1. Introduction

Power supplying wireless sensor networks in remote, rural areas on earth has always been a difficult issue to address due to the inconvenience of constantly manually changing the electrical batteries. As global population and energy consumption expands massively, the way society manages and produces energy efficiently is crucial for a sustainable future. Although solar, hydro, and wind electricity are the world leaders in renewable energy production, these sources are restricted by environmental factors, not capable of sustaining the power supply demand of wireless sensor networks in certain distant areas. However, oscillation energy source is a novel and developing source that offers abundant natural forces such as ocean waves or mechanical vibrations to generate electricity. [1,2] Though, traditional oscillation energy collectors often fail to satisfy the energy requirement for a wireless sensor module, lacking efficiency and operational range. [3]

2. Background and review of literature

2.1. Research background

In order to solve low efficiency and increase applicability of these energy harvesters, many past researchers attempted a combination of various methods to bring solutions. [4,5] Piezoelectricity, electrostatic, electromagnetic, and frictional electricity are the common mechanisms to improve this concern. [6]

2.2. Related work

Challa et al. [7] proposed a piezoelectric-electromagnetic hybrid energy harvester with a cantilever beam structure, which consists of a piezoelectric cantilever beam, a permanent magnet (as an end mass block) and an induction coil. The maximum output power of the hybrid device was experimentally measured to be 332 µW at a resonant frequency of 21.6 Hz, while the optimized maximum output power was 1.5 µW.

Zhu et al. [8]designed a piezoelectric-electromagnetic hybrid energy harvester, in which four cantilever beams of the same size were symmetrically fixed on the inner side of an annular support frame with piezoelectric ceramic sheets pasted on them, and permanent magnets were fixed at the ends of the brass cantilever beams and adsorbed on both sides of the cantilever beams, and the structure significantly improved the energy harvesting effect, and the output power was in- creased by 141.6% compared with that of a conventional piezoelectric energy harvester.

Jiang et al. [9] similarly proposed a hybrid broadband energy harvester with dual resonant frequencies piezoelectric and electromagnetic. It places two piezoelectric cantilever beams in parallel and connects the two cantilever beams with permanent magnets using two springs, which effectively improves the collection efficiency of the electromagnetic collector. At the same time, the springs help in energy storage and conversion, reduce the sudden effects of environmental vibration, and improve the durability of the piezoelectric cantilever beams. The total output power of the device is 21.94% and 22.98% higher than that of the piezoelectric harvester at 9.6 Hz and 11.2 Hz, respectively.

Zhang et al. [10] on the other hand proposed a novel piezoelectric energy harvester consisting of a piezoelectric cantilever beam and a spring pendulum. It consists of a cantilever beam, a spring pendulum and a piezoelectric element, which couples the bending vibration of the beam with the nonlinear motion of the spring pendulum in two dimensions, resulting in a multidirectional energy harvesting capability. Compared with the piezoelectric cantilever-single pendulum, the proposed structure exhibits superior performance, especially in low-frequency vibrations. x and z directions have 106.6% and 187.3% of the maximum voltage amplitude of the piezoelectric cantilever-single pendulum, respectively.

The above examples all performed well in increasing efficiency of the harvester. However, using multiple energy generation methods significantly increase the complication of the harvesters, re- quiring a stronger resilience demand of each mechanical component. In a context of producing energy from ocean waves, these examples might not guarantee a sustainable power supply due to the difficulty of designing and convoluted structure. Moreover, the operational range, or the accessibility, of these collectors is not wide, limiting the application field of these projects. The resonance frequency of the natural oscillations would hardly match the frequency of these harvesters. Therefore, this study focuses on fixing the limited operational range issue using a cross-double branch beam design with piezoelectric PZT and PVDF films that maximize accessibility and frequency range. Based on experimental results, the frequency range of the traditional oscillation energy collector is significantly improved, allowing the collectors to consistently power supply for wireless sensor networks under different scenarios.

3. Analysis and design

3.1. Analysis

Our experiment design is based on the following equation:

E=energy stored(Joules,J)

C=capacitance(Frauds,F)

V=voltage(Volts,V)

f=frequency

N=required pulses for the step motors to finish a complete cycle t=pulse interval

A=Amplitude

n=pulse number

s=linear displacement corresponding to a single step of the motor

3.2. Design

3.2.1. Problem statement

Traditional oscillation energy collectors often fail to satisfy the energy requirement for a wireless sensor module, lacking inefficiency and operational range.

