1. Introduction

Widely integrated into both domestic appliances and industrial control systems, temperature sensors play a fundamental role in thermal management by converting ambient heat into linear analog or digital signals. These electronic devices enable precise detection and quantification of temperature, supporting applications ranging from climate regulation and food processing to fluid monitoring [1]. The evolution of IoT technologies has significantly advanced Wireless Sensor Networks (WSNs), enabling their widespread adoption in environmental monitoring. By integrating sensing, processing, storage, and communication functionalities, these systems deliver continuous environmental data streams like temperature, humidity, and pollutants across diverse scenarios. They have been widely adopted in fields ranging from smart cities to national defense [2]. This study explores temperature sensing in WSNs, addressing trade-offs among accuracy, energy efficiency, and scalability, and proposing optimization strategies for Internet of Things (IoT) applications. It also explores methods to enhance the long-term stability of temperature monitoring in WSNs through sensor calibration and intelligent algorithms. Existing approaches struggle to adapt to dynamic environments, which directly affects the reliability of industrial automation and smart city systems, highlighting the need to overcome current limitations by integrating emerging materials and artificial intelligence (AI) technologies. By evaluating representative cases and synthesizing existing studies, it identifies core challenges in WSN-based temperature sensing and proposes corresponding solutions to boost data reliability across applications such as environmental monitoring, industrial automation, and smart cities. It further investigates AI-driven calibration approaches, contributing to the standardization of next-generation smart sensors and promoting the convergence of IoT technologies across domains.

2. Working principles and system architecture of temperature sensors

2.1. Basic operating principles

Temperature sensors operate based on distinct physical principles, which shape their performance across various applications. Many sensors, such as those based on semiconductor diodes, operate by exploiting the predictable relationship between temperature and electrical properties. For instance, resistance increases as temperature rises, and vice versa [3]. More specifically, temperature sensing relies on mechanisms like semiconductor voltage shifts, resistive changes in resistance temperature detectors (RTDs) and thermistors, and infrared absorption in non-contact sensors. These define their performance in accuracy, range, and environmental stability. Temperature sensors are commonly classified into contact and non-contact types according to their sensing mechanisms. In particular, contact sensors such as thermocouples and thermistors, provide accurate readings but require direct physical contact with the measured object. Conversely, non-contact sensors like infrared devices support remote temperature detection, making them ideal for high-speed or hazardous environments, although they are more prone to environmental disturbances. Accordingly, a solid grasp of these principles is necessary for selecting the appropriate sensor and achieving reliable performance under varying application constraints.

