1. Introduction

Due to its unique properties, infrared thermal imaging monitoring equipment is increasingly utilized in the field of civil security, including applications such as surveillance cameras to anti-theft alarm detectors, and high-end infrared thermal image detectors, working together to achieve 24 hours of uninterrupted security [1]. However, the field of infrared technology is still in its early stages of development. This paper mainly realizes the application of infrared thermal imaging in ship detection by studying infrared thermal imaging technology. Infrared thermal imaging can timely find the damage to ship equipment. It can solve the navigation of fog narrow sea areas in advance more timely and comprehensively guarantee the safety of ships.

2. Literature review

2.1. The principle of the infrared radiation

The essence of infrared radiation is a kind of electromagnetic wave. When the temperature of the object is above absolute zero, infrared radiation will be produced. This infrared radiation is captured by the sensor of the infrared detector and transmitted to the electronic information processing and display system, forming the infrared image [2] that the human eye can perceive. As shown in the Figure 1 is the infrared schematic diagram

Figure 1. Display of the ship on infrared thermal imaging Fig.

2.2. Infrared thermal imaging technology and its characteristics

Nondestructive detection for infrared thermal imaging is a non-contact thermal measurement method with high precision. The gray values of the infrared thermal images output by the camera represent the thermal distribution and temperature distribution of the different regions. Breaking through the limitation of dim light at night, without external interference such as strong light and flash, it can achieve long-distance all-weather observation and more adapt to the port operating environment.[3] Through the analysis of the temperature record map, the temperature and temperature changes of different parts of the object can be determined to achieve non-contact heat measurement, monitoring and diagnosis[4].

2.3. The infrared imaging system has the following characteristics:

First, in terms of adaptability to the external environment, the infrared light has excellent performance, especially at night or in poor weather, such as thunderstorms and hail, and the infrared imaging system has a strong working ability. Second, in terms of light penetration ability, infrared light is stronger than visible light. In a hazy environment, the human eye cannot perceive the surrounding objects, whereas infrared light can accurately capture the targets in the environment. Third, the target images obtained by this system have exceptionally high resolution due to the short infrared wavelength, resulting in minimal interference when propagating through the atmosphere. Fourth, in the aspect of identifying true and false targets, infrared light is obviously better than visible light and radar wave, because infrared detection mainly depends on the temperature difference and radiation rate difference between the foreground and background, the number of error detecting is less, and has a strong ability to identify camouflage targets. Fifth, in terms of concealment, the infrared detection system has good performance, which is mainly attributed to the infrared sensor passively receiving the infrared thermal radiation wave emitted by the target scene, while the radar detection system needs to emit electromagnetic waves first, and then detect the returned spectrum, which is easy to be found by the external target, poor concealment. Because the infrared imaging system has the above advantages, the infrared imaging system is widely used in ship target detection and scene matching, etc. So not only makes up for visible light detection at night and haze environment blind areas, but improve the accuracy of the detection but also improves the concealment and security of Marine comprehensive detection system [5].

Figure 2. Infrared thermal imaging working process.

3. Application of infrared thermal imaging technology in ship detection

3.1. Anti-collision detection of infrared technology during navigation

The ship is usually in operation during the navigation. In general weather, the personnel on duty can observe the obstacles in the navigation line through the naked eye or radar, such as other navigation vessels on the bridge or some floating objects, to avoid collision. The personnel on duty must promptly make adjustments to the navigation route. However, in certain extreme weather conditions and narrow sea passages, the navigation requirements are highly demanding. Therefore, infrared thermal imaging technology is necessary to ensure safe navigation. Infrared thermal imaging for common hazards provides an "early warning system", can clear obstacle images on thermal image detector, thermal image detectors system by improving visibility under the condition of low light or haze, make up for the shortcomings of the video tracking system, the tracking system can find the target, and continuously update the target orientation, range and height. According to the design principle of the infrared thermal image detector, as long as there is a temperature difference, the infrared thermal image of the infrared thermal image detector will be displayed in different colors, the lower the temperature, the darker the color, on the contrary, the higher the temperature, the brighter the color.

Making decisions at night is a challenge for all first respondents. The remote infrared thermal camera system helps users observe suspicious activities or respond quickly to emergencies. Remote thermal cameras can create more reaction time for users by helping to identify suspicious or threatening behaviors. Monitor at a safe distance, and then intervene at the right time to make changes and decisions the first time.

