1 Introduction

Flexible Electronics is a general term for a technology that involves fabricating organic/inorganic electronic devices on flexible/stretchable substrates, representing an emerging electronic technology [1]. Compared to traditional electronic products, flexible electronic products offer enhanced flexibility and can adapt to various working environments to a certain extent, meeting the requirements for device deformation. However, the development of flexible electronic products is also constrained by corresponding technical requirements. Flexible electronics encompass organic electronics, plastic electronics, bioelectronics, nanoelectronics, printed electronics, etc., and find diverse applications such as RFID technology, flexible displays, organic light-emitting diode (OLED) displays and lighting systems, chemical and biological sensors, flexible optoelectronics devices, flexible logic and storage components, flexible batteries as well as wearable devices. With its rapid advancement in recent years, interdisciplinary research hotspots lie in the field of flexible electronic products, which encompass flexible sensors, circuits, and actuators. Among these components, the former plays a pivotal role in achieving their desired flexibility.

Today, flexible sensors have a wide range of applications. Flexible sensors, made of flexible materials, have good flexibility and stretchability, allowing free bending and even folding [2]. Due to the flexibility of both the materials and structures, the flexible sensor can be arranged in any desired configuration based on the specific application scenario, thereby facilitating efficient detection of the target unit. The inherent advantages offered by flexible sensors present extensive prospects for their applications, with current devices primarily finding utility in medical electronics, environmental monitoring, wearable technology, and other related fields.

Flexible touch sensors, also known as flexible touch sensors, constitute an interdisciplinary frontier of research that combines flexible electronics, device physics, and materials science. They have great application potential in clinical diagnosis, health assessment, health monitoring, virtual electronics, flexible touch screens, flexible electronic skin, and even industrial robots. Because of its simple structure, good elasticity and convenient use, it has broad application prospects [3].

Flexible touch sensor has excellent application prospects in human activity monitoring, personal health care, artificial intelligence and other fields. Meanwhile, the pursuit of new materials and fabrication methods drives the continuous improvement of sensor performance. It is worth mentioning that some of the basic parameters of these sensors, such as sensitivity, flexibility and detection capability, can even surpass human skin. Moreover, multifunctional wearable tactile sensors, which are able to simultaneously distinguish complex stimulus information, such as multi-component forces, temperature, and humidity [4].

2 Research status

Tactile sensors are essentially touch sensors that provide information about objects in contact with the sensor. This information can include the shape, size, or even the material type of the object. The sensor is sensitive to touch, pressure, or any force on its surface. Typically, the sensor detects these characteristics in the form of electrical parameters such as capacitance or resistance.

According to MEMS Consulting, in recent years, the development of new smart materials and microstructures has given rise to a new type of tactile sensor known as ionically flexible sensors. Its sensing mechanism is similar to the tactile perception principle of human skin, relying on ion migration and ion redistribution mechanisms caused by external stimuli [2].

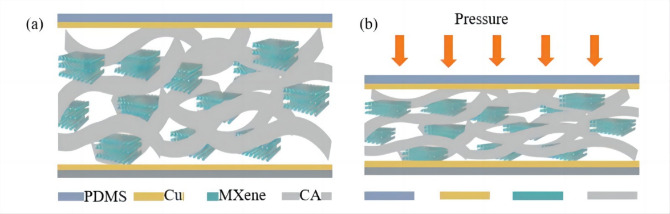

The working principle of flexible tactile sensor as shown in figure 2-1, under the action of external pressure, with pore structure of the CAMXene composite fiber film-part pore deformation, resulting in the gap between the CA fiber, the internal conductive network produce more contact sites, wrapped CA fiber MXene multilayer nanosheet contact area increases, form more 3D conductive network, so CAMXene composite fiber film electrical reduction, the relative resistance rate of flexible tactile sensor expressed as:

\( Y=\frac{∆R}{R}=\frac{R-R_{p}}{R} \)

Where, Y represents the relative resistance change rate of the flexible tactile sensor, \( ∆R \) represents the resistance change of the flexible tactile sensor under external pressure, R represents the initial resistance of the flexible tactile sensor under no external pressure, and Rp represents the resistance of the flexible tactile sensor under external pressure. When the flexible tactile sensor is subjected to greater external pressure, the gaps between CA/MXene composite fiber membrane decrease, leading to larger contact area between MXene multilayer nanosheets wrapping around CA, thus forming more 3D conductive networks. Consequently, the resistance of the flexible tactile sensor decreases. Therefore, the deformation of the flexible tactile sensor can be used to identify changes in the magnitude of external pressure on the flexible tactile sensor.

Figure 1. Working Principle of Flexible Tactile Sensor [3]

2.1 Classification of Flexible Tactile Sensors

Currently, flexible tactile sensors can be classified according to the information transmission mechanism and application scenarios, with the information transmission mechanism including resistive sensors, capacitive sensors, piezoelectric sensors, frictional sensors, inductive sensors, and optoelectronic sensors, as shown in Figure 1 [5-6].

2.2 Classification based on Information Transmission Mechanism.

The core technology of flexible tactile sensors lies in how to convert external stimuli into detectable and readable electrical signals. The information transmission mechanism of flexible tactile sensors mainly includes six categories: resistive, capacitive, inductive, piezoelectric, frictional, and optoelectronic.

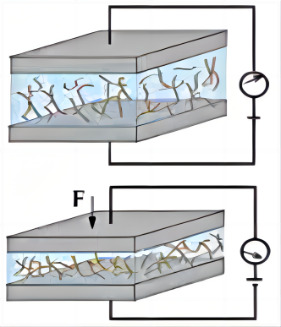

Resistive Sensors: Resistive sensors possess the advantages of simplicity in structure, ease of integration, and capability for data output. They are currently the most extensively researched variety of electronic strain sensors. The sensing factors primarily rely on resistance variations arising from electrode deformation and contact resistance between electrodes. The generic formula for resistive sensors is given as follows:

\( R=\frac{ρl}{A} \)

Figure 2. Working Principle of Resistive Sensor [3]

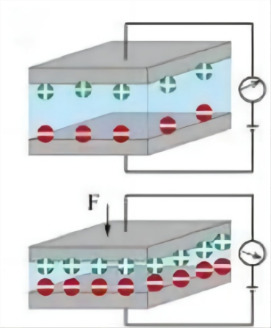

Capacitive Sensors: Capacitive sensors detect various forces by modifying the opposing area A and the distance d separating the parallel plates. Their primary benefit lies in their remarkable sensitivity to force, facilitating the detection of minor static forces with minimal power consumption. In a capacitor composed of two parallel plates, where edge effects are disregarded, the capacitance can be expressed using the formula:

\( C=\frac{ε_{0}εA}{δ} \)

Flexible capacitive sensors, constructed primarily from flexible materials like conductive thin films and fiber yarns for electrodes, along with an elastic spacer layer, offer unique advantages when integrated into clothing. These intelligent textiles exhibit not only softness, comfort, and the ability to bend and deform, but also remarkable sensitivity and spatial resolution in detecting changes in the external environment.

Figure 3. Working Principle of Capacitive Sensor [3]

Piezoelectric Sensors: Piezoelectric sensors rely on the capacity of materials to produce voltage when subjected to external mechanical pressure. By measuring the alterations in the circuit's output voltage, variations in the applied force can be determined. These sensors exhibit remarkable sensitivity and rapid response, enabling their utilization in detecting dynamic pressures, including sound vibrations and pulse beats. Given their energy harvesting capabilities, piezoelectric sensors hold significant importance in the advancement of low-power, self-powered flexible tactile sensors. Consequently, they are extensively employed in biomedical and acoustics technologies.

