1. Introduction

With the rapid growth of the global economy and population, the demand for energy is increasing day by day. Today, more than 80% of the energy consumed by mankind belongs to non-renewable energy sources and fossil resources [1]. The burning of fossil fuels leads to the release of large amounts of greenhouse gases, causing climate change and many forms of environmental pollution [2]. The development and utilization of renewable energy resources is a major challenge and it is also an effective way to alleviate the huge energy demand and global warming problems. Researchers have identified lignocellulosic biomass such as corn stover as a unique renewable carbon neutral resource that can be used to produce green fuels and value-added chemical products [3].

Lignocellulose, as an exploitable biomass renewable resource with huge reserves in China, is an important by-product of agricultural production, occupying more than 50 per cent of the total theoretical biomass resources, and as crop yields increase, so does agricultural straw production. However, the current utilization rate of straw is only about 33%, mainly through direct burning, returning to the field, incineration and use for raising livestock, etc. Straw utilized after technical treatment only accounts for 2.6% of the total production, and most of the straw has not been treated. This leads to waste of resources and environmental pollution, such as greenhouse gases (CO2, CH4) and atmospheric pollutants (particulate matter, SO2, etc.) Therefore, the development and utilization of waste straw not only reduces pollution, but also alleviates the energy crisis.

Crop straw is mainly composed of cellulose, hemicellulose, lignin and some other organic substances. Among them, the cellulose content accounts for about 31% to 40% of the total mass, hemicellulose content accounts for about 35% to 48% of the total mass, and lignin content accounts for about 11% to 25% of the total mass. The covalent bond binding form of hemicellulose and lignin wraps the cellulose molecule in it, making it not easy to contact with enzymes. Among them, cellulose is the skeleton of straw biomass and lignin is the protective layer, which are interconnected by covalent and hydrogen bonds to form a lignin-carbohydrate composite structure [4]. The three components are tightly bound to form a lignocellulosic matrix, which is tightly bound [5]. Therefore, in order to improve the subsequent reaction efficiency, effective measures need to be taken to destroy the physical barrier of straw, fully expose the cellulose structure, and increase the effective contact area between the cellulose and the reactants, so as to improve the conversion rate of straw biomass [6].

Pretreatment is a key step in different bioenergy conversion processes to open up the internal structure, change the chemical composition and improve subsequent processability [7]. After pretreatment, biomass becomes more homogeneous, has a higher binding capacity during physical densification, is more susceptible to enzymatic degradation in bioconversion, is more active in thermochemical conversion, and has a lower pyrolysis energy barrier. Therefore, various types of pretreatment methods, including physical (e.g., grinding), physicochemical (e.g., steam explosion and wet oxidation), chemical (e.g., alkali, dilute acid, oxidizing agents, and organic solvents), biological, and electrical, have been proposed by researchers and widely studied for pretreatment of lignocellulosic biomasses [8]. In recent years, a number of pretreatment techniques have been developed to destroy the structure of lignocellulosic, among which is the promising steam explosion method [4].

Steam explosion method is a very effective method of lignocellulosic pretreatment, belonging to the high temperature hydrothermal pretreatment method in the common type. Generally speaking, the method refers to the lignocellulosic material in 160 ~ 290℃ saturated water vapors, in a few tens of seconds to a few minutes after the pressure is instantly reduced to atmospheric pressure, so that the cellulosic material burst into slag, and increase its structural voids. High temperature and high pressure accelerated the destruction of cellulose internal hydrogen bonding and the change of the ordered structure, the release of new hydrogen groups and thus increase the adsorption capacity of cellulose. Typically, an increase in temperature is very favorable for the decomposition of hemicellulose within a certain temperature range. However, once a certain temperature limit is exceeded it leads to an increase in sugar loss to the extent that the yield decreases after pretreatment. It has the advantage of significant energy savings compared to conventional mechanical pulverization methods. To the extent that biomass materials such as straw are pulverized to the same particle size dimension, the steam blasting method consumes only 30% of the energy of the conventional mechanical method. However, at the same time, this pretreatment method still has the disadvantage of producing products that have inhibitory effects on fermentation and enzymatic digestion. The method of steam blasting has been used for many years.

In this paper, the process influencing factors of the steam explosion method, the changes in the biomass after steam explosion and the influence of steam explosion pretreatment on the subsequent process are reviewed. The study analyzed the steam explosion temperature, dimensional pressure time, additive types on the effect of the pretreatment method, but also further explore the steam explosion after the changes in the content and physical structure of the components in the straw as well as accompanied by the reaction of the inhibitors generated with a view to improve the improvement of the late enzyme digestion and the related pretreatment research to provide a reference.

2. Steam explosion process factors affecting

The stubborn and complex structure of biomass has become the biggest obstacle in the process of bioenergy utilization. To solve this challenge, researchers have proposed various coping strategies, such as: mechanical pulverization, radiation top treatment, acid and alkali pretreatment, oxidation pretreatment and other measures. Among them, steam explosion is an efficient, environmentally friendly and industrialized technical means. It provides a scalable method for experimental biomass pretreatment by integrating high-temperature autohydrolysis and explosive decompression to destroy the structure, which can significantly improve the processability of raw materials for some bioenergy conversion technologies [9]. China Agricultural University, College of Engineering, Professor Zhang Lianhui et al. found that the straw lignin after steam explosion treatment of its structure changes, in the scanning electron microscope its fiber bundles fracture and porous structure [10]. The structure of straw lignin was found to be changed after steam explosion treatment. Li Dongmin, Wei Ni et al. analyzed the impact of high-temperature hydrothermal pretreatment on lignocellulose and its related effects on the later enzymatic studies, found that the method in the fiber structure to become loose at the same time, but also cause some of the lignin conversion, affecting the degradation efficiency of cellulases [11]. In exploring the pretreatment of biomass steam explosion on fiber-rich materials such as straw, researchers have found that different experimental factors can have different effects on the decomposition of lignocellulose, and that the key parameters of the steam explosion process include temperature, pressure, residence time, and selection of additives. These parameters need to be adjusted according to the purpose of the pretreatment. In the transformation of lignocellulose in steam blasting straw, the intensity of each condition on the degradation rate was analyzed from the experimental results, and it was found that the effect of pressure and temperature on the results was much greater than that of the time of dimension pressure [10].

