1.Introduction

The European Space Agency (ESA) proposed the concept of building a lunar outpost in 2013. In 2019, National Aeronautics and Space Administration (NASA) proposed “lunar habitat” in its Space Action Plan [1]. In 2024, the Chinese Society of Astronautics held a conference in Harbin titled "Moon 2050, a New Vision for Humankind's Extraterrestrial Home", again mentioning five topics, including "lunar architecture" and "lunar robots". Human exploration of the moon has gradually shifted from unmanned spacecraft to lunar exploration to stationing on the moon for research. Building a habitat on the moon will become a new milestone in human exploration of the universe [2]. If people want to build on the moon, they must consider the extreme environment of the moon. It is almost impossible for humans to build on the moon in person, so this task is undertaken by intelligent building robots. Robotic construction is not only of great significance for space construction, but also has great research prospects for the construction of various extreme areas on Earth (such as Antarctic research outposts). China proposed building intelligence in its 14th Five-Year Plan for Construction Industry Development, focusing on improving the utilization rate of robots in dangerous and heavy construction operations, promoting the development of human-machine collaboration and multi-machine cooperation technology, and improving the level of building automation and intelligence. Large-scale transformation to intelligence is an inevitable trend in the development of the construction industry.

Nowadays, intelligent construction on Earth has become mature, but there are few papers on robots for lunar construction. This paper focuses on the construction of intelligent robots in extreme environments, and reviews past papers to discuss the technologies used in in-situ resource construction (ISRU) in lunar habitat construction. It uses literature analysis methods to search for literature on China National Knowledge Infrastructure and Google Scholar, and organizes and analyzes the papers involved in this field.

2.The Necessity of Lunar Construction

As a satellite of the Earth, the Moon is the starting point for human exploration of the universe and has important significance for human exploration of the universe. Ruess mentioned in the article that due to the less geological activities and weather changes on the Moon, the environment is more in line with the most primitive state of the planet, which is of great significance for the exploration of the origin of life [2]. There is less scattered light on the Moon than on the Earth, making astronomical telescopes more accurate in observing planets [2]. Xuanyi Xue et al. mentioned in the article that due to the smaller gravity of the Moon, the energy required for the spacecraft to leave the Moon is less, and the Moon can be considered as an intermediate resource supply point for humans to Mars) [3,4]. The development of lunar resources, such as nuclear fusion fuel, rare earth metals and solar energy, is of great significance to mankind [4,5]. At the same time, the Moon is also an important military area contested by various countries. The competition for lunar resources and the colonization of the Moon have become important indicators for countries to explore the universe and enhance their comprehensive strength.

3.Classification of Lunar Buildings and Acquisition of Lunar Resources

The construction of a lunar base relies on two methods: Earth-Moon transportation structure and in-situ resource utilization (ISRU)[3]. Cheng Zhou mentioned in the article that in the early stage of building a base, it is necessary to first use space transportation to transport the building structure from the earth to the moon, and then gradually develop to use the resources on the moon for construction [1]. There are basically five types of lunar bases: rigid structure, flexible structure, 3D printing structure, masonry mortise and tenon structure, underground structure, etc [2,6]. Among them, 3D printing structure, masonry mortise and tenon structure, and underground structure belong to the category of ISRU. ISRU refers to the construction of moon base using resources on the moon, and its construction site selection is relatively flexible. The Earth-Moon transportation structure is currently relatively mature, but the demand for funds and energy is extremely large, and the technical requirements are high. ISRU reduces the cost of round-trip travel between the earth and the moon, improves independent operation and maintenance and disaster resistance capabilities, and is a better solution for lunar construction [3,7].

