1. Introduction

With the rapid advancement of urbanization and the continuous development of the construction industry in China, the scale of engineering construction has been expanding, and the construction environment has become increasingly complex. Traditional safety management models can no longer meet the needs of modern engineering construction. Currently, the construction industry still belongs to a high-risk area for safety accidents. According to statistics, there were hundreds of safety accidents in housing construction and municipal engineering nationwide in 2022, resulting in significant casualties and economic losses. These accidents have exposed prominent problems in traditional safety management, such as backward supervision methods, lagging risk early warning, and poor information transmission. Against this background, the new generation of information technologies represented by Internet of Things (IoT), big data, and Artificial Intelligence (AI) has provided new solutions for Engineering Construction Safety Management. As a product of the deep integration of information technology and construction management, the “smart construction site” provides an important path for the digital transformation of Safety Management by building a technical system of comprehensive perception, intelligent analysis, and collaborative control. In recent years, national-level policy documents such as the “Guiding Opinions on Promoting the Coordinated Development of Intelligent Construction and Construction Industrialization” have been successively issued, clearly proposing to accelerate the construction of smart construction sites. Practice has shown that the Smart Construction Site System can effectively increase the safety hazard identification rate by more than 30% and reduce the Accident Rate by approximately 25% through the application of modules such as personnel positioning, environmental Surveillance, and Equipment monitoring. However, current research on the application of smart construction sites in Safety Management still has problems such as insufficient System Integration, insufficient depth of Data Analysis, and low accuracy of early warning models. In particular, research on adaptability in different project types and construction stages is still insufficient. Therefore, in-depth exploration of the innovative application of Smart Construction Site in Engineering Construction Safety Management, and systematic study of its technical architecture, implementation path and effect Evaluation are of important theoretical value and practical significance for improving the Essential Safety level of the construction industry and promoting high-quality development of the industry.

Domestic scholars have made significant progress in the research on the application of Smart Construction Site in Engineering Construction Safety Management. The influencing factor analysis framework of Smart Construction Site based on grounded theory-structural equation model developed by Shen Yuran’s team (2024) from Hebei University of Architecture, China, reveals the key roles of economic support (total effect value 0.374) and technical support (total effect value 0.348) through multi-dimensional path analysis, with an empirical explanatory power of 73.343% [1]. The construction engineering Smart Construction Site quality management system designed by Duan Wei from Beijing Jiaotong University (2023) achieves quality control throughout the construction process by integrating four modules: personnel positioning, machinery surveillance, material tracing, and BIM technology. Its management effectiveness is verified to reach the “Good” level (membership degree 0.33) through fuzzy comprehensive evaluation, significantly improving the efficiency of hidden danger rectification and closed-loop management [2]. The Smart Construction Site integrated management platform constructed by Hao Yichu’s team from Inner Mongolia University of Science and Technology (2025) realizes significant effectiveness of cost saving of 980,000 yuan and schedule advancement in the project of A City Normal College through the collaborative operation of five subsystems: personnel, machinery, materials, safety and environment [3]. The Safety Management system for construction sites in the context of smart construction sites developed by Jiao Cheng of Southeast University (2023) integrates Internet of Things (IoT), Artificial Intelligence (AI), BIM and other technologies to build a five-module Management System (personnel, machinery, environment, monitoring, Education), realizing intelligent control over 22 Safety Management influencing factors. Verified by the N engineering project, the fuzzy comprehensive Evaluation of the system Implementation effect reached the “good” level [4].

