1. Introduction

Poly(3,4-ethylenedioxythiophene) (PEDOT) is a high molecular weight organic compound, known for its unique conjugated structure, which is derived from the polymerization of 3,4-ethylenedioxythiophene (EDOT) monomers [1]. PEDOT has the characteristics of simple molecular structure, small energy gap, and high conductivity. Due to these characteristics, PEDOT is widely used in the research of organic thin film solar cell materials, OLED materials, electrochromic materials, transparent electrode materials, and other fields. Due to its precise patterning, large-area preparation, and high material utilization, PEDOT is well-suited for widespread use in inkjet printing.

One promising application of PEDOT is in inkjet printing, a non-contact printing technique that forms images or patterns by ejecting ink in the form of tiny droplets onto a substrate. Inkjet printing technology works by storing ink in a cartridge and using a precise driving mechanism to eject small droplets from nozzles. These droplets are precisely controlled by the computer control system and fall onto the printing medium, such as paper, plastic, metal, etc., according to the predetermined pattern or text information. Through the accumulation and fusion of droplets, visible images, text or patterns are finally formed. It has the advantages of high precision, flexibility, non-contact printing, fast printing, low noise, which makes it have good application prospects in the fields of digital imaging and electronic manufacturing [2].

In the context of organic thin film transistors (OTFTs), inkjet-printed PEDOT can be used to fabricate electrodes such as source, drain, and gate. By utilizing the high-precision patterning capability of inkjet printing, precise electrode fabrication can be achieved, thereby improving the performance and integration of OTFT. Furthermore, PEDOT has good compatibility with organic semiconductor materials, which helps to improve the injection and transmission efficiency of charge carriers, ultimately boosting the overall performance of OTFTs. As a result, PEDOT inkjet printing holds significant potential for applications in flexible displays, electronic tags, and other next-generation electronic devices.

2. Properties of PEDOT

2.1. High conductivity

PEDOT molecules have a conjugated π electron system, in which the π electrons are not localized to a specific atom or chemical bond, but delocalized throughout the conjugated system. This delocalization property allows electrons to move relatively freely within the molecule, providing a pathway for charge transfer and forming the basis for PEDOT's high conductivity.

Doping can further improve the conductivity of PEDOT. The common doping method is to introduce negative or positive ions, which can interact with PEDOT molecules, alter the electron cloud distribution and generate additional charge carriers (holes or electrons). This significantly boosts charge transport capacity. For example, the commonly used dopant polystyrene sulfonic acid (PSS) can form stable complexes with PEDOT, and the sulfonic acid ions in PSS can effectively increase the carrier concentration in PEDOT, significantly improving its conductivity.

PEDOT molecules have a relatively planar structure, which facilitates tight packing and interaction between molecules. In the solid state, adjacent PEDOT molecules can form good π - π stacking, allowing electrons to jump and transfer between molecules, thereby exhibiting high conductivity at the macroscopic level [3].

Transparent and conductive electrode materials are required in fields such as display devices and solar cells. The high conductivity of PEDOT enables it to effectively transmit current, while its high transparency in the visible light range meets transparency requirements and can replace traditional indium tin oxide (ITO) electrodes. In electrochemical sensors, the high conductivity of PEDOT facilitates rapid electron transfer, enabling efficient detection of electrochemical reaction signals of target analytes. As the active layer material of organic thin film transistors, PEDOT's high conductivity enables fast transport of charge carriers between the source and drain, achieving the switching function of the transistor. In supercapacitors, the high conductivity of PEDOT can provide a fast channel for the storage and release of charges, which helps to improve the charging and discharging efficiency of supercapacitors.

2.2. Good stability and modifiability

The conjugated π - electron system of PEDOT endows it with high stability. Conjugated structures make the distribution of electron clouds within molecules more uniform, with a high degree of electron delocalization. Molecules have lower energy states, are less prone to chemical reactions, and can resist the influence of external environmental factors such as light, heat, oxidation, etc., maintaining the stability of their chemical structure and properties.

