1. Introduction

As human society continues to develop, we have accelerated our exploration of the world. Amphibious robots, capable of freely operating on both land and in water, hold vast application potential and significant research value.

In existing studies, Du Tonglang et al. designed a bionic crocodile robot with crawling and rolling capabilities [1], employing a Hopf oscillator-based CPG network for gait control, integrating the ZMP principle to enhance stability, and optimizing the trot gait through tail swinging, with simulations verifying its stable motion. Zhao Yuhang performed a kinematic analysis of the robot’s limbs, spine, and tail using an enhanced D-H method, addressing both forward and inverse kinematics along with the reachable space to ascertain the model’s accuracy [2]. Huang Kefan and colleagues employed motion capture technology to gather crocodile gait data [3], determining the joint angles of a robotic crocodile, the stability of which was validated through simulations demonstrating its consistent crawling capability. You Peng devised an amphibious robot modeled after the spectacled caiman, the bio-inspired motion of which was substantiated through simulations [4]. He Weiyan et al. established a co-simulation system integrating motor dynamics and robot kinematics [5], analyzing the impact of motor torque on the high-speed running of legged robots, concluding that motor dynamics exhibit a first-order low-pass filtering characteristic. Li Hengjin et al. developed a cable-driven soft robot [6], proposing a workspace computation method based on the SOFA simulation framework, with experiments demonstrating a more uniform workspace distribution. Chen Shuai designed a cable-driven continuum robot inspired by the human spine structure [7], introducing a BP neural network-based inverse kinematics solution and verifying control precision. Feng Chuangxin et al., based on the large-amplitude slender-body theory, established a crocodile oscillation dynamics model, deriving fluid forces and propulsion efficiency calculation methods [8].

This paper primarily focuses on the mechanical structure design and circuit system installation of a bionic crocodile robot, which can be categorized into structural design descriptions and simulation analysis.

The research fills a gap in the field regarding the detailed mechanical structure of bionic crocodiles and expands the theoretical framework of crocodile biomimicry. The innovations introduced in this study reduce failure rates, enhance the adaptability of the bionic crocodile, and make the entire robot more flexible and lightweight.