The Smart Construction Site System developed by Tian Yanmin of Lanzhou New Area Guoxin Engineering Consulting and Management Co., Ltd. (2025) realizes real-time Surveillance of construction personnel’s safety helmet wearing and automatic drone inspection through Internet of Things (IoT) sensors and Artificial Intelligence (AI) technology, effectively improving the eff-iciency of safety risk early warning and the accuracy of quality management at construction sites [5]. The analysis of intelligent construction site research trends based on scientometrics conducted by Song J’s team (2021) from Tongji University, China, revealed through literature visualization technology the shift of global research hotspots from traditional performance indicators to technologies such as Internet of Things (IoT) and virtual reality [6]. The review on AI construction safety published by Rabbi and Jeelani’s team (2024) from the University of Florida, USA, pointed out that computer vision-based safety protection equipment detection systems (e.g., safety helmets, safety belts) have achieved a maximum accuracy of 94.97% in real-time monitoring through algorithms such as deep transfer learning and Faster R-CNN, significantly enhancing the active protection capability at construction sites [7].

The empirical study by Smetanková from Technical University of Kosice (2023) showed that the application rate of drones and intelligent safety helmets in construction site surveillance reached 37.6%, but 93.8% of construction enterprises considered high cost as the core obstacle to the promotion of intelligent tools [8]. The BIM+IoT Smart Construction Site safety platform developed by the team of Liu Zhen from Dalian Vocational and Technical College, China (2025), integrates Web GL lightweight models with ZigBee/GPRS sensor networks to achieve real-time monitoring of tower crane loads and structural stress, effectively reducing high-rise building construction safetyAccident Rate [9]. The worker health Surveillance system based on multi sensor fusion developed by the team of Hen Li from The Hong Kong Polytechnic University (2022) collects real-time ECG, motion and environmental data through wearable Equipment to realize Intelligent Early Warning of construction workers’ physiological status and high-risk behaviors. The intelligent construction site HSE management framework proposed by the team of Maozeng Xu from Chongqing Jiaotong University (2022) integratesInternet of Things (IoT), BIM and deep learning technologies to build a full-process real-time monitoring system covering health, safety and environmental risks [10]. The intelligent technology integration framework proposed by the team of Songshun Lin from Shanghai Jiao Tong University (2025) achieves sustainable management throughout the entire life cycle of construction projects by integrating Multi-Criteria Decision Making (MCDM) with Artificial Intelligence (AI) technologies such as big data analysis, computer vision, and machine learning [11].

The IoT-based intelligent construction platform developed by the team of Professor Lukowicz from the German Artificial Intelligence (AI) Research Center (DFKI) (2019) realizes remote real-time optimization of transportation processes in large construction sites through customized low power sensor nodes (20mA) and an adaptive cloud analysis engine, with the visualization accuracy of transportation cycles reaching over 90% in field tests [12]. The Construction 5.0 intelligent construction framework proposed by the team of Professor Skibniewski from the University of Maryland, USA (2025) promotes industry paradigm upgrading by integrating BIM, Internet of Things (IoT) and space construction technologies, predicting that China’s construction robot market will exceed 10 billion US dollars by 2030 [13]. The BIM-based construction Safety Management system developed by Wenke Yu’s team from Chongqing Jianzhu University (2021) enables early identification of potential safety hazards in the construction process through 4D virtual construction and collision detection technologies, reducing Design Change costs by 80% [14].

The BIM-AI intelligent construction management framework proposed by Yue Pan’s team from Shanghai Jiao Tong University and Limao Zhang’s team from Huazhong University of Science and Technology (2022) integrates building lifecycle data through digital twin and deep learning technologies to achieve automatic review of design Compliance and prediction of construction risks [15].

It is worth noting that international research presents three distinct characteristics: first, greater emphasis on human-machine collaboration; second, focus on the development of standard system; third, highlighting the concept of sustainable safety by organically integrating Safety Management with environmental Surveillance.In contrast, foreign research has advantages in hardware miniaturization and algorithm light weighting, but it also has problems such as excessively high system construction costs and insufficient localization adaptability. Overall, foreign research provides technical reference for China’s Smart Construction Site Safety Management, but localization innovation is still needed to adapt to the characteristics of China’s Engineering Construction.

