1. Introduction

In the present era of heightened demands for building safety, environmental friendliness, and energy efficiency, prefabricated buildings have emerged as a novel type of construction, attracting considerable attention in the construction industry as a research focus [1-3]. Prefabricated construction is a method of construction in which components are manufactured in a factory and then assembled on site. It is also called prefabricated building or modular building. This technology presents several advantages, including environmental friendliness, efficient operations, speedy implementation, and adaptable design, all of which cater to diverse construction projects. As a result, it propels the construction industry towards the path of sustainability and intelligence. However, the design and construction of prefabricated buildings face many challenges, such as component design and processing, on-site assembly and other issues.

As a comprehensive building design and management tool based on digital modelling, Building Information Modelling (BIM) technology can integrate building information into an integrated platform, so as to realize the whole process management of building design, construction and operation. The collaborative, visually informative, and data-precise qualities of BIM technology can furnish robust technical backing for the design and construction of prefabricated buildings. As a result, researching the utilization of BIM technology in this area is highly important for advancing the prefabricated building industry.

The use of BIM technology within the prefabricated building industry has gained significant attention from the academic community. A study conducted in Australia conducted survey interviews with 30 industry professionals. The results show that the use of BIM technology can significantly reduce the probability of incorrect design between designers and manufacturers, and reduce the difference between the final product model and the actual building. In addition, using BIM technology can expand the scale of prefabricated buildings [4]. According to a British study, the potential applications of BIM technology in prefabricated modular construction are extensive. By using BIM-based solutions, it is possible to increase worker safety awareness, detect hazards and scenarios, and optimize construction site layouts [5].

Chinese researchers have also investigated the use of BIM technology in the realm of prefabricated buildings. According to certain researchers, the use of BIM technology is crucial in enhancing the design of prefabricated constructions. BIM technology is recognized as an effective tool that confers numerous benefits upon prefabricated buildings, including enhanced collaboration, precise design experience, and reduced error rates. Therefore, it holds significant importance within the field of prefabricated constructions [6]. Additional scholars have asserted that the combination of prefabricated constructions and BIM technology enables the industrialization of construction. This integration can enhance the efficiency, precision, and quality of prefabricated construction projects, supporting the advancement of domestic environmentally-friendly practices [7]. Moreover, studies have shown that the utilization of BIM technology in the design of prefabricated buildings can significantly enhance its effectiveness. This improvement can aid engineering designers in identifying and rectifying design flaws promptly and avoid repetition of errors [8].

The objective of this paper is to explore the comprehensive application of BIM technology in the design and construction of prefabricated buildings. Firstly, the use of BIM technology in the design, construction and other aspects of prefabricated building visualization model is analyzed. Then combined with the detailed analysis of actual cases, the advantages and existing problems of BIM technology in prefabricated buildings are summarized. The aim of this research is to offer technical guidance to professionals engaged in prefabricated building design and construction, with the objective of enhancing the quality and productivity of the process. Furthermore, the study endeavors to promote the utilization of BIM technology within the realm of prefabricated construction, and provide practical recommendations for the industry.

2. Application of BIM technology in prefabricated building design

2.1. Digital model building

Digital modelling of prefabricated buildings is a significant direction for the application of BIM technology. By utilizing a three-dimensional digital model, digital modeling allows for rapid and precise acquisition of information concerning various building components, leading to refined design and optimization. Digital modelling needs to fully consider the shape of the building, the material and size of the components, the manufacturing process and installation and other links and details to ensure the accuracy and reliability of the digital modelling. In the process of digital modelling, relevant norms and standards must be strictly followed, and reasonable methods and technologies must be used for data collection, processing and analysis to ensure the reliability and practicability of digital modelling results [8].

Furthermore, digital modeling must take into full account the functional demands of the building, construction techniques, and environmental conditions to meet the requirements of architectural design, construction, and utilization. Through the digital modelling of BIM technology, various functions such as the preparation of digital construction plans, digital construction site management, and digital construction quality control can be realized.

2.2. Architecture collaborative design

Prefabricated buildings require collaborative design by designers in multiple fields to meet the complexity and functional requirements of the building. These fields include structure, electromechanical, water supply and drainage, facade, interior equipment, etc. However, since the design information is dispersed among different fields and teams, there are problems such as information asymmetry and coordination difficulties. Therefore, using BIM technology can integrate all design information into a digital model to achieve collaborative design across fields and teams. All designers can conduct real-time design communication and collaboration on the same platform, avoid information asymmetry, conflicts and errors, and improve design efficiency and quality. In addition, BIM technology can also perform functions such as collision detection, material and energy analysis, and provide more comprehensive support for the design, manufacture and construction of prefabricated buildings [7,9].

