1. Introduction

History of jet engine can be pursuing back to the invention of the aeolipile around 150 BC. A sphere rotated rapidly on its axis through steam power that was provided by the two nozzles [1]. It was not an engine, or even a supply of mechanical power, but a curiosity. Issac Newton was the first who suggested that a rearward-channeled explosion could thrust a machine at a very high speed [2]. This was based on his third law which was about action-reaction force. In 1906, Karavodin patented the first working pulse jet and completed a working model in 1907. Later in 1931, a pulsejet engine which was demonstrated on a jet-propelled bicycle was invented. Pulsejet is a simple and reliable early jet engine. Comparing with the jet engine nowadays, there is no compressor in it. The air enters the engine through the valves, then is mixed with fuel [3]. After the mixture is ignited and explodes, the valves close as the pressure rises and the exhausted gases expand outside through the exhaust tube. Then, the valves are opened again as the pressure reduce and the fresh air flows in again [3]. Gas turbine is the key of a practical jet engine. In the gas turbine, energy is extracted from the engine to drive the compressor [1]. The first patent that the aircraft was powered by a gas turbine was suggested by Maxime Guillaume in 1921[1]. Later on, in 1930, the technological breakthroughs had been made, a jet-driven gas turbine was patented by Frank Wittle. His single-stage centrifugal compressor coupled to a single-stage turbine was tested successfully in April 1937 [1]. This success laid the foundation of the modern jet engine. Meanwhile, the theory of jet propulsion is formulated by Hans von Ohain in German in 1933 [4]. He and Dr. Mac Hahn patented a jet engine in1936, and on August 27, 1939, the first pure jet flight in Rostock [4].

In the development of jet engine, water injection, also known as anti-detonant injection is invented to increase engine thrust at low-altitude and takeoff [5]. Tiny water droplets are sprayed into the incoming air or mixture of fuel and air, or directly into the combustor to cool the engine down. While the temperature is reduced, the evaporative cooling water increase the density so that the engine can dispose larger mass flow rates of air, in order to produce higher thrust [6]. Water injection can also improve the power and fuel efficiency and reduce some of the gases emissions. As the development of modern technology, jet engine is widely used in areas of aviation, aerospace and UAV (unmanned aerial vehicle). Jet engine is favored for its high efficiency and high velocity. In aviation, research on jet engine focuses on increasing of thrust, reduction of fuel consumption and improvement of reliability and durability so that jet engine can be used more widely in commercial aircraft. Jet engine becomes the main choice of UAV because of its high speed and long-range capability of flight. Since more attention have been paid on the environmental problem, challenges are faced in the invention and development of jet engine. Electric and hydrogen fuel become trends but they still have limitations in their ways. To understand more about the jet engine, this article explains the principle of jet engine and descriptions of different jet engine. Moreover, there is the current status and the future status of jet engine. As what is mentioned in the previous part, there is also the explanation of impacts ad limitations of jet engine.

2. Descriptions of engines

Engine of an aircraft works as propulsion system that mechanical power is generated to push the aircraft. Engines are placed below the wings of aircraft, in order to allow thrust to push the aircraft in the forwarding direction by air [7]. The modern jet engines used in aircraft are mainly turbojet, turbofan, turboprop, turboshaft and ramjet. According to their tiny difference in structure, they are applied to different areas such as military, commercial and rocket engine.

