1. Introduction

Microelectronic technology, which is the backbone of the electronic information industry and the basic technology of the information industry, is currently a rapidly evolving field of science. Microelectronic technology, particularly super large scale integrated circuit, is a novel technology that was developed alongside integrated circuit. System circuit design, device physics, process technology, material preparation, automation testing, packaging and assembly, among other specialized technologies, are all part of the microelectronics field. Microelectronic technology is the culmination of all microelectronic process technologies. High-tech electronic technology known as microelectronics is built on a variety of semiconductor devices with integrated circuits at its core [1].

It has a compact volume, is lightweight, highly reliable, and operates quickly. The information era has a significant impact from microelectronic technologies. The information age is arrived, and the global information economy is expanding quickly [2-3]. The three core subfields of microelectronic technology are film technology, microelectronic packaging technology, and the preparation of integrated circuit chips. Chip is a method of information storage, processing, and processing that is helpful for the growth of the information industry [4]. And the technology used to create chips is microelectronics. Microelectronic technology is thus a crucial component of the science and technology sector in the information society. Microelectronic technology, which is essential to the development of the electronic sector, has a wide range of development possibilities, but as it advances, a few challenges invariably come into play. The further advancement of microelectronic technology is constrained by physical constraints, materials, and procedures, for instance. The mainstream development trend for electronic devices is the downsizing of products, which is a requirement of today's society. Microelectronic technology's advancement and improvement will not only greatly improve people's quality of life and productivity but will also encourage the advancement of existing manned space technology, information and communication technology, and the manufacture of electronic materials [5]. It is important to discuss the development of micro-electronic technology and analyze the application field of micro-electronic technology because the level of micro-electronic technology development is now gradually becoming a significant consideration point to measure a country's overall national strength [6].

This article will first describe the history of the development of microelectronic technology, and then explain its various applications. The future research directions of microelectronic technology in several industries are also highlighted.

2. The development of microelectronic technology

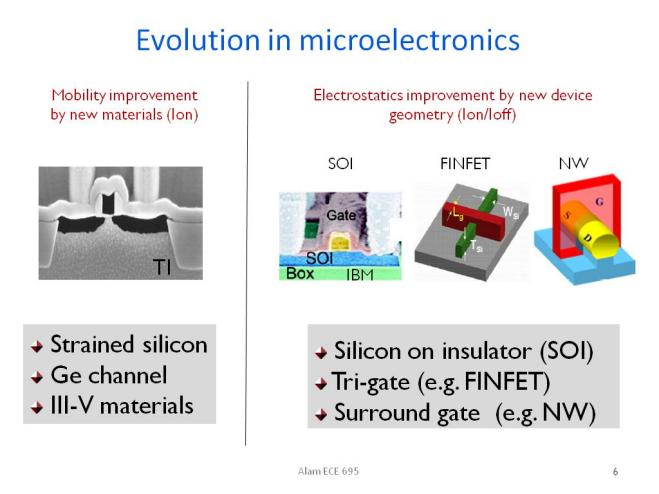

Physicists started investigating cathode ray tube discharge in 1875. German scientists made the discovery of X-rays in the latter half of the 19th century. He proposed in 1899 that there are smaller electrons than atoms and that they are the smallest unit of matter; The invention of the transistor in 1947 sparked a revolution in microelectronics and set the stage for further advancements. Using silicon plane transistor and metal vacuum coating techniques, the integrated circuit (IC) was created in 1958. It created an IC device that heralded the dawn of the human race's digital information age in September of the same year [7]. The metal-oxide-semiconductor field effect transistor (MOS), which serves as the foundation of integrated circuits (ICs), was introduced in 1962. The complementary metal oxide semiconductor (CMOS), a method for creating large-scale integrated circuits, was created in 1963 and is still utilized today in most integrated circuit chips. According to Moore's Law, which was first suggested in 1965, the performance of an integrated circuit (IC) would roughly double after every cycle of doubling the number of transistors (about every 18 months). The advent of dynamic random memory (DRAM) in 1971 marked the start of the large-scale integrated circuit industry. This revolutionary discovery signaled the beginning of a new phase in the advancement of microelectronics technology, which was primarily seen in the focus of microelectronics research, development, and application on large-scale integrated circuits and microprocessors [1]. Figure 1 is the development history of microelectronics technology

Figure 1. Development history of microelectronics technology.