2. Design Description

2.1. Overall Design

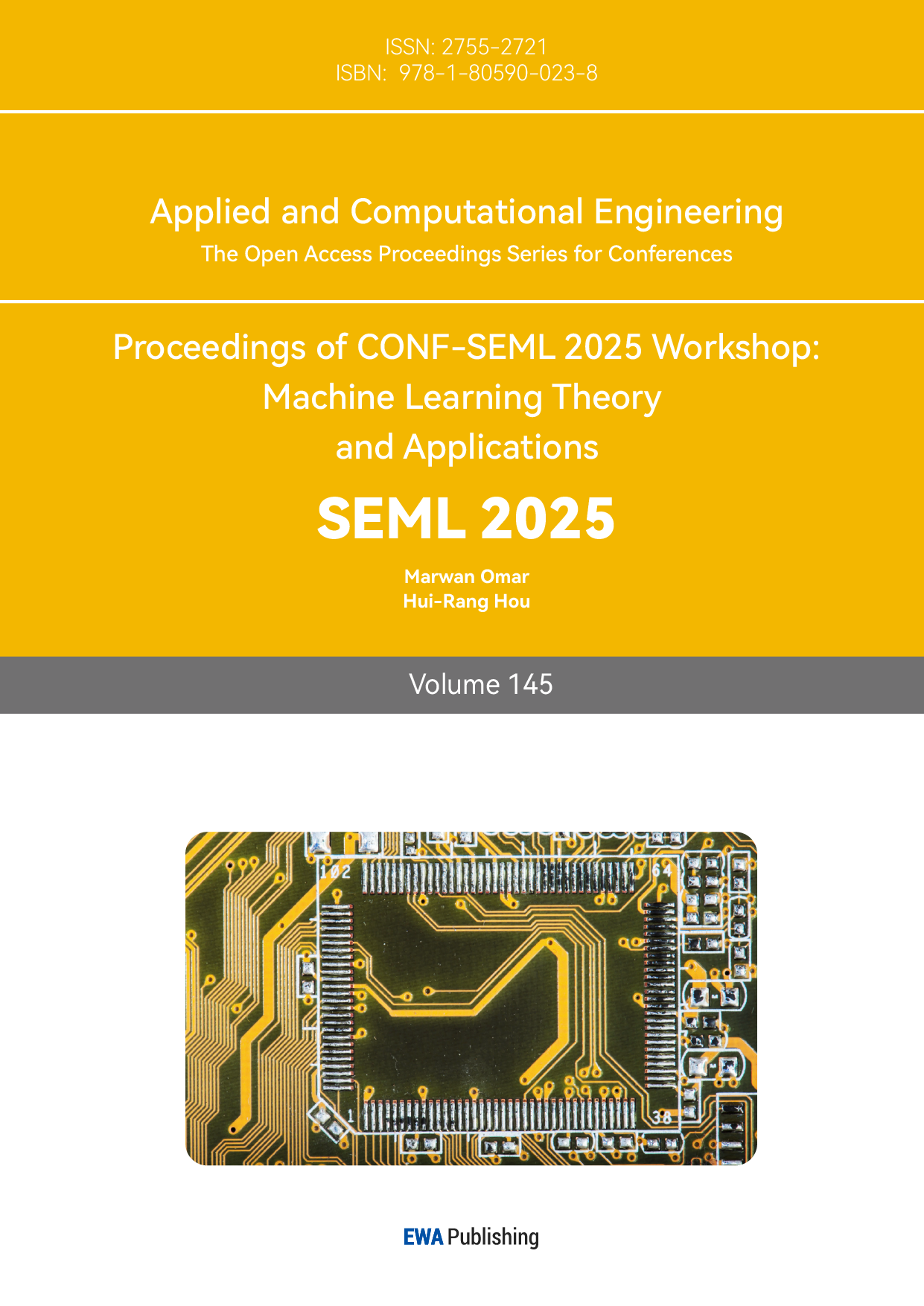

The body shape of the bionic crocodile robot mimics the streamlined form of a real crocodile to reduce resistance during movement in both water and on land (as shown in Figure 1).

·Cable-Driven System: The movement of the body and tail is achieved through a cable-driven system, which provides precise force control and a flexible range of motion.

·Spherical Gear Drive: The head's pitch and horizontal swinging movements are controlled using spherical gears.

·Power System: The robot is driven by electric motors and powered by batteries.

Figure 1: Overall Design of the Bionic Crocodile Robot

2.2. System Design

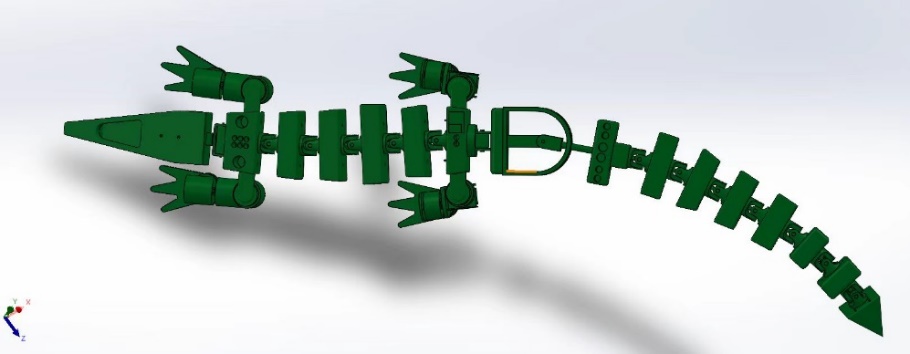

In the head of the bionic crocodile robot, the meshing design of the spherical gear and the monopole gear (as shown in Figure 2) allows multi-degree-of-freedom movement. This design not only provides high mobility but also ensures precise and flexible motion. Existing contact and stress analysis of spherical gear tooth surfaces indicate good reliability and durability.

Figure 2: Engagement Design of Spherical Gear and Monopole Gear.

The cable-driven system, renowned for its exceptional capacity for continuous deformation and environmental adaptability, has increasingly garnered attention as a focal point of research within the robotics domain. This system modulates the tension and slackness of cables to facilitate the bending and stretching of the body, thereby emulating movements such as the crawling and swimming behaviors of crocodiles. An infrared sensor ismounted on the head, equipping the crocodile robot with the capability to detect its surroundings and execute functions such as obstacle avoidance.

