1. Introduction

With the wave of the Fourth Industrial Revolution, digital manufacturing technologies demonstrate tremendous transformative potential in the field of architecture and environmental design. Emerging technologies such as 3D printing, parametric design, and digital fabrication are continuously reshaping designers' creative approaches and the presentation formats of design outcomes. Meanwhile, traditional crafts, as important carriers of human civilization, embody profound cultural connotations and unique aesthetic values, continuing to play an irreplaceable role in modern design practice. Achieving an organic integration of digital manufacturing technologies with traditional crafts amid ongoing technological advancements represents both a significant challenge and a vital pathway toward sustainable development in the design industry [1].

Research on the application of digital manufacturing technologies in architecture and environmental design has attracted widespread attention from scholars both domestically and internationally. While studies have emphasized the transformative nature of digital tools and the extension of design possibilities through robotic construction and parametric systems, existing literature often lacks systematic analysis regarding the integration of these technologies with traditional crafts. This gap is particularly evident in the interdisciplinary context of environmental design, where application-based integration remains underexplored and fragmented [2].

Technology integration theory offers key insights into this complex process. Innovation diffusion theory helps explain the mechanisms behind the adoption of digital tools within traditional craft domains, while disruptive innovation theory sheds light on the structural transformations these integrations may bring. However, the integration process is not without challenges. Technical compatibility issues, cultural misalignments, and the shortage of interdisciplinary talent constitute major barriers that hinder effective collaboration between digital and traditional design approaches.

China, possessing both a rich heritage of traditional craftsmanship and rapidly evolving digital infrastructure, is uniquely positioned to lead in this integration effort. Recent policy frameworks such as the “Guiding Opinions on Promoting Traditional Craft Revitalization” and the “Guiding Opinions on Promoting Digital Transformation of Manufacturing Industry” reflect national support for this convergence. Pilot projects like the digitization of the Palace Museum, smart ceramic production in Jingdezhen, and digital reconstruction of Suzhou gardens exemplify ongoing practical progress in this field [3].

Based on the above context, this study seeks to address the following key questions: How can digital manufacturing technologies and traditional crafts be effectively integrated into contemporary environmental design? What are the primary barriers and root causes of disconnection? What pathways and strategies can enable practical and scalable integration? And how can supportive policy systems and talent development frameworks be established? By investigating these questions, this research aims to provide theoretical grounding and practical guidance to foster innovation and cultural continuity in the field of environmental design.

2. Identification and Causal Analysis of Key Issues in the Integration Process

2.1. Technical Compatibility Issues and Their Root Causes

Technical compatibility remains a primary obstacle to the integration of digital manufacturing technologies with traditional crafts. Traditional crafts rely heavily on experiential and intuitive processes, often involving non-standardized parameters that conflict with the data-driven precision of digital manufacturing. Moreover, traditional materials such as bamboo, clay, and stone exhibit heterogeneous and anisotropic properties that complicate digital modeling. The lack of unified technical standards and quality control frameworks hampers interoperability across platforms and limits the scalability of integration. Additionally, existing digital tools are often designed with industrial logic in mind, overlooking the workflow needs of artisans. This leads to high adaptation costs and communication barriers between craftsmen and technologists, ultimately inhibiting collaboration [4].

2.2. Cultural Cognitive Differences and Value Conflicts

Significant cognitive and cultural differences between digital manufacturing technologies and traditional crafts pose persistent integration challenges. Digital approaches prioritize precision, standardization, and algorithmic problem-solving, while traditional crafts emphasize intuition, sensory experience, and cultural continuity. This divergence leads to contrasting design aesthetics—digital tools often pursue formal complexity and visual novelty, whereas traditional craftsmanship favors simplicity, harmony, and the integration of function with form. Evaluation criteria also differ markedly: digital technologies value innovation metrics such as efficiency and cost-effectiveness, while traditional crafts focus on emotional resonance, craftsmanship, and cultural symbolism. Such misalignment often results in conflicting expectations and difficulty in establishing shared benchmarks for success.

These differences are further exacerbated by gaps in mutual understanding and generational divides. Digital professionals may lack appreciation for traditional values and artisanal depth, while many master craftsmen are unfamiliar with digital tools and hesitant to adopt them. The resulting "cross-talk" undermines communication during collaboration. Additionally, traditional crafts often operate under open-sharing norms with informal knowledge transfer, conflicting with the digital domain’s emphasis on intellectual property rights and commercial protection. These value tensions can lead to disputes over ownership and benefits in joint projects, limiting trust and sustainable cooperation [5].

