1. Introduction

In the past decade, bio-inspired tactile and mechanosensory systems have revolutionized multiple technological domains, establishing themselves as fundamental elements in advanced robotics, healthcare monitoring, and prosthetic applications. These sophisticated sensing systems derive their functional principles from natural biological mechanisms, particularly human cutaneous receptors and specialized plant sensory structures. The remarkable efficiency and adaptability of natural sensing mechanisms have provided essential blueprints for developing artificial sensor systems with enhanced capabilities. Recent technological advances have enabled the systematic integration of various components, including flexible substrates, piezoelectric materials, and precisely engineered nanostructures, resulting in sensing devices that exhibit unprecedented levels of sensitivity and adaptability. These innovations have significantly improved the detection and processing of mechanical stimuli, temperature variations, and surface textures. The development of such bio-inspired sensors represents a significant advancement in creating more intuitive and responsive artificial systems. This progress has profound implications for numerous applications, from enhancing the functionality of prosthetic devices to enabling more sophisticated human-machine interactions in robotics. The emerging field continues to expand, promising transformative developments in medical diagnostics, environmental monitoring, and adaptive robotic systems.

2. Bionic tactile sensors in flexible robots

Soft robotics has become popular in healthcare and exploration due to its ability to deform, making it possible to operate in complex areas. This paper underscore the fact that intelligence necessitates the confluence of actuation and sensing elements. The current actuation techniques are pressure, electrical, and shape memory-based operating systems. Multimodal systems improve the system's sturdiness, and elasticity methods, such as proprioception and tactile feedback, are essential. The work introduces three integration strategies-surface, internal, and closed-loop – to streamline robotic intelligence. Despite significant advancements in the field, several research gaps still need to be addressed to further enhance the capabilities of soft robotics. Future research aims to optimize the integration of actuation and sensing to increase system autonomy and precision for real-world tasks.