The sulfur atoms in the molecule have a certain electronegativity and a special electron cloud distribution, which can form relatively stable chemical bonds with adjacent atoms. The presence of sulfur atoms enhances the overall stability of the molecule, making it more difficult for bond breakage and structural changes to occur in different chemical environments.

The polymer backbone of PEDOT has a certain degree of rigidity, which limits the free movement and conformational changes of molecular chains, reduces the active sites for molecules to react with external substances, and thus improves its stability.

Notly, there are multiple reactive sites on the thiophene ring in PEDOT molecules, especially the hydrogen atom on the ring, which has certain activity and can be replaced by other functional groups through various chemical reactions [4]. These substitution reactions can introduce different chemical groups without damaging the basic conjugated structure of PEDOT, thereby endowing it with new properties and functions.

PEDOT can undergo copolymerization reactions with other monomers, and by changing the type and proportion of comonomers, the structure and properties of the polymer can be precisely controlled. The copolymerization reaction can combine the characteristics of different monomers into PEDOT molecules, expanding their application range.

Multiple chemical synthesis methods can be used to prepare PEDOT and its derivatives, which can precisely control the reaction conditions during the synthesis process and achieve fine control of the molecular structure of PEDOT, such as changing the degree of polymerization, introducing different substituents, etc., further enhancing its modifiability.

In conclusion, stability ensures that PEDOT can withstand mechanical effects such as bending and stretching during the preparation and use of flexible electronic devices without performance degradation. Modifierability can modify specific functional groups on its surface, improve interface compatibility with other materials, enhance device stability and reliability, and be used for the preparation of flexible displays, wearable devices.

2.3. Excellent flexibility

The molecular chain of PEDOT has a certain degree of flexibility, with alternating single and double bonds on its main chain. Single bonds can rotate freely, allowing the molecular chain to bend and twist to a certain extent without damaging the overall structure of the molecule. The flexibility of this molecular chain is the inherent basis for the flexibility of PEDOT.

Under normal circumstances, the polymer formed by PEDOT has an amorphous structure without obvious crystalline regions. The amorphous structure makes the arrangement of molecular chains relatively loose and disordered, and the interaction force between molecular chains is weak. Molecular chains can move and deform relatively freely, thus endowing PEDOT with good flexibility.

In the preparation process of PEDOT, some preparation methods and auxiliary reagents added can further improve its flexibility. For example, in the preparation of PEDOT by solution method, the added solvents and surfactants can provide a certain lubricating effect between molecular chains, reduce the interaction between molecular chains, and improve their flexibility.

In wearable devices, PEDOT can be used to make various sensors, electrodes, and circuits. For example, a flexible sensor used to monitor human physiological signals, PEDOT's flexibility allows it to closely adhere to human skin and will not be damaged by stretching or bending during human movement, ensuring the stability and accuracy of the sensor and achieving real-time monitoring of physiological parameters such as heart rate, blood pressure, and blood sugar.

3. Inkjet printing technology

Inkjet printing technology has evolved significantly over the years, making it a versatile method for a wide range of applications, including the deposition of functional materials such as PEDOT. The key component of inkjet printers is the piezoelectric inkjet print head, which utilizes piezoelectric ceramic elements to achieve controlled ink ejection. When a voltage is applied to piezoelectric ceramics, they undergo deformation. This deformation will squeeze the inkjet chamber, causing pressure on the ink inside the chamber, resulting in the ejection of ink droplets from the nozzle. After the voltage is removed, the piezoelectric ceramic returns to its original state, and the chamber will suck in new ink to prepare for the next spray. By controlling the magnitude and duration of the applied voltage, the size and ejection speed of ink droplets can be precisely controlled [5].

The nozzle moves back and forth along the width direction of the printing medium during the printing process. Perform inkjet printing when the nozzle moves forward, do not print when returning, and then move forward again to print the next line. Repeat this process until the entire page is printed. This method is suitable for situations where the printing width is large, and can fully utilize the inkjet capability of the nozzle. However, the printing speed is relatively slow, and there may be some positioning errors during the round-trip process.