Piezoelectric materials commonly utilized encompass ceramics, quartz crystals, polyvinylidene fluoride, and nylon. Recently, scholars have successfully synthesized iron oxide (Fe3O4) / graphite oxide (G0) through a multi-step process, leading to remarkable synergistic effects upon the integration of Fe3O4 nanoparticles with graphene oxide nanosheets. Furthermore, a highly fibrous piezoelectric sensor has been developed through the integration of silk fibroin and polyvinylidene fluoride (PVDF) nanofibers.

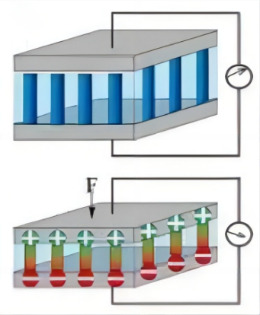

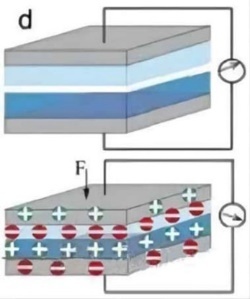

Figure 4. Working Principle of Frictional Electric Sensor [3]

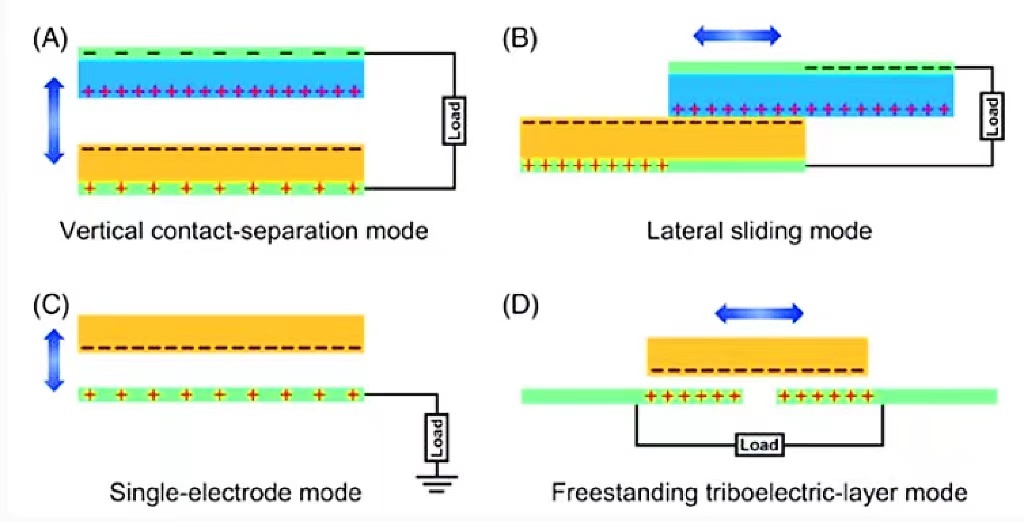

Frictional Electric Sensors:The sensor device's frictional electricity mechanism relies on the generation of charges on the surface as two distinct materials interact through rubbing. The quantity of charge produced is determined by the disparity in frictional polarity between the contacting materials. This ability to respond to diverse mechanical stimuli by generating electrical signals renders the sensor device suitable for utilization as a self-powered, flexible tactile sensor.

Figure 5. Working Principle of Frictional Electric Sensor [3]

The following figure shows four modes of the frictional nanogenerator, where (A) is the vertical contact-separation mode, (B) is the horizontal sliding mode, (C) is the single-electrode mode, and (D) is the separate-layer mode.

Figure 6. Four Modes of the Frictional Nanogenerator [7]

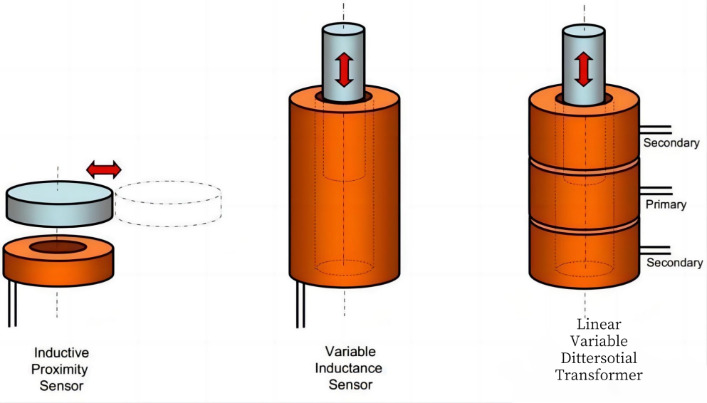

Inductive Sensors: Inductive sensors, devices that rely on alterations in self-inductance (governed by the formula L=μn²V) or mutual inductance for the purpose of non-electrical quantity measurement, possess numerous advantages. These include a straightforward design, remarkable sensitivity, elevated output power, reduced impedance, robust anti-interference capabilities, and precise measurement accuracy.

In general, the sensing coils of inductive sensors are frequently integrated with conductive fibers, yarns, and apparel, thus facilitating a range of functionalities, including the monitoring of human respiration and the capture of motion.

Figure 7. Working Principle of Inductive Sensor

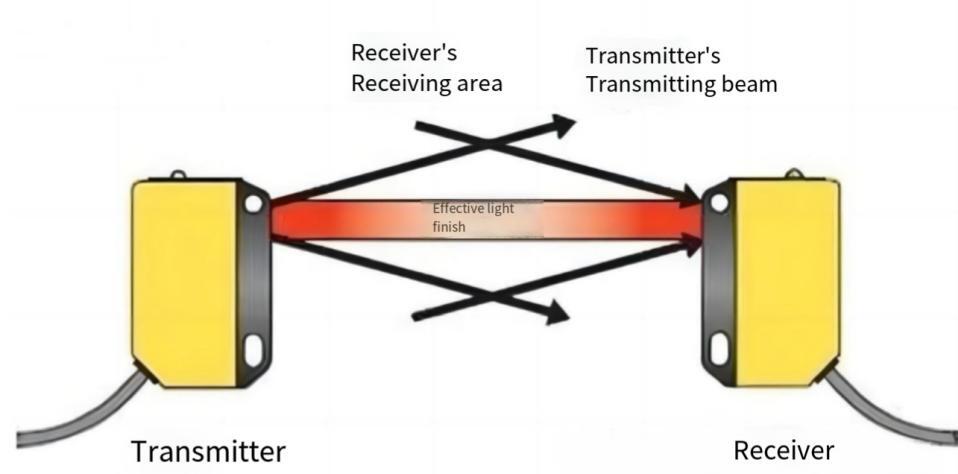

Optoelectronic Sensors: Optoelectronic sensors are devices that employ the alteration of optical properties to transform external physical parameters into measurable light signals transmitted via optical fibers. These sensors exhibit numerous superior performance attributes, enabling their utilization in lieu of human presence in hazardous environments for signal detection, including high-temperature regions and nuclear radiation zones. Furthermore, they possess the capability to detect external information beyond the perception of human senses.