2. Construction of smart construction site system

Subsection Concept Overview of Smart Construction Site Smart construction site is a modern management mode integrating information technology with construction engineering. Its core lies in building a digital management and control platform covering the entire construction process through new generation information technologies such as big data, Internet of Things(IoT), and Building Information Modeling (BIM) [1]. With “comprehensive perception, real-time interconnection, intelligent analysis, and collaborative management and control” as its technical core, the system dynamically collects data on key elements such as personnel, machinery, materials, environment and processes to realize three-dimensional monitoring of the construction site operation status. In the field of Safety Management, smart construction site upgrades traditional passive Safety Management to an active prediction and real-time intervention mode through technical means such as intelligent sensor network (e.g., UWB positioning, tower crane black box), AI visual behavior recognition, and BIM+GIS hazard source visualization, significantly improving the accuracy of hidden danger identification and the speed of risk response.Its fundamental goal is to optimize construction processes through data-driven decision-making, reduce Accident Rate, ensure personnel safety, while improving resource utilization efficiency and engineering quality management level [2]. As the core carrier of digital transformation in the construction industry, Smart Construction Site is not only an important path to realize the “Made in China 2025” strategy, but also a revolutionary change to promote Engineering Construction from extensive management to refined and intelligentization leap, providing Key Technologies support for the sustainable development of the industry.

2.1. Key technologies of smart construction site

Big data technology big data technology is gradually becoming the core support in various fields. In the context of the disruptive development of digital technologies, the rate of data generation and accumulation shows exponential growth, which urgently requires efficient data management tools and technologies for processing. Through technologies such as algorithm development, machine learning (ML), Statistical Analysis, and computational model construction, massive amounts of data can be systematically integrated to assist researchers in making precise decisions and promoting in-depth domain analysis. As a labor and data-intensive industry, the construction industry is currently facing the challenge of lagging application of new technologies. Although the construction process continuously generates huge amounts of data, its value has not been fully explored. Compared with the vigorous development of the information technology industry, big data management in the construction field is still in the primary stage, and there is a long way to go in building a mature application system.

Internet of Things (IoT) technology Internet of Things (IoT) is defined as an intelligentization infrastructure integrating information systems, human resources, and data resources to achieve eff-icient management and control of information in physical and virtual spaces. This technology constructs a system framework with collaborative functions by integrating heterogeneous components such as sensors, actuators, cloud services, and communication protocols. In recent years, breakthrough advancements in sensing and communication technologies have accelerated the popularization of IoT technology, promoting its large-scale application in fields such as transportation, security, healthcare, and intelligent construction. The introduction of IoT technology into engineering construction management enables in-depth penetration of mobile terminals into on-site operations, significantly improving Management Efficiency. The closed-loop data flow based on the on-site project management logic will substantially drive the optimization and upgrading of construction progress, quality control, and environmental Surveillance, realizing the transformation from traditional construction site management to intelligent risk prevention and control.

BIM technology provides methodological and tool support for intelligent project collaborative management. By integrating information throughout the entire project lifecycle including planning, design, construction, and Maintenance, this technology constructs an efficient collaboration platform for multiple participants. Compared with traditional 3D CAD models, the core advantage of BIM lies in its ability to carry all building element data, including structured data such as material specifications, structural nodes, and Maintenance information. As a unified data source for project information, BIM enables construction units to conduct multi-scheme simulations before construction, accurately identify professional conflicts and construction risks, and ultimately achieve the goals of information integration, collaborative efficiency, error minimization, and Project Quality optimization.

Artificial Intelligence (AI), as the core driving force of the new round of technological revolution and industrial transformation, conducts in-depth mining and continuous optimization of massive data resources through brain-like intelligent mechanisms. Currently, various fields are accelerating the research, development and application of this technology, covering Key Technologies such as deep learning (DL), natural language processing (NLP) and speech recognition. It is deeply integrated with 5G communication, cloud computing and big data infrastructure to build an integrated intelligent decision-making system. A typical practice is integrating augmented reality (AR)/virtual reality (VR) technologies into the Smart Construction Site management platform to create immersive safety training scenarios: on the one hand, improving construction workers’ safety awareness by simulating high-risk operating environments; on the other hand, enhancing emergency crisis handling capabilities through emergency scenario simulation drills [3].

