1. Introduction

More and more people pay attention to 3D printing. More and more 3D printing products are gradually applied to people's life, study, and work, ranging from housing manufacturing to micro-nano electronic equipment [1]. Compared with traditional reduced material manufacturing, 3D printing (additive manufacturing) realizes free forming of complex structures by stacking materials layer by layer, significantly reducing the manufacturing cycle and material consumption [2]. Polymers have become the main materials for 3D printing due to their mild processing and easy functional modification. Polymer materials, including thermoplastics and thermosets, are broadly employed and account for a substantial market share due to their adaptable properties. From house interiors to micro/nano electronic devices, they can be realized through 3D printing polymer materials [3]. However, 3D printing polymers are still generally faced with great challenges. Due to the low strength of 3D printing polymer materials and poor interface bonding between printing layers, the mechanical strength is significantly lower than that of traditional injection-molded parts. At the same time, its applicable materials are limited. For example, melt deposition molding (FDM) is mainly used for acrylonitrile butadiene styrene copolymer (ABS) and PLA; SLS is concentrated in PA12, and most of them are structural materials, which are difficult to meet the functional requirements of conductivity, heat conduction, biological activity, and so on [1,3]. In order to improve the strength of 3D printing polymer materials, cellulose nanocrystals, carbon nanotubes, and other nanomaterials are often used as reinforcements and polymer materials for hybrid printing, so as to prepare high-strength and multifunctional 3D printing nanocomposites [3]. The introduction of cellulose nanocrystals (CNC) and carbon nanotubes (CNT) into polymer matrix to form composite materials, and the use of nanoparticles' reinforcement effect, functional properties, and regulation of the printing process, has become an effective strategy to solve the above problems [4]. This paper will focus on two representative types of nano reinforcements, CNC and CNT, and deeply discuss and analyze the principles of various 3D printing processes (3DP), the application progress, and the mechanism of CNC/CNT nanocomposites in various 3D printing processes, as well as the advantages of the prepared nanocomposites. At the same time, the future development of the nanocomposites in various fields is also projected.