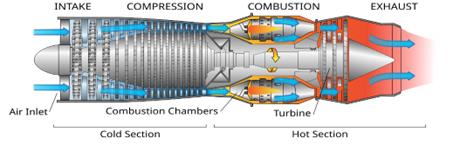

Turbojet engine is combined with diffuser, compressor, pump, fuel injector, combustion chamber (combustor), shafts, turbine, afterburner and nozzle, shown in Fig. 1 [8, 9]. It is easy to understand the concept of turbojet engine. Air flows into the diffuser which bring air molecules closer together [8]. Then, it enters the compressor and is compressed to 3 to 12 times its original pressure [2]. In combustion chamber, fuel is pumped to the air through fuel injector, the mixture is combusted to about 1100°F to 1300°F [2]. The high temperature generates high pressure energy. This energy is directed to turbine to rotate the blades and drive the compressor due to the shaft connected between the turbine and compressor [8]. The excess pressure is sent to the nozzle, where a thrust is produced by high velocity stream of gas [2]. There is also an afterburner which can increase the thrust. It is a second combustor positioned between turbine and nozzle. Finally, exhausted gases are emitted through the nozzle. It preforms better at high speeds and altitudes, so turbojet engine is mostly used in military aircraft and supersonic jets [8]. Because it's noisy operation and reduced efficiency at lower speeds, it is not enough suitable for commercial aircraft.

Figure 1. Structure of turbojet [9].

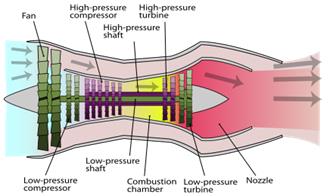

Turbofan engine was developed from turbojet and turboprop engines (seen from Fig. 2). Its principle is similar to the turbojet engine, but a large ducted fan is located at the front for suck in the air. The inlet air is separated into two streams. One enters the core of the engine (compressor, combustor and high pressure turbine) while the remaining passes through the low-pressure compressor or the fan [9]. It bypasses air and flows around the engine and is accelerated to create additional thrust without increasing consumption of fuel [9]. It converts gas streams into mechanical power to gain power. Not only the fan increases the thrust, it also cools the engine and reduces the noise of the engine. Its fuel-efficient due to the bypass airflow and better performance in lower speeds make turbofan engine be suitable for commercial aircraft [8]. Nevertheless, turbofan engine is a bit heavy because of its large frontal area.

Figure 2. Structure of turbofan [9].

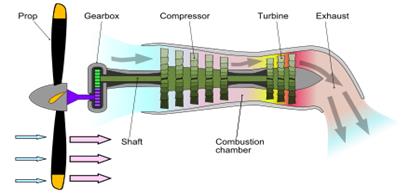

Turboprop engine is a turbojet that uses a gears system attached to the propeller of aircraft (depicted in Fig. 3) [9]. It works similar to turbojet engine that uses air and gas pressure to run the turbine, then produces power to run the compressor. What is different is that before the exhausted hot gas enters the nozzle, it passes through an additional turbine which attached to an additional drive shaft [10]. The shaft connects to a gearbox, which then connects to the propeller that creates most of the thrust. one knows that the power produced by the engine is also used to drive the propeller. Since the spinning velocity of the turbine is much faster than the propeller, the gearbox is also used to slow down the spinning shafts [9]. Therefore, the gearbox is also called reduction gearbox. The aircraft blades are scimitar-shaped, with swept-black leading edge at blade tips for higher efficiency at high speeds [2]. To accommodate the higher speed, modern turboprop engine has smaller diameter but lager number of blades [9]. Turboprop engine is used on some small airlines and transport aircraft. It performs better at a mid-range speed and altitude.

Figure 3. Structure of turboprop [9].

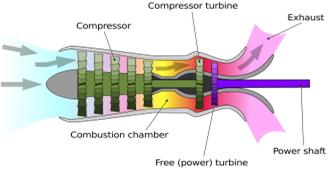

Turboshaft engine operates similar to turboprop engine, which is used on helicopters generally as illustrated in Fig. 4. In turboshaft engine, the gearbox is not used to drive a propeller but is used to produce power to the helicopter rotor [9]. The turboshaft engine has a large shaft connected from the front to the back, which makes it be different to the turbojet. Most of the power that the turboshaft engine produced is used for turning the turbine instead of producing thrust. The turbine of turboshaft is connected to the shaft to power the rotor blade transmission [9]. Similar to turbofan, it converses gases in high speed into mechanical power, in order to run compressor and turbine. The design of turboshaft engine makes the rotation of the speed of a helicopter rotor be independently and constantly [9]. The gearbox here is to propel the aircraft forward.

Figure 4. Structure of turboshaft [9].