2.2. System architecture and functional modules

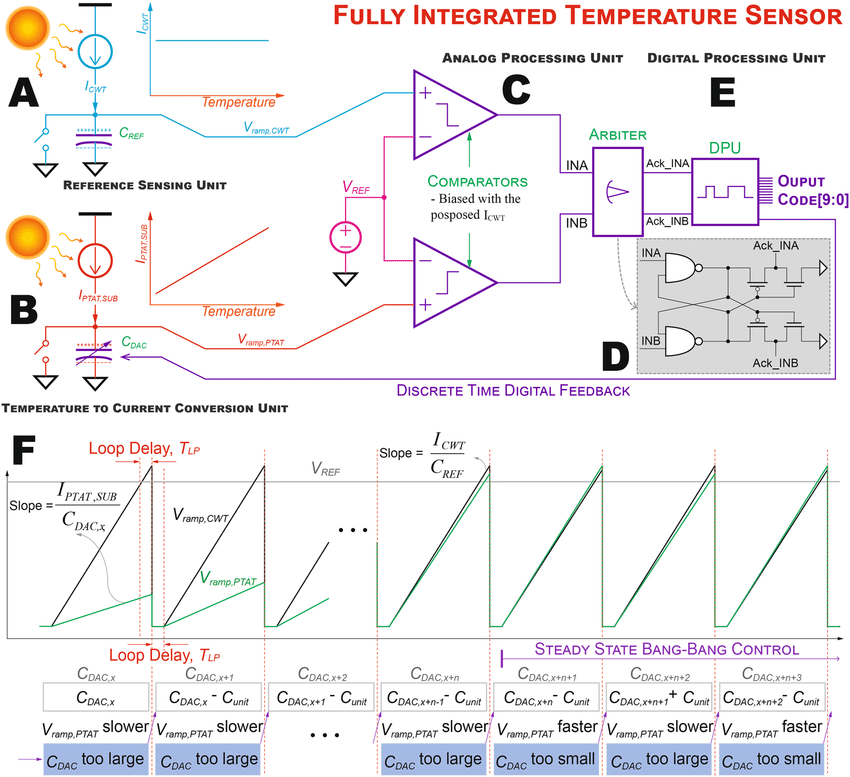

To achieve high measurement precision and system stability, the temperature sensor architecture combines analog and digital modules through synchronized signal conversion and feedback control, as shown in Figure 1. This multi-module configuration enables accurate temperature acquisition and reliable digital output through a structured flow of analog sensing, signal comparison, and closed-loop digital adjustment [4]. Through the integration of analog front-end circuits and dynamic digital control, the sensor architecture ensures reliable and accurate processing of thermal signals. Analog ramp voltages, shaped by temperature-dependent current sources and capacitive elements, serve as the basis for encoding temperature changes. The comparator logic filters and discretizes the analog signals, while a digital feedback loop dynamically adjusts timing parameters to ensure accurate quantization and stable, low-noise digital output under varying thermal conditions.

To maintain measurement stability under environmental and process variations, the system uses a closed-loop correction mechanism in which the DPU continuously monitors timing mismatches and compensates for drift by adjusting current levels. The analog and digital domains are physically isolated to minimize interference. Moreover, the sensor is designed with energy efficiency in mind. It activates computation only in response to temperature-induced events and dynamically adjusts its sampling frequency based on ambient thermal dynamics, and responds rapidly under conditions of high thermal variability while conserving power during stable periods. This architecture enables robust, low-power, and accurate temperature monitoring, making it well suited for embedded and IoT applications.

2.3. Major sensing methods and technologies

To select an appropriate temperature sensing method for specific industrial needs, it is essential to understand the operating principles, strengths, and limitations of the major sensing technologies. Despite their technical complexity, these sensors are fundamental to precise monitoring and control in industrial systems [5]. The widespread use of RTDs, thermocouples, and thermistors in industrial settings stems from their distinct advantages, each catering to specific operational needs. RTDs function by measuring the change in resistance of a platinum element with temperature, ensuring high accuracy and long-term stability. Due to their high accuracy, excellent linearity, and long-term stability, RTDs are well suited for industrial environments demanding precise temperature control. Typical applications include critical sectors like food processing and pharmaceutical manufacturing. However, RTDs are relatively expensive and exhibit slower response times compared to other sensor types, which may limit their use in time-sensitive or cost-constrained environments. Besides, thermocouples operate based on the thermoelectric effect, generating a voltage proportional to the temperature difference between two junctions of dissimilar metals. And their ability to withstand extreme temperatures makes them ideal for high-temperature applications such as metal processing, power generation, and energy systems. Despite their robustness and wide temperature range, these sensors generally have lower accuracy than RTDs and require cold-junction compensation, which increases the complexity of the measurement system. Widely used in medical, automotive, and consumer electronic systems, thermistors are valued for their high sensitivity and fast response. These temperature-sensitive resistors, typically made of semiconductor materials, exhibit significant resistance variation with temperature, hence allowing precise detection of small thermal fluctuations. However, their nonlinear response and limited operating range reduce their suitability for industrial environments that demand high linearity or broad temperature coverage.