2. Characteristics and modification strategies of nano reinforcement

2.1. Cellulose nanocrystals (CNC)

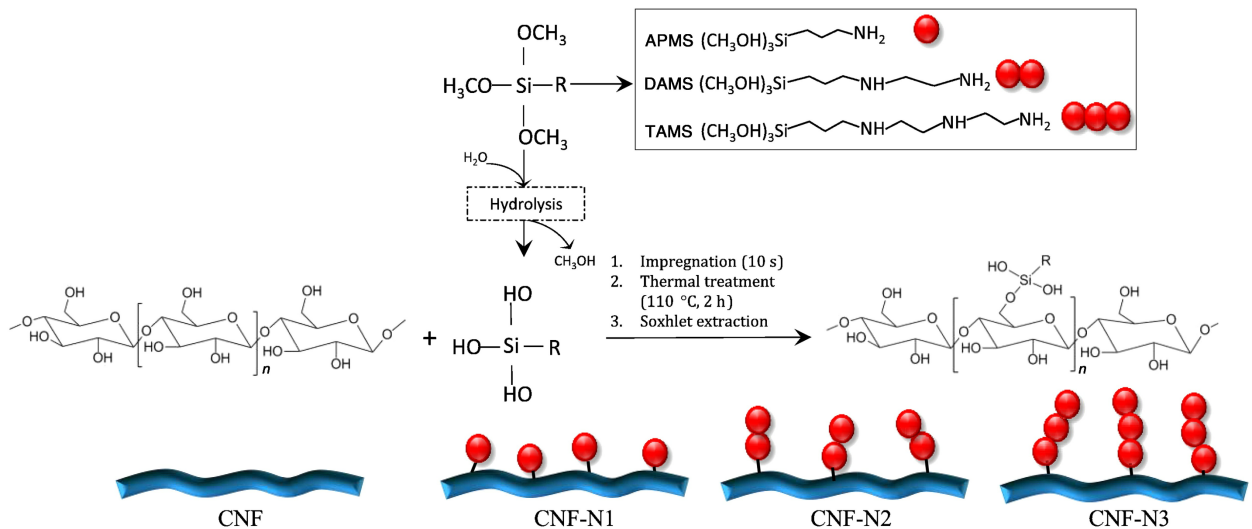

CNC comes from renewable wood fiber resources (such as wood and crop straw), which are obtained by acid hydrolysis and ultrasonic treatment, with a diameter of about 10-30 nm, a crystallinity of 60% -80%, and a theoretical modulus of 130 GPa [5]. Its density is 1.5-1.6 g/cm³, which is much lower than 2.6 g/cm³ of glass fiber or 8 g/cm³ of steel, and its specific stiffness is 85 j/g, which is significantly better than the traditional reinforcement material [5]. In addition, CNC has excellent biocompatibility and physiological inertia, which is suitable for the biomedical field. However, its strong hydrophilicity easily leads to uneven dispersion and poor interface bonding in hydrophobic polymer matrices (such as PLA, PP). Therefore, it is particularly important to appropriately modify cellulose nanocrystals without changing their basic structure and properties. The common modification method of cellulose nanocrystals is silylation, which mainly uses the silane oxy group in silane coupling agents (such as epoxy resin-based silane, methacrylic acid-based silane, and amino silane) to replace the hydroxyl group in cellulose nanocrystals, to realize the hydrophobicity of cellulose nanocrystals. The specific reaction mechanism is shown in Figure 1 [6]. Esterification modification method uses acetic anhydride to react with CNC hydroxyl under acidic conditions (acetylation) to improve its compatibility with polyester polymers [7]. Polymer grafting method grafts polymer monomers (such as lactide) onto the surface of CNC for in-situ polymerization, or directly grafts prepolymers, which significantly improves the dispersion stability in hydrophobic matrix [8]. Finally, there is non-covalent bond surface modification, which mainly adsorbs some surface modifiers, units with opposite charges, and polymer electrolytes on the surface of cellulose nanocrystals in the form of electrostatic adsorption, hydrogen bond, or van der Waals force, to change the hydrophilicity of cellulose nanocrystals [9]. In conclusion, CNC nano reinforcements can be added to materials and applied through reasonable selection and modification strategies.

2.2. Carbon nanotubes (CNTs)

Carbon nanotubes have become an ideal filler for the preparation of functional 3D printing composites due to their ultra-high aspect ratio, excellent conductivity (>10 ⁶ s/ M), thermal conductivity (~3000 W/(m·K)), and mechanical strength (elastic modulus~1 TPA). The core challenge is to solve the problem that carbon nanotubes are easy to agglomerate and disperse in polymers. Several key dispersion technologies need to be used here. The first is ultrasonic-assisted liquid phase dispersion technology, which uses ultrasonic cavitation to peel off CNT aggregates and combines with surfactants (such as sodium cholate) or polymer coating (such as thermoplastic polyurethane (TPU)) to achieve uniform dispersion in solution or melt [10]. Secondly, the solid-state shear milling (s³ m) technology realizes the peeling and uniform dispersion of CNT in polymer powders (such as nylon and TPU) in the solid state through high-strength mechanical shear force, avoiding solvent residue, which is suitable for SLs [11]. Finally, CNT is dispersed in monomer by in-situ polymerization technology, and then polymerization is initiated to ensure nano dispersion and good interface of nanotubes in the matrix [12]. Through the above technology, the diffusion problem of CNT can be improved so that it can be applied.

3. Synergy between the 3D printing process and nanocomposites

3.1. Fused Deposition Molding (FDM)

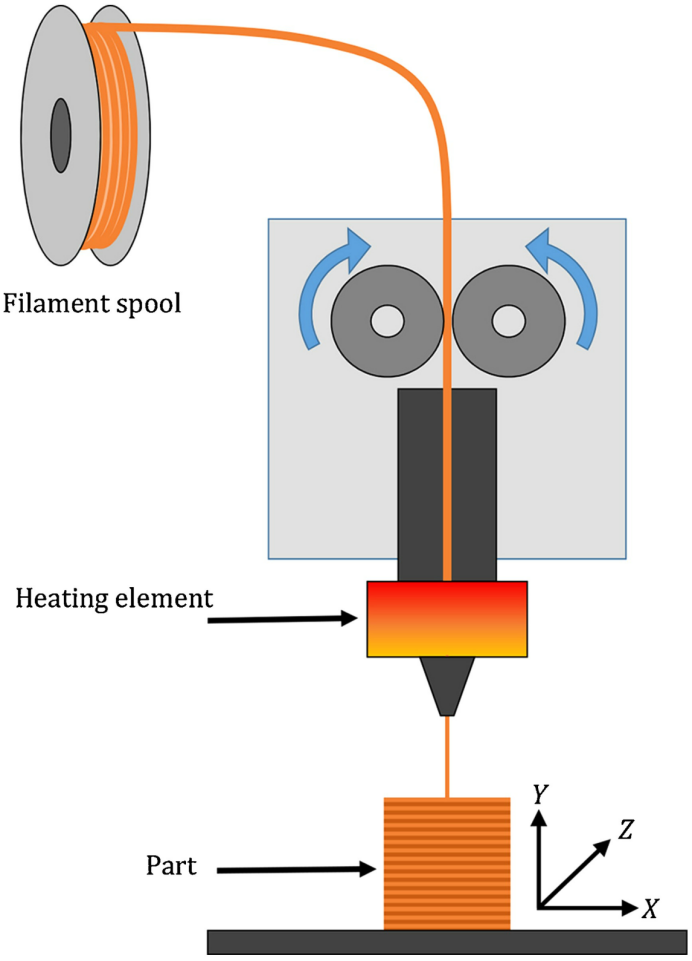

Using FDM to create conductive structures is tricky, primarily for two reasons. First, the melting point of metals is simply too high for the process. Second, conductive polymer nanocomposites (CPN), when highly filled, become too viscous when melted. This high viscosity easily clogs up the printer nozzle, which severely disrupts the printing. The FDM process itself relies on extruding a polymer melt and building up a 3D object layer by layer.