2.1. Steam explosion temperature

Unlike other hydrothermal pretreatment techniques, the steam explosion method is characterized by a physical tearing effect. Zhang and Chen, for example, found that the moisture content in the material can be optimized by maintaining the temperature, and the chip size can be optimized by the vent area, and the moisture content of the material, the vent area, and the chip size are included in the severity factor when the steam explosion can be used, which can be used as a common method for selecting the equipment and screening the steam explosion process. Engineering reference for selection of equipment and screening of steam blasting process conditions [12]. The In exploring the optimal conditions for steam explosion for lignocellulosic conversion, the cellulosic linkages were softened by heating the feedstock. Under conditions of sudden pressure reduction, water vapor expands rapidly causing the rigid structure of the biomass fibers to fracture, transforming the starting material into a fibrous dispersed solid. The shear force generated by the sudden release of pressure breaks the glycosidic and hydrogen bonds and further promotes the enzymatic hydrolysis of cellulose and hemicellulose to monomeric hexoses and pentoses, resulting in a change in the physical and chemical structure of lignocellulose [13]. With the increasing pressure of the steam explosion, the experimental results in Table 1 show that the degree of conversion of hemicellulose in straw significantly increased, and the conversion rate is high, indicating that its main constituent polysaccharides in the conditions are very easy to structural transformation. The conversion of cellulose, however, was low although some significant changes occurred with the rise in pressure. The degradation rate of lignin reached a high level (14.48%) at 0.8 MPa, but decreased to about 13.12% when the pressure was increased to 1.0 MPa [10]. The degradation rate of the degradation rate of the pressures was reduced to about 13%. Efficient temperatures and pressures can produce optimal physical tearing of the products as desired, saving time and money for the utilization of biomass energy at a later stage.

Table 1. Degradation rate of lignocellulose under different operation pressures maintained at 30 min [10]

Vapor explosion pressure/MPa |

Cellulose/% |

Hemicellulose/% |

Lignin/% |

|

0.6 |

11.29+0.47 |

69.55+2.15 |

5.75+0.01 |

|

0.8 |

16.65+0.13 |

73.38+2.71 |

14.48+0.07 |

|

1.0 |

25.05+0.20 |

74.50+3.85 |

13.12+0.57 |

|

2.2. Steam explosion time

In the steam explosion process, the time to maintain high pressure is also a key factor. It will have a direct impact on the hemicellulose conversion, lignin softening degree and the degree of water vapor penetration, so ensure that the appropriate maintenance of pressure time can improve the effect of steam explosion. In the investigation of steam explosion process of straw lignocellulose conversion experiments, the researchers in the determination of a fixed steam explosion pressure, liquid-solid ratio, material particle size and other conditions, respectively, in 20 min, 30 min and 40 min under the conditions of the dimensional pressure to deal with the observation of different dimensional pressure time cellulose, hemicellulose, lignin content changes, the results are shown in Table 2. It was proved that when the dimensional pressure time was 30 min, the conversion rate of the three ideal significantly [10]. Svein J. Horn et al. evaluated the effectiveness of steam blasting pretreatment by applying enzymatic hydrolysis and biogas testing. They explored the changes in cellulose, hemicellulose and lignin content of treated straw when carried out at a temperature range of 170-230°C and a residence time of 5-15 min. It was shown that the total enzyme release of glucose and xylose increased with the pretreatment roughness, while the maximum value was reached after 10 min pretreatment at 210°C, which was the optimal condition for steam blasting pretreatment [14]. Vivekanand et al. similarly explored different time conditions for steam explosion pretreatment and based on the experimental results it was proved that enzyme release of glucose increases with increase in severity of steam explosion pretreatment. The level of degraded glucose was as high as 97% of the theoretical maximum when it was kept at 220°C for 10 min [15].

Table 2. Degradation rate of lignocellulose Under different reaction time with the pressure of 0.6 MPa/% [10]

Pressure maintenance time/min |

Cellulose/% |

Hemicellulose/% |

Lignin/% |

20 |

11.55±0.37 |

68.53±4.43 |

8.91±0.26 |

30 |

15.26±0.32 |

71.95±2.67 |

22.67±1.26 |

40 |

19.53±0.67 |

78.09±0.67 |

22.59±0.29 |

2.3. Types of additives in the steam explosion

In the biomass steam explosion pretreatment, through different pathways of action to add the corresponding chemical substances (Table 3) is a common method to improve the efficiency of subsequent enzymatic digestion. In order to improve the efficiency of cellulase, surfactants and proteins can be added to the system to occupy the enzyme adsorption sites on lignin in order to reduce the adsorption effect of cellulase on lignin, thus promoting the binding of cellulase to the substrate. It is also possible to add a nucleophilic reagent by adding nucleophilic substances such as dimethyl homotriphenyltriol or 2-naphthol in the pretreatment process to bind to the carbon positive ions in the reaction process. This prevents them from binding to nucleophilic substances for lignin depolymerization, reduces lignin redeposition and mitigates the inhibition of cellulases [11]. Some acid catalysts are often added during steam blasting in certain types of lignocellulosic biomass, e.g., the addition of acid is necessary in the pretreatment of softwood biomass lacking acetyl groups in hemicellulose. It allows for the recovery of hemicellulose-derived saccharides at higher concentrations while keeping the concentration of inhibitors at a low level, thus maintaining the rate of cellulose decomposition. In addition, the addition of certain acid catalysts reduces the temperature required for the steam explosion process [9].