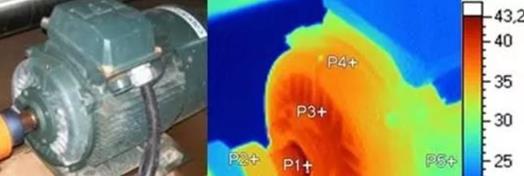

3.2. Infrared technology for the fault detection of the motor and a series of equipment

For some equipment columns such as screw compressors, the exhaust temperature of the unit exceeds 100℃, the unit current is excessive, and the current is large when the unit starts or trips, the cause of the fault is shown in Table 1 [6]. After analysis, it is concluded that not only the screw compressor but also many motors requiring the motor operation equipment will produce heat in the operation. The infrared camera can identify the abnormal conditions inside the motor, such as heating, overload, short circuit and other problems, inside the motor by measuring the temperature change of each part of the motor. Different injuries and faults will cause different hot spots and thermal anomalies, different injuries and faults, and different hot spots and thermal anomalies [7] as shown in Figure 4. According to Figure 3, the temperature spreads from high to low, from the middle to the outside. By using infrared thermal imaging nondestructive detection technology, the surface temperature distribution image of the motor winding can be obtained quickly and non-contact. Real-time monitoring for abnormal changes in motor operation can be conducted through comparative analysis, enabling early detection and handling of faults.

Table 1. Fault type analysis.

Fault types |

Fault causes |

The motor temperature is too high

|

1. The lubricating oil film on the surface of the parts is broken, the metal friction is high, which leads to the destruction of the metal crystalline structure, and the motor temperature is too high due to serious wear or burns of the motor bearings and rotors, resulting in motor failure; 2. The medium is repeatedly compressed, and the rotor is seriously worn, resulting in leakage in the compressor, resulting in insufficient suction or too large clearance between the rotor and the exhaust seat, and incomplete exhaust, resulting in the compressor suddenly stopping and jumping, and the motor temperature is too high; 3. The lack of phase of the motor leads to insufficient torque, blockage of the motor water-cooled pipe bundle, excessive current, and too high air temperature brought in by the motor fan. |

The cylinder temperature is too high |

1. Ammonia inhales too much heat, and the inlet air temperature is higher than the cylinder temperature 2. The friction heat increases due to severe wear of the friction pair; 3. The compression ratio is too high, the compressor does too much work, and generates more heat; 4. Due to the leakage of the bypass, the medium is repeatedly compressed, resulting in too high temperature. |

The exhaust temperature is too high

|

The exhaust temperature is too high due to insufficient fuel injection of the screw compressor, damage and failure of the thermocouple, blockage of the cooler, blockage of the mist eliminator, blockage of the lubricating oil filter, and failure of the cooling fan. |

The temperature of the sealed bearing is too high |

Due to insufficient oil supply pressure, oil supply, oil deterioration or emulsification, etc, the original temperature is too high, resulting in the temperature of the seal bearing |

Figure 3. Generator thermal imaging map.

3.3. Infrared technology in the refueling or oil spill situation judgment and detection

The first is oil spill detection: an infrared thermal image detector can detect oil on the sea surface because oil usually has different temperature characteristics from the surrounding water. The thermal image detector can detect the thermal characteristics of oil pollution and help quickly detect the oil spill points to take emergency response measures. The infrared oil spill image detection system requires importing the serial images from the designated infrared camera, saving the corresponding files to the local, and also supports loading video [8] from the local offline files. Secondly, oil spill range estimation: by analyzing the temperature distribution in the infrared image, the area and range of the oil spill can be estimated. This will help relevant authorities better plan emergency response operations and ensure timely measures are taken to reduce environmental damage. Subsequently, environmental monitoring: infrared thermal image detector can monitor the diffusion of the oil spills in the ocean and track the propagation path of oil spill substances in the seawater. This study aims to assess the potential impact of oil spill events on the ecological environment and to develop measures for protecting marine ecosystems. Finally, monitoring at night and in bad weather: the infrared thermal image detector is equally effective at night and in bad weather conditions, and it is not limited by light and visibility. This makes them very useful in 24-hour monitoring, ensuring a timely response to oil spill events.

The infrared thermal image detector plays a crucial role in detecting offshore oil spills. This technology enables quick and accurate identification of oil spill events, leading to prompt and effective response measures. As a result, it helps to minimize environmental impact and economic losses associated with such incidents. In combination with other monitoring technologies, the infrared thermal image detector can improve the emergency response capacity and monitoring efficiency of oil spill events.

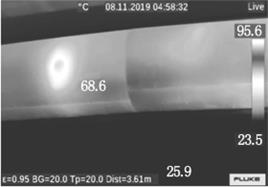

3.4. Detection of infrared technology in pressure-bearing equipment

Due to the presence of various equipment on the ship, such as steam pipes [9] operating at both low temperature and low pressure, as well as high temperature and high pressure, there is often significant pressure exerted on the pipes. This can result in pipe deformation, particularly when the pipes are covered with insulation to reduce heat exchange with the external environment. Over time, this deformation may not be visible to the naked eye, leading to poor heat transfer efficiency and potentially causing pipe rupture or damage to the insulation. As a result, uneven temperature distribution may occur. As shown in Figure 4, the upper depression is caused by the long-term work of the pipe belt, but it is not visible with the naked eye. We can find the abnormal temperature through infrared technology. We removed the outer metal protective layer to confirm that the insulation material was damaged [10].

Figure 4. Display of the damaged pipe in the thermal imaging map.