The addition of CNT or CNC can significantly improve the melt strength of the wire, reduce the cooling shrinkage, and enhance the interlayer diffusion bonding, so as to improve the mechanical properties of the printed piece. Its principle is as shown in Figure 2 [13]. In addition to enhancing mechanical properties, it can also build conductive networks. The 8 wt% CNT/ABS composite wire was prepared by solvent-free melt blending. After FDM molding, the tensile modulus was significantly improved, and CNT formed a staggered conductive network in the layer. The conductivity increased by 9 orders of magnitude, reaching 50 s/M [14]. Similarly, the interlaminar adhesion of PLA silk printouts modified by CNC increased by 30%, and the bending strength increased by 34.5% [15].

However, high content of nano fillers can easily lead to melt viscosity surge and nozzle blockage. The solution to the clogging problem is given here. First, the filler concentration should be optimized to control the CNT content below 8 wt%. If it is greater than 10 wt%, the brittleness will increase sharply [16]. Secondly, the printing process can be enhanced by optimizing both the conductive filler's size distribution and key parameters such as printing temperature, speed, residence time, and bed temperature [17]. Furthermore, a high CNT concentration of 40 wt.% was achieved in a CNT/PLA nanocomposite by employing ball milling to mix the CNTs into a PLA-dcm solution [18].

3.2. Selective Laser Sintering (SLS)

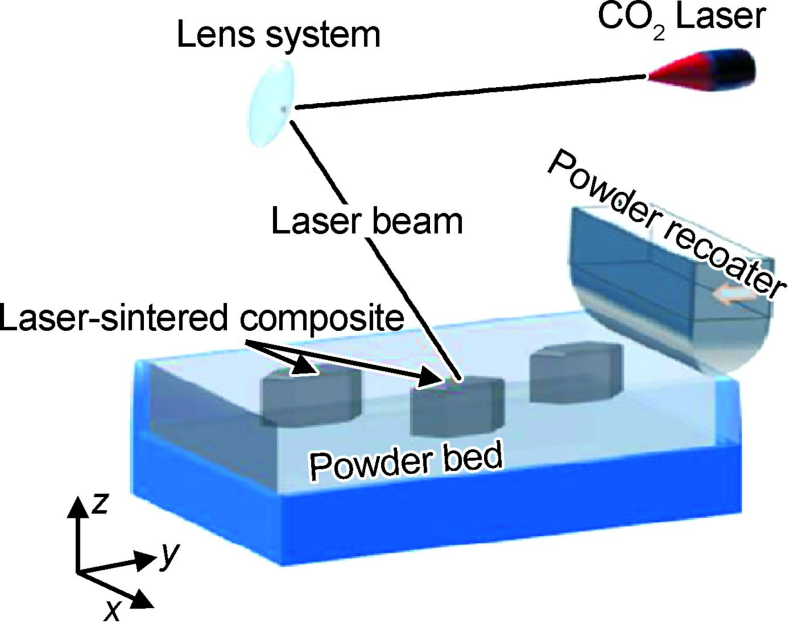

SLS is a relatively mature additive manufacturing technology. It uses a carbon dioxide laser beam to selectively sinter metal, ceramic, or polymer powders, in which the powder material is evenly spread on the powder bed through the powder roller, so that the powder bed can be moved in the z-axis direction to manufacture parts. At the same time, three-dimensional components can also be directly manufactured by selective sintering powder-based material through a computer-aided design model. Its shear-free and free-flow characteristics are conducive to the construction of a conductive isolation network with a low permeability threshold, but the mechanical properties of the products are prone to decline due to the existence of pores. Its principle is shown in Figure 3 [19].

The unique nature of the SLS process—contact-free and based on uncompacted powder—makes it especially suitable for creating segregated conductive networks of carbon nanotubes inside a polymer matrix. In one demonstration, researchers turned a 3D model directly into a flexible, electrically conductive TPU component by sintering TPU powder that had been pre-coated with lab-made CNTs. Remarkably, even with just 0.2 wt% of CNTs, the SLS-printed composite achieved a conductivity around 10⁻¹ S·m⁻¹. When the CNT content was increased to 1 wt%, the material’s conductivity outperformed conventionally injection-molded TPU/CNT composites—with the same filler amount—by seven orders of magnitude. The printed TPU/CNT part also retained excellent flexibility and durability, showing almost no change in electrical resistance even after being bent 1000 times. This method opens a straightforward route for producing intricate and flexible conductive components, such as porous piezoresistive sensors [20].