The printer is equipped with independent ink cartridges, which store ink. The ink cartridge is connected to the nozzle through a pipeline, and ink flows from the cartridge to the nozzle under pressure or gravity. When the ink in the ink cartridge is used up, a new ink cartridge needs to be replaced. This method is simple and convenient, suitable for home and small office printers, but the ink cartridge cost is relatively high and the ink capacity is limited.

Before printing, the print data in the computer is first sent to RIP, which converts the print data into instructions that the printer can understand, including information such as the color of each pixel, droplet size, and position. Then, the printer controls the inkjet action of the nozzle based on these instructions, accurately printing images or text onto the medium. This method can efficiently process print data, ensuring print quality and accuracy, and is widely used in the field of professional printing.

In summary, inkjet printing, particularly when used for the deposition of functional materials like PEDOT, offers considerable potential for diverse applications. By carefully controlling the ink ejection process and optimizing printer operation, this technique can deliver high-resolution prints with precise material deposition.

4. Current research on PEDOT inkjet printing

4.1. Brain computer interface research

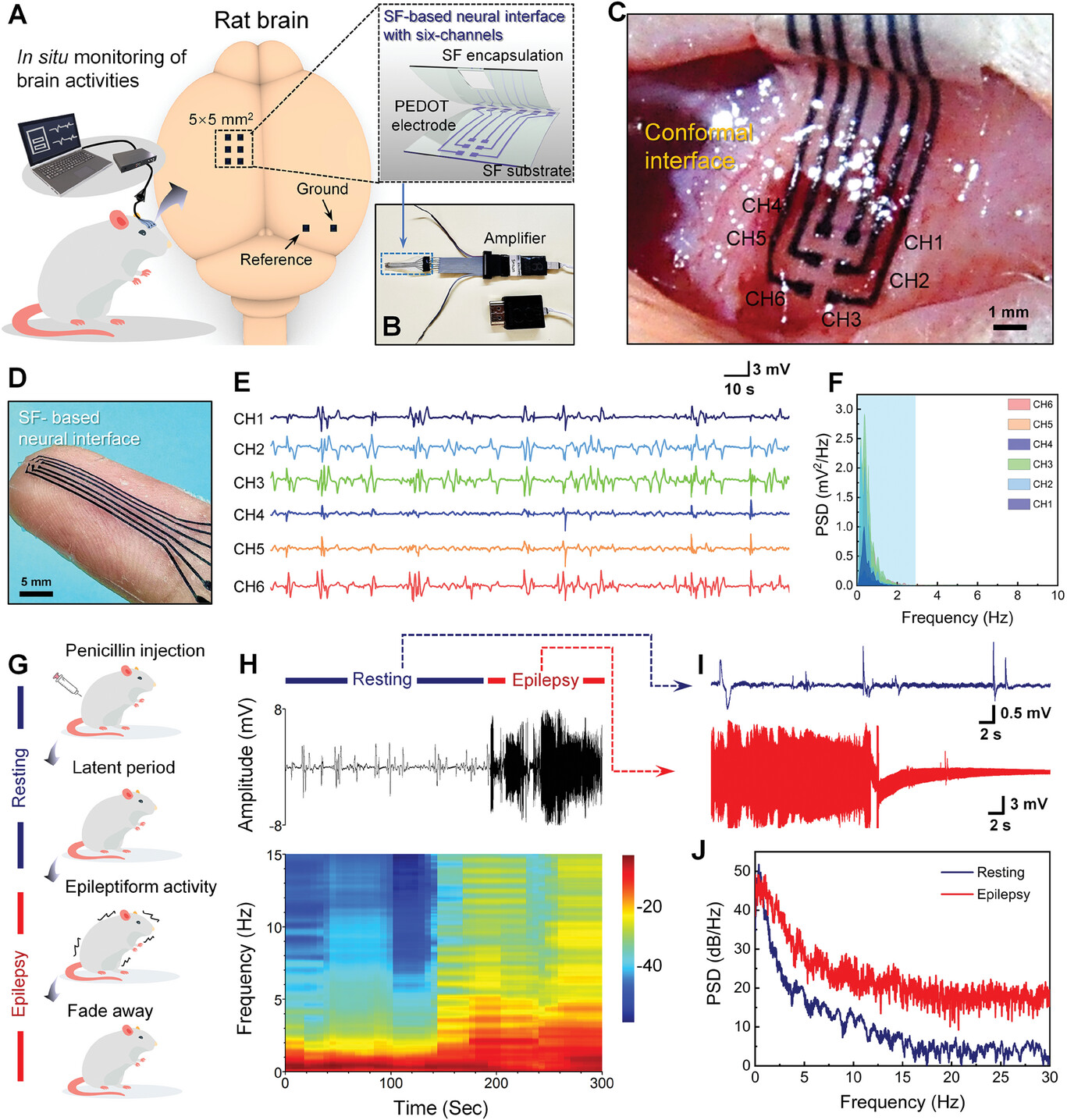

Zhang Yaopeng and Yao Xiang from the State Key Laboratory of Fiber Material Modification of Donghua University and Chen Hao from the Sixth People's Hospital Affiliated to Shanghai Jiaotong University School of Medicine developed heat temperature assisted pattern transfer technology. The non transient SF flexible neural interface produced can transfer inkjet printed PEDOT electrodes to SF flexible substrates and successfully collect ECoG signals on the surface of anesthetized rat cerebral cortex. It has higher accuracy, signal-to-noise ratio, and good biocompatibility than commercial polyimide based neural electrodes (Figure 1) [6].

Figure 1: In vivo ECoG and epileptiform activity recording. A) Rat ECoG recording schematic. B) SF neural interface connected to amplifier. C) SF neural interface (31 µm thick post-encapsulation) on rat cortex with channels CH1-CH6. D) SF neural interface on finger. E) ECoG signals via 6 channels on SF interface. F) Frequency spectrum of ECoG signals from SF interface.