3. Application of microelectronic technology

3.1. Application of microelectronic technology to automation

Automation control technology has advanced steadily and been used more and more in a variety of fields because of society's ongoing development and advancement. These advancements have led to specific successes in the application of these technologies across various industries, which are crucial to the growth and advancement of those industries [2]. Automatic control is the opposite of manual control in that it can be carried out automatically with the installation of a control device in the appropriate equipment. However, during this process, it is important to pay attention to the feedback control system. When the control part issues the corresponding instructions to the controlled part, the controlled part can promptly report the status of its activity to the control part, allowing the control part to make an appropriate activity adjustment in response to the controlled part's information. As a result of the automatic control system's use of microelectronic technology, the lines that were previously chaotic have become cleaner and more organized, the accuracy of the system has significantly improved, and its overall size is gradually decreasing. This offers users a great deal of convenience [3].

Automatic control is continuously upgraded alongside societal advancement, moving from the initial straightforward control to a more intelligent course. Microelectronics technology has slowly been incorporated into automatic control in recent years, which has directly aided in the advancement of industry and raised people's standards of living. A comprehensive intelligent control system that combines automation and microelectronics is known as microelectronic design automation technology. If the control circuit is intelligently designed, combining an electronic circuit with mechanical control can improve control effectiveness while also freeing up a lot of labor and protecting the environment. Circuits can evolve in the direction of integration, which is extremely low in power and small, thanks to microelectronic technology. The most cutting-edge microelectronic technology product available today is the SOC system, which combines the necessary circuits and functionalities on a very small chip. If the planned interface is set aside externally, the SOC system can be utilized directly in a variety of control systems. The "brain" of automation control, which regulates the regular operation of the complete automation system, is also located here [4].

The two main components of the micro-electronic design automation system are automatic operation and micro-electronic control. The system's primary processes are designing the input module, testing the module, designing the data module, and designing the simulation module.

3.1.1. The input module. The input module can issue all control commands since it serves as the control system's command input terminal. As a result, the input module is created for computer programming, which uses computer language to construct commands and analysis to scientifically separate all of the control system's operations. The input module's design quality directly affects how well the system executes, thus while developing the input module, it should employ optimization techniques to increase execution efficiency as much as feasible and minimize redundant code as much as possible.

3.1.2. The testing module. The detection module is used during system operation to identify system failures; it does not fall under the purview of the system function module. Make sure system bugs are identified and repaired as soon as possible [4].

3.1.3. Designing the date module. Because there is a lot of control information in the control system, the data module's primary purpose is to process and store more data. Since the extraction and storage of data must be done quickly due to the application of automation systems to meet increasingly strict standards for accuracy, this is the most crucial consideration when designing the data module [6].

3.1.4. Designing the simulation module. Simulating real-world operating circumstances with the aim of reflecting how the system operates allows for the early detection of system flaws and timely system function adjustments.

The rapid expansion of automation is facilitated by the advancement of microelectronic technology, and this may be viewed as promoting the advancement of industrial society. In many industrial domains nowadays, robot control that is automated is crucial. For instance, automating tasks using robots and removing human labor are fundamental to the car sector. The application of robot automation equipment is microelectronic design automation technology [7]. Industrial progress has provided a significant push for the development of all robots since they are all controlled by microelectronic technology chips. Meanwhile, it also more effectively secures the systematic advancement of human productivity and living. It is anticipated that the automatic method of microelectronic design will be utilized more frequently and have a higher value as science and technology continue to advance.

3.2. Microelectronic packaging technology

Since the turn of the 20th century, the integrated circuit business is also growing quickly, and its products have an important part in many different industries. Packaging has an impact on the electrical performance, temperature performance, and other characteristics of integrated circuit products; as a result, microelectronic packaging technology is crucial to raising the caliber of these products. followed by the microelectronics industry, which rose to prominence globally. The design, production, and packaging sectors are now the three autonomous industries that make up the microelectronics sector. These three sectors make up the backbone of our economy. The science of microelectronic packaging has evolved into a core technology of the IT industry and one of the essential elements of the microelectronic industry against the backdrop of the fast growth of contemporary society. According to the definition of microelectronic packaging technology analysis, this term primarily refers to the assembling of several semiconductor electronic components into a complete package that requires external power.