3. Typical application scenarios of temperature sensors

3.1. Industrial automation and process control

Temperature measurement is critical in industrial and manufacturing processes, ensuring production efficiency, product quality, and equipment safety. It enables precise monitoring and control, and is used in areas such as chemical reactions, heat treatment, and material drying to prevent overheating and optimise performance. In the automotive industry, temperature sensors monitor engine status, exhaust systems, and cooling mechanisms to boost fuel efficiency and prevent malfunctions. They also regulate the vehicle’s climate to maintain passenger comfort. Moreover, accurate temperature measurement enhances process consistency, cuts waste, and increases production efficiency across multiple industries [6]. Thermocouples are widely used in heavy industry and high-temperature environments because they withstand extreme heat, resist vibration and shock, respond quickly, and are cost-effective. In contrast, Resistance Temperature Detectors (RTDs) are favored in precision manufacturing due to their high accuracy, stability, linearity, and traceable calibration, which drives continued demand for platinum resistors. Meanwhile, thermistors, known for their high sensitivity, low cost, and small size, are commonly applied in consumer electronics, home appliances, and automotive systems. As these technologies advance, the temperature sensor market is shifting from single-function devices toward intelligent, integrated, and multifunctional solutions. For example, Italian company Bridgetort’s second-generation temperature-pressure sensor combines temperature and pressure data to enable precise control of thermal management systems. Additionally, this two-in-one sensor eliminates the need for matching valve seats and wiring harnesses, reducing both the overall cost and weight of vehicles. As a result, it effectively enhances the energy efficiency of air conditioning systems. Currently, this sensor is widely implemented in models from brands such as Fiat, Audi, Mercedes-Benz, BMW, and Alfa Romeo.

3.2. Environmental monitoring and climate observation

Environmental parameters like temperature, humidity, air quality, light intensity, and sound waves are detected and measured by sensors [7]. Among these, temperature sensors are fundamental to environmental monitoring networks, offering high precision, wide temperature range, and low power consumption to support global dynamic tracking. Their core strength lies in integration with other sensors: temperature and humidity sensors collaborate to correct environmental errors using dew point algorithms, such as detecting sudden temperature drops combined with high humidity in flood warnings, while pressure sensors provide altitude correction to eliminate temperature gradient biases. This multi-parameter fusion greatly improves the accuracy of pollution source tracking and climate modeling. Typical applications demonstrate its irreplaceable role. In urban heat island management, sensor networks embedded in streetlights locate high-temperature hotspots in real time and coordinate control systems. In ecological monitoring, early warning models for forest fires are developed by linking unusual temperature data with humidity and gas levels, facilitating the transition from single-point monitoring to an integrated sensing, analysis, and decision-making system. However, challenges remain in long-term drift compensation and stability under extreme environmental conditions.

3.3. Smart home systems and personal health monitoring

As a key sensing element in the smart IoT era, temperature sensors are transforming smart home and health management through continuous technological innovation. For example, Gree’s GMV6 smart multi-split system uses a high-precision digital temperature sensor to achieve more accurate temperature detection. Using adaptive fuzzy control algorithms, it adjusts temperature settings intelligently in different rooms according to household members’ activity patterns. Similarly, Haier Casarte air conditioners combine infrared temperature sensors with millimeter-wave radar, allowing them to detect both environmental and human body surface temperatures and automatically switch to an “anti-direct blow” mode for enhanced comfort. In energy-saving systems, the Nest thermostat continuously learns user habits and, combined with geofencing technology, automatically enters energy-saving mode when users leave home. By reducing heating and cooling costs, this approach also improves comfort. In addition, flexible temperature, humidity, and strain sensors have been integrated into wearable devices to monitor skin temperature, skin humidity, and respiratory status, respectively [8]. These sensors adhere closely to the skin, continuously tracking surface temperature changes to deliver essential data and accurately capture fluctuations over time. In smart home scenarios, temperature sensing is evolving from basic environmental monitoring to becoming a temperature manager that anticipates user needs. In health management, the integration of flexible electronics and artificial intelligence has shifted its role from passive monitoring to active health intervention. These innovative applications demonstrate the unique value of temperature sensing technology.