Table 3. The types of additives used in Steam explosion

kind |

food additive |

goal |

consultation |

nucleophilic reagent |

Dimethylhomotriol |

Binds positive carbon ions and reduces lignin reprecipitation. |

[16] |

2-Naphthol |

Binds positive carbon ions and reduces lignin reprecipitation. |

[16] |

|

surfactant |

Polyethylene glycol (PEG4000) |

Occupies lignin adsorption sites for the enzyme and promotes cellulase binding to the substrate. |

[17] |

carbohydrate |

Bovine serum albumin (BSA) |

Occupies lignin adsorption sites for the enzyme and promotes cellulase binding to the substrate. |

[18] |

Acid catalyst |

sulfuric acid |

Acts as a catalyst to increase hemicellulose solubility. |

[19] |

sulfur dioxide SO2 |

Acts as a catalyst to increase hemicellulose solubility. |

[19] |

|

sodium pyrophosphate |

Acts as a catalyst to increase hemicellulose solubility. |

[20] |

3. Changes in the physical and chemical structure of lignocellulose after steam explosion

Steam explosion is one of the common pretreatment methods for corn stover, which destroys the structure of lignocellulosic biomass and partially converts cellulose and hemicellulose into fermentable sugars such as glucose, xylose, arabinose, galactose and mannose. The polymers remaining from the enzymatic hydrolysis process are then converted into fermentable sugars. Depending on the process parameters, such as temperature and time, lignin is degraded to phenolics and fermentable sugars, which are mainly converted to hydroxymethylfurfural (HMF), furfural, acetic acid, acetic acid, acetylpropionic acid, ferulic acid, and glucuronic acid. The presence of these degradation products usually leads to the cessation of the fermentation process or slowing down of the reaction rate thereby reducing the biofuel yield during fermentation and are inhibitory compounds [13].

3.1. Changes in the content of lignocellulose fractions

Under the conditions of high temperature and high pressure, the acetyl group on hemicellulose in LCCs (lignin-carbohydrate complexes) with part of the connecting bond broken off, generating acetic acid, which promotes the degradation of hemicellulose to generate xylose, and the degradation of part of cellulose to generate glucose. And these monosaccharides will continue to decompose to generate aldehydes, acids, and other substances, and undergo further oxidation, reorganization, and other reactions, and ultimately form polymer compounds containing hydroxyl groups, carbonyl groups, aromatic groups, and aliphatic structures. These substances are called pseudolignin because they have a similar structure to lignin. Some of the lignin is degraded into small molecules such as phenols, which undergo migration, recombination, rearrangement, and other reactions to form new lignin [11]. The lignin is degraded into small molecules such as phenolics, which form new lignin after migration and rearrangement. In the study of Juan Chang et al. they treated corn stover with steam blasting (2.5 MPa/200 s), and the results demonstrated that the cellulose, hemicellulose, and lignin contents of blasted corn stover were reduced by 8.47, 50.45, and 36.65%, respectively, compared with that of unblasted corn stover [21]. The As Table 4 shows the changes in the content of each component for each of the different steam blasting biomass pretreatment conditions studied, respectively.

Table 4. Various conditions of pretreatment methods and their outcome [22]