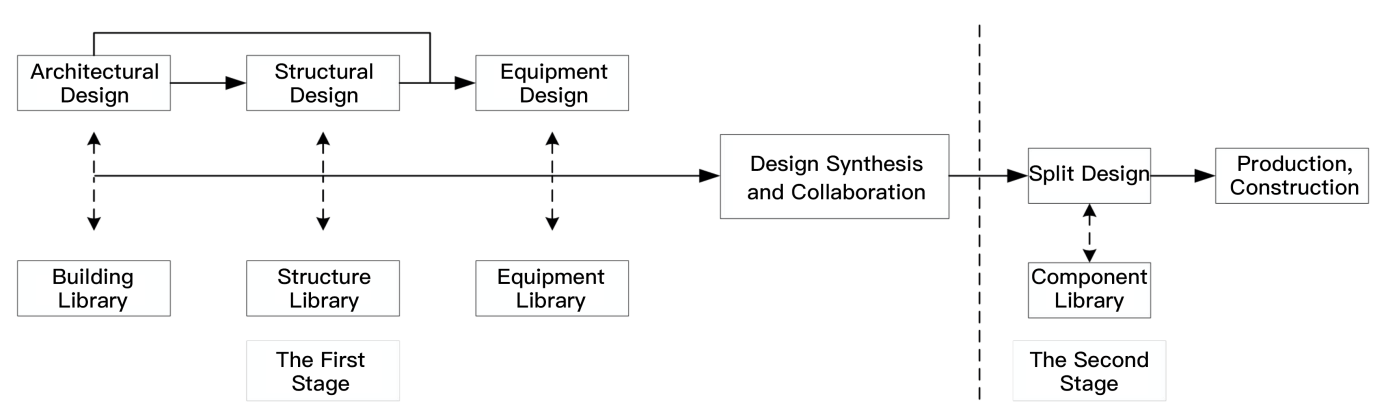

The collaborative design of prefabricated buildings is usually divided into two stages, and the specific process is shown in Figure 1. Firstly, the design team completes the overall design, which includes the design of architecture, structure and equipment. Secondly, combined with factors such as production, transportation, and on-site construction, based on the overall design, the BIM model is split to carry out detailed design such as component detail design, production process design, node large sample design, and embedded part design. Collaborative design with the help of BIM technology can coordinate designers of different teams, different professions, and different disciplines to ensure seamless overlap between components [10]. Through the collaborative design of BIM technology, the rapid design and manufacture of prefabricated buildings can be realized.

Figure 1. Collaborative design of prefabricated building [10].