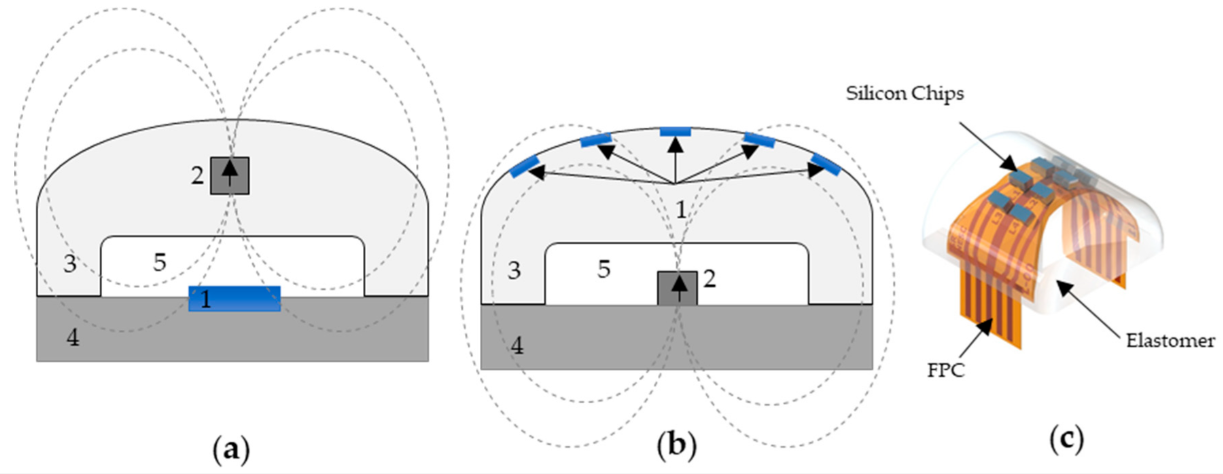

This paper has designed a biomimetic soft tactile sensor inspired by the structure of human fingerprints and Ruffini endings to augment the functional capabilities of neuroproteins. This sensor specializes in measuring static and dynamic friction forces, including slippage perception and object weight during dexterity. As a result, it can yield vast amounts of firsthand data. The substrate uses twisted silver nanowire electrodes coated in PDMS, and there is constant capacitance under normal force, but the capacitance changes with the friction forces. The research team designed a customized signal encoding circuit that transforms the capacitance variations into bionic signals as shown in Figure 1. By converting capacitance variations into bionic signals, this sensor aims to enhance the tactile feedback of neuroproteins for users. The developed sensor has been proven to facilitate a more agile design of robotic prosthetic hands, with its major discovery being a capacity of discrimination of miscellaneous frictional forces, enabling further improvement of prosthetics' control and sensory abilities [1].

Figure 1: Schematic view of the devices’ working principle [1]

Scientists have developed a technique in which a bionic tactile sensor collects vibration data pertinent to the material it is sliding on. A total of four algorithms were applied to classify these textures: SVM, random forest, K-NN, and convolutional neural networks (CNN). The CNN algorithm outperformed other systems' accuracy value, reaching up to 98.5%, compared to the average recognition rate of 94.7%-95% from traditional machine learning methods. The most significant aspect of this research is its ability to monetize machine learning efforts and perform such tasks with a high degree of accuracy and a low amount of computing resources. The study's results, with a 98.5% accuracy rate using CNN, demonstrate that bionic tactile sensors are a viable option for material identification. This high accuracy can significantly improve the performance of robotic manipulation with variably textured surfaces.

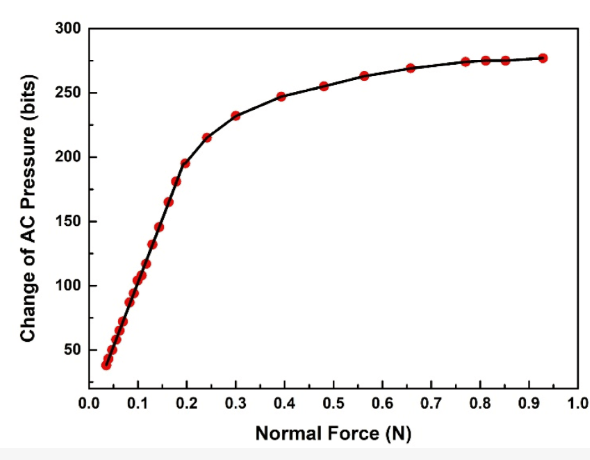

The paper "Designing a Tactile Sensor Based on Magnetics and Hybrid Flexible-Rigid Electronics for Vizzy" suggests an innovative magnetic-based tactile sensor for the one to be implanted into the Vizzy humanoid robot's hand. It incorporates an array of magneto resistive sensors set on flexible electronics. Depending on the force applied (0.1-5 N) as shown in Figure 2, the fingertip surface can sense either a stimulus or an object. The novel contributions are the innovatively designed sensor components, sensor miniaturization, and the special flexible-rigid design, which allows the system to detect force very accurately for applications associated with manipulations in robotic arms. The article also includes numerical simulations and omnidirectional characterization, which aims to improve performance for specific robotic applications.

Figure 2: The relationship between the change of AC pressure (bits) and applied normal force (N) [2]

The construction of the bionic sensor involved the integration of the 2D graphene film for touch sensing and the 3D graphene foam for pressure sensing into the entire single structure of the sensor. These two sensors work as dual-layered systems, using a 2D graphene layer addressing finer tactile stimuli and a 3D foam layer yielding larger pressures while maintaining a thin, flexible structure ideal for multimodal sensor applications. The testing setup demonstrated a strong correlation (r > 0.95) between sensor output and applied force, with the sensor accurately detecting forces ranging from 0.1 N to 100 N, showcasing its capability for both high-resolution detection of small forces and broader measurement of heavy forces [3][4].