steam explosion temperature |

steam explosion time |

Composition of raw materials before steam explosion |

post-vapor explosion content |

consultation |

100°C |

120 min |

41.5% cellulose 35.8% hemicellulose 16.2% lignin |

64.4% cellulose 5.2% hemicellulose 26.5% lignin |

[23] |

213.3°C |

5 min |

38.29% cellulose 28.50% hemicellulose 28.41% lignin |

62.44% cellulose 13.38% hemicellulose 20.08% lignin |

[24] |

170°C |

10 min |

37.4% cellulose 24.46% hemicellulose 28.8% lignin |

65.6% cellulose 4.58% hemicellulose 8.5% lignin |

[25] |

184°C |

15 min |

46% cellulose 19.26% hemicellulose 20.31% lignin |

74.59% Dextran 7.51% xylan 6.22% lignin |

[26] |

Changes in particle size of physical structure of raw materials

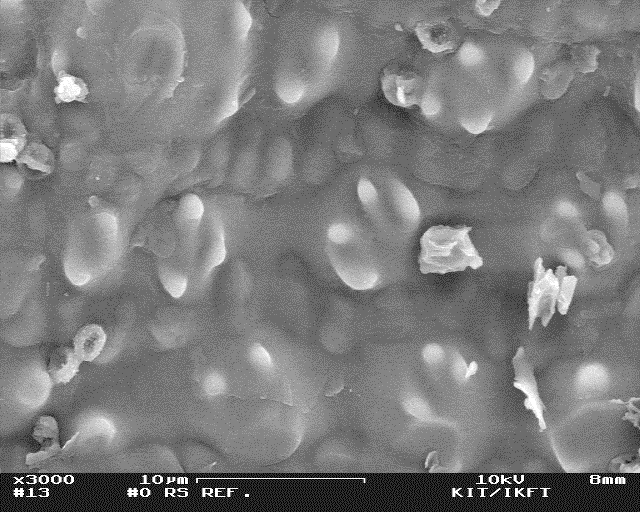

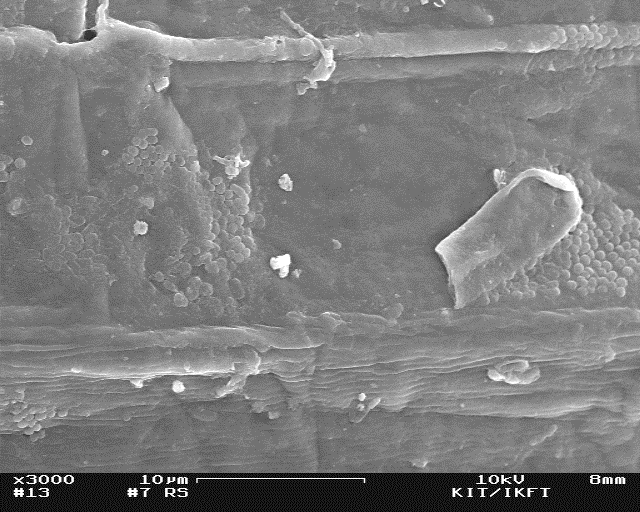

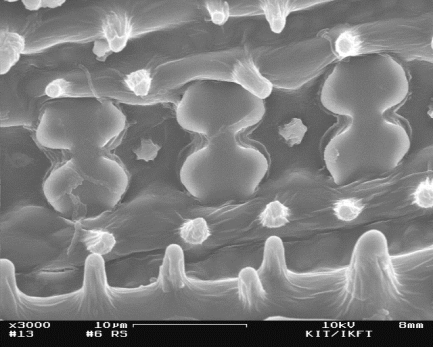

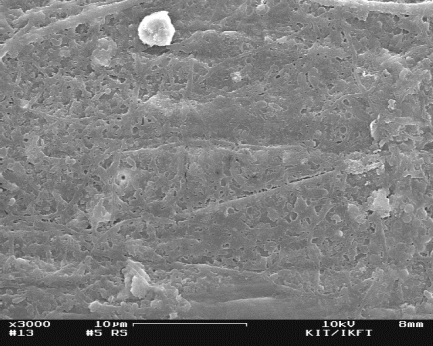

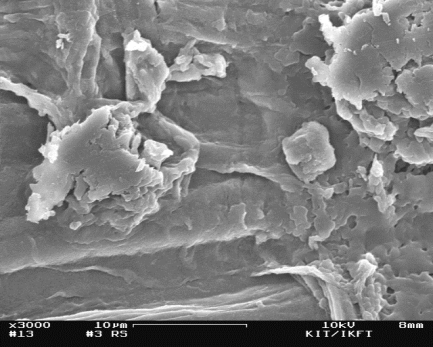

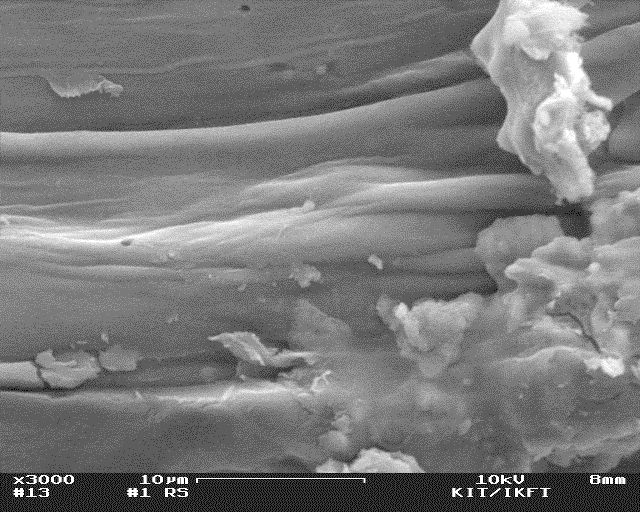

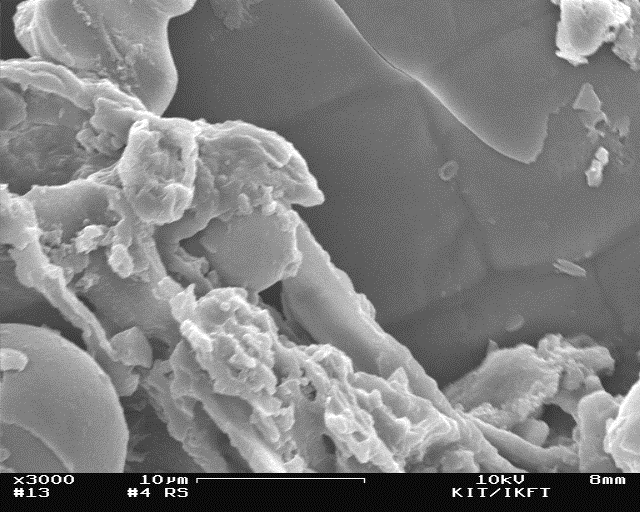

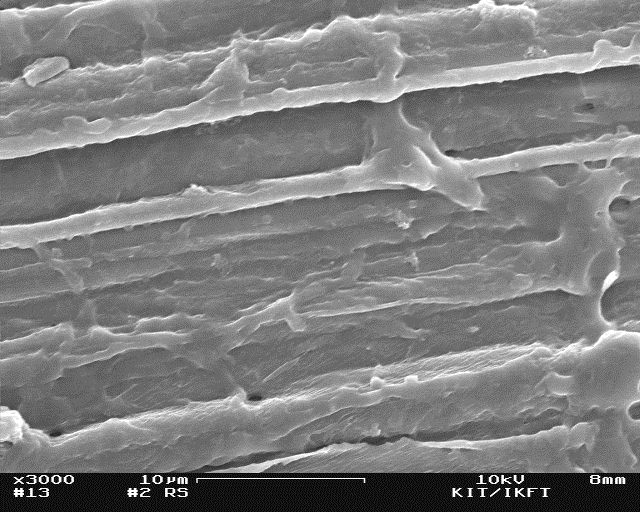

Under the scanning electron microscope observation of straw after steam explosion pretreatment, the researchers found that the fiber bundles were broken and showed a porous structure, and the fibers became fluffier and softer. The average particle size of straw after steam explosion was significantly smaller than that of the untreated biomass, which may be due to the destruction of the lignocellulosic structure of the biomass by the steam explosion pretreatment application [27]. In this destroyed structure, the enzyme can directly contact the internal site of action, very conducive to the next stage of enzyme action. According to the study, the longer the steam explosion treatment time, the smaller the aggregation, fiber and fiber fineness, and the higher the relative crystallinity of cellulose. In terms of water content, the higher the water content of the steam explosion treatment, the fluffier the fibers, the degree of cellular fragmentation and the surface of the lignin complex particles; and the lower the water content, the denser the structure. As the temperature decreases, the transferred lignin will agglomerate into clusters on the fiber; while the temperature increases, the lignin will be uniformly distributed on the fiber surface. Meanwhile, its relative crystallinity decreases with increasing temperature [28]. The experiments showed that the geometric mean particle sizes of untreated white spruce sawdust and oat straw were 0.586 mm and 0.656 mm, respectively, and the mean particle sizes of the oat straw samples after steam blasting ranged from 0.565 mm to 456 mm, whereas the corresponding values of the white spruce sawdust samples ranged from 0.512 mm to 0.389 mm [29]. Adapa et al. treated oat straw at 180°C for 4 min and found that the average particle size of the biomass decreased from 0.566 mm to about 0.367 mm [30] . In addition, Lam treated Douglas-fir wood chips by vapor explosion at 200℃ and 220℃ for 5 min and found that the average particle size decreased from 0.42 mm to 0.40 mm and 0.35 mm and 0.35 mm, respectively [29]. Low-magnification imaging of the pretreated samples showed that the higher the severity of pretreatment, the fluffier the product and the smaller the average particle size, when the steam explosion treatment was carried out under different conditions such as temperature and time [31].