2.3. Component Design

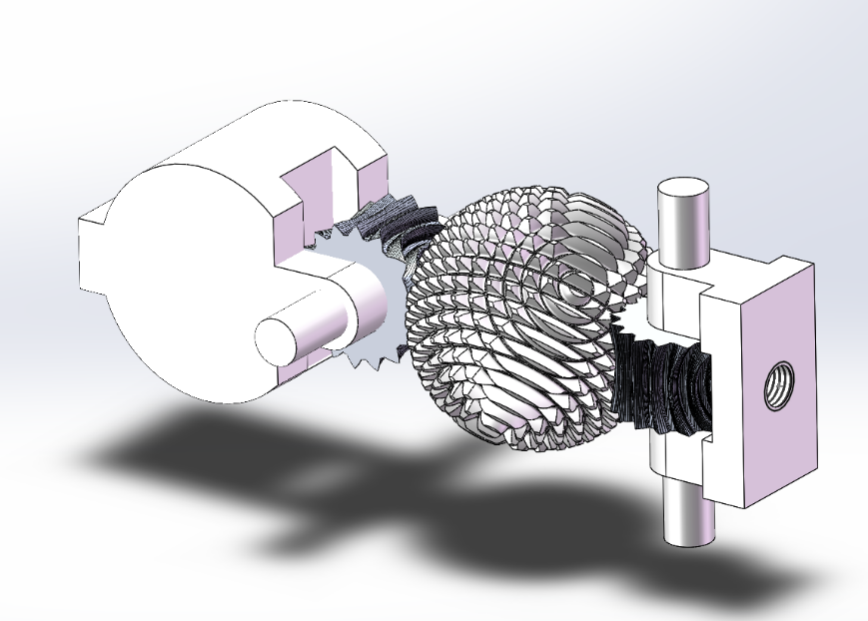

The head incorporates spherical and monopole gears to facilitate rotational movement with two degrees of freedom (as illustrated in Figure 3). Additionally, an infrared sensor is mounted atop the crocodile’s snout, enabling infrared recognition capabilities. The design of the crocodile’s head features a cavity intended to house the motor that actuates the gear movement, thereby reducing the head’s weight and contributing to the enhanced stability of the bionic crocodile robot.

Figure 3: Overall structure of the head

The trunk structure has a total of 7 degrees of freedom. The neck and waist each have 1 degree of freedom, and each segment of the spine has 1 degree of freedom, adding up to 5 degrees of freedom for the spine. Three cables are arranged to achieve lateral and pitching movements of the trunk. The motor is located at the first segment to balance the crocodile's center of gravity and facilitate wiring. The battery box is also located at the first segment.

The tail structure has a total of 9 degrees of freedom. Except for the sacrum, which has 1 degree of freedom, each segment of the tail has 1 degree of freedom. This part also uses cable-driven mechanisms, with one cable on each side to control the lateral swinging, providing steering and propulsion for the crocodile's movement in water.

The front and hind legs each have 6 degrees of freedom. The shoulder and leg of the front legs each have 3 degrees of freedom, while the waist and leg of the hind legs each have 3 degrees of freedom. Motors are installed in cylindrical housings at the joints.

3. Simulation Analysis

3.1. Motion Simulation

First, an overall plan is made for the terrestrial crawling motion simulation of the bionic crocodile robot, including trajectory planning for the robot’s foot, spine swinging, and gait planning.

The swinging trajectory of the alligator’s spine is sampled and analyzed to ascertain the movement range of the spine joints, thereby providing a reference for the motion planning of the bionic crocodile’s spine joints.

The positional data of each joint is compared with the actual spine movement data of the crocodile during its crawling motion at corresponding time points.

3.2. Mechanical Analysis

The mechanical performance indicators of each part are shown in Tables 1, 2, and 3.