The sensor's composition as a flexible bionic bodywork offers significant advantages for various applications. These include electronic skin for robots, advanced prosthetics, and smart medical devices, where high-precision force feedback is crucial for both functionality and safety. In addition, the design contains a detailed description of how the sensor kit was made, including the preparations of the graphene film and foam, the setting up of the sensor structure, and the final assembly of the sensing system.

The innovation involves its unique ability to surpass the typical pressure sensors' range trade-off versus sensitivity. In this instance, it is demonstrated that hybridizing the graphene materials in a novel way makes it possible to create sensors with high-performance sensitivity in a wide range of forces without affecting the sensor's accuracy or responsiveness. This discovery has the potential to significantly enhance smart tactile systems in robotics and medical applications. For instance, it could improve the dexterity of robotic hands in delicate tasks or enhance the sensitivity of tactile feedback in minimally invasive surgical tools. Additionally, integrated sensors with rapid response times and high sensitivity in varying force ranges provide opportunities for more responsive and adaptive tactile technologies, which can instantly sense variations in physical properties with greater accuracy.

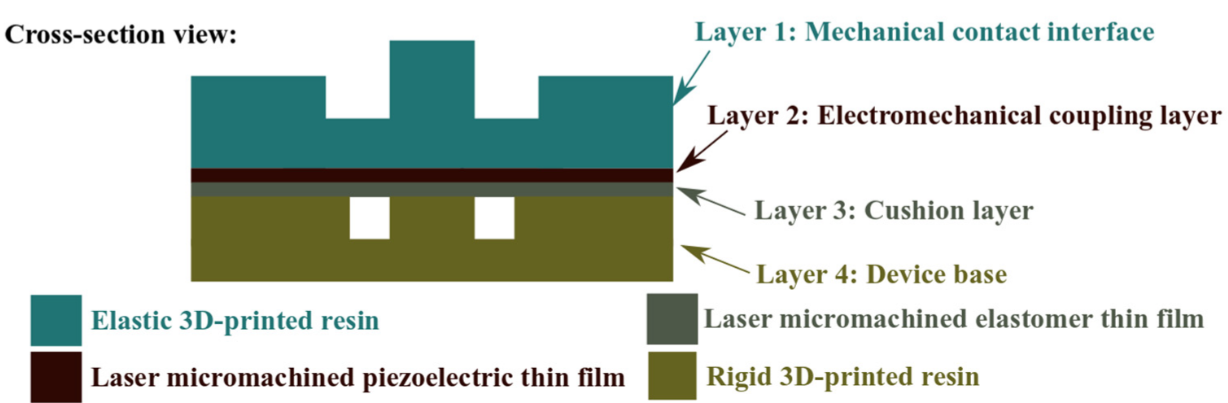

Creating an inexpensive, piezoelectric touch sensor imitating the human touch sense of palpation for medical applications is one of its goals. The sensor is built using modern 3D printing technology and laser micromachining. These advanced manufacturing techniques enable the device to classify tissue hardness and provide both qualitative and real-time feedback through palpation. The sensor has a sensitivity of 1.52 V/mm, being able to detect vertical deformation, which would allow for developing diagnostic capabilities of kit IV for medical endoscopy and surgical applications. The design is a trade-off between the two: simple yet effective. It provides comparable results to more complex systems and a fast and cost-effective manufacturing technique.

This method suggests adding the tactile sensor to disposable systems and removing medical safety and contamination concerns by designing reused electronic modules and interchanging tactile parts. The sensor will feature developed piezoelectric materials that guarantee accurate feedback, which can be compared to existing systems while being low-cost and ideal for minimally invasive procedures because of its manufacturing and integration ease. This work can be classified into two main components: experimental results and a detailed description of the sensor's function and structure. These findings position the sensor as a potentially suitable tool for robotic-assisted surgical procedures and pave the way for future developments in tactile sensing technology.

This sensor brings us closer to the possibility that biosensor platforms powered by MEMS technology could combine natural and unnatural touch for more patient-specific approaches [5].