2.2. Construction of smart construction site system

2.2.1. System design objectives

The core design objective of Smart Construction Site System is to build an integrated platform that deeply integrates technologies such as Internet of Things(IoT), big data, cloud computing, Artificial Intelligence(AI), and Building Information Modeling(BIM).

It aims to achieve an all-round upgrade of Engineering Construction management, with core focus on:

• Essential Safety improvement: Through the deployment of personnel positioning, intelligent video surveillance (AI recognition of safety helmet and reflective clothing wearing, dangerous area intrusion, smoke and fire, etc.), environmental sensors (dust, noise, harmful gases), high formwork/deep foundation pit surveillance equipment, etc., Real time Perception of risks, automatic early warning, and closed-loop disposal are realized to significantly reduce the safety accident rate (e.g., set a reduction target of more than 30%) and ensure the safety of personnel’s lives and property.

• Production Process Efficiency Improvement: Utilize Internet of Things (IoT) to automatically collect Equipment operation and material consumption data, conduct visual schedule tracking and deviation analysis in combination with BIM models, realize precise scheduling and optimal allocation of resources (personnel, machinery, materials), reduce work idleness and waste, and improve overall construction efficiency.

• Project Quality Assurance: Integrate functions such as quality inspection and evaluation system, visual documentation of concealed works, and comparison between BIM models and on-site conditions to achieve visual and standardized control and quality traceability of key links in the construction process, and improve the first-time acceptance pass rate of the project.

• Management Collaboration Optimization: Establish a unified data center and visual dashboard, break information silos, realize real-time sharing of multi-party information among owners, designers, constructors, supervisors, etc., and efficient collaborative decision-making, and improve management transparency and response speed.5. Green and intensive resources: Monitor and optimize energy consumption and water usage in real time, precisely control dust and noise pollution, and promote Green Construction and sustainable development.

The ultimate goal is to create a modern construction site management ecosystem characterized by knowable, controllable, traceable, and efficient through digital and intelligent means.

