cost: Diesel-engine vehicles generally have a higher initial price due to their more intricate design. Modern diesel engines, with advanced emission control systems, can be even more costly. Additionally, the higher price can be influenced by changes in supply and demand, not just by manufacturing or technological development costs. Diesel-powered vehicles often cost several thousand dollars more than those with petrol or gasoline engines. Diesel engines are more expensive to repair if they are not properly maintained. While they are generally more durable and reliable than gasoline engines, they require meticulous upkeep. The complexity of diesel engines means that repair costs are higher, and maintenance expenses can increase over time due to wear and tear. Diesel engines can struggle in cold climates. Diesel fuel can thicken and form waxy crystals in low temperatures, such as below 40 degrees Fahrenheit, causing potential blockages in fuel filters and lines. To combat this, engine block heaters, glow plugs, anti-gelling additives, or fuels with lower cloud and pour points may be necessary [8].

3. Hybrid electric locomotive

Hybrid electric locomotive is a very advanced form of train engine. The locomotive combines two or more power sources, such as a diesel engine and an electric engine system. This increases its efficiency and flexibility, so that the locomotive can run in different conditions. The principle of hybrid locomotives is to assemble diesel engines and batteries together. During operation, the diesel engine generates electricity to power the electrical system, which drives the train to move.

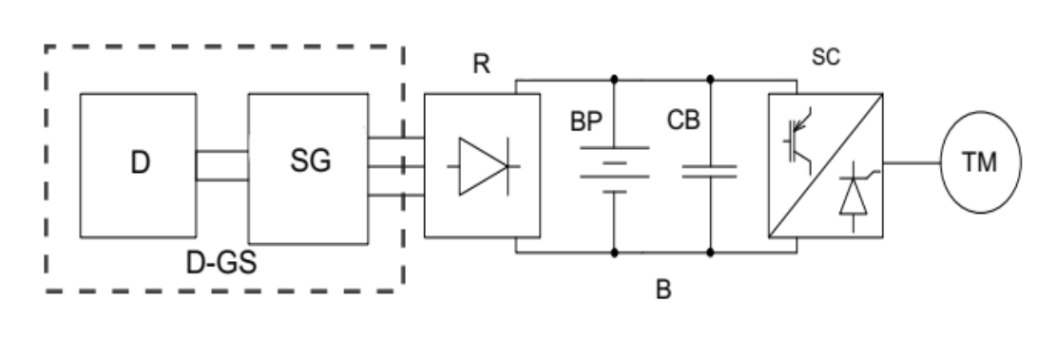

Fig. 2 illustrates the functional layout of a hybrid diesel locomotive, featuring a diesel engine (D), a synchronous generator (SG), and a diesel-generator set (D-GS). It also includes a rectifier (R), energy storage components (battery pack BP, capacitor battery CB, and supercondensers), a static converter (SC), and a traction motor (TM) [9]. On non-electrified routes, hybrid locomotives are ideal, offering a more environmentally friendly alternative to conventional pure diesel engines. In electrified railways, hybrid locomotives can run on electricity, so diesel emissions and pollution are greatly reduced. In addition, flexibility is a highlight of the hybrid locomotive, which allows the train to switch between electric and diesel power according to different conditions, making the operation very flexible. In terms of environmental protection, hybrid electric locomotives also reduce the consumption of diesel fuel and reduce the emission of other harmful gases such as carbon dioxide, contributing to green rail transport.

The hydrogen fuel cell hybrid locomotive boasts numerous advantages, including exceptional speed, power, endurance, and load capacity. Chief Engineer Zhao Mingyuan highlighted that the locomotive is engineered to reach speeds of 80 kilometers per hour and provides a continuous power output of 700 kilowatts. On a full hydrogen tank, it can operate for up to 24.5 hours and handle a maximum traction load exceeding 5,000 tons on a flat, straight track [10]. Furthermore, hybrid locomotives now achieve significantly higher fuel conversion efficiency compared to internal combustion engines, with peak values exceeding 60% in passenger cars, while internal combustion engines rarely surpass 50%. A sufficiently large traction battery is required to manage engine operation and separate its power supply from the demands of the railway [11].

Figure 2. The functional layout of a hybrid diesel locomotive [9].