The first important consideration for ISRU is the acquisition of building resources (such as concrete, cement, metal, etc.). The China National Space Administration (CNSA) has conducted a lot of research on the acquisition of lunar resources and concluded that the lunar polar regions are rich in mineral resources and water/ice resources. There are some areas of permanent daylight on the edge of the meteor crater that can be powered by solar energy [5]. Considering the lunar day and night cycle, except for the permanent daylight areas, other areas have no sunlight for about half a month, so other resources are needed for energy supply [5]. Martinez Rocamora Jr. et al. simulated the lunar environment and enabled ICR to explore, excavate and transport resources in the environment, and obtained a system for ICR to cooperate in the mining of lunar resources [8]. Under the collaboration of multiple robots, the risk of ICR failure can be greatly reduced.

4.Concept and Classification of Building Robots

Balzan et al. defined intelligent construction robots (ICR) as tools that integrate configurability, adaptability, interaction, reliability, motion, manipulation, and perception, and perform construction tasks through computer control and self-learning. The purpose is to reduce the workload and injury rate of workers and improve construction accuracy and efficiency [9,10]. CiJyun Liang et al. classified the autonomy of ICR in human-robot collaboration (HRC) from low to high in terms of advanced level: fully manual (completely performed by humans), pre-programmed (i.e., completing a single repetitive task after being programmed or remotely controlled by humans), adaptive operation (humans make plans and robots complete them), imitation learning (due to sensor defects, robots need to imitate human behavior), monitoring control (robots execute according to plans, humans monitor progress and adjust plans in a timely manner), and fully adaptive (humans issue tasks and robots plan them completely) [9]. With the development of artificial intelligence, ICRs have been put into construction, mainly including: on-site monitoring robots, earthwork robots, steel bar binding and welding robots, bricklaying robots, concrete processing robots, exoskeleton technology, etc [10]. However, most of them are pre-programmed ICR, which can only complete single repetitive tasks and cannot collaborate to complete complex tasks.

Chong Chen et al. mentioned in the article that four aspects must be considered for the ICR system: perception system (sensors, infrared radars, cameras, etc.), control system (giving instructions to the robot), drive system (providing power to the robot system), and mechanical system (performing construction operations and executing tasks) [11]. The four systems interact with each other to guide the robot's actions. The perception system and control system of the ICR are two of the more important parts, and are also the key to the ICR's transition from pre-programming to full adaptation. At the same time, multi-robot collaboration and comprehensive management and coordination are also factors that must be considered by ISRU.

5.Lunar in-situ Resource Utilization Construction Technology

5.1.D Printing Lunar Construction Technology (AM)