Furthermore, optical sensors exhibit a range of advantageous characteristics, including exceptional sensitivity, remarkable structural pliability, and compact dimensions. Consequently, the integration of optical fibers into textiles facilitates the measurement of physical parameters such as pressure and temperature, finding widespread application in aerospace, military, and communication sectors. Notably, certain scholars have utilized polysiloxane-urea copolymers in the fabrication of thermoplastic silicone resin fibers, exhibiting superior elasticity compared to traditional optical fibers. The integration of these fibers into textiles preserves the inherent elasticity and softness of the textile material. Additionally, other scholars have developed highly elastic optical fibers composed of graphene nanosheets (GNP) and polydimethylsiloxane (PDMS) composites. These fibers possess the capability to quantify tensile strain through intense absorption and scattering of light transmitted through them, offering advantages such as a low detection limit, rapid response, and high repeatability.

Figure 8. Working Principle of Optoelectronic Sensor

Classification Based on Application Fields: There are primarily three domains, namely, human-computer interaction, robotics, and medical health, based on the specific application fields.

In the Field of Human-Computer Interaction: A recently developed flexible sensor by the University of British Columbia, Canada, fulfills the sensing requirements for future foldable tablets. This sensor is constructed by sandwiching a highly conductive gel between silicone layers. These silicone layers possess the capability to detect diverse touch types, including sliding and tapping, while also maintaining the ability to stretch, fold, or bend.

According to reports, this sensor incorporates numerous sensor functionalities into a single unit. It employs gel and silicone resin as its basic materials, which are highly accessible, straightforward in processing, cost-effective, and scalable for mass production. The cost per square meter is remarkably low, merely a fraction of a few dollars. This sensor boasts remarkable expandability, adapting to various surfaces within indoor environments or wearable devices. Furthermore, it can serve as the "skin" of robots, enabling them to detect the presence of humans. Its softness also contributes to enhancing the safety of human-computer interaction environments. With the utilization of this sensor, it is anticipated that tablets will be capable of folding down from a larger size to the dimensions of a mobile phone, easily fitting into the pockets of clothing in the near future [8].

The research conducted on intelligent human-computer interaction input panels delves into crucial scientific and technological challenges, encompassing the design of electrode structures, methods for discriminating output signals, and the simplification of output signal channel designs. In this pursuit, we have developed intelligent handwriting input panels utilizing frictional electricity, supported by convolutional neural networks. Additionally, we have created 4-port touch positioning and sliding detectors leveraging resistance chain technology. The research on frictional electricity collection devices is rooted in the triboelectric effect principle. Addressing key concerns regarding the low energy conversion efficiency of LS-TENG in terms of discharge principles, device design, and droplet energy collection, we have designed and developed the IDLS-TENG, which boasts low internal resistance and high instantaneous output power. Furthermore, we have introduced the D-TENG for droplet kinetic energy collection, exhibiting remarkable energy conversion efficiency.

To address the challenges posed by excessive output channels and intricate electrode topologies in conventional grid array handwriting recognition sensors, a novel approach was proposed: the implementation of a single-channel handwriting recognition sensor that utilizes double helix flexible electrodes. This innovation involves the development of a resistance chain structure, specifically designed to extract frictional electric signal voltage ratios. Furthermore, it enables the seamless integration of multi-channel array sensing signals, achieved through the integration of one-dimensional convolutional neural network sequence feature recognition methods [9].

Table 1. Classification of Sensors Based on Information Transmission Mechanism.

Sensor Type |

Resistive |

Capacitive |

Piezoelectric |

Frictional Electric |

Inductive |

Optoelectronic |

Advantages |

Simple structure, easy integration and data output |

Soft, comfortable, flexible, capable of perceiving changes in the external environment High sensitivity, and large spatial resolution |

High sensitivity, high response speed |

①High sensitivity ②High accuracy ③Fast response speed ④Wide applicability |

Simple structure, high sensitivity, high output power, low impedance, strong anti-interference ability, and high measurement accuracy |

①High sensitivity, strong shape adaptability, small size ②Can replace human presence in high-risk areas for detection, and receive external information that humans cannot perceive |

Disadvantages |

①Affected by environmental factors such as temperature, humidity, etc. ②Small linear range, not suitable for large-scale measurements |

①High output impedance, poor load capacity ②Large parasitic capacitance effect ③Non-linear output characteristics |

Some piezoelectric materials require moisture-proof measures, and the output DC response is poor, requiring high-input impedance circuits or charge amplifiers to overcome this defect |

①Measurement limitations ②Affected by environmental factors ③Poor stability |

Slow response, not suitable for rapid dynamic measurements |

Requires special optical fibers, high cost |

Applications |

①Monitor real-time movements of the neck, fingers, and eyes ②Measure tissue deformation during surgical procedures ③Monitor strain status of flexible aerospace equipment |

Widely used in human-computer interaction, wearable electronic devices, and health monitoring systems |

①Detect dynamic pressures such as sound vibrations or pulse beats ②Widely used in biomedical, electroacoustic, and other technical fields |

①Used as self-powered flexible tactile sensors ②Can be used for measurement of physical quantities such as temperature, pressure, flow, weight, etc. |

Slow response, not suitable for rapid dynamic measurements |

①Can replace human presence in high-risk areas for detection ②When optical fibers are applied to textiles, they can be used to measure physical quantities such as pressure, temperature, etc., and are widely used in aerospace, military, communication, and other fields. |

|

|

Figure 9. Flexible Touch Screen for Tablets [8] |

Figure 10. Flexible Touch Screen for Mobile Phones [10] |

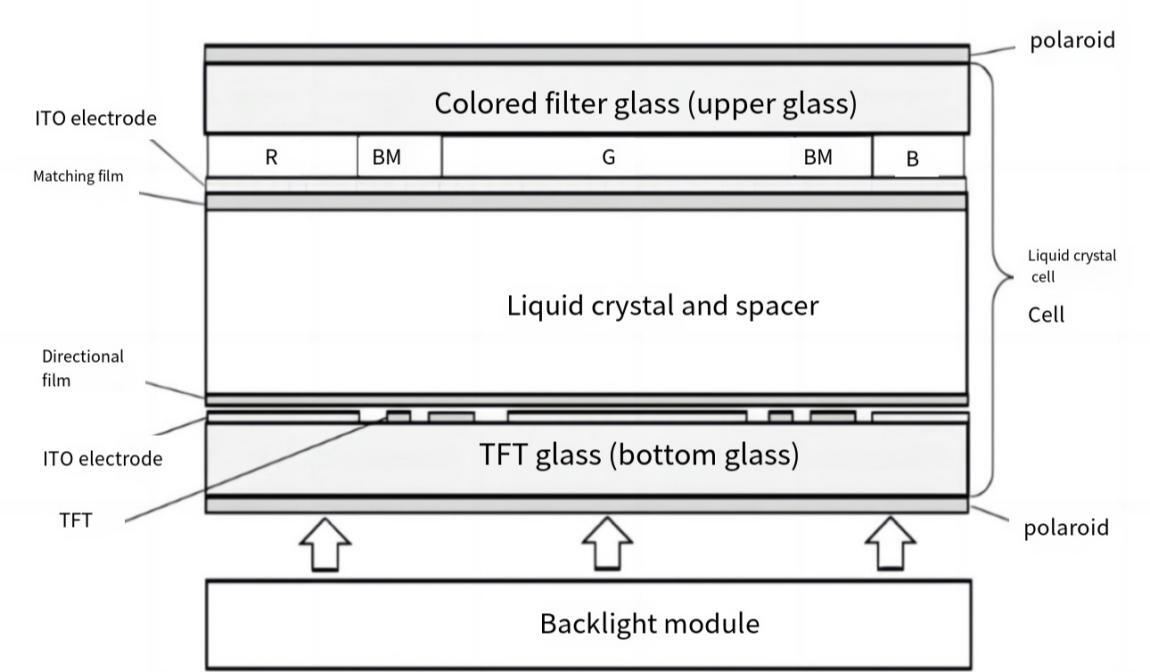

With regard to the fundamentals of mobile phone and tablet flexible touch screens, particularly the design and analysis of integrated (In-Cell) capacitive touch screen sensors, it is important to note that in the TFT-LCD structure schematic diagram presented in Figure 11, the Cell refers to the section situated between the color filter glass (CF glass) and the TFT glass within the TFT-LCD.