2.3. Structural Defects in Talent Development Systems

Talent development suffers from fragmented disciplinary training, with digital technology and traditional crafts typically taught in isolation. Curricula rarely offer integrated, hands-on experiences, and faculty capable of bridging both domains are scarce. Many institutions lack up-to-date equipment and dedicated craft workshops, resulting in theoretical instruction without applied practice. Moreover, weak collaboration between academia, industry, and heritage institutions limits student exposure to real-world problems [6]. Current assessment systems prioritize technical proficiency but neglect interdisciplinary innovation, cultural awareness, and teamwork—qualities essential for cultivating well-rounded integration professionals.

2.4. Constraining Factors of Policy Environment and Market Mechanisms

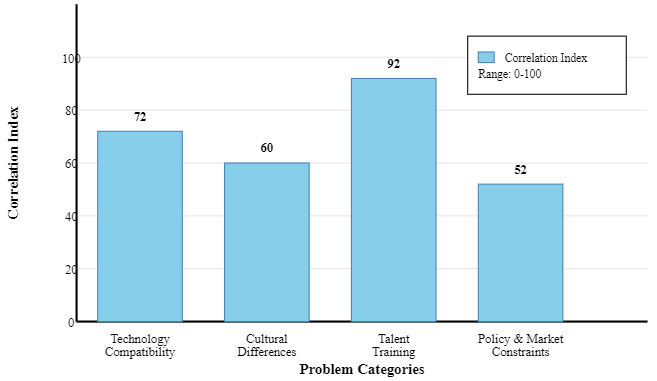

Despite some policy support for both digital technology and cultural heritage, integrated development still lacks specialized, coordinated policy frameworks. Funding channels are fragmented, legal protections for hybrid intellectual property remain vague, and existing certification systems fail to accommodate the unique traits of integrated products. Market access barriers, absence of industry standards, and unclear tax policies further restrict commercial development. For example, integrated craft-tech products struggle to meet conventional market entry criteria, and inconsistent taxation discourages enterprise investment. These structural gaps collectively weaken the policy and market foundations necessary for large-scale integration (Table 1, Figure 1).

|

Problem Category |

Specific Manifestations |

Impact Degree |

Main Causes |

|

Technical Compatibility |

Difficulty in parameter quantification, poor material compatibility |

High |

Lack of technical standards, insufficient human-machine interfaces |

|

Cultural Cognitive Differences |

Aesthetic concept conflicts, different value standards |

Medium-High |

Insufficient cross-cultural communication, generational differences |

|

Lagging Talent Development |

Scarcity of composite talents, weak practical components |

High |

Lagging curriculum systems, insufficient faculty strength |

|

Policy Market Constraints |

Lack of specialized policies, insufficient funding support |

Medium |

Policy fragmentation, imperfect standard systems |

Note: Impact degrees are classified into five levels: high, medium-high, medium, medium-low, and low

3. Implementation Pathways and Innovation Models for Technological Integration

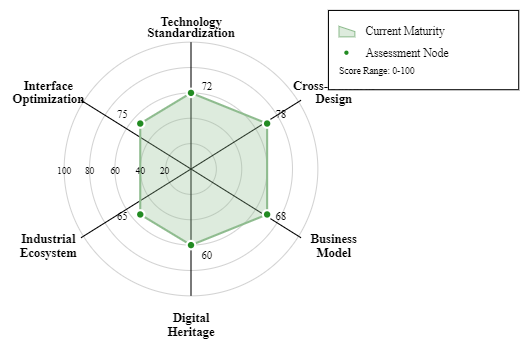

3.1. Technical Standardization and Interface Enhancement

A unified technical standard system is vital to bridging the gap between digital technologies and traditional crafts. This includes establishing quantifiable databases for craft techniques, digitized material libraries for traditional resources, and integrated workflows that balance digital automation with manual craftsmanship. Quality evaluation frameworks should account for both technical accuracy and cultural authenticity. Additionally, optimizing human-machine interfaces through VR/AR can help artisans interact with digital tools more intuitively, reducing adoption barriers and preserving traditional working habits [7].

3.2. Cross-Cultural Design and Value Integration

Effective integration requires designers and craftsmen to develop mutual cultural literacy. Digital practitioners should understand the philosophical and aesthetic foundations of traditional crafts, while artisans need to grasp the logic and potential of digital tools. Blending analytical design thinking with intuitive craft wisdom fosters a hybrid methodology. Practical collaboration on real projects enables participants to co-develop shared values and workflows, supported by experiential education programs that promote interdisciplinary competence and cultural empathy [8].