5.1.1.Concept, Application and Classification of Lunar 3D Printing Technology

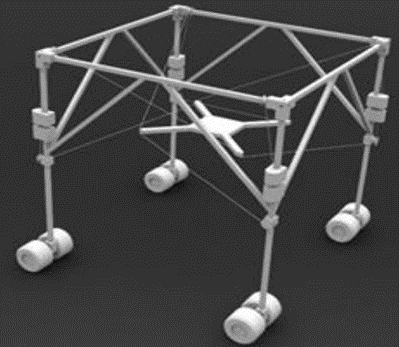

3D printing technology, also known as additive manufacturing (AM), is a technology that combines computer, numerical control and material forming technologies to construct a three-dimensional model through architectural parametric modeling software or through point cloud data to model the building in three dimensions. Then, the basic principle of material superposition is used to decompose the model into two-dimensional models of appropriate thickness and equal spacing. Finally, the CNC system analyzes and controls the mechanical device to perform layered printing and construction [12]. AM is mainly used to print the lunar base surface shell on the surface of the lunar to reduce solar radiation and the impact of small meteorites. Since there are many studies on lunar in-situ material forming technology and AM, AM has become the main method of ISRU. AM not only ensures the rationality of the shape of the building, but also excels in efficiency and material saving. It is mainly divided into two types: Mobile gantry 3D printing (Figure 1), mobile and non-mobile robotic arm 3D printing (Figure 2) [13,14]. The difference between the two is that the robotic arm has a higher degree of freedom when printing the building part, but it is immature for printing coarse aggregate materials and is relatively weak on large buildings. Gantry 3D printing (using layer-by-layer extrusion) has been more widely studied, with good precision control and good adaptability to larger buildings and coarse aggregates, but its mobility and freedom are inferior to those of robotic arm 3D printing technology [13]. In the study of 3D printing technology, the European Space Agency uses the D-Shape (photocuring technology) process for lunar construction, the main material of which is a combination of lunar soil and adhesive. NASA, on the other hand, chooses the contour forming process, which is to extrude concrete through a computer-controlled nozzle for printing. The advantage of D-Shape is that it can be printed directly on the lunar surface, and the printed product has good toughness, but its disadvantage is that its printing material depends on transportation between the earth and the moon. In addition, it can only be printed under vacuum, but liquids cannot be stored under vacuum. The contour forming process is a CNC construction process. Its advantages are high precision and no template is used during printing and construction. It is more friendly to the lunar environment while meeting the requirements of complex building structures [15].

Figure 1: Concept of mobile (passive) gantry byassembling modular beams and connectors [14]

Figure 2: Mobile robotic arm 3D printing [15]

5.1.2.Technologies to Assist Lunar 3D Printing Construction

At the level of 3D printing technology: BIM technology cannot be ignored. Nowadays, BIM has been widely used in the construction industry and has powerful capabilities for storing building information (the entire life cycle of a building), data interaction, and model construction. However, its interaction with construction management and robot control has not yet been fully realized. Yashar, M. et al. proposed the great potential of 4D BIM in 3D printing technology. It can simulate robot task planning and construction processes, form a visualization of the construction process, and convert geometric models into computer numerical control codes for the positioning of the robot arm during 3D printing [16]. Similarly, Muthumanickam et al. constructed a 4D BIM multi-objective optimization framework at the 3D printing software level, making the interaction of various complex systems in 3D printing stronger, improving work efficiency, and achieving effective monitoring and simulation during the work process [17]. For 3D printing technology,not only the drive of the robot arm should be considered, but also its mobility on the lunar surface needs to be guaranteed. Ellery proposed the All-terrain six-limb lunar probe in the article. As a robot rover chassis, it is used for robot movement of lunar 3D printing technology [4]. In addition, sensors, infrared laser searchlights and other technologies can also be used to assist in the movement of 3D printing robots.

5.1.3.D Printing Materials and Construction Technology

At the level of 3D printing materials: There is a weathering layer with a thickness of about 4-15 m on the lunar surface. The ISRU construction material is mainly the lunar weathering layer, which can be used as a good building material. By adjusting the ratio of the materials in the weathering layer, the concrete required for 3D printing can be obtained. Since the condensation of concrete requires the use of water to react, but the moon is extremely short of water resources, Peng Zhang et al. proposed in the article that two methods can be used to extract water on the moon: drilling evaporation and lunar soil hydrogen reduction [5]. In addition, methods for obtaining oxygen include reduction water extraction. In addition, metal oxide electrode oxidation, molten salt oxidation, vacuum thermal decomposition and other methods can be used to obtain oxygen for the firing of lunar soil bricks [5,7]. In a vacuum environment, the water in the lunar soil material will quickly vaporize after printing, which will affect the performance of the concrete after solidification. Therefore, some scientists have proposed the use of steam injection printing to effectively avoid the volatilization of the fusion agent. After the printed model is formed, the weathering layer material is sintered by solar concentrated irradiation or laser and microwave to obtain the outer protective shell of moon base [4-5,18-19]. However, the above methods still have defects, causing problems such as cracks, pores and cracks in buildings, posing a threat to safety [19].