Figure 11. Schematic Diagram of TFT-LCD Structure [11]

Conventionally, a capacitive touch screen encompasses three distinct components: a protective cover layer, typically crafted from glass, a touch sensor, and an LCD. These components are meticulously laminated together to form a comprehensive panel module. In contrast to this modular design, the embedded touch screen seamlessly integrates the touch sensor into the LCD, thus eliminating the need for a discrete touch sensor and the associated physical space between the LCD and the touch panel. This integration of touch and display offers a sleek and streamlined user experience. However, due to spatial constraints and performance requirements, embedded sensor designs necessitate shared signal electrodes for both touch and display signals. Ensuring the seamless flow of signal acquisition, transmission, reception, and processing for both touch and liquid crystal display signals, without any interference, poses significant challenges. Furthermore, the intricacies of embedded capacitive sensor design extend to the meticulous patterning and dimensional parameter settings of the sensor itself.

Robotics Domain: The objective in the realm of robotics is to endow robots with electronic skin (E-skin) to endow them with human-analogous sensory capabilities. By employing flexible sensors that detect pressure, temperature, and other stimuli, soft robots acquire a sensitivity comparable to human skin, enabling them to possess vivid sensory experiences akin to touch, vision, hearing, taste, and smell.

Electronic skin remains a pivotal area of interest for numerous academic institutions and corporate entities. Notably, Professor Lu Nanshu from the University of Texas at Austin has contributed significantly to this field with the introduction of a novel hybrid-responsive electronic skin. This innovation not only enhances the pressure working range of sensors but also preserves their tactile sensitivity, marking a significant milestone in the advancement of this technology.

Regarding the corporate aspect, Canstat has demonstrated a proactive engagement in the robotics sector. In conjunction with the revelation of Hanwei Technology's financial report for the second quarter, a spokesperson elucidated, "In the forthcoming era, human-like and biomimetic robots will necessitate sensing capabilities beyond mere sound and light. These include touch and force feedback via electronic skin, as well as electronic noses enabled by gas sensors. Consequently, the utilization of flexible sensors in touch, temperature, and force feedback holds utmost relevance in the realm of robotics."

Figure 12. Relevant Developments in Robotics [2]

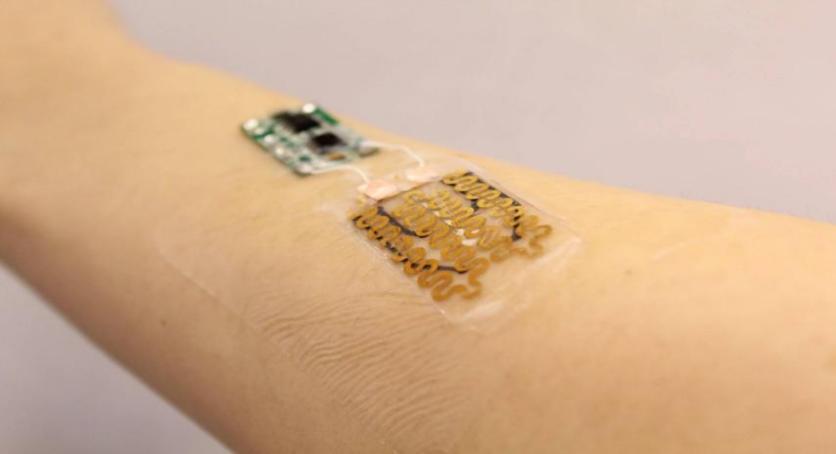

Healthcare Field: Given the inherent compatibility of flexible sensors with medical devices, the outlook in this domain appears highly optimistic. Presently, conceptual and pilot offerings encompass electronic tattoos, intelligent bandages, smart apparel, and the like.

Common products in this category encompass smart band-aids, smart bandages, and flexible pulse oximeters. Smart band-aids, in particular, differ significantly from their conventional counterparts. These band-aids incorporate flexible sensors, drugs, and medical tape to monitor the pH value of the patient's wound. This analysis allows for an accurate assessment of wound healing and inflammation, thereby mitigating the risk of infection.

Electronic tattoos (E-tattoos), which possess lightweight, thin, and flexible properties, adhere seamlessly to the human skin, facilitating the capture of biological signals and vital signs. The human body operates as an analog biological signal system, whereas machines and the electronic realm function in a digital manner. Consequently, to establish human-machine interaction, it is imperative to digitize humans, and E-tattoos are regarded as a viable method for achieving this human digitization.

Apart from the stringent standards in the medical sector, numerous consumer-oriented products exist for health monitoring. In the realm of clothing, smart clothing incorporates flexible sensors, ensuring discretionary wearability. Presently, there are ongoing investigations that aim to integrate fibers with flexible sensors. This approach involves utilizing textiles as a base, while integrating sensing materials or components in diverse manners, thereby yielding flexible sensor components tailored to fit the requirements of diverse wearable devices.

From the perspective of the current market landscape, analysts predict that functional and sports clothing will be the two primary domains where flexible sensors will make significant advancements. Specifically, in harsh environments like deserts, where workers wear smart clothing, these sensors can monitor both the worker's vital signs and the surrounding environmental conditions, such as temperature and humidity. This enables workers to have real-time access to their health status and the environmental conditions, ensuring their safety and well-being [11-12]

Figure 13. Smart Band-Aid (Extracorporeal Sensor [13])

Table 2. Classification According to Application Scenario

Category |

Tablet |

Smartphone |

Robotics |

Biomedical and Healthcare Field |

Production Method |

Consists of a flexible display with a resolution of up to 2K, which can be curled or unfolded around a cylinder made by 3D printing. The cylinder contains internal components running like a computer, with two rotating wheels at each end. |

Formation of touch-sensitive patterns and pixel shapes using transparent electrode materials between two substrates. Pixels are formed on the lower substrate, and touch patterns are formed on the upper one using transparent electrode materials such as ITO to allow light to pass through. |

Aimed at adding electronic skin (E-skin) to robots to give them human-like perception. |

For example, smart band-aids integrate flexible sensors, drugs, and medical tape, enabling detection of the pH value of the patient’s wound site to assess wound healing and inflammation, thus preventing infection. |

Features |

Can be moved or rotated for convenient portability. |

Reduces the overall thickness of foldable smartphones. |

Through flexible pressure, temperature, and other sensors, soft robots acquire sensitivity similar to human skin, providing vivid sensory capabilities like touch, vision, hearing, taste, and smell. |

Provides more accurate assessments for certain specialized fields, facilitating remote real-time monitoring, and making wearable devices imperceptible. |