At the same time, it can also be used to improve the mechanical properties of materials. Zhang and his team developed a low-cost, sustainable material for SLS, combining wood fiber and PES powder with a minimal amount of carbon nanotubes (0.05–0.15 wt%) [21]. The addition of CNTs led to a dramatic improvement in mechanical performance. With only 0.10 wt% CNTs, the composite's tensile strength, flexural strength, and elastic modulus increased by approximately 176%, 328%, and 229%, respectively, compared to the unmodified material. These gains are linked to two key functions of the CNTs: their high thermal conductivity promoted more efficient heat transfer from the laser to the powder, resulting in significantly denser parts, and they became embedded in the partially melted polymer to form a reinforcing network that directly enhanced the component strength. In addition, the mechanical strength of CNT was reduced at 0.15% CNT/WPCs. This kind of carbon nanotube/wood plastic manufactured by SLS has higher strength, lower cost, and higher sintering precision, which has a wide impact on additive manufacturing [21].

3.3. Stereolithography (SLA/DLP)

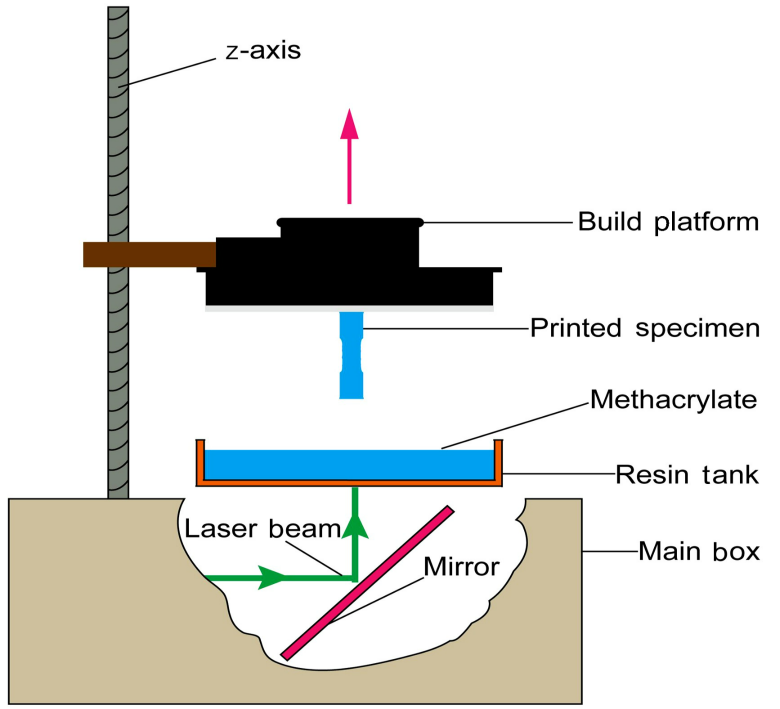

SLA/DLP is cured by liquid photosensitive resin under UV irradiation, with high precision (up to 100 nm). Its principle is shown in Figure 4 [22]. The products prepared by CNT or CNC based on this technology have better application fields, and can be used to improve the mechanical properties of materials or prepare functional intelligent devices. However, the resin has large curing shrinkage, high brittleness, and functional resins are scarce.

Owing to their exceptional strength and stiffness, carbon nanotubes (CNTs) are highly promising for reinforcing parts made by SLA or DLP 3D printing. Their tendency to clump together in photopolymer resins, however, poses a major obstacle, as achieving a uniform dispersion is critical for enhancing material performance. Studies indicate that a solvent exchange method can effectively disperse multi-walled carbon nanotubes (MWCNTs) in such resins. One complicating factor is that CNTs absorb UV light, which can interfere with the resin's curing. However, by optimizing the dispersion process and applying post-treatment thermal curing, the mechanical properties of SLA parts can be markedly improved.For example, incorporating a mere 0.25 wt% of CNTs into the resin was shown to raise the tensile stress and elongation at break of printed parts by 70% and 46%, respectively. The optimized protocol produced components with a tensile strength of about 48 MPa and a Young's modulus near 885 MPa—bringing their overall mechanical performance to a level competitive with ABS injection molding. While the material's elongation remains lower than that of ABS, this gap has been substantially reduced. The achieved ductility is considered satisfactory for the inherently more brittle thermosetting polymers used in SLA. These collective advances in mechanical properties significantly broaden the potential for using stereolithography in functional, load-bearing applications [23]. In addition, it is also found that 0.05 wt% MWCNT can increase the tensile strength of SLA epoxy resin by 17% [24].

The sample ink made from the mixture of light-cured resin and multi-walled carbon nanotubes (MWCNT) was studied. The concentration and printing parameters of MWCNT were studied to produce the best conductivity and printing quality. We found that 0.3 wt% MWCNT loaded in the resin matrix can provide a maximum conductivity of 0.027s/m at the resin viscosity limit, thus achieving high print quality. Due to its electrical conductivity, printed MWCNT nanocomposites can be used as smart materials and structures with strain sensitivity and shape memory effect. We have demonstrated the versatility of DLP 3D printing in complex conductive structures, such as hollow capacitance sensors, electrically activated shape memory composites, and stretchable circuits. In addition, mechanical tests show that the addition of MWCNT can slightly increase the modulus and ultimate tensile stress, and slightly reduce the ultimate tensile stress, indicating that the new function is not obtained at the expense of mechanical properties [25]. At the same time, we also found that using polyethylene glycol diacrylate/aminated MWCNT as ink to print nerve scaffold, the conductivity of MWCNT promotes the proliferation and differentiation of neural stem cells, and combined with electrical stimulation can synergistically accelerate nerve regeneration [26].