40% of the components in the regolith can be used to make glass, and high-strength glass fibers can be mixed into concrete to enhance its toughness. Cast regolith refers to the material formed after the regolith on the lunar surface melts. Due to its strong wear resistance and pressure resistance, it is suitable for the outer and load-bearing parts of buildings. However, the regolith contains a lot of oxygen, and refining requires large-scale workshops, and the energy consumption during smelting is high [8]. Regarding the materials used in 3D printing, Robert P et al. mentioned that sulfur concrete, silicate cement concrete, Sorel cement concrete, plastic, basalt and metal can be used as deposition media for automated additive manufacturing system [18].

Still a need for technological breakthroughs in the storage, printing and structural hardening of weathered layer materials in 3D printing technology[3].

5.2.ISRU Uses Fully Adaptable Robots to Build Prefabricated Buildings

5.2.1.Mortise and Tenon Technology

For lunar construction, in addition to 3D printing buildings, traditional Chinese mortise and tenon structures have great advantages for lunar construction. Mortise and tenon structures have good performance in terms of flexible disassembly, stability and durability. The key point is that they can achieve the purpose of structural stability without welding or bonding. Ding, L. et al. proposed a new concept of lunar prefabricated buildings in the article, namely planetary Lego blocks, which are assembled by assembling lunar soil bricks of different shapes, it can get a solid lunar base, similar to traditional Chinese mortise and tenon structures [20]. Lunar mortise and tenon structures are also a type of prefabricated buildings. At the same time, Cheng Zhou et al. proposed in the article that the technology of making bricks from lunar soil can be used as a prerequisite for the assembly of lunar mortise and tenon structures [21]. After 3D printing bricks of unconventional shapes, fully adaptive robots are used to identify and assemble them to obtain lunar building structures.

5.2.2.Prefabricated Construction Robot Technology

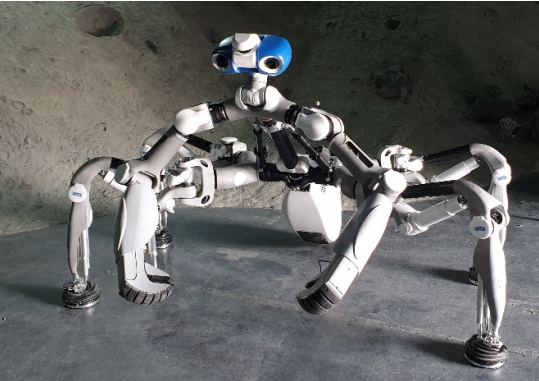

Brinkmann proposed a six-legged walking mantis robot (Figure 3), which has high mobility and two arms for grasping objects. It can be used for assembly structure installation and cooperate with 3D printing gantry. It adapts to the environment through limb sensors, head cameras and infrared scanners. Brinkmann described the Mantis system's collaborative task completion without human assistance (PRO-ACT)[22]. Govindaraj proposed the Robotic Work Agent (RWA) and ISRU factory, and explained the potential of the IBIS Mobile exploring robot, demonstrating the PRO-ACT multi-robot collaborative cooperation and task planning capabilities, bringing humans one step closer to fully adaptive robot construction [14]. Compared with the manufacturing industry, the construction site is a relatively complex site. Each building is different and the scenes are more varied. It is not enough for humans to program and control the robot to cope with the construction situation.

Figure 3: Six-legged walking mantis robot [14,22]