3.2.2. Design details

This study focuses on designing an innovative mechanical structure that is capable of collecting two dimensional oscillations from nature simultaneously. Instead of the traditional single cantilever design, the study attempted customizing the collectors using a cross-double branch cantilever that is composed of one horizontal cantilever and two vertical cantilevers connected to the end of the horizontal structure. Image of the novel design is shown above in Figure 1. The multidimensional oscillation energy collector of this research is installed using manganese steel pieces, PVDF and PZT piezoelectric thin films, and a 3D printed component that connects the cantilevers together as shown above in Figure 1. PZT thin film is chosen for its strong durability and high efficiency in piezoelectric coefficient. Similarly, PVDF thin film is chosen for its excellent flexibility and wide operational range, increasing the applicability of the energy collector.

In order to simulate the vibration in a realistic scenario, an oscillation table, shown in Figure 2, was constructed in this study, and the vibration in two dimensions was simulated by a horizontal stepping motor and a vertical stepping motor. Meanwhile, in order to evaluate the performance of the device in terms of energy harvesting, a supercapacitor was used in this study to harvest the power generated by the device, and the energy and power generated by the device were measured by measuring the relationship between the voltage and time at the two ends of the capacitor.

4. Experimental procedure

The experimental steps are as follows:

1. Build the experimental vibration table (which consists of a vibration table that makes two- dimensional natural vibration simulation through a horizontal and a vertical stepper motor. The platform includes a horizontal stepper motor with a controller, a slider connected to it, and three acrylic plates).

2. Debug and test the circuit equipment of the single-arm and double-arm vibration energy collectors and install them on the second acrylic plate of the experimental platform.

3. According to the pre-designed oscillation collector’s circuit, complete the electrical wire connection of the power generation device and connect the oscilloscope probe to the electrode of the power generation sheet to test the open circuit voltage of the power generation device.

4. Write the computer controlled program of the step motors, control the experimental platform to generate the required test vibration through the code, conduct comprehensive tests within the expected coverage vibration frequency range, and record the data and feedback from the computer. 5. Record the data of current output using an electrical load instrument and draw relevant charts for analysis.