3.4. Solvent Casting (SC-3DP)

The principle of sc-3dp technology is to use the rapid volatilization of solvent in the printing process to promote the curing of the polymer solvent mixture. This method has the advantages of simple structure and low cost, and can change the ink viscosity by adjusting the solvent concentration, so as to realize the accurate printing of various nano-composite materials with a high concentration of nano filler.

Using carbon nanotubes/polylactic acid (CNT/PLA) nanocomposites, high conductivity 3D printable inks with conductivity up to~5000s · M-1 were successfully prepared. With the help of solvent casting 3D printing technology, we constructed the conductive support microstructure and systematically studied the effects of different key structural parameters (such as fiber spacing, number of layers, and printing mode) on the transparency and electromagnetic shielding effectiveness of the material. The experimental results show that compared with CNT/PLA nanocomposites formed by solid-state hot pressing, CNT/PLA nanocomposites with 3D printing support structure have significantly improved electromagnetic shielding effectiveness per unit area (~70dBG 1/cm³ vs.~37dBG 3). By adjusting the printing mode and fiber spacing, the transparency of the support material can be freely adjusted in the range of~0%-~75% [27].

4. Expansion of application fields

In addition to manufacturing traditional parts and devices, this technology can also be applied in various fields. For example, in the biomedical field, a team successfully prepared personalized jaw models and bone scaffolds by printing PVA/pla/ha biological composite wires through FDM. The introduction of HA significantly improved cell compatibility and osteogenic activity [28]. A well-dispersed MWCNT hydrogel composite nerve scaffold with adjustable porous structure was prepared by using a stereolithography 3D printer. 3D printing can easily manufacture complex 3D scaffolds with extremely complex microstructure and controlled porosity. Compared with the scaffolds without MWCNT, MWCNT-incorporated scaffolds promoted the proliferation of neural stem cells and early neuronal differentiation. In addition, the biphasic pulse stimulation of 500 μ current promoted the maturation of neurons by quantitative polymerase chain reaction protein expression analysis. The research results show that the combination of conductive MWCNT stent and electrical stimulation may have a synergistic effect on promoting the growth of neurites, which is used for the treatment of nerve regeneration [26].

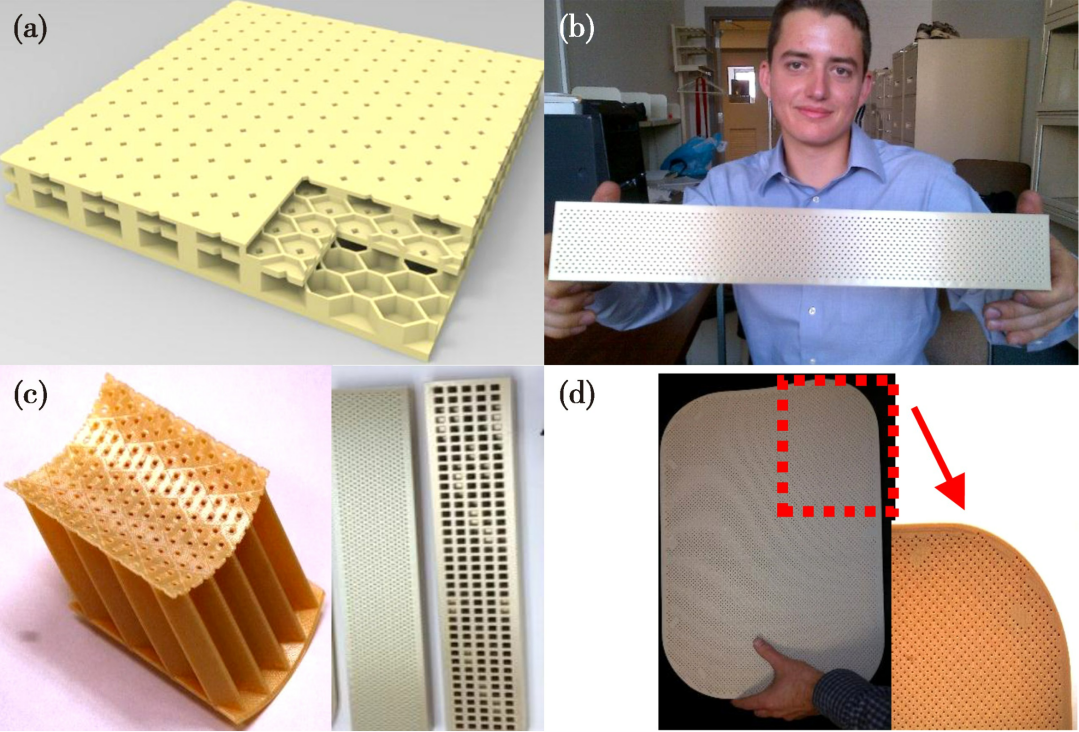

It can also be used in the aerospace field. NASA reported in 2015 that carbon fiber reinforced polyetherimide can be used to form engine sound insulation panels for aircraft in one step through FDM printing (Figure 5), which can replace metal sound insulation materials [29].