Due to the complexity of lunar construction and the diversity of geographical environments, the perception, task and path planning of robots play a vital role in their adaptive construction. Compared with traditional technologies, robot positioning is captured by cameras, analyzed by computer vision, and then path planning is performed after processing dynamic environments by reinforcement learning, or location recognition is performed by specific markers. Xu X. et al. proposed a new framework that uses data sensing that builds dynamic environments into virtual models to achieve positioning. After collecting data using laser scanning, edge detection, and stereo images, the required materials are automatically identified through deep neural networks. In terms of task planning, Xu X. proposed using deep learning technology (deep neural network reinforcement learning framework, inverse reinforcement learning) to train robots to find the optimal task planning and execution sequence [23]. These technologies can be used to achieve a high level of autonomy in robot construction. Similarly, Gawel et al. proposed a method for autonomous mobile robots to perform assigned tasks using onboard sensors, that is, by calculating the construction plan from the virtual building model and then using laser sensors to locate in the real feedback, achieving self-path planning and construction [24]. In addition, Follini proposed using 4D BIM design models, BIM and robots to interact with building data and store construction progress, and by installing sensors on the robot to monitor the construction progress while updating data in BIM to guide the robot's path planning [25]. Although these technologies for robot positioning, task planning, and object recognition are applied to earth construction, they provide ideas for ISRU. However, to achieve the purpose of robot learning, high-quality training and pre-data on construction are required for the robot [3].

Fully adaptive robots have already taken shape in construction on Earth. Despite their high flexibility and autonomy, they still face huge challenges in construction on the Moon. Under solar radiation, the sensors, communication capabilities and data processing capabilities of fully adaptive construction robots will be affected, thus affecting the stability and accuracy of their work [1].

5.2.3.Lunar Underground Construction

Current research on lunar underground construction mainly focuses on lunar lava tubes. Lunar lava tubes are underground passages formed naturally by volcanic eruptions under the lunar surface. The use of lava tubes reduces the cost of underground excavation for ICR on the one hand, and on the other hand, the temperature under the lava tube changes slowly during the alternation of day and night, with less solar particle radiation and a stable environment [3]. Thangavelautham mentioned in the article the control method of bionic artificial neural tissue (ANT), which is mainly used on the lunar surface and has higher autonomy and adaptability. It can be used for the construction of lunar lava tubes and the excavation and transportation of lunar soil [26]. Lava tubes can be constructed in stages to form complex LHs. However, there are many unknown factors in underground construction, which is risky, so exploration robots are needed to conduct visual analysis of the interior of the lava tube.

6.Conclusion

In-situ resource utilization construction has become an important way to explore the universe. This article briefly introduces the necessity of human beings to build infrastructure and other buildings on the moon from four aspects: the development of various disciplines, the exploration of the universe, resources and military. The methods of lunar construction (earth-moon transportation and ISRU) and lunar bases are classified, and the advantages of lunar in-situ resource utilization construction and the necessity of its development are listed. The classification of intelligent robots in terms of intelligence and function by scholars in recent years is discussed. Then, the technologies currently used in lunar in-situ resource utilization construction are introduced in detail: 3D printing technology and fully adaptive robot prefabricated buildings. For 3D printing technology, the concept, use, classification, development, auxiliary 3D printing construction technology, and 3D printing materials and construction technology are introduced. For fully adaptive robot prefabricated construction, the advantages of mortise and tenon assembly, as well as the types of assembly robots, perception technology, task planning and coordination capabilities are analyzed by example. Finally, underground construction technology is briefly introduced. This paper systematically analyzes the key technologies involved in the construction of lunar intelligent robots.

Through the analysis of lunar construction technology, humans have already conducted some research on 3D printing technology (AM) and fully adaptive robot construction technology, but there is still a lot of research to be done before fully realizing the robot construction mode without human intervention. To realize robot construction, multidisciplinary integration is required. If robots want to smoothly cooperate to complete construction tasks, they cannot be limited to civil engineering disciplines. Computer vision, artificial intelligence algorithms, remote sensing control and other technologies should be integrated into it. In addition, if you want to realize the construction of fully adaptive robots, you still need a lot of data for robots to learn. Finally, construction on the moon needs to take into account the extreme environment of the moon, such as extreme temperature, day and night length, low gravity, strong radiation, and more moon dust and small meteorites. Intelligent construction must be simulated in accordance with the lunar environment.

References

[1]. Cheng Zhou, Yue Yu, Yuyue Gao, et al. Analysis and enlightenment of ESA Moon Village construction plan [J]. Journal of Civil Engineering and Management, 2024,41(02):1-9. DOI:10.13579/j.cnki.2095-0985.2024.20230544.