2.3. Architectural design optimization

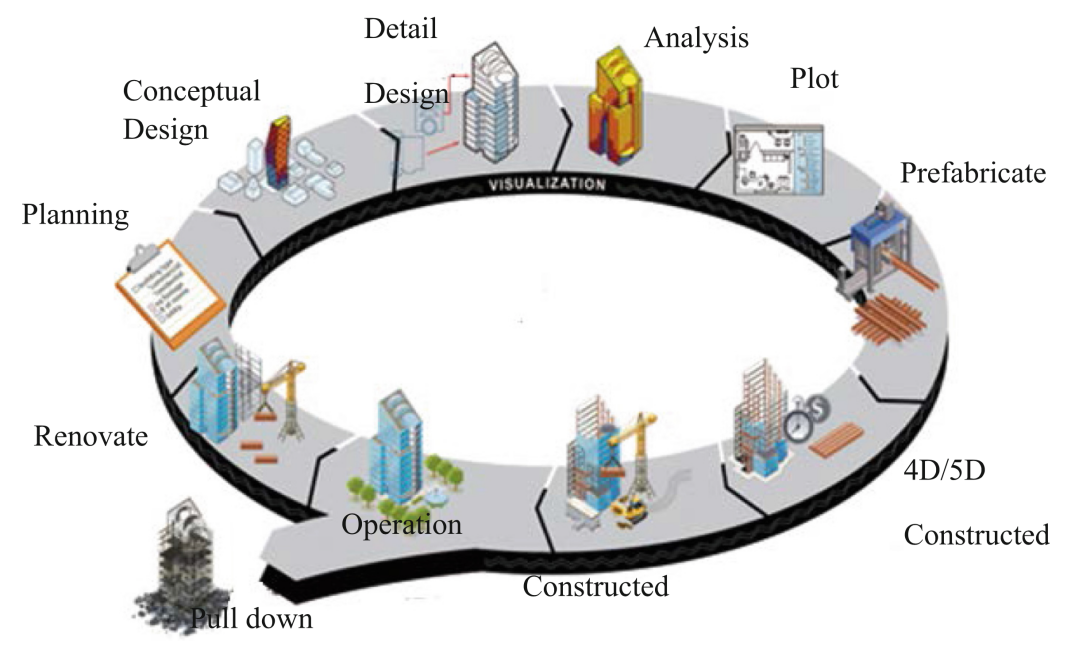

The calculation system of BIM technology provides more practical assistance than traditional building physical analysis software. It can integrate information throughout the construction cycle, as shown in Figure 2, and optimize the whole project process through visualization and BIM pipeline integration. For prefabricated buildings, digital simulation is essential. BIM technology can be used to predict building performance such as energy consumption, air flow and light exposure for optimal design. Numerical simulations need to consider the influence of multiple factors, such as building shape, climatic conditions, indoor air quality, and building physical performance. The physical environment of a building can be directly analyzed using a BIM model. If analysis feedback design is required, the BIM model can also be imported into traditional analysis software, such as Ecotect Analysis and Weather Tools [11].

Figure 2. Based on BIM implementation project life cycle information [8].

Compared with traditional construction models, BIM models have more advantages. The information fed back by the BIM model has higher timeliness and accuracy, and the use of parametric construction methods can make real-time corrections and change conversions more convenient and quicker. The intuitive presentation of results can greatly enhance the designer's overall control over the project [4,11].

3. Application of BIM technology in prefabricated building construction

3.1. Construction plan formulation

The formulation of a prefabricated building construction plan requires comprehensive consideration of multiple factors, including construction period, safety guarantees, and on-site resource utilization. Among other things, the precision and quality of planning is critical to the overall efficiency and success of a construction project. BIM technology realizes efficient digital simulation and collaboration by combining construction plans with digital models, thereby realizing the visual management of plans. Simultaneously, the complete process of constructing a prefabricated building can be simulated by using BIM technology. This feature provides valuable aid in the design, production, and transportation of prefabricated components [8].

By utilizing BIM technology to simulate the construction schedule, any issues that arise during the construction process can be accurately identified. This approach assists managers in efficiently organizing the construction process and managing personnel access while reducing the likelihood of safety incidents on the construction site. In addition, BIM technology can also help managers identify risks and bottlenecks in construction, and provide a scientific basis for the formulation of construction plans, thereby improving the controllability and flexibility of construction plans [5]. Therefore, incorporating BIM technology in the planning and management of prefabricated building construction holds significant practical importance and potential for development.

3.2. Construction site management

On the construction site of prefabricated buildings, fine coordination and management are required for the processing, transportation and installation of building components. In order to achieve efficient construction and quality control, BIM technology is widely used in construction sites. By establishing digital models, BIM technology can provide a virtual environment for real-time monitoring and management of construction progress and quality conditions. In addition, BIM technology can also assist in the realization of construction process simulation and conflict detection functions, effectively reducing construction risks and errors, and improving construction efficiency and quality [10].

Compared with traditional construction management methods, BIM technology has obvious advantages in prefabricated building construction. Firstly, BIM technology visualizes construction management and collaboration, making the construction process more transparent and efficient. Secondly, BIM technology can simulate and analyse factors in the construction process in the digital model, including construction period, safety guarantee and resource utilization rate, etc., provide scientific basis for construction plan formulation, and help construction managers identify risks and bottlenecks in construction. Finally, BIM technology provides a virtual environment for real-time monitoring and management of construction progress and quality status to ensure safety and quality during construction [10].

3.3. Construction quality control

Throughout the construction process of prefabricated buildings, each component must undergo a thorough examination and assessment to verify that it conforms to the design specifications and quality standards. BIM technology can track and monitor each component through a digital model, provide real-time data feedback and quality assessment, and record the location and status of components, so that managers and construction personnel can keep abreast of construction progress and quality status [11]. In addition, BIM technology can also combine component information with quality inspection records, supply chain information, personnel arrangement and other data for comprehensive analysis and decision-making, so as to enhance the quality and efficiency of construction by optimizing the construction process.