4. Limitations and prospects

Hybrid electric locomotive is a technology product that has made great progress today, but it still faces some limitations and challenges. These deficiencies are critical to the development of a more efficient and sustainable rail system. The first is cost. Compared with conventional diesel and electric locomotives, hybrid cars are more expensive to develop. Because it requires the use of advanced batteries and supercapacitors, as well as the cost of its complex hybrid system. Investment in research and development is a barrier, especially in some economically underdeveloped regions. Second, the requirements for battery technology are high in hybrid locomotives. As battery performance and life continue to evolve, current battery technology cannot provide the energy, density, or life required. As a result, batteries need to be replaced frequently to ensure operation, which leads to higher maintenance costs. Third, the energy efficiency of hybrid vehicles, while higher than that of conventional diesel engines, is still lower than that of all-electric trains. Especially on long-distance electrified routes. Fuel cell (FC)-powered railroad propulsion systems (RPSs) have become environmentally friendly alternatives due to the zero-emission nature of FCs. While traditional internal combustion engines (ICE) operate at 28%–30% efficiency, electric motors achieve 85%–95% efficiency. Additionally, ICE-based systems experience greater transmission losses compared to the relatively lower losses in electrical power transmission. Early hybrid vehicles used diesel engines as the primary power source and batteries to optimize the ICE's performance by handling additional loads that could disrupt efficiency. Although advancements in battery technology have enhanced the level of electrification in hybrids, batteries alone have not yet completely replaced ICEs [1]. In the future, it is thought there is a huge space for improvement in battery technology. In addition, hybrid vehicles can also be combined with renewable energy, such as the use of solar and wind power as a battery power source, to further reduce environmental pollution.

5. Conclusion

In general, the history of trains from the early days of steam locomotives to today's high-speed electric trains has been long and significant. At first, the emergence of steam power changed the mode of transportation by train, which provided a lot of convenience for people at that time. The introduction of diesel engines has further improved reliability and flexibility. With industrial development, high-speed rail networks are expanding, and more new technologies are being developed, such as hydrogen and other renewable energy fuels. In the future, scholars will create a more connected, more efficient and more environmentally friendly transportation.

References

[1]. Gibbs K 2012 The Steam Locomotive: An Engineering History Amberley Publishing Limited

[2]. Stapleton D H 2017 The origin of American railroad technology 1825-1840 In The Civil Engineering of Canals and Railways before 1850 pp 339-351

[3]. Lo C 2015 Tracks in time: 200 years of locomotive technology Railway Technology p 19

[4]. Dickinson H W 2022 A short history of the steam engine Routledge

[5]. Diesel engines Retrieved from: https://wwwexplainthatstuffcom/diesel-engineshtml

[6]. Andersen M H G, Frederiksen M, Saber A T, Wils R S, Fonseca A S, Koponen I K and Vogel U 2019 Health effects of exposure to diesel exhaust in diesel-powered trains Particle and fibre toxicology vol 16 pp 1-14

[7]. Boretti A 2019 Advantages and disadvantages of diesel single and dual-fuel engines Frontiers in Mechanical Engineering vol 5 p 64

[8]. Ehsani M, Gao Y, Longo S and Ebrahimi K 2018 Modern electric hybrid electric and fuel cell vehicles CRC press

[9]. Boretti A 2023 High-efficiency internal combustion engine for hybrid hydrogen-electric locomotives International Journal of Hydrogen Energy vol 48(4) pp 1596-1601

[10]. Buriakovskyi S, Maslii A, Pomazan D and Pasko O 2020 Prospective model of the hybrid shunting diesel locomotive MATEC Web of Conferences vol 317 p 03002

[11]. Abbas M, Cho I and Kim J 2020 Analysis of high-power charging limitations of a battery in a hybrid railway system Electronics vol 9(2) p 212

Cite this article

Chen,Z. (2024). Analysis the Principle and Applications for Locomotive Engine. Applied and Computational Engineering,98,47-51.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Gibbs K 2012 The Steam Locomotive: An Engineering History Amberley Publishing Limited

[2]. Stapleton D H 2017 The origin of American railroad technology 1825-1840 In The Civil Engineering of Canals and Railways before 1850 pp 339-351

[3]. Lo C 2015 Tracks in time: 200 years of locomotive technology Railway Technology p 19

[4]. Dickinson H W 2022 A short history of the steam engine Routledge

[5]. Diesel engines Retrieved from: https://wwwexplainthatstuffcom/diesel-engineshtml

[6]. Andersen M H G, Frederiksen M, Saber A T, Wils R S, Fonseca A S, Koponen I K and Vogel U 2019 Health effects of exposure to diesel exhaust in diesel-powered trains Particle and fibre toxicology vol 16 pp 1-14

[7]. Boretti A 2019 Advantages and disadvantages of diesel single and dual-fuel engines Frontiers in Mechanical Engineering vol 5 p 64

[8]. Ehsani M, Gao Y, Longo S and Ebrahimi K 2018 Modern electric hybrid electric and fuel cell vehicles CRC press

[9]. Boretti A 2023 High-efficiency internal combustion engine for hybrid hydrogen-electric locomotives International Journal of Hydrogen Energy vol 48(4) pp 1596-1601

[10]. Buriakovskyi S, Maslii A, Pomazan D and Pasko O 2020 Prospective model of the hybrid shunting diesel locomotive MATEC Web of Conferences vol 317 p 03002

[11]. Abbas M, Cho I and Kim J 2020 Analysis of high-power charging limitations of a battery in a hybrid railway system Electronics vol 9(2) p 212