5. Conclusion

3DP technology is a material manufacturing process with epoch-making significance. Compared with the traditional process, 3DP technology has the unique advantages of no mold, high material utilization, simple molding, and low cost. Although it still faces challenges such as low strength of polymer materials, poor interface bonding between printing layers, and limited applicable materials. However, the introduction of CNC/CNT nano reinforcement into polymer to prepare composites can effectively improve the performance of materials, and various nano reinforcement composites can be prepared through mainstream 3D printing technologies such as melt deposition molding (FDM), selective laser sintering (SLS), light curing molding (SLA/DLP), and solvent casting molding (SC-3DP). Its better performance can be applied in various fields, and has a very broad development prospect. The same type of 3DP process has its own characteristics and advantages, showing the status quo of a hundred flowers blooming and a hundred schools of thought contending. Of course, 3DP technology still has some difficulties and bottlenecks to be solved, so it has attracted the attention of a large number of scholars. This paper summarizes the research status of CNT/CNC composites prepared by different types of processes, and further analyzes the characteristics of each molding process. At the same time, it also introduces its expansion in the biomedical field and the aerospace field, as well as various achievements. In general, the research progress of 3D printing polymer nanocomposites has made great progress. Although 3DP technology still has some bottlenecks and difficulties, its development potential and prospect are still huge.

References

[1]. Ligon, S. C., Liska, R., Stampfl, J., et al. (2017). Polymers for 3D printing and customized additive manufacturing. Chemical Reviews, 117(15), 10212–10290.

[2]. Gibson, I., Rosen, D., & Stucker, B. (2015). Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing (2nd ed., pp. 1–20). New York, NY: Springer.

[3]. Yang, Z. Z., Kong, Z. W., Wu, G. M., et al. (2021). Research progress on 3D-printed polymer nanocomposites. Materials Reports, 35(13), 13177–13185.

[4]. Farahani, R. D., Dubé, M., & Therriault, D. (2016). Three-dimensional printing of multifunctional nanocomposites: Manufacturing techniques and applications. Advanced Materials, 28(28), 5794–5821.

[5]. Habibi, Y., Lucia, L. A., & Rojas, O. J. (2010). Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chemical Reviews, 110(6), 3479–3500. https: //doi.org/10.1021/cr900339w

[6]. Saini, S., Belgacem, M. N., & Bras, J. (2017). Surface modification of cellulose nanofibers for enhanced interfacial adhesion in polymer nanocomposites. Materials Science and Engineering: C, 75, 760–768. https: //doi.org/10.1016/j.msec.2017.02.092

[7]. Braun, B., & Dorgan, J. R. (2009). Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules, 10(2), 334–341.

[8]. Roy, D., Semsarilar, M., Guthrie, J. T., et al. (2009). Chemical modification of cellulose by in situ reactive compatibilization. Chemical Society Reviews, 38(7), 2046–2064.

[9]. Habibi, Y. (2014). Chemical Society Reviews, 43(5), 1519.

[10]. Li, Z. C., Gan, X. P., Fei, G. X., et al. (2017). Selective laser sintering 3D printing: A way to construct 3D electrically conductive segregated network in polymer matrix. Macromolecular Materials and Engineering, 302(11), 1700211.

[11]. Zhang, Z. Y., Chen, Y. H., Qi, F. W., et al. (2017). Preparation of Nylon 12/Carbon nanotubes co-powders through solid state shear milling and their selective laser sintering 3D printing. Polymer Materials Science and Engineering, 33(3), 122–127.

[12]. Chen, Y., Xia, H. S., Zhang, J., et al. (2017). Polymer-based carbon nano-functional composites processing 3D printing research. Polymer Bulletin, (10), 85–88. https: //doi.org/10.1007/s00289-017-2065-2

[13]. Stansbury, J. W., & Idacavage, M. J. (2016). Dental Materials, 32(1), 54. https: //doi.org/10.1016/j.dental.2015.11.008

[14]. Dul, S., Fambri, L., & Pegoretti, A. (2018). Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterials, 8(1), 49.

[15]. Xu, S., Girouard, N., Schueneman, G., et al. (2013). Mechanical and thermal properties of waterborne epoxy composites containing cellulose nanocrystals. Polymer, 54(24), 6589–6598. https: //doi.org/10.1016/j.polymer.2013.09.038

[16]. Dorigato, A., Moretti, V., Dul, S., et al. (2017). Electrically conductive nanocomposites for fused deposition modelling. Synthetic Metals, 226, 7–14. https: //doi.org/10.1016/j.synthmet.2017.05.012

[17]. Gnanasekaran, K., Heijmans, T., Van Bennekom, S., et al. (2017). 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Applied Materials Today, 9, 21–28. https: //doi.org/10.1016/j.apmt.2017.08.002