4.2. Solar cell research

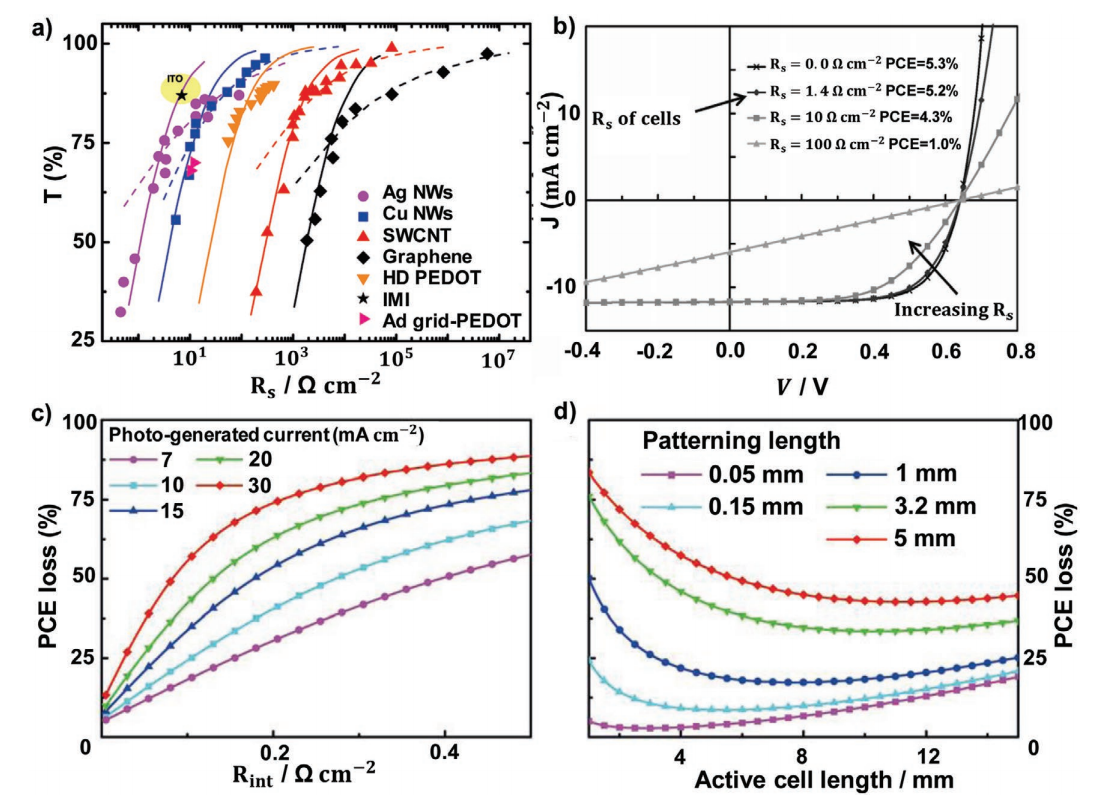

Saudi researchers have developed inkjet printable organic solar cells with PEDOT electrodes PSS. The energy conversion efficiency tested on the glass plate reached 4.73%, breaking the previous record of 4.1% for fully printed batteries. The use of inkjet printing technology makes it more scalable than other ultra-thin solar cells, and it does not contain toxic rare metals such as indium. When printed on a flexible substrate, the conversion efficiency is 3.6%, which can be used to power low-energy devices such as small sensors and wearable electronic devices (Figure 2). [7]

Figure 2: a) Transmittance at 550 nm versus sheet resistance of some of the most popular and promising transparent electrodes. b) The effect of Rs variation on J–V characteristics for OSCs based on P3HT: PCBM. c) Electrical simulations of the influence of Rint variation on PCE loss. d) Electrical simulations of active cell length L versus PCE loss under different patterning length l. a,c,d) Reproduced with permission. Copyright 2015, Wiley-VCH. Reproduced with permission. Copyright 2010, Wiley-VCH.