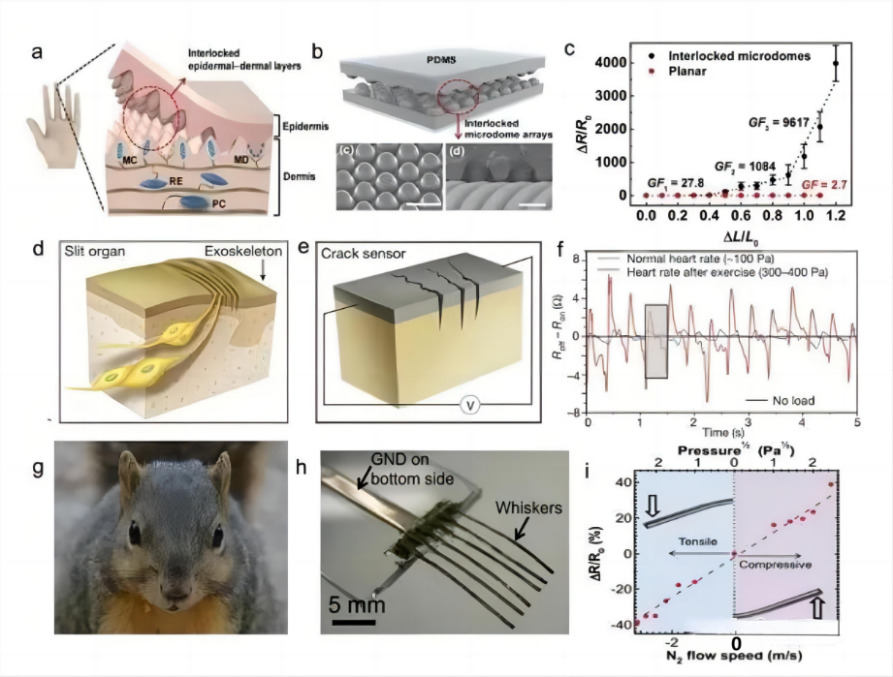

The reliability of material selection, innovative device designs, and mature manufacturing processes underlie the performance of flexible tactile sensors, characterized by their high sensitivity, rapid response, and low detection limits. Conventional bulk materials, however, hinder device performance due to their substantial viscosity, necessitating the development of unconventional microstructures. Biomimetic microstructure-based flexible tactile sensors are particularly significant in reducing manufacturing costs and enhancing device performance. Addressing energy consumption concerns, self-powered flexible tactile sensors, such as those leveraging piezoelectric and frictional effects, have been successfully developed. Furthermore, single-function tactile sensors are evolving towards multifunctionality, including three-dimensional force sensing, temperature sensing, humidity sensing, and more, to meet practical application requirements. Due to their exceptional sensing capabilities, flexible tactile sensors find applications in human health monitoring, motion tracking, and artificial intelligence.

Figure 14. Design and Application of Devices [3]

As shown in Figure 14, flexible tactile sensors based on biomimetic microstructures: (a-c) mimic the interlocking structure of skin surface; (d-f) mimic the cracks of spider sensory organs; (g-i) mimic animal whiskers.

the realm of biology to encompass electronic skin, intelligent robots, wearable electronics, and medical health. Addressing challenges related to reduced sensitivity and inadequate response/cyclic performance in resistive flexible touch sensors, a near-field electrohydrodynamic direct-writing approach is proposed. This method involves the fabrication of flexible touch sensors based on a cellulose acetate/MXene (CAYMXee) multilayer nanosheet composite fiber structure. By utilizing porous cellulose acetate (CA) fibers as bridging elements, MXene nanosheets are organized into continuous two-dimensional (2D) conductive networks with a porous structure. When compared to conventional methods of fabricating flexible touch sensors, this approach significantly enhances the electrical properties of the CA/MXene composite fiber films through the application of high-voltage electrostatic fields. Consequently, the sensing capabilities of the flexible touch sensor are improved. Testing has revealed that the flexible touch sensor exhibits a tactile pressure sensing range of 9 Pa to 10.2 kPa. Within the pressure range of 9 Pa to 5.6 kPa, the sensor demonstrates a sensitivity of 17.36 kPa⁻¹ and possesses rapid response/recovery times ranging from 60.31 to 74.35 ms. Experimental results confirm that this flexible touch sensor is capable of discerning signals related to finger movement, breathing, and pulse. Its versatile nature makes it suitable for applications in human motion detection and physiological signal monitoring.

2.3 Analysis of the development trends of flexible touch sensors

As smart terminals become increasingly prevalent, flexible electronic products exhibit immense market potential. Tactile sensors, a novel electronic device, enable interactions between machines and their surrounding environment. Following the rapid advancement of flexible electrodes, this emerging field offers opportunities for machines to engage in friendly interactions with humans or other machines. These sensors possess attributes such as flexibility, lightness, multifunctionality, and cost-effectiveness, making them highly desirable for wearable electronic devices and artificial intelligence applications. Given the non-planar nature of the human body, flexible electronic products offer an advantageous platform for testing skin-related parameters.

The flexibility of sensors, as opposed to rigidity, is achieved through the utilization of flexible substrates. These substrates, commonly referred to as thin films, are primarily composed of materials such as polyimide (PI), polyester (PET), and polydimethylsiloxane (PDMS). This significant shift from rigidity to flexibility has significantly broadened the range of sensor applications. These applications encompass not only gaming industry-related smart wearable devices, but also encompass electronic skins, equipment for disease diagnosis, health monitoring devices, smart neck pillows, and smart massagers in the medical and health sector. Furthermore, it extends to smart bracelets, metaverse gloves in the consumer market, smart mattresses in the smart home domain, and even brain-machine interfaces proposed by Musk.

Flexible touch sensors possess immense potential across diverse fields including human activity monitoring, personal healthcare, and artificial intelligence. Simultaneously, the relentless pursuit of innovative materials and preparation techniques has facilitated the steady enhancement of sensor performance. Notably, certain fundamental parameters of these sensors, such as sensitivity, flexibility, and detection capabilities, have even surpassed the capabilities of human skin. Furthermore, multifunctional wearable tactile sensors have undergone extensive research, enabling them to simultaneously discern intricate stimulus information encompassing multi-component forces, temperature, and humidity[13].

2.3.1 Issues

(1) Obstacles to the Development of Flexible Touch Sensors (from the perspective of preparation): Firstly, concerning materials, there are many materials used for making flexible sensors, mainly including metallic materials, inorganic semiconductor materials, organic materials, and flexible substrates. Regarding metallic materials, it is not difficult to use conductive materials such as gold, silver, and copper to make electrodes and conductors; inorganic semiconductor materials include many options, and scientists have reportedly used ZnO and ZnS to produce a flexible sensor using the photoelectric effect. However, the challenge lies in the limited curvature of the materials. Organic materials have better flexibility, but they are less sensitive to pressure and capacitance signals compared to metallic materials, limiting their development in high-precision measurement fields. The materials for flexible substrates are very limited, with polydimethylsiloxane (PDMS) being relatively successful. However, there are still many materials waiting to be explored in the future. Recently, research institutions have discovered that carbon materials can also be used to manufacture flexible sensors, but they need to be combined with graphene materials, which has been a material that has been difficult to mass-produce for a long time. There is still a need to vigorously search for new materials that can replace production with low cost and easy availability.

Secondly, regarding the manufacturing methods, achieving high-performance flexible sensors necessitates the utilization of specialized techniques. Notably, the use of active materials and flexible substrates is paramount, as flexible sensors have stringent dimensional and thickness requirements that must be met to ensure optimal performance. Furthermore, a significant hurdle lies in the high conductivity demands during the manufacturing process, which significantly impacts the overall yield. To address these challenges, it is imperative to enhance precision in controlling dimensions and thicknesses, while also exploring materials exhibiting superior conductivity, thereby optimizing the manufacturing workflow and mitigating the need for excessive manpower.