[2]. Ruess, Florian, J.Schaenzlin, and H. Benaroya. Structural design of a lunar habitat. [J] Journal of Aerospace Engineering 19.3 (2006): 133-157.

[3]. Xuanyi Xue, Jianmin Hua, Chang Xiao, et al. Prospects for Intelligent Construction Technology for Lunar Base in Extreme Environments [J]. Science and Technology Foresight, 2024,3(1):109-115. doi: 10.3981/j.issn.2097-0781.2024.01.009

[4]. Ellery, Alex. "Leveraging in situ resources for lunar base construction."Canadian Journal of Civil Engineering 49.5(2022):657-674.

[5]. Peng Zhang, et al. "Overview of the Lunar In Situ Resource Utilization Techniques for Future Lunar Missions."Space: Science & Technology 3 (2023): 0037.

[6]. Lieyun Ding, Cheng Zhou,Yuyue Gao, et al. Research progress and scientific and technological challenges of extraterrestrial construction [J].China Civil Engineering Journal, 2024, 57(06): 26-42. DOI: 10.15951/j.tmgcxb.2024.05.1212.

[7]. Sanders, Gerald B., and William E. Larson. Progress made in lunar in situ resource utilization under NASA's exploration technology and development program. [J] Journal of Aerospace Engineering 26.1 (2013): 5-17.

[8]. Martinez Rocamora Jr, Bernardo, et al. Multi-robot cooperation for lunar In-Situ resource utilization. Frontiers in Robotics and AI 10 (2023): 1149080.

[9]. Ci-Jyun Liang, et al. Human–robot collaboration in construction: Classification and research trends. [J] Journal of Construction Engineering and Management 147.10 (2021): 03121006.

[10]. Balzan, Alberto, Claudia Cabrera Aparicio, and Dario Trabucco. Robotics in construction: State-of-art of on-site advanced devices. [J] International Journal of High-Rise Buildings 9.1 (2020): 95-104.

[11]. Chong Chen, et al. Research Progress of Construction Robots. Journal of Architecture and Civil Engineering 39.04(2022):58-70. doi:10.19815/j.jace.2022.03025.

[12]. Lieyun Ding, Jie Xu, Yawei Qin. A review of research and application of 3D printing digital construction technology for buildings [J]. Journal of Civil Engineering and Management, 2015, 32(03): 1-10. DOI: 10.13579/j.cnki.2095-0985.2015.03.001.

[13]. Puzatova, Anastasia, et al. "Large-scale 3D printing for construction application by means of robotic arm and Gantry 3D Printer: A Review." Buildings 12.11 (2022): 2023.

[14]. Govindaraj, Shashank, et al. "PRO-ACT: Planetary robots deployed for assembly and Construction of Future Lunar ISRU and Supporting Infrastructures." Proceedings of the 15th Symposium on Advanced Space Technologies in Robotics and Automation (ASTRA-2019). 2019.

[15]. Leach N,Weiran Zhu . Space 3D printing[J]. Architectural Technology, 2020, 26(08): 27-31.

[16]. Yashar, M., et al. "Building information modeling (BIM) workflows for construction sequencing and 4D-Planning of 3D-Printed ISRU surface habitats." Earth and Space 2021. 2021. 1394-1408.

[17]. Muthumanickam, Naveen Kumar, et al. "BIM for design generation, analysis, optimization, and construction simulation of a Martian habitat." Earth and Space (2021): 1208-1219.

[18]. Robert P. Mueller, Scott Howe, Dennis Kochmann, et al., Automated Additive Construction (AAC) for Earth and Space Using In-situ Resources [C] Proceedings of the Fifteenth Biennial ASCE Aerospace Division International Conference on Engineering, Science, Construction, and Operations in Challenging Environments (Earth & Space 2016), American Society of Civil Engineers, Reston, Virginia, USA, 2016.