4.3. Transistor research

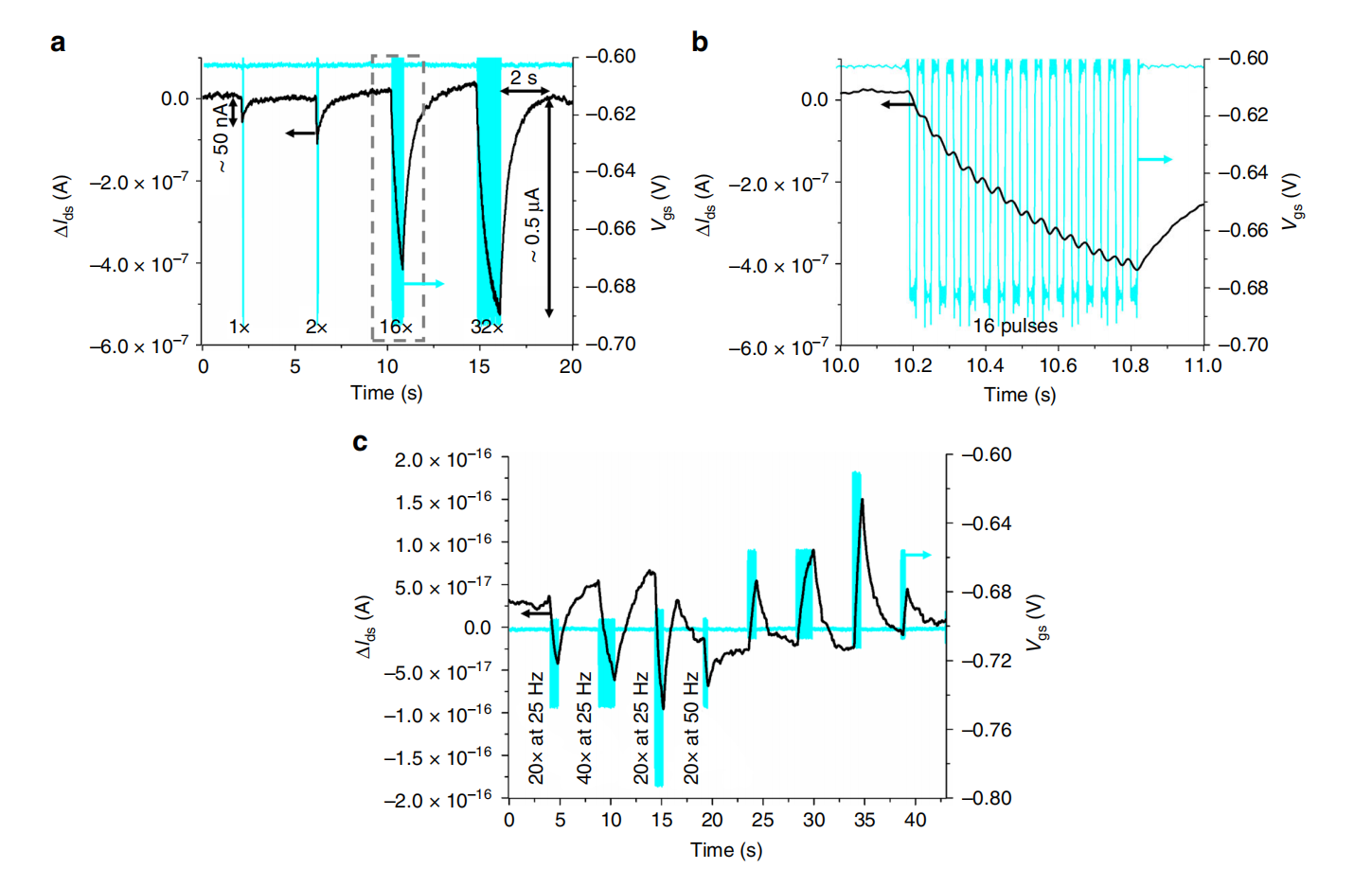

Professor Bao Zhennan's team at Stanford University used layer by layer inkjet printing technology to prepare a flexible field-effect transistor with PEDOT: PSS as the source electrode. The device has an average field-effect mobility of 27 ± 5 cm ² V ⁻¹ s ⁻¹ and a switching current ratio of 10 ⁴ (Figure 3) [8].

Figure 3: Synaptic behavior of the inkjet (IJ)-printed stretchable field effect transistors (FETs). a Source–drain current variation (ΔIds, on the left axis) response over time to small gate voltage pulses (Vgs, on the right axis) that imitates neuron presynaptic potential spikes for FETs with W/L = 1000 µm/50 µm. The pulses consist of a square signal of −80 mV of amplitude b Zoom-in on the part of the signal delimited by the dashed box in a. The ripple in ΔIds observed for each individual pulse of only −80 mV highlights the good voltage resolution of the devices. c Source–drain current variation (ΔIds, on the left axis) over time for the same devices when voltage pulse trains are applied to the gate.

5. Challenges and perspectives

5.1. Material stability

PEDOT materials are greatly affected by factors such as humidity and oxygen in the environment. As traditional PEDOT: PSS is often treated with water, water molecules can easily enter the interface, leading to degradation of charge extraction at the interface, and may also penetrate into the nanocavities of organic semiconductor films, forming charge carrier traps that affect material properties.

The chemical stability of PEDOT ink needs to be improved. Ink may undergo chemical reactions during storage and use, resulting in changes in ink properties. For example, aggregation or precipitation may occur between ink components, affecting the uniformity and printability of the ink [9].

In practical applications, PEDOT printing materials may experience performance degradation after long-term use. In organic solar cells, PEDOT material as a hole transport layer may experience a decrease in its hole transport ability under long-term light and electric field effects, affecting the photoelectric conversion efficiency and stability of the cell.

