1. Introduction

Carbon fiber is a novel form of fiber material, which contains more than 90% carbon. It has high modulus, high strength and excellent comprehensive performance. A type of polymer known as epoxy resin is any polymer with more than two epoxy groups in its molecular structure. The composite of carbon fiber reinforced material and epoxy resin matrix is called carbon fiber epoxy resin composite material. Carbon fiber can be utilized as both a load-bearing structural material and a functional material, so the development of carbon fiber and its composite materials is very rapid in recent ten years at home and abroad. In order to summarize the performance and application of CFERCM, improve its properties in the future and broaden its aviation path field research, this paper introduces the development history of CFERCM by review and experimental results. Then the basic preparation method is introduced, three methods are introduced on the surface treatment of carbon fiber, which are gas phase oxidation method, liquid phase oxidation method and plasma treatment method. After that, the thermal and mechanical properties of CFERCM are introduced, and their main applications in aviation are summarized. The high mechanical properties and low density of CFERCM are mainly used for its applications. The appearance of carbon fiber epoxy resin composites provides excellent materials for modern industry and modern science and technology. As a kind of high-performance material with wide application prospects, it will play an advantage in future development and serve the production and life of human beings. This paper makes people understand the basic information of CFERCM, puts forward the direction for the development of CFERCM in the future, and provides help for research in the field of aerospace.

2. The development of carbon fiber epoxy resin composite material

2.1. History of development

Epoxy compounds have been synthesized since the late 1890s. In 1936, a low melting epoxy resin was produced by Pierre Castan of DeTrey Freres Co., but it didn't get attention in the market. After World War Ⅱ, epoxy resin was used in coating applications. From 1940 to 1970, many different epoxy resins were studied for certain fields. In the 1980s, electronics and computer industries made epoxy resin have better performance, and the electrical property of epoxy resin increased a lot. In the 1990s, with low dielectric constants, higher glass transition temperatures and higher thermal decomposition temperatures epoxy resin was required because of the growth of portable electronics [1]. And for carbon fiber, Joseph Swan initially created it in 1860 to be used in light bulbs. In 1879, Edison created the first carbon fiber filament for incandescent light bulbs by baking strips of cotton or bamboo at high temperatures [2]. The enormous potential of carbon fiber was realized in 1963 by a method created by W. Johnson and W. W. LN. Phillips at the Royal Aircraft Company in Farnborough, Hampshire, and carbon fiber has been used in aircraft ever since. After 1990, CFERCM is developed for its specific stiffness and strength.

2.2. Preparation of carbon fiber epoxy resin composite material

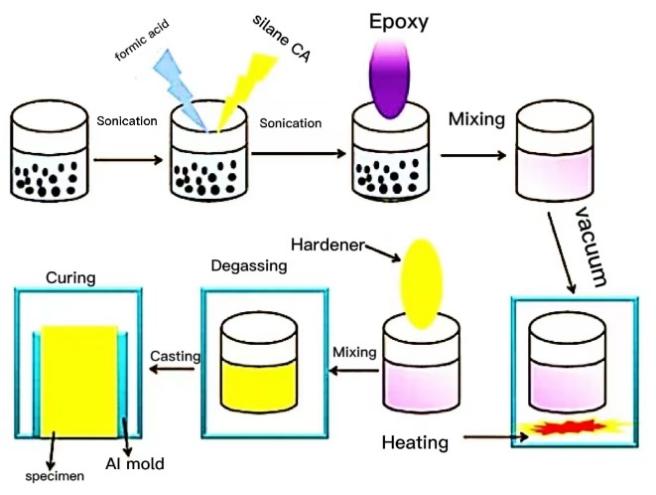

Figure 1. Flowchart of preparation of CFERCM [3].