3.3. Innovative Business and Ecosystem Models

Emerging business models such as personalized customization and cultural IP monetization drive integration forward. Platform-based ecosystems connect stakeholders across design, production, and consumption, encouraging open innovation and resource sharing. Collaborative production networks allow traditional workshops and tech enterprises to complement each other’s strengths. Sustainable development models, combining ecological craft practices and digital efficiency, create new economic value aligned with environmental priorities [9].

3.4. Digital Heritage Mechanisms and Knowledge Management Systems

Digital preservation ensures the continuity of traditional craft knowledge. Techniques such as 3D scanning, motion capture, and VR simulations document and transmit skills with high fidelity [10]. AI enables tacit knowledge extraction, while blockchain secures IP ownership and automates benefit-sharing via smart contracts. Online learning platforms further democratize access to heritage skills, enabling scalable and interactive transmission of craft knowledge across generations and geographies (Figure 2).

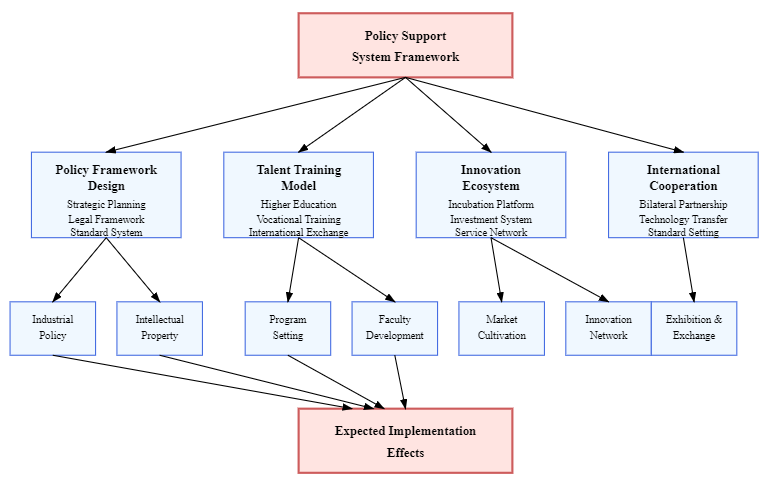

4. Policy Support Systems and Innovation in Talent Development Models

4.1. Policy Framework Design and Implementation Mechanisms

A coherent policy framework is essential to guide the integrated development of digital manufacturing and traditional crafts. Policies should address technological innovation, cultural preservation, industrial advancement, and talent development in a coordinated manner. It is recommended to incorporate integration into national strategies on cultural revitalization and advanced manufacturing, establish dedicated industry development funds, and introduce tailored tax incentives and market access policies [11]. Intellectual property protections must be updated to accommodate hybrid innovations, while unified certification and evaluation systems should reflect both technical and cultural value dimensions [12]. International cooperation should be institutionalized to strengthen global presence and standards influence (Figure 3).

4.2. Construction of Diversified Talent Development Pathways

Talent cultivation should be driven by interdisciplinary education reforms, including new programs that blend digital technology with traditional crafts. Joint training platforms involving academia, industry, and heritage institutions can promote applied learning. Lifelong learning opportunities, including modular training for professionals, must be expanded. Faculty development and international exchange initiatives are also crucial for building teaching capacity and global competence [13].

4.3. Innovation and Entrepreneurship Ecosystem Optimization

Specialized incubators and funding mechanisms for integrated innovation are vital. Government procurement should support early-stage market entry for integrated products [14]. Reforming investment evaluation systems and strengthening public education can improve resource flow. Innovation networks—such as alliances and exchange platforms—should be established to foster collaboration [14]. Intellectual property service systems must be enhanced to support knowledge commercialization [15].

4.4. International Cooperation and Exchange Mechanism Construction

Global engagement should include participation in international standard-setting, bilateral cooperation on technology and culture, and joint talent programs. Exhibitions and cultural exchange activities can boost China’s international visibility. Technology transfer centers and industrialization platforms should facilitate two-way flows of innovation, supporting global deployment and resource optimization (Table 2).

|

Development Pathway |

Main Measures |

Expected Effects |

Implementation Difficulty |

|

Academic Education Reform |

Establish interdisciplinary programs, reconstruct curriculum systems |

Cultivate 500 composite talents/year |

Medium |

|

Industry-Academia-Research Collaboration |

Establish 20 joint training bases |

Improve practical abilities by 30% |

Medium-High |

|

Continuing Education Training |

Develop 50 specialized training projects/year |

Train 2000 in-service personnel/year |

Low |

|

Faculty Development |

Introduce 50 experts, train 200 teachers |

Improve faculty levels by 40% |

High |

|

International Training |

Establish 10 overseas internship bases |

200 international talents/year |

Medium-High |

Note: Expected effects are 5-year planning targets; implementation difficulty is classified into five levels: high, medium-high, medium, medium-low, and low

5. Conclusion

This research systematically analyzed the theoretical foundations, practical problems, and implementation pathways for the integrated development of digital manufacturing technologies and traditional crafts, forming the following core findings. The integration of digital manufacturing technologies and traditional crafts possesses technical feasibility and important value, capable of promoting technological innovation while protecting traditional culture, achieving dual enhancement of cultural value and economic value.