4. Challenges and future directions

4.1. Technical challenges in temperature sensing

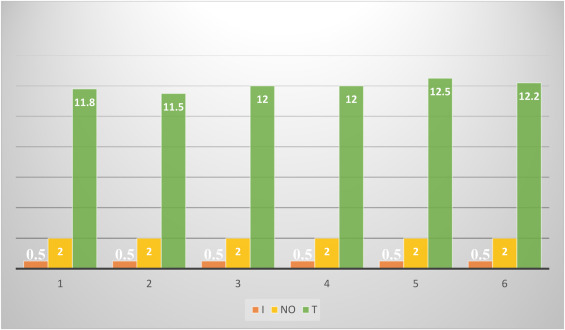

In WSNs, temperature sensors still face multi-dimensional technical challenges, including accuracy drift, energy consumption, nonlinearity, electromagnetic interference, as well as system integration. In particular, long-term operation leads to temperature drift in sensors, undermining measurement accuracy and stability. This drift is mainly caused by the gradual degradation of material properties under high-temperature or extreme environments, resulting in reference value deviations and signal distortion. In real-world implementations, periodic calibration is typically conducted by aligning sensor outputs with a reference temperature and plays a key role in ensuring measurement reliability. However, early studies on sensors still report enduring problems such as accuracy degradation and unstable output [9]. Besides, inherent nonlinearity between sensor output and temperature is often observed, which complicates subsequent signal processing. For example, thermistors often follow an exponential temperature-resistance curve as a result of the intrinsic conduction properties of semiconductor materials. In engineering applications, analog compensation via Wheatstone bridges and digital processing through polynomial regression are commonly adopted to linearize output signals and improve processing compatibility. Figure 2 shows how node communication contributes to energy consumption based on the analysis results [9].

Moreover, strong electromagnetic interference in industrial environments can couple into signal transmission paths, affecting measurement accuracy. Typical interference sources include inverter discharges and power grid harmonics, which introduce noise during transmission. An effective mitigation approach involves combining physical shielding (e.g., metal enclosures) with Kalman filtering algorithms to form a hardware-software collaborative noise suppression system. In terms of system integration, multi-parameter fusion in IoT applications often causes signal crosstalk, limiting overall performance. Using shared frequencies and power in sensors like temperature and humidity can cause signal interference when running at the same time. This requires designing frequency-division multiplexing and power decoupling circuits to balance accuracy and energy efficiency.

4.2. Future development directions

To ensure the long-term reliability of temperature sensors in WSNs, continuous breakthroughs are required in key domains such as data integrity, energy efficiency, intelligent scheduling, and fault diagnosis. The extensive deployment, constrained resources, and harsh environments of wireless temperature sensing systems pose challenges that conventional protocols and tools are ill-equipped to address. Thus, it is essential to develop more adaptive mechanisms and algorithmic frameworks tailored to the stringent conditions of such architectures. For example, in ensuring data integrity, redundancy-checking strategies based on spatiotemporal correlation can be employed. By analyzing the inter-node correlation, anomalous measurements can be detected, while memory-based adaptive filters can continuously correct transmission-induced data distortion, thereby enhancing overall data integrity [10]. In the context of task scheduling, a reinforcement learning-enabled multi-objective optimization strategy can effectively balance sampling precision, energy efficiency, and real-time communication delay. Additionally, monitoring frequency can be dynamically adjusted based on temperature gradient variations to enhance system responsiveness and adaptability. To enhance energy efficiency and ensure long-term operation, it is vital to develop stochastic models of energy intake and usage that support the optimal design of storage and scheduling strategies. For fault diagnosis and system maintenance, fault diagnosis can be significantly improved by fusing features from time, frequency, and spatial domains into a multi-scale feature extraction framework. In parallel, transfer learning-based semi-supervised algorithms provide a viable solution to the scarcity of labeled data and the variability of real-world failure scenarios. Thus, the proposed approaches provide a coherent framework for overcoming major technical bottlenecks in wireless temperature sensor networks, and should serve as focal points for future research and practical applications.