Microelectronic encapsulation can help an IC run normally and minimize outside interference, to a certain extent. Microelectronic packaging must, therefore, satisfy the user's unique design needs for electronic equipment and guarantee that the quality and other indications are appropriate and trustworthy [8]. Microelectronic packaging technology has gone through three phases of evolution. The first step of microelectronics packaging technology took place in the late 1970s and primarily used cartridge types. Dual-in-line packaging (DIP) technology, the primary application path of molded polymers, laminated porcelain packaging, etc., is the foundation of this technology. Although this technology has advantages such as simple operation, high dependability, and compact package size, it is also limited by the high cost of the components used, particularly the printed circuit board PWBS.

The surface mount welding technology, or SM packaging, was developed in the 1980s as part of the second generation of packaging technology. A novel package series, four side lead flat package with airfoil leads on all four sides plain packaging, has emerged to satisfy the demand for greater density. The 1990s saw the final era. The advent and widespread use of LSI, VLSI, and ULSI, along with the quick growth of integrated circuit technology, led to a sharp rise in the number of IO connections and new specifications for integrated circuit packaging. Smaller chip size packaging (CSP), which was constantly created in the late 1990s because of market pressure, gradually entered the market. While packaging technology was moving in the direction of compact size, low power, and high density, multi-chip components were evolving quickly [9].

3.3. Common microelectronic packaging technology

3.3.1. BGA packaging technology. BGA packaging, also known as welding ball array packaging, is one of the most popular microelectronics packing methods now. The welding ball can be used in lieu of the lead wire during packaging because of its superior electrical performance, short cutting and leading route, and decreased pin delay. Additionally, due to the planar arrangement of the welding pellets on the electronic plate. More pins of microelectronic components are packed using BGA packing technology under the same area's premise. Additionally, there is a close connection between this technology and the tools and setup procedures presently employed in microelectronic packing. It can increase the dependability of packing technology, successfully prevent the lead deformation problem during packaging, and significantly boost assembly productivity.

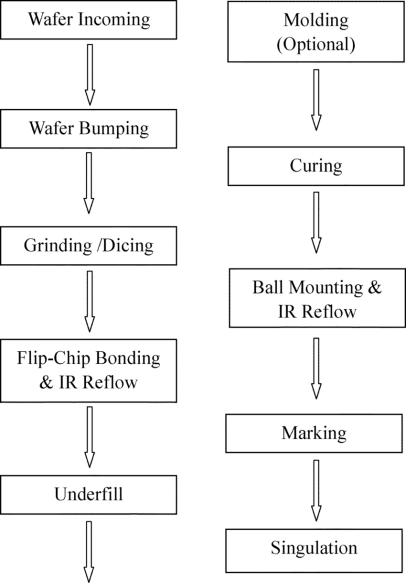

These benefits make BGA packing technology very well-liked by the public. It has quickly grown. Because various substrate materials require distinct BGA packaging technologies, there are some differences in the types of array packaging that are frequently used, including PBGA, TBGA, FCBGA, PQFP, etc. There are rules regarding the pitch of the leads when PQFP is utilized for packaging. The complexity of assembly will increase if the pitch is more than 0.5mm. As a result, when employing this technology, the number of leads is typically limited to 208, and the package body size must be more than 28mm. The technology with the most promising future development is FCBGA. It has all the benefits of BGA packaging technology and has been enhanced on this foundation with better thermal performance, reliability, and repairability [10]. Figure 2 is the schematic diagram of BGA packaging technology process.

Figure 2. Schematic diagram of BGA packaging technology process.

3.3.2. System-in-packing (Sip). A technique called System-in-Package (SiP) combines several chips, packages, and other electronic parts in a single package. To fulfill the demands of current electronic equipment for high performance, low power consumption, and downsizing, system level packaging can achieve better integration, smaller package volume, and lower power consumption. Multiple chips, packages, and other electronic components that have been combined using sophisticated packaging techniques often make up system-level packages. System level packaging has a better degree of integration than typical multi-chip systems since it may incorporate numerous functional modules in a single package, which lowers system complexity and packaging costs.