The main obstacles in the integration process include four aspects: insufficient technical compatibility, cultural cognitive differences, lagging talent development, and policy environment constraints. These problems are interconnected and require systematic solutions from technological, cultural, educational, and policy dimensions. The implementation pathways for technological integration encompass technical standardization construction, cross-cultural design concept cultivation, innovative business model construction, and digital heritage mechanism establishment, forming a complete development system.

International experience comparisons indicate that China possesses rich traditional craft resources and rapidly developing digital technology industry advantages, but still needs strengthening in theoretical research, industrial promotion, and talent development. Looking toward the future, the integrated development of digital manufacturing technologies and traditional crafts will become more diversified, intelligent, and internationalized. The application of emerging technologies such as artificial intelligence, Internet of Things, and blockchain, globalized cultural exchange cooperation, and the deepening of sustainable development concepts will inject new momentum into integrated development, open new spaces, and provide new value orientations.

References

[1]. Liu, G. , Shi, Q. , Yao, Y. , Feng, Y. L. , Yu, T. , Liu, B. , & Diao, Y. (2024, May). Learning from Hybrid Craft: Investigating and Reflecting on Innovating and Enlivening Traditional Craft through Literature Review. In Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems (pp. 1-19).

[2]. Kofler, I. , & Walder, M. (2024). Crafts and their social imaginary: How technological development shapes the future of the crafts sector. Social Sciences, 13(3), 137.

[3]. Song, M. J. (2022). Craftspeople’s new identity: The impact of digital fabrication technologies on craft practices. International Journal of Technology and Design Education, 32(4), 2365-2383.

[4]. Mourtzis, D. , Angelopoulos, J. , & Panopoulos, N. (2022). Digital Manufacturing: The evolution of traditional manufacturing toward an automated and interoperable Smart Manufacturing Ecosystem. In The digital supply chain (pp. 27-45). Elsevier.

[5]. Pandey, A. , Janga, V. , Wako, D. A. , Genale, A. S. , Sundaram, B. B. , & Karthika, P. (2022, April). Deep Learning Technology using New Media on Traditional Arts and Crafts of Complex Forms. In 2022 6th International Conference on Trends in Electronics and Informatics (ICOEI) (pp. 1359-1365). IEEE.

[6]. Zbuchea, A. (2022). Traditional crafts. A literature review focused on sustainable development. Culture. Society. Economy. Politics, 2(1), 10-27.

[7]. Gomaa, M. , Jabi, W. , Soebarto, V. , & Xie, Y. M. (2022). Digital manufacturing for earth construction: A critical review. Journal of Cleaner Production, 338, 130630.

[8]. Yanyan, C. (2025). Innovation of environmental thermal energy management equipment for robot precision industrial manufacturing process: Digital product design. Thermal Science and Engineering Progress, 103281.

[9]. Yin, S. , Zhang, N. , Ullah, K. , & Gao, S. (2022). Enhancing digital innovation for the sustainable transformation of manufacturing industry: a pressure-state-response system framework to perceptions of digital green innovation and its performance for green and intelligent manufacturing. Systems, 10(3), 72.

[10]. Li, L. , Lei, B. , & Mao, C. (2022). Digital twin in smart manufacturing. Journal of Industrial Information Integration, 26, 100289.

[11]. Chen, X. , Kurdve, M. , Johansson, B. , & Despeisse, M. (2023). Enabling the twin transitions: Digital technologies support environmental sustainability through lean principles. Sustainable Production and Consumption, 38, 13-27.

[12]. Bag, S. , Sahu, A. K. , Kilbourn, P. , Pisa, N. , Dhamija, P. , & Sahu, A. K. (2022). Modeling barriers of digital manufacturing in a circular economy for enhancing sustainability. International Journal of Productivity and Performance Management, 71(3), 833-869.

[13]. Verma, P. , Kumar, V. , Daim, T. , Sharma, N. K. , & Mittal, A. (2022). Identifying and prioritizing impediments of industry 4. 0 to sustainable digital manufacturing: A mixed method approach. Journal of Cleaner Production, 356, 131639.