Compared with traditional construction quality control methods, BIM technology has more obvious advantages in prefabricated building construction. Firstly, BIM technology can employ artificial intelligence and data mining techniques to anticipate and alert potential issues that may arise during the construction process. This approach assists in promptly identifying and resolving problems, thereby reducing the likelihood of construction quality issues and safety incidents. Secondly, BIM technology can establish a virtual environment of the construction process through digital models, conduct process simulation and conflict detection, avoid construction risks, reduce errors and error correction costs, and improve construction efficiency and quality [5]. In short, BIM technology provides powerful tools and support for prefabricated building construction, and provides a reliable guarantee for high-quality, high-efficiency and safe construction.

4. Case analysis

4.1. Wuhan greenland centre of China

The design of high-rise prefabricated buildings commonly employs BIM technology. Digital models accurately model each component, ensuring precision and consistency during fabrication and installation. In the design process, BIM technology can also simulate different construction schemes, provide scientific basis for designers, and ensure the feasibility and construction efficiency of the final design scheme. Taking the Wuhan Greenland Centre project in China as an example, BIM technology has been widely promoted and applied in its architectural design phase.

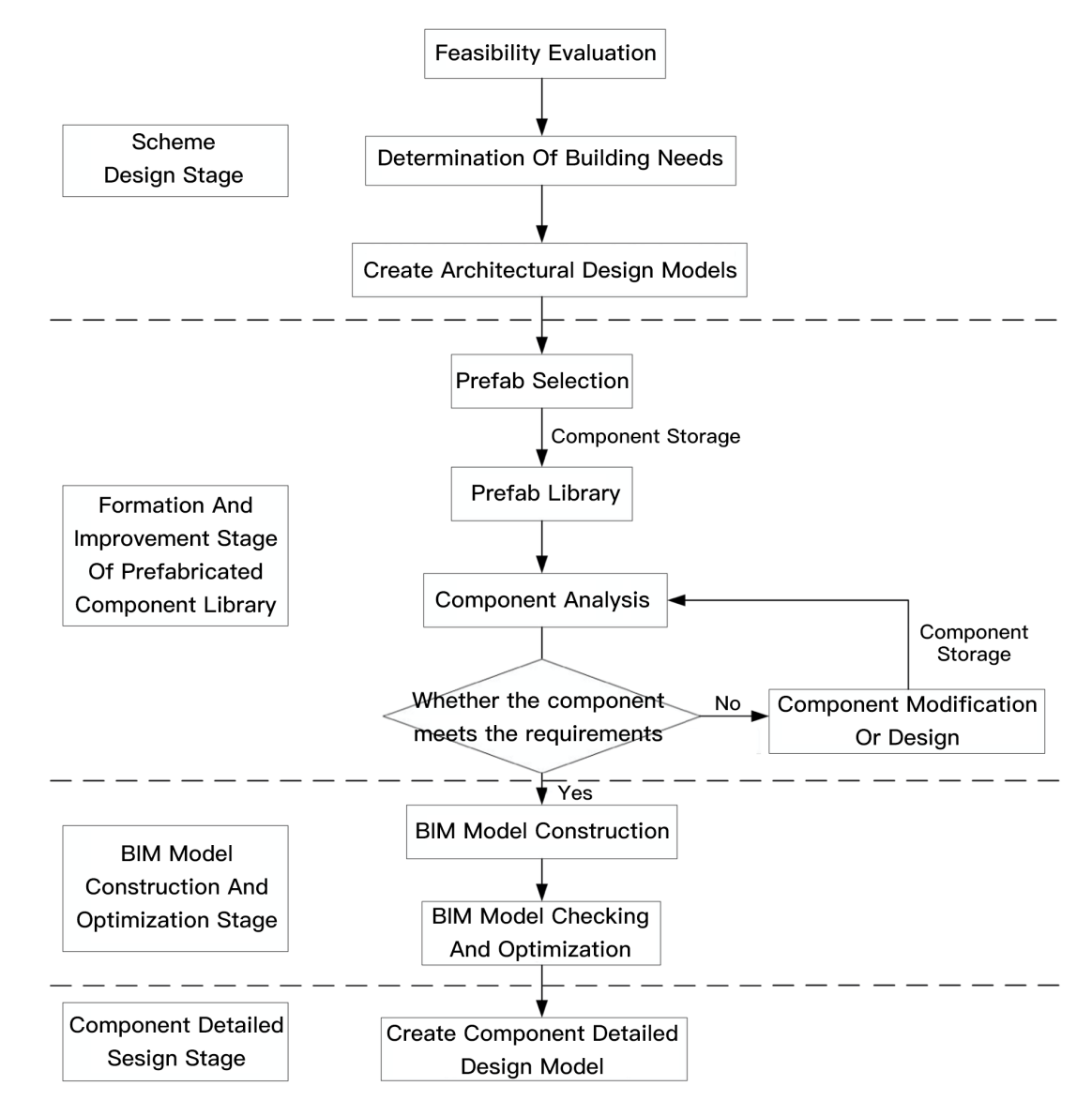

China Wuhan Greenland Centre is a high-rise prefabricated building located in Wuhan, Hubei Province, China, with a building height of 475 meters. The project adopts advanced prefabricated construction technology and steel structure frame, which is composed of many modular components. The utilization of BIM technology in this project involves BIM model construction, detailed design of prefabricated components and optimization of architectural design, etc. The specific process is shown in Figure 3.

BIM software provides a comprehensive digital building model, which integrates various information such as building structure, mechanical and electrical equipment and piping system. It provides a comprehensive design platform for design teams. Designers can adjust and optimize the building according to the actual situation, thereby improving design efficiency and accuracy. BIM technology simulates various structural situations through digital models, tests the performance and effect of each component, and ensures the structural stability and safety of the final building. In addition, digital models can simulate various conditions and environments of buildings, such as factors such as wind pressure, earthquakes, and temperature, to optimize building structures.

On the digital model, members of the design team can carry out collaborative design in real time, reducing information asymmetry and isolation in traditional design, and improving design efficiency and quality. Simultaneously, the visual demonstration of the digital model can also help the owner to better understand the design scheme. In conclusion, the use of BIM technology in the design of high-rise prefabricated buildings is extremely important since it enhances design quality and efficiency while decreasing design costs and risks.