5.2. Printing accuracy

The size and shape of droplets are difficult to precisely control. The viscosity, surface tension, and other properties of ink, as well as the parameter settings of the print head, can all affect the formation of droplets. For example, when viscosity is unstable, it may lead to uneven droplet size, affecting the resolution and accuracy of printed patterns [10].

PEDOT particles or impurities in ink may clog the nozzle. Once the nozzle is blocked, it can cause unstable inkjet printing, resulting in missed or insufficient spraying, incomplete printing patterns, and reduced printing accuracy.

During the printing process, changes in environmental factors such as temperature and humidity can also affect printing accuracy. Temperature changes can cause changes in the physical properties of ink, thereby affecting the ejection and landing positions of droplets.

5.3. Interface adhesion force

There are differences in the interfacial adhesion between PEDOT and different substrate materials. Some base materials have low surface energy and poor adhesion to PEDOT, which can easily cause the printed PEDOT film to peel off and peel off during use, affecting the stability and performance of the device.

In order to improve the adhesion between PEDOT and the substrate, it is usually necessary to perform surface treatment on the substrate, such as chemical treatment, physical etching, etc. But these processing techniques may increase preparation costs and process complexity, and the consistency of processing effects is difficult to guarantee [11].

In some complex device structures, PEDOT needs to be tightly integrated with other functional layers. However, there may be differences in the thermal expansion coefficient and chemical properties between different materials. During the preparation and use process, factors such as thermal stress and chemical interactions may lead to a decrease in interfacial adhesion between PEDOT and other layers, resulting in delamination and other issues.

6. Conclusion

PEDOT, as a conductive polymer, exhibits great potential in the field of flexible electronic devices due to its high conductivity, good transparency, stability, strong modifiability, and excellent flexibility. Inkjet printing technology, as a non-contact printing technology, has the advantages of low equipment cost, high resolution, strong medium adaptability, good material compatibility, and easy operation, providing new possibilities for the application of PEDOT. However, PEDOT inkjet printing still faces some challenges, such as conductivity optimization difficulties, poor ink stability, significant coffee ring effect, difficulty in precise droplet control, nozzle clogging, substrate compatibility, and other issues. To overcome these challenges, researchers are exploring new PEDOT materials and printing processes to improve print quality and device performance. For example, developing highly conductive PEDOT derivatives, optimizing PEDOT composite systems, designing new ink formulations, adopting new printing technologies, and improving substrate surface properties. With the continuous development of these technologies, PEDOT inkjet printing technology is expected to make breakthrough progress in the future, widely used in fields such as organic field-effect transistors, flexible electronic circuits, sensors, solar cells, bioelectrodes, organic light-emitting diodes, etc., bringing more possibilities to people's lives.

References

[1]. Angelo, P.D., Farnood, R.R. Deposition of PEDOT/SWCNT Composites by Inkjet Printing. MRS Online Proceedings Library 1260, 702 (2010). https://doi.org/10.1557/PROC-1260-T07-02

[2]. M. Chen, A. Iyer and R. Opila, "Developing Inkjet Printed PEDOT/PSS Films for Solar Cells," 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 2019, pp. 0443-0446, doi: 10.1109/PVSC40753.2019.8980819. keywords: {inkjet printing;printable solar cells;photovoltaic cells;silicon},

[3]. Morice S, Sherehiy A, Wei D, et al. Characterization of the Direct Write Inkjet Printing Process for Automated Fabrication of PEDOT: PSS Thin Films[C]//International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2022, 85802: V001T01A021.

[4]. Olowo O O, Zhang R, Sherehiy A, et al. Inkjet printing of PEDOT: PSS inks for robotic skin sensors[C]//International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2022, 85802: V001T07A004.

[5]. Wilson P, Lekakou C, Watts J F. System design and process optimization for the inkjet printing of PEDOT: Poly (styrenesulfonate)[J]. Journal of Micro-and Nano-Manufacturing, 2014, 2(1): 011004.

[6]. Hu Z, Liang Y, Fan S, et al. Flexible Neural Interface From Non‐Transient Silk Fibroin With Outstanding Conformality, Biocompatibility, and Bioelectric Conductivity[J]. Advanced Materials, 2024, 36(46): 2410007.