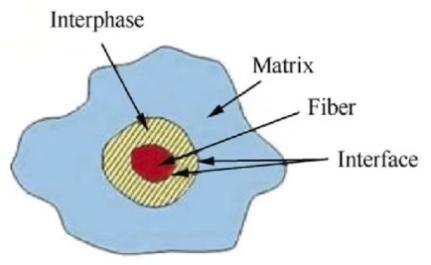

In the preparation of CFERCM, there are three main steps, which are carbon fiber surface treatment, preparation of matrix resin and preparation of composite material [4]. The preparation of CFERCM is shown in figure 1. With regard to carbon fiber surface treatment, because of the relatively poor compatibility between epoxy resin and carbon fiber, the surface of carbon fiber should be treated first. The surface treatment of carbon fiber is to increase the adherence of the fiber to the resin matrix and to increase the interlaminar shear force of the composite. The binding course is shown in figure 2. There are many methods of surface treatment, which are introduced below. The second step is the preparation of matrix resin. Firstly, a certain amount of epoxy resin is weighed with a balance and a beaker, diluted with a certain amount of dispersant for reserve, and then weigh the curing agent of the required mass with a beaker for the next step. The final step is the preparation of composite material, first weight the carbon fiber of the required mass, and the carbon fiber was ultrasonic dispersed in an acetone solution. Then the ultrasonic dispersed carbon fiber was added into the epoxy resin diluted with dispersing agent, and the glass rod was fully stirred with a small motion range to avoid bubbles, and the curing agent was added after being evenly stirred. Pour the reagent into the mold and cure at room temperature. And CFERCM is prepared. The following are several common surface treatments for carbon fiber.

Figure 2. The binding course between carbon fiber and epoxy resin [5].

1.1.1. Gas phase oxidation process. The oxidizing agents used in gaseous phase oxidation are oxygen, ozone and other oxygen-containing gases. This oxidation, usually carried out by adding ozone to a tube furnace at 600 degrees Celsius, works by converting some of the C-H bonds on the surface of the carbon fiber into oxygen-containing groups [6]. The advantages of this surface treatment are simple process, short processing time, easy to control, so it's suitable for mass production.

1.1.2. Liquid phase oxidation process. The liquid phase oxidation method means immersing carbon fiber into some oxidizing solution and oxidize the surface of carbon fiber through oxidant. The liquid phase oxidation method is very effective in improving the interlaminar shear strength of composite materials, which can be increased by about twice, but correspondingly, the fiber strength will decrease. Nitric acid, sodium hypochlorite, hydrogen peroxide and so on can be used for liquid phase oxidation. After oxidation, hydroxyl, carboxyl and acid groups will be produced on the surface of carbon fiber, these groups will get more with the extension of oxidation time and the increase of temperature, effectively improving the binding force of fiber and collective material. Through nitric acid solution, Jang and Yang found that 60 min treated carbon fiber has a specific surface area that is 10 times more than untreated carbon fiber [7]. For the reaction process, the liquid phase oxidation process is milder than the gas phase oxidation process.

1.1.3. Plasma surface treatment. Plasma surface treatment means bombarding carbon fiber with high-energy plasma generated by a plasma generator, so that chemical reactions occur on the surface of carbon fiber, after that active groups are introduced to enhance the surface properties of carbon fiber. On the one hand, high-energy particles bombarding the fiber surface leads to the excitation, ionization, and chemical bond breaking of fiber molecules, generating a variety of polar groups and free radicals on the fiber surface, improving the wettability of the fiber surface, thus increasing the adhesion of resin on the fiber surface. On the other hand, high-energy electrons cause sputtering effect by accelerating active ions at lower temperatures, which can remove impurities on the fiber surface, coarsing the fiber surface and forming mechanical interlocks between the resin matrix and the fiber. Oxygen plasma treatment can also enhance the surface roughness of the fiber by increasing the concentration of oxygen groups on the surface of carbon fiber. Plasma treatment only changes the chemical and physical structure of the fiber surface to enhance the bonding ability between the matrix and the fiber surface, but does not change most of the mechanical properties of the fiber [8].