[18]. Chizari, K., Daoud, M. A., Ravindran, A. R., et al. (2016). 3D printing of highly conductive nanocomposites for the functional optimization of liquid sensors. Small, 12(44), 6076–6082. https: //doi.org/10.1002/smll.201602262

[19]. Yuans, Zheng, & Ychua, C. K., et al. (2018). Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Composites Part A, 105, 203–213. https: //doi.org/10.1016/j.compositesa.2017.12.009

[20]. Li, Z. C., Wang, Z. H., Gan, X. P., et al. (2018). Flexible TPU/MWCNTs strain sensor with ultrahigh sensitivity and tunable strain range prepared by selective laser sintering. Macromolecular Materials and Engineering, 303(6), 1700371. https: //doi.org/10.1002/mame.201700371

[21]. Zhang, Y., Fang, J. H., Li, J., et al. (2017). The effect of carbon nanotubes on the mechanical properties of wood plastic composites by selective laser sintering. Polymers, 9(12), 728. https: //doi.org/10.3390/polym9120728

[22]. Feng, X., Yang, Z., Chmely, S., et al. (2017). Carbohydrate Polymers, 169, 272. https: //doi.org/10.1016/j.carbpol.2017.05.053

[23]. Eng, H., Maleks Aedi, S., Yu, S., et al. (2017). Development of CNT-filled photopolymer for projection stereolithography. Rapid Prototyping Journal, 23(1), 129–136. https: //doi.org/10.1108/RPJ-04-2016-0050

[24]. Sandoval, J. H., Soto, K. F., Murr, L. E., et al. (2007). Nanotailoring photopolymerizable epoxy resins with multi-walled carbon nanotubes for stereolithography layered manufacturing. Journal of Materials Science, 42(1), 156–165. https: //doi.org/10.1007/s10853-006-0191-3

[25]. Mu, Q. Q., Wang, L., Dunn, C. K., et al. (2017). Digital light processing 3D printing of conductive complex structures. Additive Manufacturing, 18, 74–83. https: //doi.org/10.1016/j.addma.2017.10.002

[26]. Lee, S. J., Zhu, W. P., Nowicki, M., et al. (2018). 3D printing nano conductive multi-walled carbon nanotube scaffolds for nerve regeneration. Journal of Neural Engineering, 15(1), 016018. https: //doi.org/10.1088/1741-2552/aa9040

[27]. Chizari, K., Arjmand, M., Liu, Z. T., et al. (2017). Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Materials Today Communications, 11, 112–118. https: //doi.org/10.1016/j.mtcomm.2017.09.002

[28]. Wu, J. T., Chen, N., Bai, F., et al. (2018). Preparation and fused deposition modeling of poly(vinyl alcohol)/poly(lactic acid)/hydroxyapatite composite filaments for tailored biomedical scaffolds. RSC Advances, 8(55), 31511–31519. https: //doi.org/10.1039/c8ra05047a

[29]. Chuang, K. C., Grady, J. E., Draper, R. D., et al. (2015). Additive manufacturing and characterization of Ultem polymers and composites. In Proceedings of the Composites and Advanced Materials Expo (pp. 1–7). USA.

Cite this article

Tang,B. (2025). Research Progress of 3D Printing Polymer Nanocomposites. Applied and Computational Engineering,200,41-49.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MCEE 2026 Symposium: Advances in Sustainable Aviation and Aerospace Vehicle Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Ligon, S. C., Liska, R., Stampfl, J., et al. (2017). Polymers for 3D printing and customized additive manufacturing. Chemical Reviews, 117(15), 10212–10290.

[2]. Gibson, I., Rosen, D., & Stucker, B. (2015). Additive manufacturing technologies: 3D printing, rapid prototyping, and direct digital manufacturing (2nd ed., pp. 1–20). New York, NY: Springer.

[3]. Yang, Z. Z., Kong, Z. W., Wu, G. M., et al. (2021). Research progress on 3D-printed polymer nanocomposites. Materials Reports, 35(13), 13177–13185.

[4]. Farahani, R. D., Dubé, M., & Therriault, D. (2016). Three-dimensional printing of multifunctional nanocomposites: Manufacturing techniques and applications. Advanced Materials, 28(28), 5794–5821.

[5]. Habibi, Y., Lucia, L. A., & Rojas, O. J. (2010). Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chemical Reviews, 110(6), 3479–3500. https: //doi.org/10.1021/cr900339w

[6]. Saini, S., Belgacem, M. N., & Bras, J. (2017). Surface modification of cellulose nanofibers for enhanced interfacial adhesion in polymer nanocomposites. Materials Science and Engineering: C, 75, 760–768. https: //doi.org/10.1016/j.msec.2017.02.092

[7]. Braun, B., & Dorgan, J. R. (2009). Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules, 10(2), 334–341.

[8]. Roy, D., Semsarilar, M., Guthrie, J. T., et al. (2009). Chemical modification of cellulose by in situ reactive compatibilization. Chemical Society Reviews, 38(7), 2046–2064.

[9]. Habibi, Y. (2014). Chemical Society Reviews, 43(5), 1519.