Thirdly, the existence of a notable absence of coordination within the industry chain restricts the potential for application and imagination in terms of flexible sensors. After all, the creation of a comprehensive product necessitates the integration of numerous devices. When sensors are bent, ensuring the continued performance of other associated devices poses a significant challenge for all sectors. Therefore, it is imperative to identify materials that possess a reduced hardness, facilitating ease of bending, while simultaneously aiming to produce more devices at the lowest possible application cost, without compromising production efficiency.

Lastly, the existing methods for measuring high temperatures are hindered by their bulky equipment, requirement for structural alterations, disruption of airflow patterns, and sensitivity to environmental factors. Consequently, these limitations prevent the effective implementation of non-destructive, real-time temperature monitoring within temperature fields. To address this challenge and overcome the limitations of flexible temperature sensors, Professor Tian Bian's team from the Institute of Precision Engineering at Xi'an Jiaotong University made an innovative decision. They selected aluminum silicate aerogel felt, renowned for its wide temperature tolerance, as the flexible substrate for the temperature sensor. However, due to the uneven surface and substantial roughness of this substrate, traditional micro-nano manufacturing processes found it challenging to achieve film deposition and functionalization. To overcome these obstacles, the team elected to employ screen printing technology to prepare thick films [14].

(2) Technical Characteristics Issues of Flexible Touch Sensors

Stability: Sensors require stability to guarantee their reproducibility and dependability amidst constantly evolving environments, particularly during extended monitoring periods.

The challenge of ensuring stability in flexible sensors often arises from the utilization of organic and polymer materials during the manufacturing process. These materials are prone to degradation over time, and their characteristics are susceptible to variations caused by environmental factors.

Furthermore, wearable biosensors that incorporate biomolecules encounter additional biological instability due to the environment in which they are deployed, particularly in terms of extreme physical and chemical stresses encountered in bodily tissues and biofluids, as well as in deep-sea and high-altitude environments, all of which exacerbate this challenge.

The most direct and effective method to address stability challenges is to enhance the environmental stability of sensor materials. Designing traditional rigid sensor materials into flexible and stretchable forms is an effective approach, but the complexity of manufacturing limits scalability and cost-effectiveness.

In circumstances where direct contact between stimuli and sensing materials is not essential, for instance, in the utilization of certain mechanical, temperature, and light sensors, a more effective method entails the application of protective layers onto sensitive materials, encompassing the entire device. Therefore, there is a notable requirement for moisture and oxygen barrier materials that exhibit superior performance characteristics.

The challenge of ensuring stability is particularly acute for flexible chemical sensors, particularly wearable biosensors, as biological fouling and biomolecule deactivation are significant factors that can compromise sensor performance over extended periods of time (spanning multiple days).

In uncontrolled wearable applications (e.g., changes in temperature and pH), the low stability of immobilized biomolecules is another issue. Biological receptors like enzymes can easily detach from anchored substrates/electrodes in the fluid environment and lose their recognition function outside their operating window.

Selectivity: Selectivity refers to the ability of a sensor to differentiate between target analytes and potential interferents. In practical application scenarios, multiple chemical substances and mechanical forces typically coexist, interacting with sensing materials through similar mechanisms, resulting in ambiguous sensor responses that prevent the desired signal from being detected.

Sensor selectivity can be approached through two general methodologies: through the utilization of specific sensors or through the employment of selective sensor arrays. Ideally, a specific sensor is designed to respond solely to a particular analyte, and with the aid of such sensor arrays, the precise composition of mixtures can be determined without the need for extensive data analysis. However, the realization of highly specific sensors often poses significant challenges.

In comparison, within selective sensor arrays, each sensor exhibits distinct responses towards a set of analytes, which collectively produce a unique fingerprint of the mixture. Subsequently, through rigorous data analysis, the precise composition of the mixture can be ascertained. These principles have found widespread application in mechanical sensors, biosensors, and gas sensors.

Biological sensors possess exceptional selectivity, making them invaluable tools for analyzing intricate mixtures within biological samples. These mixtures encompass a diverse array of components, ranging from ions and small molecules such as metabolites, cytokines, lipids, and neurotransmitters, to macromolecules like proteins and nucleic acids, and even microorganisms like viruses, bacteria, and cells.

Selectivity becomes crucial when analyzing complex mixtures containing closely related interferents (e.g., biological precursors and metabolites). In this regard, nature provides many biomolecular recognition elements that offer high specificity through interactions with metabolites and biomarkers.

Employing biological affinity-based receptors, such as ion carriers, DNA/RNA, aptamers, and antibodies, on flexible biosensors enables the in situ recognition of targets. However, this approach sometimes requires complex fabrication and handling processes and may exhibit relatively low stability.

Sensitivity:High sensitivity is crucial for sensors, enabling them to detect minute variations in stimuli. This reduced incidence of false negative signals, enhances the signal-to-noise ratio, and thereby enhances precision. Majority of the flexible physical sensors, including mechanical sensors, temperature sensors, and photoelectric detectors, possess sensitivity that meets the requirements of standard applications.

Mechanical sensors often exhibit a compromise between sensitivity and sensing range. However, when it comes to chemical sensors, sensitivity becomes a paramount factor, particularly when detecting analytes present in biological fluids at low concentrations.

The majority of mechanical sensors encounter a balancing act between sensitivity and sensing range, alongside nonlinear challenges, with pressure sensors being notably susceptible. The significance of signal conversion lies in its ability to enhance event signals to measurable thresholds, thereby optimizing sensitivity.

Unique Characteristics of Flexible Sensors — Mechanical Properties: Aside from the previously mentioned attributes of stability, selectivity, and sensitivity, there exist distinct challenges pertinent to flexible sensors. These challenges encompass mechanical deformation, transmission proficiency of wearable biosensors, maintaining precision, ensuring a dependable correlation between sensor signals and object states, resilience against mechanical deformation and damage, durability for prolonged usage and mechanical robustness amidst significant deformations, software-hardware interfaces, and material fatigue resistance. These primarily pertain to the mechanical performance characteristics of flexible sensors.

A noteworthy advantage of flexible sensors lies in their resilience against substantial deformation, ensuring neither physical failure nor performance compromise. This trait renders flexible sensors highly suitable for diverse applications where rigid sensors encounter difficulties, including skin patches/tattoos and smart clothing. Nonetheless, this flexibility introduces considerable complexities in preserving sensor integrity and performance amidst unpredictable mechanical interactions between the sensor and its environment.

The mechanical robustness of sensors refers to their capacity to endure diverse forms of deformation without experiencing mechanical failure. Extreme conditions, such as unusually large strains, intense impacts, prolonged cyclic strains, and continuous friction, are among the challenges sensors must withstand. Traditional rigid sensors can benefit from high-performance ceramics, metals, and thermosetting materials to safeguard against mechanical damage. However, the deformability of flexible sensors precludes the traditional utilization of these mechanical protective materials.

Moreover, considering the diverse range of materials utilized in the fabrication of flexible sensors, each material exhibits distinct mechanical attributes encompassing elastic modulus, Poisson's ratio, and viscoelasticity, alongside surface characteristics like surface energy and chemical composition. Consequently, interface mismatch emerges as a primary contributor to mechanical instability [15].