2.3. Main properties

For any material, its properties determine its application. For CFERCM, which is widely used in the aerospace field, its mechanical properties must be good. As mentioned above, since the appearance of CFERCM, it has become an excellent structural material because of its high strength, good fatigue resistance and high stiffness.

1.1.1. Mechanical property. CFERCM became a good structure material for its high specific modulus and high specific strength, there are two main reasons why CFERCM has these two properties. One is that the carbon atom has a lower relative molecular mass compared with that of metal atom. The other one is carbon fiber has high tensile strength. The high strength of carbon fiber is due to the high performance of carbon fiber bundles, the entire carbon fiber is extracted to present a graphitized structure. The carbons in graphite are hexagonal, each carbon atom keeps each other in check, making it difficult for each carbon atom to shift, so stretching it in the plane where the carbon atoms are located will hardly deform the internal structure. Carbon fiber is anisotropic, the mechanical properties of carbon fiber perpendicular to the direction of the fiber are better than those parallel to the direction of the fiber, so in practical applications, people often use layup design, which means adding carbon fiber in different directions to maximize the performance advantage. Carbon fiber material has the characteristics of high tensile strength, high toughness, good heat resistance, low density, good corrosion resistance, but it also has some disadvantages. It is easy to break, processing is not easy, and it has poor mechanical properties, so adding epoxy resin is a good way to solve this problem. Epoxy resin has the characteristics of high mechanical properties, small curing shrinkage, good technology, good bonding performance, great stability and so on. Carbon fiber and epoxy resin complement each other, making CFERCM have many good properties. According to the experiment, the longitudinal strength of the epoxy matrix combined with carbon fiber of 390 GPa was 591 MPa, however, the longitudinal strength of the same matrix combined with glass fiber of 74 GPa was 356 MPa [3]. We can see that the strength of CFERCM is much higher than that of glass fiber epoxy resin composite material.

1.1.2. Thermal property. The thermal property of composite material is intimately connected to the matching of the thermal expansion coefficient of the component materials, in addition to being directly related to the thermal characteristics of the component materials. The internal tension will be produced when the temperature changes because of the variations in thermal expansion performance between the components of composite materials. The interface between the components will get destroyed when the internal stress is high to a certain amount, and the performance of composite materials will suffer. In CFERCM, carbon fiber is formed by preoxidation high temperature treatment, the general temperature is about 2000 ℃. Carbon fiber itself has undergone high temperature treatment, high temperature resistance is relatively excellent. However, the resin matrix is different. Resin is solid or semi-solid organic polymer at room temperature, and will melt into liquid shape after high temperature heating. Moreover, the thermal expansion coefficient of epoxy resin is approximately 40 times of that of carbon fiber, so CFERCM doesn't have very high temperature resistance, about 180 degrees below. Although its high temperature resistance is not very good, but compared with pure epoxy resin, its thermal performance has improved a lot [9], and for structural materials, the temperature tolerance of 180 degrees has been fully up to standard.

3. Applications in aerospace and aviation

3.1. Application in aerospace

1.1.3. Atomic oxygen tolerance. Atomic oxygen refers to the residual gas environment of atomic oxygen in low Earth orbit. It is formed by the interaction between oxygen molecules and ultraviolet rays of sunlight and decomposition. A great quantity of experiments on space flight has shown that most organic materials will be eroded due to high-speed impact of atomic oxygen and high temperature oxidation on spacecraft surface, thus reducing spacecraft performance and shortening life. Therefore, the atomic oxygen effect is also considered to be the most severe environmental effect in low Earth orbit. CFERCM is a good material to cope with the atomic oxygen effect. Zhang and Yi et al. simulated the atomic oxygen effect of graphene-doped epoxy composite material, after that they compared them with pure epoxy resins, the mass loss of CFERCM was reduced by 46% and the atomic oxygen corrosion rate was reduced by 47% [10].