This paper describe a whole new category of biomimetic mechanosensory based on the Venus flytrap's trigger hairs, which react to tiny mechanical disturbs in the environment. The imitation of cantilever beam structures with a wide variety of stiffness found in these hairs led to the development of a synthetic mechanosensory more sensitive to mechanical waves harbored by such signals as force, displacement, or vibration. This mechanosensory consists of a rigid rod featuring a flexible base, which also contains a crack made from a piezo resistor made of Au, which boosts mechanical signal detection [6].

Biomimetic mechanosensory reveals remarkable performance in terms of sensitivity, stability, and fast response to the desired stimuli. The flexible base construction allows for pressure concentration, enhancing the sensor's sensitivity to mechanical stimuli. Inspired by nature, this sensor is designed to detect small mechanical responses, micro-airflows, and low-frequency vibrations, showcasing its versatility in sensing various environmental stimuli. This development, with its vast applications in ecology, robot technology, medical equipment, and proprioception systems, is promising [7].

On top of that, the nano-crack structuring and carefully measured constructions of the mechanosensory play a huge role in its accuracy, enabling the detection of subtle environmental alterations without adding mechanical noise. Extensive testing reveals that the device can sense both small-scale forces and airflows with high precision. This capability ensures its potential for advanced mechanoenzyme applications, particularly in situations where accurate mechanical sensing is critical. The sensor's design, consisting of material choice and nanoscale fabrication, forms the prerequisite for subsequent optimization and integration into larger system structures. As shown in Figure 3, the fabrication process shows promise for achieving scalability in the long run. This scalability could lead to cost-effective production of highly sensitive mechanoenzyme devices, making them accessible for a wide range of applications [8].

Figure 3: The general structure of the polymeric piezoelectric tactile sensor cross-section view [3]

This research paves the way for the transfer of mechanical sensing technologies inspired by biological structures to practical applications. By utilizing sophisticated materials and advanced fabrication techniques, it opens up new possibilities for developing highly sensitive biosensing elements. These innovations could revolutionize fields such as robotics, environmental monitoring, and medical diagnostics.

3. Conclusion

The integration of bio-inspired tactile and mechanosensory systems into soft robotics and healthcare applications has yielded remarkable improvements in autonomous functionality, detection sensitivity, and operational precision. The successful development of sensors that effectively replicate biological sensing mechanisms, particularly those found in human sensory structures and specialized plant mechanisms like the Venus flytrap, represents a significant breakthrough in the field. These innovations have substantially enhanced the performance capabilities across multiple domains, notably in neuroprosthetic applications, environmental monitoring systems, and adaptive robotics. The research outcomes demonstrate the feasibility of creating highly responsive and adaptable sensing platforms that can effectively process complex environmental stimuli. Current technological developments focus on optimizing manufacturing processes to achieve cost-effective, scalable production methods while maintaining high performance standards. These advancements establish a robust foundation for the next generation of intelligent systems, promising transformed capabilities in human-machine interfaces, medical diagnostics, and autonomous robotics. The successful implementation of these bio-inspired sensing technologies marks a crucial step toward more sophisticated and intuitive mechanical systems, opening new possibilities for applications in healthcare, environmental monitoring, and advanced robotics.

References

[1]. Lan, N., Hao, M., Niu, C. M., Cui, H., Wang, Y., Zhang, T., Fang, P., & Chou, C. H. (2021). Next-Generation Prosthetic Hand: from Biomimetic to Biorealistic. Research, 2021, Article 4675326. https://doi.org/10.34133/2021/4675326

[2]. Neto, M., Ribeiro, P., Nunes, R., Jamone, L., Bernardino, A., & Cardoso, S. (2021). A Soft Tactile Sensor Based on Magnetics and Hybrid Flexible-Rigid Electronics. Sensors, 21(15), 5098. https://doi.org/10.3390/s21155098

[3]. Sha, B., Lü, X., & Jiang, L. (2022). High Sensitivity and Wide Range Biomimetic Tactile-Pressure Sensor Based on 2D Graphene Film and 3D Graphene Foam. Micromachines, 13(7), 1150. https://doi.org/10.3390/mi13071150