Table 5. Photographs and SEM images of untreated straw and steam-exploded residue [32]

S0 is the parameter used to calculate the strength of the vapor explosion [33], is: S0 =log \( \int_{0}^{t}exp{(}\frac{T[℃]-100℃}{14.75})dt \) [34]

steam explosion strength |

epigraph |

SEM |

Untreated rice straw |

|

|

S0 = 3.05 |

|

|

S0 = 3.54 |

|

|

S0 = 4.10 |

|

|

S0 = 4.20 |

|

|

S0 = 4.32 |

|

|

S0 = 4.48 |

|

|

S0 = 5.29 |

|

|

T is the temperature and t is the time

3.2. Inhibitor generation accompanying the reaction

The steam explosion process is accompanied by the formation of degradation products called inhibitors that have an inhibitory effect on fermentation enzymolysis. Depending on the source, inhibitors can be categorized into three main groups: organic acids, furan derivatives, and phenolic compounds, as shown in Table 6. These substances interfere with the fermentation of sugars in microorganisms, and are a major impediment to the conversion of biomass to ethanol [35]. Pretreated lignocellulose contains a large number of organic acids, and these acidic small molecules can change the pH value inside and outside the cell, thus affecting cell activity and even leading to cell death [36]. Furans can inhibit the fermentation process by reducing cell growth rate and productivity. In Saccharomyces cerevisiae, furfural inhibits alcohol, aldehyde, and pyruvate dehydrogenation and thus glycolysis by inhibiting dehydrogenases [37]. Whereas, a wide variety of phenolic compounds that are formed during pretreatment have the potential to inhibit the activity of certain enzymes within the cell and inactivate pathways, such as the xylitol pathway in C. athensensis[38]. The Pseudolignin, which is hydrophobic to lignin, can bind to some of the active sites of cellulases, thus forming a spatial barrier that affects enzyme-substrate contact and inhibits lignocellulose digestion [11]. Zhang Zhang et al. investigated the potential fermentation inhibitors and their concentrations in hydrolysis products under different steam blasting conditions, and identified the inhibitors in the hydrolysis products of corn stover after steam blasting at 471 K for 8 min, and found that formic acid, acetic acid, HMF, and furfural produced by the degradation of hemicellulose in corn stover were the main compounds present in the hydrolysis products, which accounted for 82-96% of the total inhibitors. P-coumaric acid, vanillin, 4-hydroxybenzaldehyde and butyric acid constituted a very large portion of the lignin-derived compounds in the hydrolysis products, accounting for 3-14% of the total inhibitors. In contrast, p-hydroxybenzoic acid and ferulic acid were present in very small amounts in the hydrolysis products, accounting for less than 3% of the total inhibitors [39].