Figure 3. The design process of prefabricated building based on BIM technology [10].

4.2. Wuxi international expo centre of China

Using BIM technology during the construction of prefabricated buildings can enhance construction efficiency, guarantee construction safety and quality, and mitigate construction expenses and risks. Taking Wuxi International Expo Centre in China as an example, the implementation of BIM technology has been crucial during the construction phase.

Jiangsu Wuxi International Expo Centre is a large-scale prefabricated building located in Wuxi City, Jiangsu Province, China, with a total construction area of 170,000 square meters. The whole building is composed of many modular components, using advanced steel structure frame and prefabricated construction technology. Incorporating BIM technology into this project has significantly enhanced construction efficiency and quality while decreasing construction risks and expenses.

During the initial phase of construction, BIM technology accurately models each component through a digital model to ensure the accuracy and safety of components during manufacturing and transportation. Digital component information and parameters can realize automatic management of component production and transportation, and improve construction efficiency and quality. The digital model also provides detailed instructions and steps for component installation, avoiding mistakes and repeated work during the installation process.

During the construction process, BIM technology provides real-time construction monitoring and management. The construction site has established a digital construction management system through BIM technology to monitor construction progress and quality status in real time, reducing problems and mistakes in construction, and improving construction efficiency and quality. In addition, BIM technology can utilize artificial intelligence and data mining techniques for anticipating and alerting potential issues during the construction process. This allows for timely identification and resolution of issues, leading to a decrease in construction quality defects and accidents, ultimately ensuring construction quality and safety. To sum up, BIM technology provides an efficient, accurate, safe and sustainable solution for the construction of the prefabricated building project of Wuxi International Expo Centre in China.

5. Conclusion

This paper explores the use of BIM technology in prefabricated building design and construction, focusing on the case studies of the Wuhan Greenland Centre and Wuxi International Expo Centre. Results shows that BIM technology has important application value in the design and construction of prefabricated buildings. In terms of design, BIM technology utilizes digital model construction, collaborative design, and design optimization to provide a scientific foundation for prefabricated building design. This optimization improves building structure while increasing design efficiency and quality. In terms of construction, BIM technology can improve construction efficiency and quality, reduce construction risk and cost, and achieve a win-win situation in construction period and quality through the application of construction plan formulation, site management and quality control. The popularity and promotion of BIM technology in prefabricated buildings are evident from the case studies, with its potential applications expected to expand further as technology advances.