[14]. Assunção, J. , Chadha, K. , Vasey, L. , Brumaud, C. , Escamilla, E. Z. , Gramazio, F. , & Habert, G. (2024). Contribution of production processes in environmental impact of low carbon materials made by additive manufacturing. Automation in Construction, 165, 105545.

[15]. Schiavone, F. , Leone, D. , Caporuscio, A. , & Lan, S. (2022). Digital servitization and new sustainable configurations of manufacturing systems. Technological Forecasting and Social Change, 176, 121441.

Cite this article

Liu,Z. (2025). Integration of Digital Manufacturing Technology and Traditional Crafts in Contemporary Environmental Design. Communications in Humanities Research,72,19-26.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of ICADSS 2025 Symposium: Art, Identity, and Society: Interdisciplinary Dialogues

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Liu, G. , Shi, Q. , Yao, Y. , Feng, Y. L. , Yu, T. , Liu, B. , & Diao, Y. (2024, May). Learning from Hybrid Craft: Investigating and Reflecting on Innovating and Enlivening Traditional Craft through Literature Review. In Proceedings of the 2024 CHI Conference on Human Factors in Computing Systems (pp. 1-19).

[2]. Kofler, I. , & Walder, M. (2024). Crafts and their social imaginary: How technological development shapes the future of the crafts sector. Social Sciences, 13(3), 137.

[3]. Song, M. J. (2022). Craftspeople’s new identity: The impact of digital fabrication technologies on craft practices. International Journal of Technology and Design Education, 32(4), 2365-2383.

[4]. Mourtzis, D. , Angelopoulos, J. , & Panopoulos, N. (2022). Digital Manufacturing: The evolution of traditional manufacturing toward an automated and interoperable Smart Manufacturing Ecosystem. In The digital supply chain (pp. 27-45). Elsevier.

[5]. Pandey, A. , Janga, V. , Wako, D. A. , Genale, A. S. , Sundaram, B. B. , & Karthika, P. (2022, April). Deep Learning Technology using New Media on Traditional Arts and Crafts of Complex Forms. In 2022 6th International Conference on Trends in Electronics and Informatics (ICOEI) (pp. 1359-1365). IEEE.

[6]. Zbuchea, A. (2022). Traditional crafts. A literature review focused on sustainable development. Culture. Society. Economy. Politics, 2(1), 10-27.

[7]. Gomaa, M. , Jabi, W. , Soebarto, V. , & Xie, Y. M. (2022). Digital manufacturing for earth construction: A critical review. Journal of Cleaner Production, 338, 130630.

[8]. Yanyan, C. (2025). Innovation of environmental thermal energy management equipment for robot precision industrial manufacturing process: Digital product design. Thermal Science and Engineering Progress, 103281.

[9]. Yin, S. , Zhang, N. , Ullah, K. , & Gao, S. (2022). Enhancing digital innovation for the sustainable transformation of manufacturing industry: a pressure-state-response system framework to perceptions of digital green innovation and its performance for green and intelligent manufacturing. Systems, 10(3), 72.

[10]. Li, L. , Lei, B. , & Mao, C. (2022). Digital twin in smart manufacturing. Journal of Industrial Information Integration, 26, 100289.

[11]. Chen, X. , Kurdve, M. , Johansson, B. , & Despeisse, M. (2023). Enabling the twin transitions: Digital technologies support environmental sustainability through lean principles. Sustainable Production and Consumption, 38, 13-27.

[12]. Bag, S. , Sahu, A. K. , Kilbourn, P. , Pisa, N. , Dhamija, P. , & Sahu, A. K. (2022). Modeling barriers of digital manufacturing in a circular economy for enhancing sustainability. International Journal of Productivity and Performance Management, 71(3), 833-869.

[13]. Verma, P. , Kumar, V. , Daim, T. , Sharma, N. K. , & Mittal, A. (2022). Identifying and prioritizing impediments of industry 4. 0 to sustainable digital manufacturing: A mixed method approach. Journal of Cleaner Production, 356, 131639.

[14]. Assunção, J. , Chadha, K. , Vasey, L. , Brumaud, C. , Escamilla, E. Z. , Gramazio, F. , & Habert, G. (2024). Contribution of production processes in environmental impact of low carbon materials made by additive manufacturing. Automation in Construction, 165, 105545.

[15]. Schiavone, F. , Leone, D. , Caporuscio, A. , & Lan, S. (2022). Digital servitization and new sustainable configurations of manufacturing systems. Technological Forecasting and Social Change, 176, 121441.