5. Results and evaluation

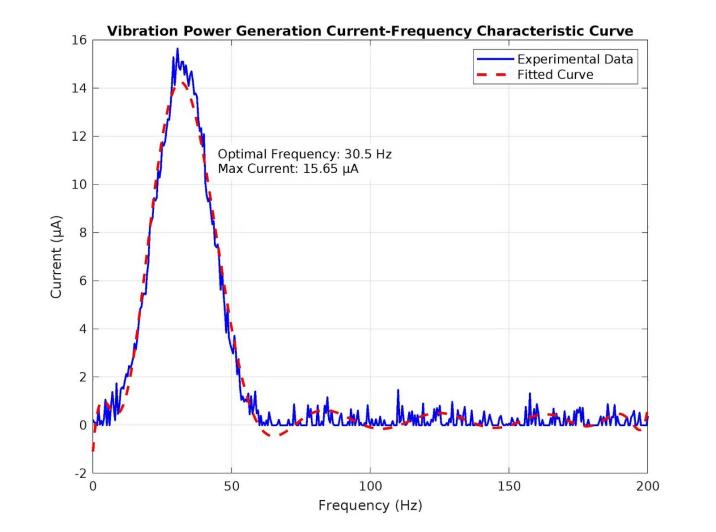

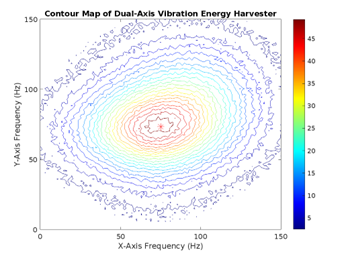

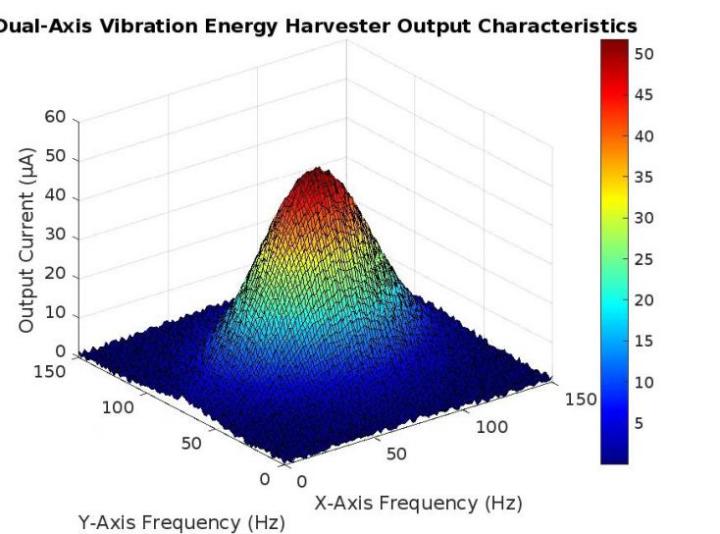

This research involved a controlled experiment for the power generation device to compare the power output and operating frequency range of a single-arm beam in a unidirectional configuration versus a dual-arm beam in a multidirectional configuration. First, only the single arm of the power generation device was installed on the test platform. A vibration generator was used to generate vibration signals with a frequency range of 0 Hz to 200 Hz and a step size of 0.5 Hz, collecting a total of 400 data points. Subsequently, the frequency and power generation current data were plotted into a line graph and fitted using a polynomial function (results as shown in the figure). From the graph, it can be seen that the power generation peak appears at 30.5 Hz, corresponding to a power generation current of 15.65 µA, while the effective operating range of the device is approximately 25 Hz to 35 Hz. Next, the entire power generation device was installed, and biaxial vibrations were generated on the test platform. The frequency range for each axis was 0 Hz to 150 Hz, with a step size of 1.5 Hz, resulting in a total of 10,000 data points through the combination of biaxial frequencies. Then, the biaxial frequency and power generation current data were plotted into a three-dimensional surface plot and fitted using a polynomial function (results as shown in the figure). After analyzing the data using Matlab, it was found that the power generation peak appears at X-axis 66.7 Hz,Y-axis 70.8 Hz, and the operating frequency range of the device is: X-axis 39.0 Hz to 111.0 Hz, Y-axis 49.5 Hz to 105.0 Hz. The current-frequency graphs are shown below in Figure 3 and Figure 4.

|

Maximum Output Current |

51.69 μA |

|

Optimal X-Axis Frequency |

75.00 Hz |

|

Optimal Y-Axis Frequency |

73.50 Hz |

|

X-Axis Frequency Range Covered |

39.0 Hz - 111.0 Hz |

|

Y-Axis Frequency Range Covered |

49.5 Hz - 105.0 Hz |

|

Peak 1: (66.7 Hz, 70.8 Hz) |

Amplitude: 26.27 μA |

|

Peak 2: (102.4 Hz, 94.0 Hz) |

Amplitude: 15.98 μA |

|

Peak 3: (72.5 Hz, 77.8 Hz) |

Amplitude: 19.58 μA |

As shown in the above table, the test frequency coverage range of the crossed arms is: X-axis, 39 Hz to 111 Hz, Y-axis, 49.5 Hz to 105 Hz. The traditional single-arm design covers a range of 25 Hz to 35 Hz. Based on the diagrams illustrated above, the y axis represents the current, and the x axis represents frequency. The wider the frequency is, the better the electricity covered range is. As shown in the experimental data, the test frequency coverage range of the crossed double branch collector is: X-axis, 39 Hz to 111 Hz, Y-axis, 49.5 Hz to 105 Hz. It can be seen that the crossed arms design can effectively improve the coverage of the device. Compared to the one branch design, the cross double branch design of the oscillation collector is capable of absorbing from two dimensional oscillation simultaneously which other studies cannot achieve. Although other studies can generate in many directions, they can not generate simultaneously and cover a longer range. On the same dimension, the cross double branch design is able to cover more frequency than the traditional one. To conclude, the cross double branch is generated from two dimensional frequency, making the design more effective and powerful.