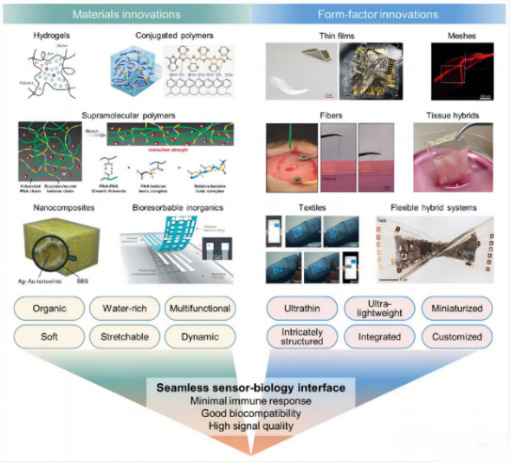

Figure 15. Flexible Sensor Bio Interface [15]

(3) Power Supply Issues

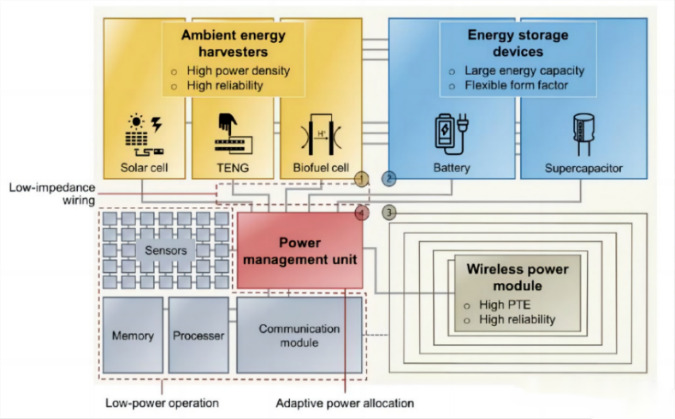

Figure 16. Power Supply Issues [15]

The fundamental prerequisite for the smooth functioning of sensing systems is a reliable power supply. Given the increasing utilization of flexible sensors across diverse use cases, which possess more advanced capabilities and varying shapes and sizes, sustainable and dependable power solutions for sensing systems and networks have become a key challenge. The authors primarily delve into matters pertaining to high-powered environmental energy harvesters, large-capacity energy storage devices, efficient wireless power transmission, and power management systems.

The energy consumption of integrated sensing systems encompasses various components such as sensors, signal processing circuits, microcontrollers, and communication modules, as well as the interconnection among them. Notably, the overall energy consumption of these systems can exceed the energy usage of individual sensors by a substantial margin. Additionally, systems designed for continuous monitoring necessitate a consistent power supply. Consequently, the next generation of flexible sensing systems pose significant power demands that traditional energy storage devices are unable to meet.

The traditional rigid and bulky batteries possess shape factors that impede the miniaturization of systems, leading to instability at the soft-hard interface. This obstacle hinders the progress of compact and compatible sensing systems. Furthermore, battery safety emerges as a significant concern, with incidents involving battery failures resulting in fires and explosions drawing attention to this crucial aspect.

In human-centered sensing applications, the safety of the power supply system holds utmost importance. To prevent accidents, it is necessary to incorporate accident prevention design. Additionally, factors such as biocompatibility and heating considerations must be carefully addressed. Presently, four potential solutions exist to tackle these challenges: environmental energy harvesters, energy storage devices, wireless power transmission, and system power management.

By seamlessly integrating miniaturized environmental energy harvesters into the sensor power supply system, the surrounding energy is efficiently converted into usable electrical power. This supplemental energy can act as a complement to batteries for power-intensive systems, potentially enabling the powering of devices or systems solely through harvested energy.

Certain energy harvesters possess sensing capabilities, allowing them to function as self-powered sensors. Environmental energy harvesters pave the way for battery-free sensors, significantly simplifying maintenance and mitigating carbon emissions. The primary methods for achieving miniaturized environmental energy harvesters are solar cells and triboelectric nanogenerators.

The utilization of electrochemical energy storage devices (ESDs) as a power source for flexible sensors is superior to in-situ energy harvesting. ESDs commonly employed for flexible sensors encompass batteries (such as ion batteries and zinc ion batteries) and supercapacitors. The objectives in designing ESDs tailored for flexible sensors are to achieve high capacity (high energy density), imperceptible form factor (flexibility, stretchability, miniaturization), and high cycling stability (both electrically and mechanically). However, the pursuit of these objectives often encounters conflicting material and device design principles, presenting formidable challenges in the development of effective ESD solutions for flexible sensors.

The wireless power transmission methods that are currently prevalent encompass near-field and far-field radio frequency (RF) technologies. These RF technologies possess the dual capabilities of power transmission and data communication, thereby facilitating the development of lightweight, tetherless, and minimally maintained sensors that are highly autonomous or perpetual. Such sensors are particularly well-suited for applications pertaining to automation, security, safety, and productivity.

Near-field technology is based on inductive coupling and magnetic resonance, while far-field technology is based on radiation power transmission. Near-field technology can achieve efficient power transmission but only within a limited distance (a few centimeters) and requires strict requirements for transmitter-receiver pairs. Far-field technology can cover large areas (several square meters), but due to its omnidirectionality, its power transmission efficiency is low and it is susceptible to obstruction interference (especially from human interference).

Finally, power management must be approached from multiple perspectives at the system level. Firstly, it is imperative to minimize the power consumption of individual modules within the sensor system. This involves the utilization of sensing mechanisms or material engineering that facilitate sensors operating with ultra-low to zero power consumption, low-power wireless communication technologies, flexible memory exhibiting ultra-low switching current density, and flexible complementary circuits operating with ultra-low driving voltage. Secondly, a comprehensive approach must be taken to integrate various energy harvesting and storage strategies, tailored to meet the specific requirements and constraints of the application. The optimization of low-impedance interconnections within integrated systems is also crucial for enhancing power efficiency [15].

2.3.2 Future outlook

In the field of bio-interface sensors, cell fields, and future mechanical fields, flexible touch sensors will play a significant role.

Firstly, in the realm of bio-interface sensors, the acquisition of high-quality biological signals via the bio-non-bio interface is of utmost importance, while simultaneously ensuring non-interference with the normal biological functions. These distinct qualities are heavily reliant on the compatibility of the interface between biology and electronics. Given its distinctive physicochemical properties, this application poses additional challenges beyond those related to sensor performance previously discussed.

Secondly, in the cell field, the most important consideration in developing bio-interface materials is biocompatibility. Depending on the location and duration of tissue contact devices, the required tests may vary. These may include tests such as cytotoxicity, sensitization, irritation or intracutaneous reactivity, systemic/acute toxicity, subacute and subchronic toxicity, genetic toxicity, etc.

The sole reliance on individual cytotoxicity tests is inadequate for establishing biocompatibility. Additionally, considering biocompatibility without taking into account the location and duration of tissue contact lacks relevance, as the biological impact of materials or devices on tissues differs significantly based on these two factors.

An important aspect of biocompatibility that must be addressed is the potential for immune responses. It is crucial to recognize that immune reactions can vary significantly among individuals, meaning that materials that are generally considered biocompatible for the majority of users may still cause allergic reactions in a subset of individuals. As an example, there are rare cases where patients who have circulating anti-polyethylene glycol (PEG) antibodies may experience severe allergic reactions to PEG-grafted drugs. Therefore, it is imperative to evaluate the risks associated with hypersensitive immune systems and to communicate these risks clearly to potential users.

On the contrary, even though certain immune reactions, such as fibrous capsule formation, do not pose a harmful threat to the human body as they do not result in severe inflammation, they nonetheless have a significant impact on sensor performance by degrading their overall functionality.