Silicon interlayer, stacked packaging, side connection packaging, TSV packaging, and other packaging technologies are examples of system level packaging. Due to their ability to provide greater integration and improved performance, silicon interlayers and stacked packages are among those that are most frequently employed. System level packaging, in general, is a type of packaging technology with high integration and outstanding performance that may satisfy the demands of contemporary electronic equipment for high performance, low power consumption, and miniaturization.

Microelectronic packaging technology is a very important application of microelectronic technology. Microelectronics technology is an important foundation and core industry of the modern information society. It will continue to occupy the peak of the times and will continue to unwaveringly promote its development and progress as the only means to achieve modernization in the era of science and technology as the primary productive forces. Microelectronic technology will therefore continue to play a crucial role in advancing society both now and in the future.

4. Conclusion

This thesis focuses on microelectronic technology. Some important events in the development process of microelectronics technology are narrated in chronological order, so that readers can understand the development process of microelectronics technology and better understand the microelectronics technology. Then, two practical applications of microelectronic technology are put forward: automation application and microelectronic packaging technology.

Readers can understand the automation of microelectronics and microelectronics packaging, and understand the many practical applications of microelectronics, and give researchers some ideas about the application of microelectronics technology. Microelectronic technology has many applications in chip and integration and other important fields. But it has not been used effectively in many areas or has encountered difficulties. Therefore, it is worthwhile for future researchers to conduct more research on it and break down its technical barriers. So that it can be applied in more fields, can better serve the world.

References

[1]. Li X. (2016) Application and Development analysis of microelectronic technology. Electronic Fabrication, 16(16): 98.

[2]. Yan W., Li H. (2021) Discussion on Research and Application of micro-electronic Design Automation Technology. Electronic Testing, 21(18): 117-118+100.

[3]. Yan L., Sun Z. (2019) Research on Electronic Design Automation Technology and its Application. Science and Technology Innovation and Application, 19(26): 137-138.

[4]. Liu X. (2014) Research and Application of micro-electronic Design Automation Technology. Electronic Technology and Software Engineering, 31(5): 260.

[5]. Zhai G. (2019) On Research and Application of Micro-electronic Design Automation Technology. Electronic production, 366(1): 91-92.

[6]. Baum T H., Comita P B. (1992) Laser-induced chemical vapor deposition of metals for microelectronics technology. Thin Solid Films, 218(2): 80-94.

[7]. Xu G. (2008) Electronics and Automation Technology. Dalian: Dalian University of Technology Press.

[8]. Chang Y. (2020) Research on the application and Development Direction of Epoxy Resin in Electronic Packaging. Contemporary Chemical Industry Research, 20(17): 8-9.

[9]. Zhou T. (2018) Research on the Development Trend of Microelectronic Packaging Technology. Modern Information Technology, 2(8): 52-53.

[10]. Liao Z. Discussion on Microelectronic Packaging Technology. Computer Products & Distribution, 23(2): 150.

Cite this article

Liu,P. (2023). Current development status and application analysis of microelectronics technology. Applied and Computational Engineering,11,210-215.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li X. (2016) Application and Development analysis of microelectronic technology. Electronic Fabrication, 16(16): 98.

[2]. Yan W., Li H. (2021) Discussion on Research and Application of micro-electronic Design Automation Technology. Electronic Testing, 21(18): 117-118+100.

[3]. Yan L., Sun Z. (2019) Research on Electronic Design Automation Technology and its Application. Science and Technology Innovation and Application, 19(26): 137-138.

[4]. Liu X. (2014) Research and Application of micro-electronic Design Automation Technology. Electronic Technology and Software Engineering, 31(5): 260.

[5]. Zhai G. (2019) On Research and Application of Micro-electronic Design Automation Technology. Electronic production, 366(1): 91-92.

[6]. Baum T H., Comita P B. (1992) Laser-induced chemical vapor deposition of metals for microelectronics technology. Thin Solid Films, 218(2): 80-94.

[7]. Xu G. (2008) Electronics and Automation Technology. Dalian: Dalian University of Technology Press.

[8]. Chang Y. (2020) Research on the application and Development Direction of Epoxy Resin in Electronic Packaging. Contemporary Chemical Industry Research, 20(17): 8-9.

[9]. Zhou T. (2018) Research on the Development Trend of Microelectronic Packaging Technology. Modern Information Technology, 2(8): 52-53.

[10]. Liao Z. Discussion on Microelectronic Packaging Technology. Computer Products & Distribution, 23(2): 150.