5. Conclusion

Widely used in industry and daily life, temperature sensors efficiently convert temperature into electrical signals. Key technologies such as thermocouples, thermistors, RTDs, and infrared sensors each offer distinct advantages for applications including high and low-temperature monitoring, precise control, medium to low-temperature measurement, and non-contact detection. With the development of IoT and AI technologies, sensors are rapidly evolving towards miniaturisation, low power consumption, and intelligence. However, research on reliability in extreme environments, data security, and system compatibility is limited, especially in cost optimization and interference reduction for high-precision sensors. Future research should prioritize advances in nanomaterials, edge computing calibration algorithms, and standardized communication protocols. And these improvements will address measurement stability and system integration challenges, offering more reliable temperature monitoring for applications like smart homes and the industrial internet, and driving the industry’s digital transformation.

References

[1]. Nvs, B. and Saranya, P.L. (2020) Water pollutants monitoring based on Internet of Things. Inorganic Pollutants in Water. Elsevier, 371-397.

[2]. Moslehi, M.M (2025) Exploring coverage and security challenges in wireless sensor networks: a survey. Computer Networks, 260, 111096.

[3]. Encardio Rite (2019) Temperature sensors: types, how it works, & applications. https: //www.encardio.com/blog/temperature-sensor-probe-types-how-it-works-applications.

[4]. Wang, H. and Mercier, P.P. (2017) Near-zero-power temperature sensing via tunneling currents through complementary metal-oxide-semiconductor transistors. Sci Rep 7, 4427.

[5]. Biedulski, J. (2024) Exploring temperature sensor technology: types, uses and benefits. ControlByte. https: //controlbyte.tech/blog/exploring-temperature-sensor-technology-types-uses-and-benefits/.

[6]. Pyrosens. (2023) Types of Industrial Temperature Sensors. https: //pyrosens.com/types-of-industrial-temperature-sensors/.

[7]. SparkFun. (2025) Environmental sensors. https: //www.sparkfun.com/sensors/environmental-sensors.html.

[8]. Matsumura, G., et al. (2024) Real-time personal healthcare data analysis using edge computing for multimodal wearable sensors. Device, 100597-100597.

[9]. Hossain, N., et al. (2024) Prospects and challenges of sensor materials: A comprehensive review. e-Prime-Advances in Electrical Engineering, Electronics and Energy, 7, 100496.

[10]. Elkhediri, S., et al. (2023) Integration of Artificial Intelligence (AI) with sensor networks: Trends and future research opportunities. Journal of King Saud University - Computer and Information Sciences, 101892.

Cite this article

Li,J. (2025). Emerging Advances Challenges and Future Directions for Temperature Sensors in Wireless Sensor Networks. Applied and Computational Engineering,187,13-19.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Nvs, B. and Saranya, P.L. (2020) Water pollutants monitoring based on Internet of Things. Inorganic Pollutants in Water. Elsevier, 371-397.

[2]. Moslehi, M.M (2025) Exploring coverage and security challenges in wireless sensor networks: a survey. Computer Networks, 260, 111096.

[3]. Encardio Rite (2019) Temperature sensors: types, how it works, & applications. https: //www.encardio.com/blog/temperature-sensor-probe-types-how-it-works-applications.

[4]. Wang, H. and Mercier, P.P. (2017) Near-zero-power temperature sensing via tunneling currents through complementary metal-oxide-semiconductor transistors. Sci Rep 7, 4427.

[5]. Biedulski, J. (2024) Exploring temperature sensor technology: types, uses and benefits. ControlByte. https: //controlbyte.tech/blog/exploring-temperature-sensor-technology-types-uses-and-benefits/.

[6]. Pyrosens. (2023) Types of Industrial Temperature Sensors. https: //pyrosens.com/types-of-industrial-temperature-sensors/.

[7]. SparkFun. (2025) Environmental sensors. https: //www.sparkfun.com/sensors/environmental-sensors.html.

[8]. Matsumura, G., et al. (2024) Real-time personal healthcare data analysis using edge computing for multimodal wearable sensors. Device, 100597-100597.

[9]. Hossain, N., et al. (2024) Prospects and challenges of sensor materials: A comprehensive review. e-Prime-Advances in Electrical Engineering, Electronics and Energy, 7, 100496.

[10]. Elkhediri, S., et al. (2023) Integration of Artificial Intelligence (AI) with sensor networks: Trends and future research opportunities. Journal of King Saud University - Computer and Information Sciences, 101892.