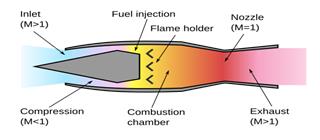

Ramjet engine is essentially a turbojet engine without rotary compressor as presented in Fig. 5. It is the lightest engine which has no moving parts [9]. It compresses the air by using the forward motion of the engine [11]. The compression ratio depends on the forward speed of the aircraft [2]. Since the compression changes with the speed, in ramjet, the efficiency of the engine drops as the speed of the aircraft increase. This is because the temperature of air increases due to the change in compression [8]. Different to the other engines, the ramjet dose not develop static thrust. Its thrust is generally below the sound speed [9]. Therefore, assistance is needed for takeoff, such as another aircraft. Space vehicles and some guided-missile systems use this type of engine.

Figure 5. Structure of ramjet [9].

3. Principle of jet engine

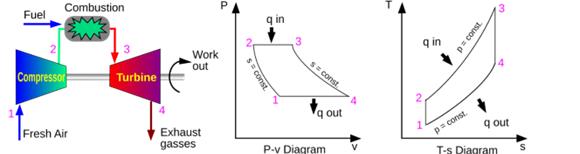

All the jet engines have the identical work principle. The engine sucks in air through the inlet fan. The air enters the compressor which consists with many blades attached to a shaft [2]. The blades spin at high speed to squeeze the air to raise the pressure. Fuel is then spayed to the compressed air, then electric sparks ignite the mixture [2]. The burning gases expand and blast out through the nozzle. According to the third law of Newton, The aircraft is thrust forward as the shoot back of the gases [2]. Before the gases exhaust through the nozzle, they pass through another group of blades called turbine which is connect to compressor through the shaft [2]. The spinning of compressor is caused by the spinning of the turbine [2]. This process is called Brayton thermodynamic cycle.

Thrust is the reaction force that pushes the aircraft forward. According to the third law of Newton, every action in nature there is an equal and opposite reaction. The jet engine uses this principle. When the air leaves the engine, there is a reaction force that thrusts the aircraft forward. The process of Brayton Cycle is shown in Fig. 6 with following processes [12]:

• 1-2 adiabatic process: air enters the compressor

• 2-3 isobaric process: the compressed air then flows into the combustor where fuel is sprayed. Sparks then ignite the mixture.

• 3-4 adiabatic process: Expansion of the burning gases.

• 4-1 isobaric process: Heat rejection.

Figure 6. Process of a Brayton cycle [12].

Brayton cycle is most applied to airbreathing jet engine and gas turbine engines. As isentropic compression and expansion can only exist ideally, losses through the compressor and the expander is the root of inefficiency of the cycle. The efficiency of the ideal Brayton cycle is:

\( \eta=1 - \frac{T_1}{T_2}=1 - \left(\frac{P_1}{P_2}\right)^{\frac{\gamma - 1}{\gamma }\ } \) (1)

where \( \gamma \) is the heat capacity ratio.

4. State of art facilities

The Trent Family is a group of aircraft engine invented by Rolls-Royce. There are seven family members including Trent 7000, Trent XWB, Trent 1000, Trent 900, Trent 500, Trent 800 and Trent 700. The Trent is designed to power the Airbus A330, the Airbus A380, the Boeing 787 and the Airbus A350 XWB. The family has light weight, shorter and more rigid engine with lower performance degradation [13]. Trent XWB is the World’s most efficient large aircraft engine. This engine is designed for the A350 and reduces 25% fuel burn and carbon dioxide emissions with 22 blades and 9.6:1 bypass ratio. Trent XWB-84(2015) has a thrust of 84000lbs while the Trent XWB-97(2018) has 97000lbs thrust. There are more than 1800 Trent XWB engines are in service [14]. As the aerospace industry always tries to find the balance between environmentally friendly and efficient of the engine technology, the significant player like Rolls-Royce invents the world’s largest jet engine UltraFan, which can be run at full power on 100% Sustainable Aviation Fuel [15]. UltraFan is still a demonstrator aero engine and is expected to be used in the 2050s. It has an efficiency 10% more than Trent XWB with thrust of 25000lb to 110000lb (as shown in Fig. 7) [15].