[19]. Yiwei Liu, XianZhang, ChaoWang, et al. Research on 3D printing densification of simulated lunar soil [J]. Chinese Space Science and Technology, 2023, 43(06): 66-73. DOI: 10.16708/j. cnki.1000-758X.2023.0085.

[20]. Zhou, C., Tang, B., Ding, L., Sekula, P., Zhou, Y., & Zhang, Z. (2020). Design and automated assembly of Planetary LEGO Brick for lunar in-situ construction. Automation in Construction, 118, 103282.

[21]. Cheng Zhou, , et al. "In-situ construction method for lunar habitation: Chinese Super Mason." Automation in Construction 104 (2019): 66-79.

[22]. Brinkmann, Wiebke, et al. "Enhancement of the six-legged robot mantis for assembly and construction tasks in lunar mission scenarios within a multi-robot team." Proceedings: International Symposium on Artificial Intelligence, Robotics and Automation in Space. 2020.

[23]. Xu, X., and B. Garcia De Soto. "On-site autonomous construction robots: A review of research areas, technologies, and suggestions for advancement." ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction . Vol. 37. IAARC Publications, 2020.

[24]. Gawel, Abel, et al. "A fully-integrated sensing and control system for high-accuracy mobile robotic building construction." 2019 IEEE/RSJ international conference on intelligent robots and systems (IROS). IEEE, 2019.

[25]. Follini, Camilla, et al. "BIM-integrated collaborative robotics for application in building construction and maintenance." Robotics 10.1 (2020): 2.

[26]. Thangavelautham, Jekanthan, et al. "Autonomous multirobot excavation for lunar applications." Robotica 35.12 (2017): 2330-2362.

Cite this article

Du,Z. (2024). Development of Intelligent Construction Robots for In-situ Lunar Resource Utilization. Communications in Humanities Research,48,75-83.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Art, Design and Social Sciences

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Cheng Zhou, Yue Yu, Yuyue Gao, et al. Analysis and enlightenment of ESA Moon Village construction plan [J]. Journal of Civil Engineering and Management, 2024,41(02):1-9. DOI:10.13579/j.cnki.2095-0985.2024.20230544.

[2]. Ruess, Florian, J.Schaenzlin, and H. Benaroya. Structural design of a lunar habitat. [J] Journal of Aerospace Engineering 19.3 (2006): 133-157.

[3]. Xuanyi Xue, Jianmin Hua, Chang Xiao, et al. Prospects for Intelligent Construction Technology for Lunar Base in Extreme Environments [J]. Science and Technology Foresight, 2024,3(1):109-115. doi: 10.3981/j.issn.2097-0781.2024.01.009

[4]. Ellery, Alex. "Leveraging in situ resources for lunar base construction."Canadian Journal of Civil Engineering 49.5(2022):657-674.

[5]. Peng Zhang, et al. "Overview of the Lunar In Situ Resource Utilization Techniques for Future Lunar Missions."Space: Science & Technology 3 (2023): 0037.

[6]. Lieyun Ding, Cheng Zhou,Yuyue Gao, et al. Research progress and scientific and technological challenges of extraterrestrial construction [J].China Civil Engineering Journal, 2024, 57(06): 26-42. DOI: 10.15951/j.tmgcxb.2024.05.1212.

[7]. Sanders, Gerald B., and William E. Larson. Progress made in lunar in situ resource utilization under NASA's exploration technology and development program. [J] Journal of Aerospace Engineering 26.1 (2013): 5-17.

[8]. Martinez Rocamora Jr, Bernardo, et al. Multi-robot cooperation for lunar In-Situ resource utilization. Frontiers in Robotics and AI 10 (2023): 1149080.

[9]. Ci-Jyun Liang, et al. Human–robot collaboration in construction: Classification and research trends. [J] Journal of Construction Engineering and Management 147.10 (2021): 03121006.