[7]. Wang G, Adil M A, Zhang J, et al. Large‐area organic solar cells: material requirements, modular designs, and printing methods[J]. Advanced Materials, 2019, 31(45): 1805089.

[8]. Molina-Lopez F, Gao T Z, Kraft U, et al. Inkjet-printed stretchable and low voltage synaptic transistor array[J]. Nature communications, 2019, 10(1): 2676.

[9]. Li J, Cao J, Lu B, et al. 3D-printed PEDOT: PSS for soft robotics[J]. Nature Reviews Materials, 2023, 8(9): 604-622.

[10]. Basak I, Nowicki G, Ruttens B, et al. Inkjet printing of PEDOT: PSS based conductive patterns for 3D forming applications[J]. Polymers, 2020, 12(12): 2915.

[11]. Lee Y, Bandari V K, Paliakkara V P, et al. Monolithic Integration of Printable PVDF‐TrFE Piezoelectric Multifunctional Devices: From Sensing to Actuation[J]. Advanced Functional Materials, 2025, 35(3): 2413500.

Cite this article

Zhao,Z. (2025). Inkjet Printing of Poly (3,4-ethylenedioxythiophene). Applied and Computational Engineering,149,12-19.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MSS 2025 Symposium: Automation and Smart Technologies in Petroleum Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Angelo, P.D., Farnood, R.R. Deposition of PEDOT/SWCNT Composites by Inkjet Printing. MRS Online Proceedings Library 1260, 702 (2010). https://doi.org/10.1557/PROC-1260-T07-02

[2]. M. Chen, A. Iyer and R. Opila, "Developing Inkjet Printed PEDOT/PSS Films for Solar Cells," 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 2019, pp. 0443-0446, doi: 10.1109/PVSC40753.2019.8980819. keywords: {inkjet printing;printable solar cells;photovoltaic cells;silicon},

[3]. Morice S, Sherehiy A, Wei D, et al. Characterization of the Direct Write Inkjet Printing Process for Automated Fabrication of PEDOT: PSS Thin Films[C]//International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2022, 85802: V001T01A021.

[4]. Olowo O O, Zhang R, Sherehiy A, et al. Inkjet printing of PEDOT: PSS inks for robotic skin sensors[C]//International Manufacturing Science and Engineering Conference. American Society of Mechanical Engineers, 2022, 85802: V001T07A004.

[5]. Wilson P, Lekakou C, Watts J F. System design and process optimization for the inkjet printing of PEDOT: Poly (styrenesulfonate)[J]. Journal of Micro-and Nano-Manufacturing, 2014, 2(1): 011004.

[6]. Hu Z, Liang Y, Fan S, et al. Flexible Neural Interface From Non‐Transient Silk Fibroin With Outstanding Conformality, Biocompatibility, and Bioelectric Conductivity[J]. Advanced Materials, 2024, 36(46): 2410007.

[7]. Wang G, Adil M A, Zhang J, et al. Large‐area organic solar cells: material requirements, modular designs, and printing methods[J]. Advanced Materials, 2019, 31(45): 1805089.

[8]. Molina-Lopez F, Gao T Z, Kraft U, et al. Inkjet-printed stretchable and low voltage synaptic transistor array[J]. Nature communications, 2019, 10(1): 2676.

[9]. Li J, Cao J, Lu B, et al. 3D-printed PEDOT: PSS for soft robotics[J]. Nature Reviews Materials, 2023, 8(9): 604-622.

[10]. Basak I, Nowicki G, Ruttens B, et al. Inkjet printing of PEDOT: PSS based conductive patterns for 3D forming applications[J]. Polymers, 2020, 12(12): 2915.

[11]. Lee Y, Bandari V K, Paliakkara V P, et al. Monolithic Integration of Printable PVDF‐TrFE Piezoelectric Multifunctional Devices: From Sensing to Actuation[J]. Advanced Functional Materials, 2025, 35(3): 2413500.