2.2.2. System overall framework

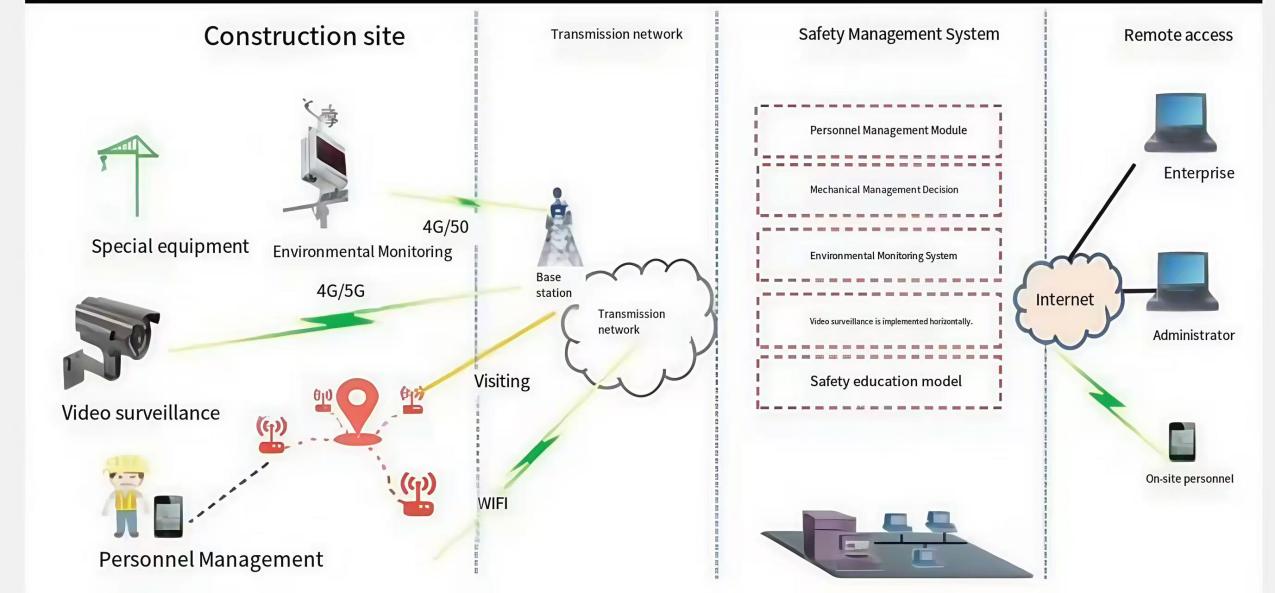

In the context of Smart Construction Site, the Safety Management system for construction sites integrates intelligent hardware and software technologies to build a unified management platform, organically integrating and connecting various modules of the system. The system operates according to the preset development logic: first, various Equipment deployed at the front-end of the construction site (such as sensors, thermometers, surveillance cameras, RFID smart helmets, environmental monitors, outdoor displays, etc.) collect multi-source data in real time [4]. These reliable data collected by various intelligent terminals are aggregated and uploaded to the cloud platform in real-time through the transmission network composed of on-site wireless WiFi network or dedicated 100M optical fiber. In the cloud, cloud computing and big data technology are used to analyze and process massive amounts of information. The processed results and key information are visually presented through the backend system management platform to assist managers in decision-making and judgment. Decision information can be timely fed back to on-site personnel, thereby realizing the digitization and intelligentization of the entire construction management process and ensuring that the safety status of construction projects is real-time controllable.

The Safety Management system is structurally divided into three core parts:

• front-end hardware equipment layer: Includes the above-mentioned various intelligent sensing and acquisition terminals, responsible for acquiring on-site environment and operation information.

• transmission network layer: Composed of wired (leased line 100M optical fiber) and wireless (full-coverage WiFi) networks to ensure stable and high-speed back haul of front-end data.