Table 1: Properties of Servos and Motors, Values, and Units

Property | Value | Unit |

Elastic Modulus | 210000 | N/mm^2 |

Poisson's Ratio | 0.28 | Not Applicable |

Shear Modulus | 79000 | N/mm^2 |

Mass Density | 7700 | kg/m^3 |

Tension Strength | 723.8256 | N/mm^2 |

Compression Strength | N/mm^2 | |

Yield Strength | 620.422 | N/mm^2 |

Thermal Expansion Coefficient | 1.3e-05 | /K |

Thermal Conductivity | 50 | W/(m·K) |

Specific Heat | 460 | J/(kg·K) |

Material Damping Ratio | Not Applicable |

Table 2: Properties of Main Material, Values, and Units

Property | Value | Unit |

Elastic Modulus | 204999.9984 | N/mm^2 |

Poisson's Ratio | 0.29 | Not Applicable |

Shear Modulus | 79999.99987 | N/mm^2 |

Mass Density | 7858.000032 | kg/m^3 |

Tension Strength | 425.0000032 | N/mm^2 |

Compression Strength | N/mm^2 | |

Yield Strength | 282.685049 | N/mm^2 |

Thermal Expansion Coefficient | 1.2e-05 | /K |

Thermal Conductivity | 52 | W/(m·K) |

Specific Heat | 486 | J/(kg·K) |

Material Damping Ratio | Not Applicable |

Table 3: Properties of Cross Joints Material, Values, and Units

PROPERTY | VALUE | UNIT |

ELASTIC MODULUS | 210000 | N/mm^2 |

POISSON'S RATIO | 0.28 | Not Applicable |

SHEAR MODULUS | 79000 | N/mm^2 |

MASS DENSITY | 7700 | kg/m^3 |

TENSION STRENGTH | 723.8256 | N/mm^2 |

COMPRESSION STRENGTH | N/mm^2 | |

YIELD STRENGTH | 620.422 | N/mm^2 |

THERMAL EXPANSION COEFFICIENT | 1.3e-05 | /K |

THERMAL CONDUCTIVITY | 50 | W/(m·K) |

SPECIFIC HEAT | 460 | J/(kg·K) |

MATERIAL DAMPING RATIO | Not Applicable |

A 300N load was applied to key stress-bearing components, such as universal joints, footpads, and connection points of the front and rear legs. Elastic supports were installed at the footpads. Meshing analysis and buckling analysis revealed that all components could withstand the specified loads, exhibiting a uniform stress distribution across each section.

4. Conclusion

This study explores the crocodile as a bionic research subject, drawing inspiration from its natural locomotion to inform robotic design. A comprehensive analysis is conducted on the relative positions and angular variations of various body segments under different motion states. Furthermore, the research examines the mechanical properties of the crocodile’s limb structure, joint flexibility, and overall movement patterns in depth. Based on these findings, an amphibious bionic crocodile robot is designed, characterized by a low mechanical failure rate, high operational reliability, strong adaptability to complex environments, and a lightweight yet structurally flexible framework. These attributes contribute to enhancing the theoretical foundation for the topological design of bionic robotic systems inspired by crocodilian biomechanics. Nevertheless, certain limitations persist in this study, particularly concerning the acquisition of extensive prototype testing data and the experimental validation of multimodal motion control strategies. Future research will be dedicated to addressing these challenges by conducting further empirical studies and refining the control mechanisms to enhance the robot’s performance across diverse terrains and operational conditions.

Acknowledgement

I would like to express my deepest gratitude to my alma mater, Tianjin University, for providing me with a solid academic foundation and an inspiring research environment. My sincere appreciation goes to my professors, Professor Junlan Li, Professor Bo Wang, and Professor Fumiya Lida, for their invaluable guidance, support, and encouragement throughout this study. Additionally, I am grateful to my friends, Xiaoya He, Jing Huang, Senhao Wang, Shuyi Wang, and Xiangqian Meng, for their continuous support and insightful discussions, which have greatly enriched the research journey.

References

[1]. Du Tonglang & Zhou Zupeng. The Design and Gait Optimization Research of Bionic Crocodile Robots. Mechanical Science and Technology for Aerospace Engineering1-8.doi:10.13433/j.cnki.1003-8728.20240008.

[2]. Zhao Yuhang.(2023) Design and Motion Analysis of a Bionic Amphibious Crocodile Robot ( Master's Thesis, China University of Mining and Technology) Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27623/d.cnki.gzkyu.2023.001970doi:10.27623/d.cnki.gzkyu.2023.001970.

[3]. Huang Kefan, Jia Wenzhen, Han Lulu &Jiang Jianping.(2024) Bionic Gait Planning Method for Motion of Crocodile Robot. Mechanical Science and Technology for Aerospace Engineering, 2024, 43(04):566-572.DOI:10.13433/j.cnki.1003-8728.20220287.