Figure 7. A sketch of UltraFan [15].

GE9X is purposely built for the Boeing 777X family by GE Aerospace. It is the largest and most powerful commercial aircraft engine with 16 composite fan blades, bypass ratio of 10:1 and thrust of 60k Newtons [16]. The XA100 adaptive cycle engine is designed by GE Aerospace, which is capable for the F-35 military aircraft. The thrust of XA100 can reach more than 200k Newtons. Its lighter weight and more durable materials allow the aircraft to operate more than 20% of acceleration [17]. The technology of adaptive cycle engine makes XA100 exceed other military jet engines. Many countries start the invention on the UAV. Turbofan engines which have larger thrust and higher efficiency become the first choice of these unmanned aerial vehicle to satisfy its requirement of long-range flight. The Korean KUS-LW is equipped with AI322 designed by Ivchenko Progress Zaporozhye Motor Sich JSC. AE300H with 40kN thrust from Rolls-Royce is equipped on RQ-4 of the US while RQ-170 is equipped by TF34 of GE Aerospace.

Turboshaft and turboprop are mostly used at mid-range UAV. It has lower fuel consumption than turbofan engines. Mojave of GA-ASI is equipped by M250-B17F from Rolls-Royce. The ‘Catalyst’ engine of GE Aerospace is used on Eurodrone of INTA while an Aarok is equipped by a PT6 turboprop engine. Meanwhile, turbojet engine is capable for high-speed flight, so aircraft like unmanned scout use these engines. The LEAP-1C integrated propulsion system of the CFM International team achieved the certification of both the European Aviation Safety Agency and the US Federal Aviation Administration. This engine is selected for the COMAC C919 airplane with a maximum thrust of 31000lbs and bypass ratio of 11:1 (depicted in Fig. 8) [18].

Figure 8. A sketch of LEAF-1C [18].

5. Impact of jet engine

A jet engine is a machine that transform energy-rich, liquid fuel into thrust. They work by burning the fuel in air to exhaust hot gases. As a result, aviation takes the responsibility of air pollutions. In fact, 2% of global man-made greenhouse effect are because of aviation. The scientist discovered that nitrogen oxides, contrails and carbon dioxide account for 97% of negative effects in environment and health, so these three components are mainly reviewed here. Aircraft engines produce emissions that are similar to the other emissions due to fossil fuel combustion. There are loads of gases and particles are emitted during combustion such as, suspended particulates and carbon monoxide etc. The most important one except carbon dioxide is nitrogen oxides. Nitrogen in the air react with oxygen in the extremely high temperature and pressure in the combustor to form nitrogen monoxide. It then reacts with oxygen in the air spontaneously to form the brown nitrogen dioxide. For these compounds, a series of environmental problems are created. For example, nitrogen oxides and unburnt hydrocarbon cause photochemical smog. Nitrogen oxides and sulphur dioxide cause acid rain while acid rain corrodes marble buildings, destroy soil and kill plants. Despite these, the emissions also attack human’s respiratory system and cause health problems either.

For carbon dioxides, fuel replacement can be useful. First is biofuel. Sugar cane and recycled cooking oil are the mainly sources of sustainable aviation fuels [19]. They are renewable and less polluting than jet fuel. They exhaust fewer pollutant even when mixed with jet fuel. The dilemma for airlines is that biofuels are four times more expensive than traditional jet fuel. Hydrogen fuel is also a way out. Liquid hydrogens are stored at minus 250 degree Celsius in a special tank in the rear fuselage during the flight [19]. Thus, the flight could the fly non-stop form London to San Francisco. The public still have the misconception of hydrogen fuel that it is not safe. Actually, they all have the impressive safety record due to the extensive safety precautions that are considered in the design and operation of the hydrogen fuel aircraft. There is also electric power. Research into greener global transport suggested that electric power is a crucial element to meet future environmental targets [19]. While electric aircrafts have existed for decades, experts agree that the battery technology have to take a balance advanced in weight and storage to make large, commercial electric planes a reality.