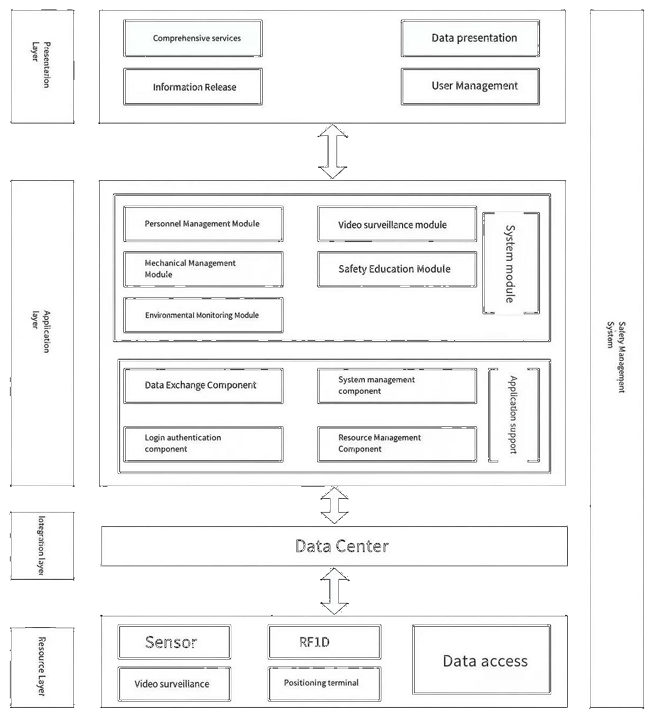

• system management platform layer: As the system core, the platform is based on B/S architecture and adopts distributed regional management technology, allowing convenient access via Web browser. It integrates core business functions such as project approval, multi-dimensional Data Analysis, security early warning, user Authorities management, and basic Service configuration, and can visually display processed data. Meanwhile, the platform provides remote mobile terminal (mobile App) support, enabling authorized users to access and process data within their authorization scope via wired/wireless networks at any time, regardless of being local or remote, for real-time monitoring and management.Managers can also orienteering push information to on-site construction personnel in real time through mobile terminals. The system takes building and efficient Operation management platform as the core goal, scientifically integrates various internet resources, and has a friendly and intuitive interface. It is supported by advanced Internet of Things (IoT) and intelligent technologies at the bottom layer, and constructs a comprehensive application system covering multiple fields and levels to meet the actual needs of refined project supervision. The system is divided into four parts according to the architecture level: Resource Layer, Integration Layer, Application Layer, Display Layer [5]. The overall system architecture is shown in Figure 1.

3. Smart construction site application in safety management

As a pillar industry of the national economy, the construction industry has always been faced with severe challenges in work safety. Traditional Safety Management models rely on manual inspection, Experience based Judgment and Post event Accountability, which have pain points such as multiple regulatory blind spots, response lagging, and weak risk prediction capability. By deeply integrating new-generation information technologies such as Internet of Things (IoT), big data, Artificial Intelligence (AI), Building Information Modeling(BIM), and cloud computing, Smart Construction Site is fundamentally reshaping the construction site Safety Management model and building an active defense system featuring Real time Perception, dynamic early warning, intelligent decision-making, and efficient collaboration. The Smart Construction Site Safety Management platform based on BIM and Internet of Things (IoT) technologies proposed by the Liu Zhen team from Dalian Vocational and Technical College in China has undergone comprehensive application testing in a high-rise office building construction project (covering an area of 35,536m² with a building height of 93.1m). By integrating three major functions: 3D visualization model, real time environmental Surveillance, and intelligent control of large-scale Equipment, the platform has achieved a systematic improvement in Safety Management efficiency.At the BIM Application Layer level, the platform performs lightweight processing on building structure models, site layouts, and sensor locations (such as pressure gauges, temperature and humidity sensors), then conducts real-time rendering on the Web side using Web GL technology, enabling managers to remotely view the construction site digital twin in 360 degrees. For example, by simulating the rotation trajectory of tower cranes through BIM models, automatic collision detection identifies spatial interference risks with scaffolding to guide the Classification of Locations; in the event of an accident (e.g., fire alarm), the platform quickly locates the accident point and displays the escape route in linkage, improving rescue efficiency. The BIM model views are shown in Figure 2 and Figure 3.

To scientifically evaluate the application effectiveness of the system in Project N, 10 experts from the construction unit, construction company, and supervision unit were invited. The Analytic Hierarchy Process (AHP) was used to determine the weights of various influencing factors, and the fuzzy comprehensive evaluation method was combined to conduct a quantitative analysis of the system implementation effect. The final evaluation results show that the system has achieved a “good” level in “human unsafe behaviors”, “poor environment”, and management defects, with only a slight deficiency in “unsafe state of objects” (evaluated as “average”). The overall comprehensive evaluation is “good”, indicating that the system can effectively identify, warn, and control most safety hazards at construction sites, improve safety management efficiency, reduce accident rates, and has high practicality and promotion value. At the same time, it also points out the direction for subsequent system optimization (especially in the aspects of in-depth monitoring and fault prediction of mechanical equipment).

Smart construction sites have made significant progress in safety management, but still face challenges such as insufficient system integration, limited depth of Data Analysis, low accuracy of early warning models, and high costs. Future research can be carried out in depth from the following aspects:

• Strengthen multi-technology integration and system integration, promote the in-depth integration of BIM, IoT, AI and digital twin technologies, and build a more intelligent integrated management and control platform.