[4]. You peng.(2022). Design and Research of Alligator-inspired Amphibious Robot (Master's Thesis, China University of Mining and Technology). Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27623/d.cnki.gzkyu.2022.000287doi:10.27623/d.cnki.gzkyu.2022.000287.

[5]. He Weiyan, Ma Jien, Wang Hongtao, Xu Bowen & Fang Xiaotong.(2023). Dynamic Characteristics of Robot Joint Motor Torque. Electric Machines and Control (12), 12-20.doi:10.15938/j.emc.2023.12.002.

[6]. Li Hengjin & Tang Qing. (2023). Analysis of Workspace and Maximum Theoretical Load of Wire Driven Continuous Soft Robot. Modular Machine Tool & Automatic Manufacturing Technique(02), 138-142.doi:10.13462/j.cnki.mmtamt.2023.02.032.

[7]. Chen Shuai.(2024). Research on the Design and Control Method of Wire-driven Continuum Robot (Master's Thesis, Jilin University). Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27162/d.cnki.gjlin.2024.005067doi:10.27162/d.cnki.gjlin.2024.005067.

[8]. Feng Chuangxin, Jiang Jianping, Bai Honglei, He Junxuan, Zeng Qin & Zhuo Zhiqin.(2024). Dynamical Analysis of Propulsive Mechanism of Bionic Crocodile Swimming in Water. ACTA SCIENTIARUM NATURALIUM UNIVERSITATIS SUNYATSENI (01), 113-120.doi:10.13471/j.cnki.acta.snus.2023B041.

Cite this article

Zhang,Z. (2025). A Structural Design of a Bionic Crocodile Prototype. Applied and Computational Engineering,145,64-69.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Software Engineering and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Du Tonglang & Zhou Zupeng. The Design and Gait Optimization Research of Bionic Crocodile Robots. Mechanical Science and Technology for Aerospace Engineering1-8.doi:10.13433/j.cnki.1003-8728.20240008.

[2]. Zhao Yuhang.(2023) Design and Motion Analysis of a Bionic Amphibious Crocodile Robot ( Master's Thesis, China University of Mining and Technology) Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27623/d.cnki.gzkyu.2023.001970doi:10.27623/d.cnki.gzkyu.2023.001970.

[3]. Huang Kefan, Jia Wenzhen, Han Lulu &Jiang Jianping.(2024) Bionic Gait Planning Method for Motion of Crocodile Robot. Mechanical Science and Technology for Aerospace Engineering, 2024, 43(04):566-572.DOI:10.13433/j.cnki.1003-8728.20220287.

[4]. You peng.(2022). Design and Research of Alligator-inspired Amphibious Robot (Master's Thesis, China University of Mining and Technology). Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27623/d.cnki.gzkyu.2022.000287doi:10.27623/d.cnki.gzkyu.2022.000287.

[5]. He Weiyan, Ma Jien, Wang Hongtao, Xu Bowen & Fang Xiaotong.(2023). Dynamic Characteristics of Robot Joint Motor Torque. Electric Machines and Control (12), 12-20.doi:10.15938/j.emc.2023.12.002.

[6]. Li Hengjin & Tang Qing. (2023). Analysis of Workspace and Maximum Theoretical Load of Wire Driven Continuous Soft Robot. Modular Machine Tool & Automatic Manufacturing Technique(02), 138-142.doi:10.13462/j.cnki.mmtamt.2023.02.032.

[7]. Chen Shuai.(2024). Research on the Design and Control Method of Wire-driven Continuum Robot (Master's Thesis, Jilin University). Master https://afffgee62dc72a18c4273sf6wpxvfk6kvb6bvqfgfy.eds.tju.edu.cn/doi/10.27162/d.cnki.gjlin.2024.005067doi:10.27162/d.cnki.gjlin.2024.005067.

[8]. Feng Chuangxin, Jiang Jianping, Bai Honglei, He Junxuan, Zeng Qin & Zhuo Zhiqin.(2024). Dynamical Analysis of Propulsive Mechanism of Bionic Crocodile Swimming in Water. ACTA SCIENTIARUM NATURALIUM UNIVERSITATIS SUNYATSENI (01), 113-120.doi:10.13471/j.cnki.acta.snus.2023B041.