For nitrogen oxides, catalytic convertors are commonly used in the car engines to transfer nitrogen oxides to nitrogen gases. However, it is too heavy for most of the airplanes. A method called water injection is invented to help reducing the emission of nitrogen oxides. On many early aircraft engines, water was sprayed into the engine combustors to reduce the temperature of the engines. This approach increased thrust without increasing inlet temperature of turbine. Despite the thrust benefits, it can reduce nitrogen oxides emissions by up to 80% in turbofan engine. For shorter range flight within 3000km, the effect of carrying the extra water is offset by the benefit, whereas for longer range missions beyond 3000 km, the weight penalty outweighs the performance benefit in most cases. However, there are impacts that caused by water injection. Since the contrail formation is caused by water in the plume of aircraft, the presence of additional water may deteriorate this impact [6]. In addition, soot formation may also increase because of the reduction in flame temperature [6].

There are some pollutants that are mainly produced by airplane, which is contrails. Hot water vapor condensed in atmosphere due to combustion cools and freezes to form cirrus clouds [20]. These clouds are insufficient to reflect much sunlight [20]. Clouds like contrails also trap that heat that try to radiates from the surface into space during the radiative cooling of the Earth at night [21]. The heat energy keeps in the atmosphere and warm up the climate. Therefore, the contrails-formed clouds do not like other low-level clouds that have a net cooling effect [20]. The fact is that the plane contrails actually have a larger warming effect than all the carbon dioxide emitted by planes that has accumulated in the atmosphere [22].

For contrails, rerouting planes can be a solution. American Airlines employed satellite imagery, weather data, software models, and AI prediction tools in 70 test flights over six months, and the subsequent satellite data indicated that 54% of total length of contrails are reduced, relative to the flights that were not rerouted [23]. The warming effect of contrails are reduced by 73% with only 0.11% of increase in fuel cost [23]. There are other methods, such as switching to different types of fuels or continuing to develop more capable electric or hydrogen-powered aircraft, that can also help to control the formation of contrails while rerouting flights could be one of the simplest ways. Nevertheless, more fuel means greater expenses, so airlines may not likely to voluntarily implement such measures if it’s not relatively affordable [23].

6. Limitations and prospects

Although the technology is very advanced nowadays, there are still some limitations and challenges that the scientists and engineers have not overcome yet, such as excessive temperature, weather conditions, materials etc. What should be believed is that people will find the solutions as the further invention on aerospace. There is a limitation of the temperature of jet engines. Once the blades of engine expose to the temperature higher than the limitation, the blades begin to ‘creep’ [24]. The blade tip clearances between the compressor and the turbine are designed to against their respective boundary walls. The blades will begin to scratch against the walls if they elongate too much. The rubbing slows the rate of the turbine’s rotation and cause a higher fuel consumption rate. To produce the rated thrust, hot-section temperatures are increased [24]. Moreover, high amplitude shaft vibrations and blade wear will be caused by the worse situation. This may cause catastrophic failure of the whole engine [24]. Because of the wear, the performance may also be degraded through the time. This excessive temperature may be caused by weak battery. The rate of the turbine is insufficient to provide enough cooling air in the combustion chamber. Problems come with the benefits that brought from the development of engine. Harmful gases are exhausted from the working engine and cause different environmental problems such as global warming and acid rain. These primary impacts lead to other secondary impacts that affect humans’ life in long term such as corrosion of buildings, ice melting and water flooding. It is always hard to find the balance between beneficials of human beings and the effect of human beings on the Earth. No matter military used jet engine or the jet engine used on commercial aircraft, the cost of production and maintenance are usually high because of the sophisticated designs and expensive materials. Small engines can cost between $40000 and $70000 while larger business engine cost between $1.5 and $3.5 million [25]. Large aircraft like Boeing 777 and A380, their engines can range from $25 to $45 million [25]. Meanwhile, military used engines are even more expensive than that. As the crucial role of jet engine in aviation, its working frequency affect the life span of the engine. The excessive temperature and cost of maintenance both can make jet engine be wore. Typically, the aircrafts can fly between 25000 and 45000 flight cycle before the retirement of jet engine [26].