[4]. Zhou, S., Li, Y., Wang, Q., & Lyu, Z. (2024). Integrated Actuation and Sensing: Toward Intelligent Soft Robots. Cyborg and Bionic Systems, 5, Article 0105. https://doi.org/10.34133/cbsystems.0105

[5]. Huang, S., & Wu, H. (2021). Texture Recognition Based on Perception Data from a Bionic Tactile Sensor. Sensors, 21(15), 5224. https://doi.org/10.3390/s21155224

[6]. Ge, C., & Cretu, E. (2022). A Polymeric Piezoelectric Tactile Sensor Fabricated by 3D Printing and Laser Micromachining for Hardness Differentiation during Palpation. Micromachines, 13(12), 2164. https://doi.org/10.3390/mi13122164

[7]. Li, Y., Cao, Z., Li, T., Sun, F., Bai, Y., Lu, Q., Wang, S., Yang, X., Hao, M., & Lan, N. (2020). Highly Selective Biomimetic Flexible Tactile Sensor for Neuroprosthetics. Research, 2020, Article 8910692. https://doi.org/10.34133/2020/8910692

[8]. Wang, Q., Lu, Z., Wang, D., & Wang, K. (2024). Mechanosensor for Proprioception Inspired by Ultrasensitive Trigger Hairs of Venus Flytrap. Cyborg and Bionic Systems, 5, Article 0065. https://doi.org/10.34133/cbsystems.0065

Cite this article

Wang,J. (2025). Study of Bionic Tactile Sensors in Flexible Robots. Applied and Computational Engineering,128,66-71.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Lan, N., Hao, M., Niu, C. M., Cui, H., Wang, Y., Zhang, T., Fang, P., & Chou, C. H. (2021). Next-Generation Prosthetic Hand: from Biomimetic to Biorealistic. Research, 2021, Article 4675326. https://doi.org/10.34133/2021/4675326

[2]. Neto, M., Ribeiro, P., Nunes, R., Jamone, L., Bernardino, A., & Cardoso, S. (2021). A Soft Tactile Sensor Based on Magnetics and Hybrid Flexible-Rigid Electronics. Sensors, 21(15), 5098. https://doi.org/10.3390/s21155098

[3]. Sha, B., Lü, X., & Jiang, L. (2022). High Sensitivity and Wide Range Biomimetic Tactile-Pressure Sensor Based on 2D Graphene Film and 3D Graphene Foam. Micromachines, 13(7), 1150. https://doi.org/10.3390/mi13071150

[4]. Zhou, S., Li, Y., Wang, Q., & Lyu, Z. (2024). Integrated Actuation and Sensing: Toward Intelligent Soft Robots. Cyborg and Bionic Systems, 5, Article 0105. https://doi.org/10.34133/cbsystems.0105

[5]. Huang, S., & Wu, H. (2021). Texture Recognition Based on Perception Data from a Bionic Tactile Sensor. Sensors, 21(15), 5224. https://doi.org/10.3390/s21155224

[6]. Ge, C., & Cretu, E. (2022). A Polymeric Piezoelectric Tactile Sensor Fabricated by 3D Printing and Laser Micromachining for Hardness Differentiation during Palpation. Micromachines, 13(12), 2164. https://doi.org/10.3390/mi13122164

[7]. Li, Y., Cao, Z., Li, T., Sun, F., Bai, Y., Lu, Q., Wang, S., Yang, X., Hao, M., & Lan, N. (2020). Highly Selective Biomimetic Flexible Tactile Sensor for Neuroprosthetics. Research, 2020, Article 8910692. https://doi.org/10.34133/2020/8910692

[8]. Wang, Q., Lu, Z., Wang, D., & Wang, K. (2024). Mechanosensor for Proprioception Inspired by Ultrasensitive Trigger Hairs of Venus Flytrap. Cyborg and Bionic Systems, 5, Article 0065. https://doi.org/10.34133/cbsystems.0065