In conclusion, the current strategies in the field of mechanical engineering primarily concentrate on managing the mechanical characteristics of sensors, such as decreasing thickness and employing soft polymer materials to minimize bending stiffness. Nonetheless, the surface chemistry and morphology of devices play crucial roles in cell-material interactions, necessitating the exploration of sensors compatible with bio-interfaces.

3 Conclusion

To foster my research proficiency and expand my capabilities in the realm of scientific exploration, I diligently engaged in the study of flexible electronic touch sensors pertaining to intelligent sensing technology. Leveraging the competencies I had previously honed, I undertook a more profound learning process, integrating the theoretical knowledge I had acquired in the classroom into practical applications. Following this meticulous research, I have compiled the following observations and insights.

Firstly, I realize that learning scientific research methods is not something that can be achieved overnight; it requires the accumulation of rich experience. On the one hand, I mistakenly believed that mastering specialized knowledge was sufficient, and I should spend more time on theoretical learning. However, I now deeply understand that I violated the truth of “combining theory with practice.” Merely copying knowledge from textbooks is far from enough; what I lack is the ability to apply theory to real scientific experiments. On the other hand, I understand that scientific research is a profound field that demands a high level of expertise in one’s professional knowledge. Therefore, I lacked the confidence to try it myself, but with the encouragement of my teacher, I actively participated. Through the training of this research, the once vague knowledge became clear in my mind, which was truly beneficial.

Secondly, I learned to clarify my preferred research field and identify research problems. In recent years, to comfortably watch videos without occupying too much carrying space, domestic mobile phone brands such as Huawei, Xiaomi, and OPPO have launched foldable screen phones. Not only has it significantly increased the screen area, providing a broader field of view, but it has also reduced the size of the device, making it easy to hold with one hand, greatly facilitating us. I am very curious about how this technology is achieved, what knowledge learned in university is applied, and what are its advantages and disadvantages? With the help of my teacher, we jointly determined the topic of this research — flexible electronic touch sensors.

Finally, this research project tests personal comprehensive abilities, with many areas to learn. Unlike the group project research I participated in during my junior year, I need to complete various research tasks on my own with the assistance of my teacher. Therefore, after the teacher taught me the basic framework and methods of literature collection, I also watched many videos to strengthen my knowledge in this area to improve efficiency. After several attempts, in order to encompass more knowledge levels, it was not feasible to simply search for keywords like “flexible electronic touch sensors.” I needed to search at a broader level, such as “flexible sensing,” “touch screen,” “flexible electronics,” and “advantages and disadvantages of certain types of sensors,” etc.

Now my report has been completed, and I have gained a lot from this process. I have improved my ability to read literature, accelerated my reading speed of English literature, mastered many English expressions of professional terms, and learned to allocate time more effectively.

References

[1]. [1] Shanghai Zhongyi Technology Co., LTD., (2021), Comprehensive Introduction about "Flexible Electronics", https://zhuanlan.zhihu.com/p/407289955

[2]. [2] Intelligent Cloud Creation Global Investment Attraction. (2022). The rise of flexible sensors, the era of “smart perception” has arrived. Retrieved from https://zhuanlan.zhihu.com/p/582604867#

[3]. [3] Lai, Q. P. (2019). Flexible tactile sensor for intelligent robots. Retrieved from https://zhuanlan.zhihu.com/p/76708033

[4]. [4] Latest developments in flexible tactile sensors. (2022). Retrieved from https://www.zhihu.com/question/52381020

[5]. [5] Understanding flexible sensors in one article, although in the initial stage, the potential is huge. (2022). Retrieved from https://www.sensorexpert.com.cn/article/61532.html

[6]. [6] Zhongke Sensing Technology Qingdao Research Institute. (2022). Classification and preparation process application of flexible sensors. Retrieved from https://www.sensorexpert.com.cn/article/58099.html

[7]. [7] Triboelectric Nanogenerator. (2021). Micromachines.

[8]. [8] World’s first flexible touch screen tablet computer. (2018). World Knowledge.

[9]. [9] Xu, W. (2022). Research on intelligent self-powered human-machine interaction system based on triboelectric nanogenerator [Doctoral dissertation, Beijing Jiaotong University].

[10]. [10] Samsung applies for patent on “Flexible Touch Screen (TSP) Integrated Display.” (2020). Sensor World.

[11]. [11] Fan, G. J. (2007). Design and analysis of embedded capacitive touch screen sensors [Master’s thesis, Harbin Institute of Technology].

[12]. [12] Li, J. G., & Hao, Y. (2023). Research on quality control technology of medical wearable flexible electronic devices. China Medical Devices.

[13]. [13] “The era of flexibility” has arrived | Huge potential for flexible sensor industry. (2019). Sohu. Retrieved from https://www.sohu.com/a/347559715_12013059

[14]. [14] Biyou Sensing Network. (2019). What are the obstacles to the development of flexible sensors? Retrieved from https://www.sohu.com/a/299595822_99903201

[15]. [15] Sensor Expert Network. (2023). Why is it so difficult to develop flexible sensors with huge potential? 142 scholars join forces to publish this heavyweight paper! Retrieved from https://www.zhihu.com/question/52381020

Cite this article

Jia,Q. (2024). Application and analysis of contemporary flexible tactile sensors. Advances in Engineering Innovation,7,17-31.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. [1] Shanghai Zhongyi Technology Co., LTD., (2021), Comprehensive Introduction about "Flexible Electronics", https://zhuanlan.zhihu.com/p/407289955

[2]. [2] Intelligent Cloud Creation Global Investment Attraction. (2022). The rise of flexible sensors, the era of “smart perception” has arrived. Retrieved from https://zhuanlan.zhihu.com/p/582604867#

[3]. [3] Lai, Q. P. (2019). Flexible tactile sensor for intelligent robots. Retrieved from https://zhuanlan.zhihu.com/p/76708033

[4]. [4] Latest developments in flexible tactile sensors. (2022). Retrieved from https://www.zhihu.com/question/52381020

[5]. [5] Understanding flexible sensors in one article, although in the initial stage, the potential is huge. (2022). Retrieved from https://www.sensorexpert.com.cn/article/61532.html

[6]. [6] Zhongke Sensing Technology Qingdao Research Institute. (2022). Classification and preparation process application of flexible sensors. Retrieved from https://www.sensorexpert.com.cn/article/58099.html

[7]. [7] Triboelectric Nanogenerator. (2021). Micromachines.

[8]. [8] World’s first flexible touch screen tablet computer. (2018). World Knowledge.

[9]. [9] Xu, W. (2022). Research on intelligent self-powered human-machine interaction system based on triboelectric nanogenerator [Doctoral dissertation, Beijing Jiaotong University].

[10]. [10] Samsung applies for patent on “Flexible Touch Screen (TSP) Integrated Display.” (2020). Sensor World.

[11]. [11] Fan, G. J. (2007). Design and analysis of embedded capacitive touch screen sensors [Master’s thesis, Harbin Institute of Technology].

[12]. [12] Li, J. G., & Hao, Y. (2023). Research on quality control technology of medical wearable flexible electronic devices. China Medical Devices.

[13]. [13] “The era of flexibility” has arrived | Huge potential for flexible sensor industry. (2019). Sohu. Retrieved from https://www.sohu.com/a/347559715_12013059

[14]. [14] Biyou Sensing Network. (2019). What are the obstacles to the development of flexible sensors? Retrieved from https://www.sohu.com/a/299595822_99903201

[15]. [15] Sensor Expert Network. (2023). Why is it so difficult to develop flexible sensors with huge potential? 142 scholars join forces to publish this heavyweight paper! Retrieved from https://www.zhihu.com/question/52381020