1.1.4. Debris prevention. In the universe, spacecraft may be hit by space debris at high speed at any time, so spacecraft need a kind of high-strength protective structure to improve the protection ability, and CFERCM plays a very crucial part in the protection system of spacecraft. Chinese scientists have carried out high-speed impact experiments with aramid fiber epoxy resin composite material similar to CFERCM, and the results show that this kind of material can prevent the ultra-high-speed impact of aluminum alloy projectiles [10].

3.2. Application in aviation

Structural weight loss: On the basis of ensuring high mechanical properties, the weight of materials should be reduced as far as possible in aviation structures. For every kilogram of weight lost by commercial aircraft, fuel savings are $3,000 a year. For every kilogram the spacecraft loses, it saves $10,000 in fuel. If the weight can be reduced, the payload can increase and the cost of flight can be reduced. So the high speed area is very sensitive to material weight. Because carbon fiber composites are valued for their extremely high specific strength, it is natural for them to be a good structural material to meet the weight reduction requirements. Using resin-based composites instead of metal to make aircraft parts, can reduce the quality of parts by 25% to 50% [11].

4. Conclusion

This paper mainly discusses the development history, preparation methods, properties and applications of carbon fiber epoxy resin composite material. It can be seen that carbon fiber epoxy resin composite material is an excellent structural material, it has very high specific strength, excellent fatigue resistance, high toughness and corrosion resistance, and it plays a significant role in the field of aerospace. This paper does not introduce the electrical properties of carbon fiber. Meanwhile, this paper can also compare the properties of carbon fiber under different epoxy resin matrixes. However, for the sake of continuing to enhance the performance of carbon fiber resin matrix composite material in the future and explore its application, further research can be conducted from the following aspects. The first is to explore new nanomaterials and matrix resins to improve the mechanical properties and flame retardant properties of composite materials; the second is to explore new processing techniques and to improve the processing efficiency; the third is to explore new preparation methods to make the combination of carbon fiber and resin more closely, reduce the internal stress between materials, consequently enhance the mechanical thermal properties of composite materials.

References

[1]. Pham, H., & Marks, M. J. (2005). Epoxy Resins. Ullmann’s Encyclopedia of Industrial Chemistry. https://doi.org/10.1002/14356007.a09_547.pub2

[2]. Park, S. J. (2018). History and Structure of Carbon Fibers. Springer Series in Materials Science, 1–30. https://doi.org/10.1007/978-981-13-0538-2_1

[3]. Rafique, I., Kausar, A., & Muhammad, B. (2016). Epoxy Resin Composite Reinforced with Car-bon Fiber and Inorganic Filler: Overview on Preparation and Properties. Polymer-Plastics T-echnology and Engineering, 55(15), 1653–1672. https://doi.org/10.1080/03602559.2016.1163597

[4]. Kong Junjia, Ming Hao & Wu Shangfeng. (2019). Preparation and characterization of carbon fiber/modified epoxy resin composites. Liaoning Chemical Industry (11),1077-1079. doi:10.14029/j.cnki.issn1004-0935.2019.11.009.

[5]. Zheng, H., Zhang, W., Li, B., Zhu, J., Wang, C., Song, G., Wu, G., Yang, X., Huang, Y., & Ma, L. (2022). Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Composites Part B-Engineering, 233, 109639. https://doi.org/10.1016/j.compositesb.2022.109639

[6]. Nelyub, V. A., & Berlin, A. (2015). A study of the chemical structure of the surface of carbon fi-bers before and after oxidation. Polymer Science. Series D. https://doi.org/10.1134/s1995421215030107

[7]. Tiwari, S., & Bijwe, J. (2014). Surface Treatment of Carbon Fibers - A Review. Procedia Technology, 14, 505–512. https://doi.org/10.1016/j.protcy.2014.08.064

[8]. Yuan, L. Y., Shyu, S., & Lai, J. K. L. (1991). Plasma surface treatments on carbon fibers. II. Mechanical property and interfacial shear strength. Journal of Applied Polymer Science, 42(9), 2525–2534. https://doi.org/10.1002/app.1991.070420918