[10]. Li, Z. C., Gan, X. P., Fei, G. X., et al. (2017). Selective laser sintering 3D printing: A way to construct 3D electrically conductive segregated network in polymer matrix. Macromolecular Materials and Engineering, 302(11), 1700211.

[11]. Zhang, Z. Y., Chen, Y. H., Qi, F. W., et al. (2017). Preparation of Nylon 12/Carbon nanotubes co-powders through solid state shear milling and their selective laser sintering 3D printing. Polymer Materials Science and Engineering, 33(3), 122–127.

[12]. Chen, Y., Xia, H. S., Zhang, J., et al. (2017). Polymer-based carbon nano-functional composites processing 3D printing research. Polymer Bulletin, (10), 85–88. https: //doi.org/10.1007/s00289-017-2065-2

[13]. Stansbury, J. W., & Idacavage, M. J. (2016). Dental Materials, 32(1), 54. https: //doi.org/10.1016/j.dental.2015.11.008

[14]. Dul, S., Fambri, L., & Pegoretti, A. (2018). Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterials, 8(1), 49.

[15]. Xu, S., Girouard, N., Schueneman, G., et al. (2013). Mechanical and thermal properties of waterborne epoxy composites containing cellulose nanocrystals. Polymer, 54(24), 6589–6598. https: //doi.org/10.1016/j.polymer.2013.09.038

[16]. Dorigato, A., Moretti, V., Dul, S., et al. (2017). Electrically conductive nanocomposites for fused deposition modelling. Synthetic Metals, 226, 7–14. https: //doi.org/10.1016/j.synthmet.2017.05.012

[17]. Gnanasekaran, K., Heijmans, T., Van Bennekom, S., et al. (2017). 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Applied Materials Today, 9, 21–28. https: //doi.org/10.1016/j.apmt.2017.08.002

[18]. Chizari, K., Daoud, M. A., Ravindran, A. R., et al. (2016). 3D printing of highly conductive nanocomposites for the functional optimization of liquid sensors. Small, 12(44), 6076–6082. https: //doi.org/10.1002/smll.201602262

[19]. Yuans, Zheng, & Ychua, C. K., et al. (2018). Electrical and thermal conductivities of MWCNT/polymer composites fabricated by selective laser sintering. Composites Part A, 105, 203–213. https: //doi.org/10.1016/j.compositesa.2017.12.009

[20]. Li, Z. C., Wang, Z. H., Gan, X. P., et al. (2018). Flexible TPU/MWCNTs strain sensor with ultrahigh sensitivity and tunable strain range prepared by selective laser sintering. Macromolecular Materials and Engineering, 303(6), 1700371. https: //doi.org/10.1002/mame.201700371

[21]. Zhang, Y., Fang, J. H., Li, J., et al. (2017). The effect of carbon nanotubes on the mechanical properties of wood plastic composites by selective laser sintering. Polymers, 9(12), 728. https: //doi.org/10.3390/polym9120728

[22]. Feng, X., Yang, Z., Chmely, S., et al. (2017). Carbohydrate Polymers, 169, 272. https: //doi.org/10.1016/j.carbpol.2017.05.053

[23]. Eng, H., Maleks Aedi, S., Yu, S., et al. (2017). Development of CNT-filled photopolymer for projection stereolithography. Rapid Prototyping Journal, 23(1), 129–136. https: //doi.org/10.1108/RPJ-04-2016-0050

[24]. Sandoval, J. H., Soto, K. F., Murr, L. E., et al. (2007). Nanotailoring photopolymerizable epoxy resins with multi-walled carbon nanotubes for stereolithography layered manufacturing. Journal of Materials Science, 42(1), 156–165. https: //doi.org/10.1007/s10853-006-0191-3

[25]. Mu, Q. Q., Wang, L., Dunn, C. K., et al. (2017). Digital light processing 3D printing of conductive complex structures. Additive Manufacturing, 18, 74–83. https: //doi.org/10.1016/j.addma.2017.10.002

[26]. Lee, S. J., Zhu, W. P., Nowicki, M., et al. (2018). 3D printing nano conductive multi-walled carbon nanotube scaffolds for nerve regeneration. Journal of Neural Engineering, 15(1), 016018. https: //doi.org/10.1088/1741-2552/aa9040

[27]. Chizari, K., Arjmand, M., Liu, Z. T., et al. (2017). Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Materials Today Communications, 11, 112–118. https: //doi.org/10.1016/j.mtcomm.2017.09.002

[28]. Wu, J. T., Chen, N., Bai, F., et al. (2018). Preparation and fused deposition modeling of poly(vinyl alcohol)/poly(lactic acid)/hydroxyapatite composite filaments for tailored biomedical scaffolds. RSC Advances, 8(55), 31511–31519. https: //doi.org/10.1039/c8ra05047a

[29]. Chuang, K. C., Grady, J. E., Draper, R. D., et al. (2015). Additive manufacturing and characterization of Ultem polymers and composites. In Proceedings of the Composites and Advanced Materials Expo (pp. 1–7). USA.