Table 6. Various types of inhibitors and their sources

Type of inhibitor |

name (of a thing) |

source (of information etc) |

low dosage |

acetic acid (CH3COOH) |

hemicellulose |

low dosage |

levulinic acid |

cellulose |

low dosage |

formic acid |

cellulose |

Furan derivatives |

furfural (chemistry) |

hemicellulose |

Furan derivatives |

5-Hydroxymethylfurfural |

hemicellulose |

Furan derivatives |

5-Methyl-2-furaldehyde |

hemicellulose |

phenolic compound |

phenol C6H5OH |

lignin |

phenolic compound |

2,6-Dimethoxyphenol |

lignin |

phenolic compound |

o-Methoxyphenol |

lignin |

4. The impact of steam explosion on the production process

Vapor explosion pretreatment often has a direct effect on the composition (chemical, proximate and final) of the biomass. These compositional changes tend to further affect the properties of biomass, including its density, porosity, particle size, hydrophobicity, abradability, acidity and so on. In turn, all these changes affect to some extent the subsequent process of steam blasting pretreatment, so that the straw can be converted into other bioenergy products by physical, biological, and thermochemical means. For example, carbohydrates from biomass can be hydrolyzed to sugar, fermented into liquid biofuels; densification of biomass can produce other solid fuels such as coal briquettes; through certain thermochemical means, such as combustion, pyrolysis and gasification, can produce heat and other chemical products. In production applications, the steam explosion method is used to effectively pretreat corn stover fibers, destroying the proportion of lignin in the stover and increasing the fiber bundle content. When the steam temperature is higher and the residence time is longer, the fiber will be more uniform, the surface wettability will be improved, and the quality of the fiber is improved due to the reduction of ash and phenylethanol extractives. The experimental results indicate that the fibers pretreated by steam explosion will have improved thermal stability and higher mechanical properties, which will meet the standard requirements for building materials for thermal insulation applications. In addition, there are also scholars of corn stover through the acid pre-impregnation steam explosion method to produce a weight of 80 g/m2 prototype (APSE) treatment of corn stover material (1.6 Mpa/5 min), they found that the breakage-resistant pressure strength of hand-written paper as high as 0.99 kPa m2 /g, and its strength index is close to that of waste corrugated pulp. Removal of straw structure from lignin and dissolution of hemicellulose by steam bursting technique is an economical and convenient operation process that can increase sugar yield. It has been found that the addition of a catalyst to the process enhances the hydrolysis of cellulose and improves sugar recovery. For example, when 1-8% of H2 S04 was added as a catalyst and stayed at 160-190°C for 2-10 min, the saccharification rate could be as high as 73%. When corn stover was treated with the steam explosion method (200 °C/5 min), the glucose conversion rate was as high as 91.5% compared with the traditional mechanical pulverization method. Adding dilute acid pretreatment can improve the efficiency of enzymatic hydrolysis, and the sugar yield from lignocellulosic biomass will be higher. Therefore, acid pretreatment in combination with steam blasting is a common method to obtain higher sugar yields in production. Biofuels can be extracted from biomass by thermochemical or biochemical conversion, whereas the steam blasting method can modulate the morphology, composition, and properties of the biomass to accommodate multiple conversion processes for subsequent biofuel production. Pretreatment of corn stover using steam explosion technology at 450°C was found to achieve a bio-oil yield of 51 wt% [40].

On the one hand the steam explosion method can facilitate the production of durable densification products and improve the accessibility of enzymes during enzymatic hydrolysis. At the same time, it can also improve the heat and mass transfer and reaction performance in the subsequent thermochemical conversion process. Its impact on different bioenergy conversion processes in changing the physical and chemical properties of biomass feedstocks induces changes in the structure and composition of the biomass, which improves the quality and yield of renewable fuels in solid (pellets and biochar), liquid (bioethanol and bio-oil), and gaseous (biogas and syngas) states [9]. As shown in Table 7, in the study of steam blasting corn stover, researchers found that the parenchyma cells and epidermis of the treated corn stalks were crushed and separated, and the specific surface area was significantly increased, which could accelerate the fermentation rate in the production of biogas and biofuels [40]. It can also break the bond between cellulose and lignin in corn stover by decreasing the polymerization of lignin, allowing rumen microorganisms to better attach to the cellulose, and increasing the porosity of the stover and the surface area for microbial colonization to promote further degradation of corn stover [41].

Table 7. The Impact of Explosions in the Automotive Industry on Productivity

raw materials |

steam explosion conditions |

goal |

effect |

consultation |

rice straw |

206°C 30 min |

methane CH4 |

Yield increased from 0.368 m3 N kg DM−1 to 0.542 m3 N kg DM−1 |

[32] |

wheat straw |

200°C 15 min |

glucose C6H12O6 |

Yield increased from 18.8 g/L to 41.2 g/L |

[42] |

wheat straw |

190°C 10 min |

xylose (type of sugar) |

Yield increased from 13.8 g/L to 18.9 g/L |

[42] |

rape straw |

210°C 2 min |

biochar |

Specific surface area increased by approximately 16 times |

[43] |

water hyacinth |

190°C 10 min |

ethanol |

Yield increased from 1.289 g /L to 7.13 g/L |

[44] |

wheat straw |

165°C 10 min |

methane CH4 |

Yield increased by 24-34% of the original |

[45] |

rice straw |

210°C 5 min |

glucose C6H12O6 |

Content increased from 37.8% to 53.1% |

[46] |

rice straw |

170°C 5 min |

xylan |

Content increased from 18.3% to 21.0% |

[46] |

wheat straw |

220°C 3 min |

reducing sugar |

Reducing sugar concentration reached 5.12 g/L (highest) |

[47] |

wheat straw |

220°C 3 min |

glucose C6H12O6 |

Glucose conversion rate of 86.42% (highest) |

[47] |

On the other hand, some hemicellulose and lignin are degraded during the steam blasting pretreatment process, leading to the formation of a number of inhibitory compounds that negatively affect enzymes and microorganisms, and affect the efficiency of enzymatic digestion. Although the technique of steam blasting in combination with organic acids has many advantages, blasting is an extremely energy intensive process due to the high temperatures (260℃) and high pressures (5000 kPa) usually used. In addition, it leads to thermal decomposition of sugars into fermentation inhibitors such as formic acid, furfural, and 5-hydroxymethylfurfural, which significantly reduces microbial growth activity and consequently sugar and ethanol production rates [48, 49]. In the steam explosion technique, some acids may lead to the dissolution of cellulose and hemicellulose to the point of dry matter loss as well as reduced product quality and recovery. It is difficult to further utilize the residual material by drying treatment before treating the straw biomass for recycling, so its need for better process treatments such as higher temperatures, more expensive reaction instrumentation for better biomass treatment [40].