New energy aircrafts have been promoted such as hydrogen fuel and electricity. In the previous work of state of art facilities of the new engines, some demonstrator engines and new engines have already been able to run on sustainable aviation fuels, which different airlines promote to refine their potential of decarbonization ambition. However, the technology has not been completed to be widely promote and used on all kind of aircraft.

7. Conclusion

To sum up, this study generally introduces the application of jet engine, starting with the history and principle of each type of jet engine. Some latest use on the aircraft of this engine is lay out in the fourth part of the article. The benefits of jet engine in the modern society are well shown in the sorting of information. What come with the benefits is the negative impacts on environmental due to this human being. Polluted gases are exhausted from the combustion of jet fuel. This becomes a big challenge of the further development of this technology. Not only the pollutions, but there are also some limitations in the invention and improvement of jet engine, such as complicated manufactured materials and the excessive temperature during operating. Because of the limitations, electrical jet engine and hydrogen fuel jet engine are the new trend of jet engine technology.

References

[1]. Rolls Royce P 2015 The jet engine John Wiley & Sons

[2]. NASA 2021 National Aeronautics and Space Administration Engines Retrieved from: https://gonasagov/471U4NY

[3]. Hussain S 2008 Theoretical and Experimental Evaluation of Pulse Jet Engin Master dissertation of University of Khartoum

[4]. Wenzel J 2022 The history of jet engines John Wiley & Sons

[5]. Zhu S, Hu B, Akehurst S, et al 2019 A review of water injection applied on the internal combustion engine Energy conversion and management vol 184 pp 139-158

[6]. Syed S Z 2022 Impact of Water Injection on Emissions of Nitrogen Oxides from Aircraft Engines Unpublished Master dissertation of Purdue University

[7]. Mechanic Realm 2021 Aircraft Engine BIT publisher

[8]. Testbook Ed 2023 Turbojet Engine: Learn Diagram Parts Working Advantages and Applications BIT publisher

[9]. Aero Corner 2021 The 5 Main Types of Aircraft Jet Engines BIT publisher

[10]. Lange R H 1986 A review of advanced turboprop transport aircraft Progress in Aerospace Sciences vol 232 pp 151-166

[11]. Avrashkov V N, Metelkina E S and Meshcheryakov D V 2010 Investigation of high-speed ramjet engines Combustion Explosion and Shock Waves vol 46 pp 400-407

[12]. Le Roux W G, Bello-Ochende T and Meyer J P 2013 A review on the thermodynamic optimisation and modelling of the solar thermal Brayton cycle Renewable and sustainable energy reviews vol 28 pp 677-690

[13]. Pugh P 2015 The Magic of a Name: The Rolls-Royce Story Part 2: The Power Behind the Jets Icon Books Ltd

[14]. Todd D and Eriksson S 2015 Engines The Global Commercial Aviation Industry pp 107-137

[15]. Decher R 2020 Powering the World's Airliners: Engine Developments from the Propeller to the Jet Age Air World

[16]. GE Aerospace Ed GE9X Retrieved from: https://bitly/3MoTd0u

[17]. GE Aerospace Ed XA100 Retrieved from: https://bitly/3AGYcqI

[18]. Mongia H C 2014 Future trends in commercial aviation engines’ combustion In Novel combustion concepts for sustainable energy development pp 113-176 Springer India

[19]. World Economic Forum 3 ways we can keep flying with zero-carbon emissions Retrieved from: https://bitly/3AEfVyV

[20]. Camero K 2019 Aviation’s dirty secret: Airplane contrails are a surprisingly potent cause of global warming Science p 2806

[21]. Singh D K, Sanyal S and Wuebbles D J 2024 Understanding the role of contrails and contrail cirrus in climate change: a global perspective Atmospheric Chemistry and Physics vol 2416 pp 9219-9262

[22]. Le Page M 2019 It turns out planes are even worse for the climate than we thought New Scientist p 27

[23]. Sausen R, Hofer S M, Gierens K M, Bugliaro Goggia L, Ehrmanntraut R, Sitova I and Miller N 2023 Can we successfully avoid persistent contrails by small altitude adjustments of flights in the real world? Meteorologische Zeitschrift