[10]. Balzan, Alberto, Claudia Cabrera Aparicio, and Dario Trabucco. Robotics in construction: State-of-art of on-site advanced devices. [J] International Journal of High-Rise Buildings 9.1 (2020): 95-104.

[11]. Chong Chen, et al. Research Progress of Construction Robots. Journal of Architecture and Civil Engineering 39.04(2022):58-70. doi:10.19815/j.jace.2022.03025.

[12]. Lieyun Ding, Jie Xu, Yawei Qin. A review of research and application of 3D printing digital construction technology for buildings [J]. Journal of Civil Engineering and Management, 2015, 32(03): 1-10. DOI: 10.13579/j.cnki.2095-0985.2015.03.001.

[13]. Puzatova, Anastasia, et al. "Large-scale 3D printing for construction application by means of robotic arm and Gantry 3D Printer: A Review." Buildings 12.11 (2022): 2023.

[14]. Govindaraj, Shashank, et al. "PRO-ACT: Planetary robots deployed for assembly and Construction of Future Lunar ISRU and Supporting Infrastructures." Proceedings of the 15th Symposium on Advanced Space Technologies in Robotics and Automation (ASTRA-2019). 2019.

[15]. Leach N,Weiran Zhu . Space 3D printing[J]. Architectural Technology, 2020, 26(08): 27-31.

[16]. Yashar, M., et al. "Building information modeling (BIM) workflows for construction sequencing and 4D-Planning of 3D-Printed ISRU surface habitats." Earth and Space 2021. 2021. 1394-1408.

[17]. Muthumanickam, Naveen Kumar, et al. "BIM for design generation, analysis, optimization, and construction simulation of a Martian habitat." Earth and Space (2021): 1208-1219.

[18]. Robert P. Mueller, Scott Howe, Dennis Kochmann, et al., Automated Additive Construction (AAC) for Earth and Space Using In-situ Resources [C] Proceedings of the Fifteenth Biennial ASCE Aerospace Division International Conference on Engineering, Science, Construction, and Operations in Challenging Environments (Earth & Space 2016), American Society of Civil Engineers, Reston, Virginia, USA, 2016.

[19]. Yiwei Liu, XianZhang, ChaoWang, et al. Research on 3D printing densification of simulated lunar soil [J]. Chinese Space Science and Technology, 2023, 43(06): 66-73. DOI: 10.16708/j. cnki.1000-758X.2023.0085.

[20]. Zhou, C., Tang, B., Ding, L., Sekula, P., Zhou, Y., & Zhang, Z. (2020). Design and automated assembly of Planetary LEGO Brick for lunar in-situ construction. Automation in Construction, 118, 103282.

[21]. Cheng Zhou, , et al. "In-situ construction method for lunar habitation: Chinese Super Mason." Automation in Construction 104 (2019): 66-79.

[22]. Brinkmann, Wiebke, et al. "Enhancement of the six-legged robot mantis for assembly and construction tasks in lunar mission scenarios within a multi-robot team." Proceedings: International Symposium on Artificial Intelligence, Robotics and Automation in Space. 2020.

[23]. Xu, X., and B. Garcia De Soto. "On-site autonomous construction robots: A review of research areas, technologies, and suggestions for advancement." ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction . Vol. 37. IAARC Publications, 2020.

[24]. Gawel, Abel, et al. "A fully-integrated sensing and control system for high-accuracy mobile robotic building construction." 2019 IEEE/RSJ international conference on intelligent robots and systems (IROS). IEEE, 2019.

[25]. Follini, Camilla, et al. "BIM-integrated collaborative robotics for application in building construction and maintenance." Robotics 10.1 (2020): 2.

[26]. Thangavelautham, Jekanthan, et al. "Autonomous multirobot excavation for lunar applications." Robotica 35.12 (2017): 2330-2362.