5. Conclusion

In this review, steam explosion technology for biomass used in lignocellulosic energy processes is explored in depth, focusing on the effects of steam explosion pretreatment under different process conditions, such as the steam explosion temperature, the duration of the dimensional pressure, and the type of additives in the steam explosion. It also describes the changes in the lignocellulosic feedstock in the biomass after treatment, such as changes in the content of the components, the size of the physical structure of the particles in the straw and the inhibitors produced by the accompanying reaction. This area of research has great potential for uncovering new modes of energy development and utilization as well as mitigating the problem of global warming. Specifically, it can be used to increase the yield of fiber and glucose, bio-oil and bio-fuels such as methane and ethanol for the production of life. However, there are some limitations of this technology, the severity of high temperature and pressure can consume a lot of energy, and the inhibitors produced along with the vapor explosion reaction may hinder the enzyme-substrate contact in the subsequent process. Although experiments by many researchers have screened some of the biomass straw for better process conditions, there are still factors that influence the subsequent steps adversely after pretreatment. More in-depth investigation is still needed to solve the lignin condensed lignin, formic acid, furfural and other inhibitory factors produced by the pretreatment of lignocellulosic steam explosion, and thus continue to improve the recovery yield of biomass resources, to promote the development of this field, energy saving, and reduce pollution.

CRediT author statement

Zhuoyu Li: Conceptualization, Writing - Original Draft Xiang Cheng:Data Curation, Writing - Review & Editing

Zhuoyu Li and Cheng Xiang have the equal contribution

References

[1]. Malico, I., Nepomuceno Pereira, R., Gonçalves, A. C., & Sousa, A. M. O. (2019). Current status and future perspectives for energy production from solid biomass in the European industry. Renewable and Sustainable Energy Reviews, 112, 960-977.

[2]. Awasthi, M. K., Sarsaiya, S., Patel, A., Juneja, A., Singh, R. P., Yan, B., Awasthi, S. K., Jain, A., Liu, T., Duan, Y., et al. (2020). Refining biomass residues for sustainable energy and bio-products: An assessment of technology, its importance, and strategic applications in circular bio-economy. Renewable and Sustainable Energy Reviews, 127, 109876.

[3]. Zhou, X., & Xu, Y. (2019). Integrative process for sugarcane bagasse biorefinery to co-produce xylooligosaccharides and gluconic acid. Bioresource Technology, 282, 81-87.

[4]. Yin, X., Wei, L., Pan, X., Liu, C., Jiang, J., & Wang, K. (2021). The Pretreatment of Lignocelluloses With Green Solvent as Biorefinery Preprocess: A Minor Review. Frontiers in Plant Science, 12.

[5]. Zhou, Z., Lei, F., Li, P., & Jiang, J. (2018). Lignocellulosic biomass to biofuels and biochemicals: A comprehensive review with a focus on ethanol organosolv pretreatment technology. Biotechnology and Bioengineering, 115(11), 2683-2702.

[6]. Zhang, J., Wang, Y., Du, X., & Qu, Y. (2020). Selective removal of lignin to enhance the process of preparing fermentable sugars and platform chemicals from lignocellulosic biomass. Bioresource Technology, 303, 122846.

[7]. Zabed, H. M., Akter, S., Yun, J., Zhang, G., Awad, F. N., Qi, X., & Sahu, J. N. (2019). Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renewable and Sustainable Energy Reviews, 105, 105-128.

[8]. Chen, H., Liu, J., Chang, X., Chen, D., Xue, Y., Liu, P., Lin, H., & Han, S. (2017). A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Processing Technology, 160, 196-206.

[9]. Yu, Y., Wu, J., Ren, X., Lau, A., Rezaei, H., Takada, M., Bi, X., & Sokhansanj, S. (2022). Steam explosion of lignocellulosic biomass for multiple advanced bioenergy processes: A review. Renewable and Sustainable Energy Reviews, 154(C), S1364032121011382.

[10]. Zhang, L., Shi, L., Wang, T., et al. (2008). Conversion of wheat stalk lignocellulose during the process of steam explosion. Transactions of the CSAE, 24(10), 195-199.

[11]. Li, D., Wei, N., Zhang, H., Shen, N., Li, F., & Wu, G. (2023). Effect of high temperature hydrothermal pretreatment on lignocellulose and its enzymatic hydrolysis: A review. Renewable Energy Resources, 41(08), 1001-1007.

[12]. Zhang, Y., & Chen, H. (2012). Multiscale modeling of biomass pretreatment for optimization of steam explosion conditions. Chemical Engineering Science, 75, 177-182.

[13]. Baral, N. R., & Shah, A. (2017). Comparative techno-economic analysis of steam explosion, dilute sulfuric acid, ammonia fiber explosion and biological pretreatments of corn stover. Bioresource Technology, 232, 331-343.

[14]. Horn, S. J., Estevez, M. M., Nielsen, H. K., Linjordet, R., & Eijsink, V. G. H. (2011). Biogas production and saccharification of Salix pretreated at different steam explosion conditions. Bioresource Technology, 102(17), 7932-7936.

[15]. Vivekanand, V., Olsen, E. F., Eijsink, V. G. H., & Horn, S. J. (2013). Effect of different steam explosion conditions on methane potential and enzymatic saccharification of birch. Bioresource Technology, 127, 343-349.