[24]. Smith M L 2013 Search engine liability for autocomplete defamation: Combating the power of suggestion U Ill JL Tech & Pol'y p 313

[25]. Cumpsty N and Heyes A 2015 Jet propulsion Cambridge University Press

[26]. Ackert S 2011 Engine maintenance concepts for financiers Aircraft Monitor vol 2 pp 1-43

Cite this article

Huang,K.W. (2024). Analysis of the Principle of Jet Engine and State-of-art Application. Applied and Computational Engineering,98,52-60.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Rolls Royce P 2015 The jet engine John Wiley & Sons

[2]. NASA 2021 National Aeronautics and Space Administration Engines Retrieved from: https://gonasagov/471U4NY

[3]. Hussain S 2008 Theoretical and Experimental Evaluation of Pulse Jet Engin Master dissertation of University of Khartoum

[4]. Wenzel J 2022 The history of jet engines John Wiley & Sons

[5]. Zhu S, Hu B, Akehurst S, et al 2019 A review of water injection applied on the internal combustion engine Energy conversion and management vol 184 pp 139-158

[6]. Syed S Z 2022 Impact of Water Injection on Emissions of Nitrogen Oxides from Aircraft Engines Unpublished Master dissertation of Purdue University

[7]. Mechanic Realm 2021 Aircraft Engine BIT publisher

[8]. Testbook Ed 2023 Turbojet Engine: Learn Diagram Parts Working Advantages and Applications BIT publisher

[9]. Aero Corner 2021 The 5 Main Types of Aircraft Jet Engines BIT publisher

[10]. Lange R H 1986 A review of advanced turboprop transport aircraft Progress in Aerospace Sciences vol 232 pp 151-166

[11]. Avrashkov V N, Metelkina E S and Meshcheryakov D V 2010 Investigation of high-speed ramjet engines Combustion Explosion and Shock Waves vol 46 pp 400-407

[12]. Le Roux W G, Bello-Ochende T and Meyer J P 2013 A review on the thermodynamic optimisation and modelling of the solar thermal Brayton cycle Renewable and sustainable energy reviews vol 28 pp 677-690

[13]. Pugh P 2015 The Magic of a Name: The Rolls-Royce Story Part 2: The Power Behind the Jets Icon Books Ltd

[14]. Todd D and Eriksson S 2015 Engines The Global Commercial Aviation Industry pp 107-137

[15]. Decher R 2020 Powering the World's Airliners: Engine Developments from the Propeller to the Jet Age Air World

[16]. GE Aerospace Ed GE9X Retrieved from: https://bitly/3MoTd0u

[17]. GE Aerospace Ed XA100 Retrieved from: https://bitly/3AGYcqI

[18]. Mongia H C 2014 Future trends in commercial aviation engines’ combustion In Novel combustion concepts for sustainable energy development pp 113-176 Springer India

[19]. World Economic Forum 3 ways we can keep flying with zero-carbon emissions Retrieved from: https://bitly/3AEfVyV

[20]. Camero K 2019 Aviation’s dirty secret: Airplane contrails are a surprisingly potent cause of global warming Science p 2806

[21]. Singh D K, Sanyal S and Wuebbles D J 2024 Understanding the role of contrails and contrail cirrus in climate change: a global perspective Atmospheric Chemistry and Physics vol 2416 pp 9219-9262

[22]. Le Page M 2019 It turns out planes are even worse for the climate than we thought New Scientist p 27

[23]. Sausen R, Hofer S M, Gierens K M, Bugliaro Goggia L, Ehrmanntraut R, Sitova I and Miller N 2023 Can we successfully avoid persistent contrails by small altitude adjustments of flights in the real world? Meteorologische Zeitschrift

[24]. Smith M L 2013 Search engine liability for autocomplete defamation: Combating the power of suggestion U Ill JL Tech & Pol'y p 313

[25]. Cumpsty N and Heyes A 2015 Jet propulsion Cambridge University Press

[26]. Ackert S 2011 Engine maintenance concepts for financiers Aircraft Monitor vol 2 pp 1-43