• Deepen data mining and intelligent algorithm application, develop high precision risk early warning models, and improve the accuracy and timeliness of safety hazard identification.

• Promote the research and development of low-cost and lightweight solutions to reduce the application threshold for small and medium-sized construction sites.

• Establish and improve the standard system and evaluation mechanism, standardize the construction and operation of smart construction sites, and promote the standardized promotion of achievements.

• Expand the integration of smart construction sites with green construction and carbon neutrality goals to achieve the coordinated development of safety, environmental protection and efficiency.

Through continuous innovation and optimization, smart construction sites will play a more important role in improving the intrinsic safety level of the construction industry and promoting high quality development of the industry. The topology diagram of the smart construction site safety management system is shown in Figure 4.

4. Conclusion and outlook

This paper systematically studies the theoretical basis, system construction and innovative application of smart construction sites in safety management of engineering construction. The research shows that smart construction sites integrate technologies such as IoT, big data, artificial intelligence and BIM to build a digital management platform, realizing the transformation from passive safety management to active prediction and real-time intervention. In terms of system construction, an overall architecture with core goals such as improving intrinsic safety is proposed, and a four-layer technical system including resources layer, integration layer, application layer and presentation layer is established. Typical cases show that smart construction sites have achieved significant results in personnel positioning, mechanical monitoring, etc., which can reduce the accident rate by more than 30% and improve the efficiency of hidden danger identification and response. Smart construction sites still face challenges such as insufficient system integration, limited depth of Data Analysis,low warning accuracy, and high costs. In the future, efforts should be made to strengthen multi-technology integration and system integration, deepen data mining and intelligent algorithm application, develop low-cost solutions, establish and improve the standard system, and expand the integration with green construction and carbon neutrality, so as to enhance the intrinsic safety level of the construction industry and promote high-quality development.

References

[1]. Shen YR. (2024) Research on Influencing Factors and Pathways of Smart Construction Site Development. Hebei Institute of Architecture and Civil Engineering.

[2]. Duan W. (2023) Design Research on Quality Management System for Smart Construction Sites in Building Engineering. Beijing Jiaotong University.

[3]. Hao YC. (2025) Application of Smart Construction Site Management Platform in Construction Projects - Taking A Normal College as an Example. Inner Mongolia University of Science and Technology.

[4]. Jiao C. (2023) Research on Construction Site Safety Management system under the Background of Smart Construction Sites. Southeast University.

[5]. Tian YM. (2025) Application of Smart Construction Site System in Housing Building Site Management. Comprehensive Corrosion Control, 39 (06): 132-135.

[6]. Liu HL, Song Jiule, Wang Guangbin. (2021) A Scientometric Review of Smart Construction Site in Construction Engineering and Management: Analysis and Visualization. Sustainability, 13 (16): 8860.

[7]. Ahmed B.K.R., Idris J., (2024) AI integration in construction safety: Current state, challenges, and future opportunities in text, vision, and audio based applications, Automation in Construction, Volume 164, 105443, ISSN 0926-5805.

[8]. Jana S.K.K., (2023) Application of Smart Construction Site in Construction Practice. 7th EAI International Conference on Management of Manufacturing Systems. 03. 55.

[9]. Liu Z. (2025) Construction of Smart Site Safety Platform Based on BIM+IoT Technology. ce /papers, 8(2): 1379-1385.

[10]. Xu MZ , Nie XY, Li H, Jack C.P. Cheng, Zhong YM, (2022) Smart construction sites: A promising approach to improving on-site HSE management performance, Journal of Building Engineering, Volume 49, 104007, ISSN 2352-7102.

[11]. Lin SS, Shen SL, Zhou AN, Chen XS. (2025) Smart Techniques Promoting Sustainability in Construction Engineering and Management. Engineering, 45(2): 262 282.