In the future, exploring the implementation of BIM technology in the design and construction of prefabricated buildings can facilitate achieving the goals of building environmental protection, building energy management, and building operation and maintenance.

References

[1]. Zang G 2020 Research on the whole process management of intelligent construction of prefabricated buildings (Master's thesis, Hunan University)

[2]. Onyszkiewicz J and Sadowski K 2022 Proposals for the revitalization of prefabricated building facades in terms of the principles of sustainable development and social participation J. Build. Eng. 46 103713

[3]. Ismail F, Shahrestani M, Vahdati M, Boyd P and Donyavi S 2021 Climate change and the energy performance of buildings in the future-a case study for prefabricated buildings in the UK J. Build. Eng. 39 102285

[4]. Mostafa S, Kim K, Tam V and Rahnamayiezekavat P 2020 Exploring the status, benefits, barriers and opportunities of using BIM for advancing prefabrication practice Int. J. Constr. Manag. 20(2) pp 146-156

[5]. Chatzimichailidou M and Ma Y 2022 Using BIM in the safety risk management of modular construction Saf. Sci. 154 105852

[6]. Liao F, Pan H and Zhang J 2021 Application of BIM technology in the design of prefabricated architecture IOP Conf. Series: Earth and Environmental Science 760(1) p 012005

[7]. Wang Y and Wang Y 2021 Research on the integration of BIM technology in prefabricated buildings World J. of Eng. and Tech. 9(3) pp 579-588

[8]. Peng L, Peng Y and Pan J 2021 The application practice of BIM technology in prefabricated building design Big Data Analytics for Cyber-Physical System in Smart City (BDCPS 2020, 28-29 December 2020, Shanghai, China) pp 383-388

[9]. Ma B 2022 Prefabricated modern wood structure micro-building design and application research based on BIM technology (Master's thesis, Jilin Jianzhu University)

[10]. Qu L 2019 Application exploration of BIM technology in prefabricated building design and construction management (Doctoral dissertation, China University of Mining and Technology)

[11]. Dai W 2017 Based on BIM technology installation type construction research (Doctoral dissertation, Wuhan University)

Cite this article

Liu,Y. (2023). Application of BIM technology on the design and construction of prefabricated buildings. Applied and Computational Engineering,24,58-65.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zang G 2020 Research on the whole process management of intelligent construction of prefabricated buildings (Master's thesis, Hunan University)

[2]. Onyszkiewicz J and Sadowski K 2022 Proposals for the revitalization of prefabricated building facades in terms of the principles of sustainable development and social participation J. Build. Eng. 46 103713

[3]. Ismail F, Shahrestani M, Vahdati M, Boyd P and Donyavi S 2021 Climate change and the energy performance of buildings in the future-a case study for prefabricated buildings in the UK J. Build. Eng. 39 102285

[4]. Mostafa S, Kim K, Tam V and Rahnamayiezekavat P 2020 Exploring the status, benefits, barriers and opportunities of using BIM for advancing prefabrication practice Int. J. Constr. Manag. 20(2) pp 146-156

[5]. Chatzimichailidou M and Ma Y 2022 Using BIM in the safety risk management of modular construction Saf. Sci. 154 105852

[6]. Liao F, Pan H and Zhang J 2021 Application of BIM technology in the design of prefabricated architecture IOP Conf. Series: Earth and Environmental Science 760(1) p 012005

[7]. Wang Y and Wang Y 2021 Research on the integration of BIM technology in prefabricated buildings World J. of Eng. and Tech. 9(3) pp 579-588

[8]. Peng L, Peng Y and Pan J 2021 The application practice of BIM technology in prefabricated building design Big Data Analytics for Cyber-Physical System in Smart City (BDCPS 2020, 28-29 December 2020, Shanghai, China) pp 383-388

[9]. Ma B 2022 Prefabricated modern wood structure micro-building design and application research based on BIM technology (Master's thesis, Jilin Jianzhu University)

[10]. Qu L 2019 Application exploration of BIM technology in prefabricated building design and construction management (Doctoral dissertation, China University of Mining and Technology)

[11]. Dai W 2017 Based on BIM technology installation type construction research (Doctoral dissertation, Wuhan University)