6. Application

Tidal energy exists widely in the ocean and is an energy source that can be obtained uninterrupted and stably. Using oscillation energy harvesters to power nodes in ocean wireless sensor networks is a relatively excellent choice. The project’s energy harvester is capable of harvesting energy across a wide range of vibration frequencies and multi-dimensional vibrations, and its characteristics are also consistent with the vibration characteristics caused by natural ocean tides. The single-beam and double-beam branch vibration collectors designed in this project can maximize the power generation efficiency compared with the traditional single-beam vibration col- lector. The experiments verified the feasibility of this composite beam design and its ability to generate electricity over a wide frequency range. This multi-beam design enables the vibration collector to operate properly in marine environments. Factory contains rotational machines, and installing oscillation energy collectors onto these machines could effectively power supply air quality sensors or detectors without the need of a battery. [11] In addition, bridges, especially wooden bridges, generate high-frequency vibrations during windy weather or when a large number of cars pass over them, thus enabling the harvester to generate electricity for wind speed detection. [12] Using multiple vibration collectors working in parallel increases the overall power generation. A power management circuit is designed to integrate and store energy from multiple sources. When one collector generates insufficient power, others can compensate. Supercapacitors are used as energy buffers to smooth power output fluctuations. The number of collectors can be flexibly configured according to actual power consumption needs.

7. Conclusions

The traditional single branch collector can generate electricity in a range of 10 Hz. In comparison, the cross double branch on the same dimension can generate in a range of 55.5 Hz, not including the electricity generation from the X - axis. After calculating the improvement in frequency range, the hypothesis is supported that the range is enlarged by 5.6 times, validating the hypothesis that the cross double branch beam improves the oscillation frequency for power generation.

8. Future work

With the continuous improvement of the device, the power performance of the device in the low frequency will be gradually improved in the future, while retaining a larger frequency coverage according to the actual application scenarios in order to enhance the power output, which will further expand its application scenarios, so that it is able to effectively collect energy in human activities [13] and wave.

Acknowledgements

Mingfei Xu (Eric); abstract, analysis and design, implementation, results and evaluation, conclusion. Yuheng Zhang (Ken); editing original draft, introduction, background and Lit. Review, application, future work.

References

[1]. Renwen Liu, Lipeng He, Xuejin Liu, Shuangjian Wang, Limin Zhang, and Guangming Cheng. A review of collecting ocean wave energy based on piezoelectric energy harvester. Sustain- able Energy Technologies and Assessments, 59:103417, 2023.

[2]. Ch Madhav and Shaikh Faruque Ali. Harvesting energy from vibration absorber under ran- dom excitations. IFAC-PapersOnLine, 49(1):807–812, 2016.

[3]. Jens Twiefel and Henrik Westermann. Survey on broadband techniques for vibration energy harvesting. Journal of Intelligent Material Systems and Structures, 24(11):1291–1302, 2013.

[4]. Renwen Chen, Long Ren, Huakang Xia, Xingwu Yuan, and Xiangjian Liu. Energy harvest- ing performance of a dandelion-like multi-directional piezoelectric vibration energy harvester. Sensors and Actuators A: Physical, 230:1–8, 2015.

[5]. Huaxia Deng, Yu Du, Zhemin Wang, Jin Zhang, Mengchao Ma, and Xiang Zhong. A multi- modal and multidirectional vibrational energy harvester using a double-branched beam. Ap- plied Physics Letters, 112(21), 2018.

[6]. J Rastegar, C Pereira, and H-L Nguyen. Piezoelectric-based power sources for harvest- ing energy from platforms with low-frequency vibration. In Smart Structures and Materials 2006: Industrial and Commercial Applications of Smart Structures Technologies, volume 6171, page 617101. SPIE, 2006.

[7]. Vinod R Challa, MG Prasad, and Frank T Fisher. A coupled piezoelectric–electromagnetic energy harvesting technique for achievingincreased power output through damping match- ing. Smart materials and Structures, 18(9):095029, 2009.

[8]. Y. Zhu, Z. Zhang, P. Zhang, andY. Tan. A magnetically coupled piezoelectric–electromagnetic low-frequency multidirection hybrid energy harvester. Micromachines, 13(5):761, 2022.

[9]. B. Jiang, F. Zhu, Y. Yang, J. Zhu, Y. Yang, and M. Yuan. A hybrid piezoelectric and elec- tromagnetic broadband harvester with double cantilever beams. Micromachines, 14(2):240, 2023.