[9]. Tariq, F., Shifa, M., & Baloch, R. A. (2018). Mechanical and Thermal Properties of Multi-scale Carbon Nanotubes–Carbon Fiber–Epoxy Composite. Arabian Journal for Science and Engineering, 43(11), 5937–5948. https://doi.org/10.1007/s13369-018-3091-8

[10]. Jiang Hong & Peng Daoqi. (2022). Application of advanced composite materials in space aircraft. New material industry(01),2-7. doi:10.19599/j.issn.1008-892x.2022.01.002.

[11]. Chen Lijun, Wu Fengqin & Wu Zhang Xinyu. (2007). Forming process and application of epoxy resin/carbon fiber composites. Engineering plastics application 35(10):77-80. doi: 10.3969/j.issn.1001-3539.2007.10.020.

Cite this article

Li,Y. (2023). The development of carbon fiber epoxy resin composite material and its applications in aerospace. Applied and Computational Engineering,23,75-80.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Pham, H., & Marks, M. J. (2005). Epoxy Resins. Ullmann’s Encyclopedia of Industrial Chemistry. https://doi.org/10.1002/14356007.a09_547.pub2

[2]. Park, S. J. (2018). History and Structure of Carbon Fibers. Springer Series in Materials Science, 1–30. https://doi.org/10.1007/978-981-13-0538-2_1

[3]. Rafique, I., Kausar, A., & Muhammad, B. (2016). Epoxy Resin Composite Reinforced with Car-bon Fiber and Inorganic Filler: Overview on Preparation and Properties. Polymer-Plastics T-echnology and Engineering, 55(15), 1653–1672. https://doi.org/10.1080/03602559.2016.1163597

[4]. Kong Junjia, Ming Hao & Wu Shangfeng. (2019). Preparation and characterization of carbon fiber/modified epoxy resin composites. Liaoning Chemical Industry (11),1077-1079. doi:10.14029/j.cnki.issn1004-0935.2019.11.009.

[5]. Zheng, H., Zhang, W., Li, B., Zhu, J., Wang, C., Song, G., Wu, G., Yang, X., Huang, Y., & Ma, L. (2022). Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Composites Part B-Engineering, 233, 109639. https://doi.org/10.1016/j.compositesb.2022.109639

[6]. Nelyub, V. A., & Berlin, A. (2015). A study of the chemical structure of the surface of carbon fi-bers before and after oxidation. Polymer Science. Series D. https://doi.org/10.1134/s1995421215030107

[7]. Tiwari, S., & Bijwe, J. (2014). Surface Treatment of Carbon Fibers - A Review. Procedia Technology, 14, 505–512. https://doi.org/10.1016/j.protcy.2014.08.064

[8]. Yuan, L. Y., Shyu, S., & Lai, J. K. L. (1991). Plasma surface treatments on carbon fibers. II. Mechanical property and interfacial shear strength. Journal of Applied Polymer Science, 42(9), 2525–2534. https://doi.org/10.1002/app.1991.070420918

[9]. Tariq, F., Shifa, M., & Baloch, R. A. (2018). Mechanical and Thermal Properties of Multi-scale Carbon Nanotubes–Carbon Fiber–Epoxy Composite. Arabian Journal for Science and Engineering, 43(11), 5937–5948. https://doi.org/10.1007/s13369-018-3091-8

[10]. Jiang Hong & Peng Daoqi. (2022). Application of advanced composite materials in space aircraft. New material industry(01),2-7. doi:10.19599/j.issn.1008-892x.2022.01.002.

[11]. Chen Lijun, Wu Fengqin & Wu Zhang Xinyu. (2007). Forming process and application of epoxy resin/carbon fiber composites. Engineering plastics application 35(10):77-80. doi: 10.3969/j.issn.1001-3539.2007.10.020.