4. Conclusion

The thermal imaging technology described in this paper plays a vital role in the safety of devices on board and ships. Infrared thermal imaging can detect potential overheating faults in advance, reducing equipment damage and downtime. It can help to identify overload, short circuits, and poor contact within the electrical system.

Infrared thermal imaging can also assist the crew in better identifying other ships and floating objects, enhancing navigation safety. However, applying infrared thermal imaging technology on ships is subject to certain limitations, including the complex shipboard environment, such as intense exposure to sunlight, reflection from the sea surface, and high temperatures and humidity. The resolution of some infrared thermal imaging devices may not be high enough to make it difficult to present and distinguish clearly and accurately for some small parts or subtle temperature differences. The surface material, color, roughness and other characteristics of the object will affect its emission and absorption of infrared radiation, thus affecting the measurement accuracy of thermal imaging. As well as the future infrared automatic scanning directly on the computer to form thermal imaging and automatic alarm in danger are the need for more in-depth exploration, hope that infrared technology can be more widely used in ships in the future.

References

[1]. Xue Sheng Yue. Research on the application of infrared thermal imaging technology in the field of perimeter protection[J]. China Security,2023,(Z1):89-93.

[2]. WANG Yong, WANG Bairong, MU Dongdong. Research status and prospect of infrared ship detection[J]. Journal of Dalian Maritime University,2023,49(04):103-115.

[3]. XU Chengjun, JI Yubali, WANG Kun. Position acquisition and identification of nearshore vessels based on infrared thermal imaging[J]. Port Technology,2024,(02):1-5.

[4]. DU Jingwei, BER Yang, DONG Yun, SHI Yunlei. Application of infrared detection technology in ship electrical equipment[J]. China Ship Repair,2023,36(02):34-36.

[5]. Liu Cheng,Research on motion ship detection technology based on infrared image[J]. Wuhan university of technology,2015,(04).

[6]. Li Ang,Wang Chuanping,Rao Binyuan,Luan Sijia,Hu Feng,Chen Yuntao. Research on screw compressor fault monitoring system based on infrared temperature measurement technology[J]. Equipment Management and Maintenance,2023,(15):55-58.

[7]. Pašagić V, Mužević M, Kelenc D. Infrared thermography in marine applications[J]. Brodogradnja: An International Journal of Naval Architecture and Ocean Engineering for Research and Development, 2008, 59(2): 123-130.

[8]. Deng Qianqian. Research on oil spill area detection method of infrared image[J]. Huazhong University of Science and Technology,2020,(05).

[9]. MENG Lingmin, NIU Shuai, ZHAO Shuyi, ZHANG Shaokun, ZHANG Xin, YE Jiayan. Typical application of infrared thermal imaging detection technology in pressure class special equipment[J]. Nondestructive Testing,2024,48(03):44-46.

[10]. SAUNDERS, Craig T.: ‘The Use of Thermal Imagery in Locating Stress Fractures in Yachts’, Thermal Imaging Techniques InfraMation 2004.

Cite this article

Kong,B. (2024). Application Research of Infrared Technology in Safety Detection in Ship Field. Applied and Computational Engineering,102,193-198.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Xue Sheng Yue. Research on the application of infrared thermal imaging technology in the field of perimeter protection[J]. China Security,2023,(Z1):89-93.

[2]. WANG Yong, WANG Bairong, MU Dongdong. Research status and prospect of infrared ship detection[J]. Journal of Dalian Maritime University,2023,49(04):103-115.

[3]. XU Chengjun, JI Yubali, WANG Kun. Position acquisition and identification of nearshore vessels based on infrared thermal imaging[J]. Port Technology,2024,(02):1-5.

[4]. DU Jingwei, BER Yang, DONG Yun, SHI Yunlei. Application of infrared detection technology in ship electrical equipment[J]. China Ship Repair,2023,36(02):34-36.

[5]. Liu Cheng,Research on motion ship detection technology based on infrared image[J]. Wuhan university of technology,2015,(04).

[6]. Li Ang,Wang Chuanping,Rao Binyuan,Luan Sijia,Hu Feng,Chen Yuntao. Research on screw compressor fault monitoring system based on infrared temperature measurement technology[J]. Equipment Management and Maintenance,2023,(15):55-58.

[7]. Pašagić V, Mužević M, Kelenc D. Infrared thermography in marine applications[J]. Brodogradnja: An International Journal of Naval Architecture and Ocean Engineering for Research and Development, 2008, 59(2): 123-130.

[8]. Deng Qianqian. Research on oil spill area detection method of infrared image[J]. Huazhong University of Science and Technology,2020,(05).

[9]. MENG Lingmin, NIU Shuai, ZHAO Shuyi, ZHANG Shaokun, ZHANG Xin, YE Jiayan. Typical application of infrared thermal imaging detection technology in pressure class special equipment[J]. Nondestructive Testing,2024,48(03):44-46.

[10]. SAUNDERS, Craig T.: ‘The Use of Thermal Imagery in Locating Stress Fractures in Yachts’, Thermal Imaging Techniques InfraMation 2004.