[10]. Yunshun Zhang, Guangsong Zhang, and Wanshu Wang. A piezoelectric cantilever-beam- spring-pendulum oscillator for multi-directional vibration energy harvesting. Communications in Nonlinear Science and Numerical Simulation, 138:108199, 2024.

[11]. YC Shu, WC Wang, and YP Chang. Electrically rectified piezoelectric energy harvesting induced by rotary magnetic plucking. Smart Materials and Structures, 27(12):125006, 2018.

[12]. ZC Ong, YX Ooi, SY Khoo, and YH Huang. Two-stage multi-modal system for low frequency and wide bandwidth vibration energy harvesting. Measurement, 149:106981, 2020.

[13]. Wei Wang, Junyi Cao, Nan Zhang, Jing Lin, and Wei-Hsin Liao. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Con- version and Management, 132:189–197, 2017.

Cite this article

Xu,M.;Zhang,Y. (2025). A Novel Approach to Improved Operational Capability: Multi-Dimensional Oscillation Energy Collector. Applied and Computational Engineering,162,231-238.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Renwen Liu, Lipeng He, Xuejin Liu, Shuangjian Wang, Limin Zhang, and Guangming Cheng. A review of collecting ocean wave energy based on piezoelectric energy harvester. Sustain- able Energy Technologies and Assessments, 59:103417, 2023.

[2]. Ch Madhav and Shaikh Faruque Ali. Harvesting energy from vibration absorber under ran- dom excitations. IFAC-PapersOnLine, 49(1):807–812, 2016.

[3]. Jens Twiefel and Henrik Westermann. Survey on broadband techniques for vibration energy harvesting. Journal of Intelligent Material Systems and Structures, 24(11):1291–1302, 2013.

[4]. Renwen Chen, Long Ren, Huakang Xia, Xingwu Yuan, and Xiangjian Liu. Energy harvest- ing performance of a dandelion-like multi-directional piezoelectric vibration energy harvester. Sensors and Actuators A: Physical, 230:1–8, 2015.

[5]. Huaxia Deng, Yu Du, Zhemin Wang, Jin Zhang, Mengchao Ma, and Xiang Zhong. A multi- modal and multidirectional vibrational energy harvester using a double-branched beam. Ap- plied Physics Letters, 112(21), 2018.

[6]. J Rastegar, C Pereira, and H-L Nguyen. Piezoelectric-based power sources for harvest- ing energy from platforms with low-frequency vibration. In Smart Structures and Materials 2006: Industrial and Commercial Applications of Smart Structures Technologies, volume 6171, page 617101. SPIE, 2006.

[7]. Vinod R Challa, MG Prasad, and Frank T Fisher. A coupled piezoelectric–electromagnetic energy harvesting technique for achievingincreased power output through damping match- ing. Smart materials and Structures, 18(9):095029, 2009.

[8]. Y. Zhu, Z. Zhang, P. Zhang, andY. Tan. A magnetically coupled piezoelectric–electromagnetic low-frequency multidirection hybrid energy harvester. Micromachines, 13(5):761, 2022.

[9]. B. Jiang, F. Zhu, Y. Yang, J. Zhu, Y. Yang, and M. Yuan. A hybrid piezoelectric and elec- tromagnetic broadband harvester with double cantilever beams. Micromachines, 14(2):240, 2023.

[10]. Yunshun Zhang, Guangsong Zhang, and Wanshu Wang. A piezoelectric cantilever-beam- spring-pendulum oscillator for multi-directional vibration energy harvesting. Communications in Nonlinear Science and Numerical Simulation, 138:108199, 2024.

[11]. YC Shu, WC Wang, and YP Chang. Electrically rectified piezoelectric energy harvesting induced by rotary magnetic plucking. Smart Materials and Structures, 27(12):125006, 2018.

[12]. ZC Ong, YX Ooi, SY Khoo, and YH Huang. Two-stage multi-modal system for low frequency and wide bandwidth vibration energy harvesting. Measurement, 149:106981, 2020.

[13]. Wei Wang, Junyi Cao, Nan Zhang, Jing Lin, and Wei-Hsin Liao. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Con- version and Management, 132:189–197, 2017.