[12]. Antonio B, De M S, Peter H, Antonio B, De M S , Peter H, et al. (2019) Smart Construction: Remote and Adaptable Management of Construction Sites through IoT. IEEE Internet of Things Magazine, 2 (3): 38-45.

[13]. Mirosław J. Skibniewski, (2025) The Present and Future of Smart Construction Technologies. Engineering, Volume 44, Pages 21-23, ISSN 2095-8099.

[14]. Yu WK, Zeng L, Hong D and Wang XY, (2021) Research and Development of Building Construction Safety Management System Based on BIM Technology, 2021 International Conference on Intelligent Transportation, Big Data Smart City (ICITBS), Xi’an, China, pp. 137-140.

[15]. Pan, Y., Zhang, L. (2023) Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch Computat Methods Eng 30, 1081–1110.

Cite this article

Wang,Y. (2025). Research on the Application of Smart Construction Site in Safety Management of Engineering Construction. Applied and Computational Engineering,187,65-74.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Shen YR. (2024) Research on Influencing Factors and Pathways of Smart Construction Site Development. Hebei Institute of Architecture and Civil Engineering.

[2]. Duan W. (2023) Design Research on Quality Management System for Smart Construction Sites in Building Engineering. Beijing Jiaotong University.

[3]. Hao YC. (2025) Application of Smart Construction Site Management Platform in Construction Projects - Taking A Normal College as an Example. Inner Mongolia University of Science and Technology.

[4]. Jiao C. (2023) Research on Construction Site Safety Management system under the Background of Smart Construction Sites. Southeast University.

[5]. Tian YM. (2025) Application of Smart Construction Site System in Housing Building Site Management. Comprehensive Corrosion Control, 39 (06): 132-135.

[6]. Liu HL, Song Jiule, Wang Guangbin. (2021) A Scientometric Review of Smart Construction Site in Construction Engineering and Management: Analysis and Visualization. Sustainability, 13 (16): 8860.

[7]. Ahmed B.K.R., Idris J., (2024) AI integration in construction safety: Current state, challenges, and future opportunities in text, vision, and audio based applications, Automation in Construction, Volume 164, 105443, ISSN 0926-5805.

[8]. Jana S.K.K., (2023) Application of Smart Construction Site in Construction Practice. 7th EAI International Conference on Management of Manufacturing Systems. 03. 55.

[9]. Liu Z. (2025) Construction of Smart Site Safety Platform Based on BIM+IoT Technology. ce /papers, 8(2): 1379-1385.

[10]. Xu MZ , Nie XY, Li H, Jack C.P. Cheng, Zhong YM, (2022) Smart construction sites: A promising approach to improving on-site HSE management performance, Journal of Building Engineering, Volume 49, 104007, ISSN 2352-7102.

[11]. Lin SS, Shen SL, Zhou AN, Chen XS. (2025) Smart Techniques Promoting Sustainability in Construction Engineering and Management. Engineering, 45(2): 262 282.

[12]. Antonio B, De M S, Peter H, Antonio B, De M S , Peter H, et al. (2019) Smart Construction: Remote and Adaptable Management of Construction Sites through IoT. IEEE Internet of Things Magazine, 2 (3): 38-45.

[13]. Mirosław J. Skibniewski, (2025) The Present and Future of Smart Construction Technologies. Engineering, Volume 44, Pages 21-23, ISSN 2095-8099.

[14]. Yu WK, Zeng L, Hong D and Wang XY, (2021) Research and Development of Building Construction Safety Management System Based on BIM Technology, 2021 International Conference on Intelligent Transportation, Big Data Smart City (ICITBS), Xi’an, China, pp. 137-140.

[15]. Pan, Y., Zhang, L. (2023) Integrating BIM and AI for Smart Construction Management: Current Status and Future Directions. Arch Computat Methods Eng 30, 1081–1110.