[16]. Pielhop, T., Larrazábal, G. O., Studer, M. H., Brethauer, S., Seidel, C.-M., & Rudolf von Rohr, P. (2015). Lignin repolymerisation in spruce autohydrolysis pretreatment increases cellulase deactivation. Green Chemistry, 17(6), 3521-3532.

[17]. Börjesson, J., Peterson, R., & Tjerneld, F. (2007). Enhanced enzymatic conversion of softwood lignocellulose by poly(ethylene glycol) addition. Enzyme and Microbial Technology, 40(4), 754-762.

[18]. Kim, Y., Kreke, T., Ko, J. K., & Ladisch, M. R. (2015). Hydrolysis-determining substrate characteristics in liquid hot water pretreated hardwood. Biotechnology and Bioengineering, 112(4), 677-687.

[19]. Mackie, K. L., Brownell, H. H., West, K. L., & Saddler, J. N. (1985). Effect of Sulphur Dioxide and Sulphuric Acid on Steam Explosion of Aspenwood. Journal of Wood Chemistry and Technology, 5(3), 405-425.

[20]. López-Linares, J. C., Cara, C., Moya, M., Ruiz, E., Castro, E., & Romero, I. (2013). Fermentable sugar production from rapeseed straw by dilute phosphoric acid pretreatment. Industrial Crops and Products, 50, 525-531.

[21]. Chang, J., Cheng, W., Yin, Q., Zuo, R., Song, A., Zheng, Q., Wang, P., Wang, X., & Liu, J. (2012). Effect of steam explosion and microbial fermentation on cellulose and lignin degradation of corn stover. Bioresource Technology, 104, 587-592.

[22]. Shukla, A., Kumar, D., Girdhar, M., Kumar, A., Goyal, A., Malik, T., & Mohan, A. (2023). Strategies of pretreatment of feedstocks for optimized bioethanol production: distinct and integrated approaches. Biotechnology for Biofuels and Bioproducts, 16(1), 44.

[23]. Fan, X., Cheng, G., Zhang, H., Li, M., Wang, S., & Yuan, Q. (2014). Effects of acid impregnated steam explosion process on xylose recovery and enzymatic conversion of cellulose in corncob. Carbohydrate Polymers, 114, 21-26.

[24]. Gao, H., Wang, Y., Yang, Q., Peng, H., Li, Y., Zhan, D., Wei, H., Lu, H., Bakr, M. M. A., El-Sheekh, M. M., et al. (2021). Combined steam explosion and optimized green-liquor pretreatments are effective for complete saccharification to maximize bioethanol production by reducing lignocellulose recalcitrance in one-year-old bamboo. Renewable Energy, 175, 1069-1079.

[25]. Banoth, C., Sunkar, B., Tondamanati, P. R., & Bhukya, B. (2017). Improved physicochemical pretreatment and enzymatic hydrolysis of rice straw for bioethanol production by yeast fermentation. 3 Biotech, 7(5), 334.

[26]. Nasir, A., Chen, H. Z., & Wang, L. (2020). Novel Single-step Pretreatment of Steam Explosion and Choline Chloride to De-lignify Corn Stover for Enhancing Enzymatic Edibility. Process Biochemistry, 94, 273-281.

[27]. Iroba, K. L., Baik, O.-D., & Tabil, L. G. (2017). Torrefaction of biomass from municipal solid waste fractions II: Grindability characteristics, higher heating value, pelletability and moisture adsorption. Biomass and Bioenergy, 106, 8-20.

[28]. He, X., Wang, L., & Lau, A. (2020). Investigation of Steam Treatment on the Sorption Behavior of Rice Straw Pellets. Energies, 13(20), 5401.

[29]. Onyenwoke, C., Tabil, L. G., Dumonceaux, T., Cree, D., Mupondwa, E., Adapa, P., & Karunakaran, C. (2022). Investigation of Steam Explosion Pretreatment of Sawdust and Oat Straw to Improve Their Quality as Biofuel Pellets. Energies, 15(19), 7168.

[30]. Adapa, P. K., Tabil, L. G., Schoenau, G. J., Canam, T., & Dumonceaux, T. (2011). Quantitative Analysis of Lignocellulosic Components of Non-Treated and Steam Exploded Barley, Canola, Oat and Wheat Straw Using Fourier Transform Infrared Spectroscopy. Agricultural science and technology: B, 1(2), 177-188.

[31]. Auxenfans, T., Crônier, D., Chabbert, B., & Paës, G. (2017). Understanding the structural and chemical changes of plant biomass following steam explosion pretreatment. Biotechnology for Biofuels, 10(1), 36.

[32]. Steinbach, D., Wüst, D., Zielonka, S., Krümpel, J., Munder, S., Pagel, M., & Kruse, A. (2019). Steam Explosion Conditions Highly Influence the Biogas Yield of Rice Straw. Molecules, 24(19), 3492.

[33]. Overend, R., Chornet, E., & Gascoigne, J. A. (1987). Fractionation of Lignocellulosics by Steam-Aqueous Pretreatments [and Discussion]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences.

[34]. Montané, D., Overend, R. P., & Chornet, E. (1998). Kinetic models for non-homogeneous complex systems with a time-dependent rate constant. The Canadian Journal of Chemical Engineering, 76(1), 58-68.

[35]. Zheng, R., Zhang, H., Zhao, J., Lei, M., & Huang, H. (2011). Direct and simultaneous determination of representative byproducts in a lignocellulosic hydrolysate of corn stover via gas chromatography–mass spectrometry with a Deans switch. Journal of Chromatography A, 1218(31), 5319-5327.

[36]. Pampulha, M. E., & Loureiro-Dias, M. C. (1989). Combined effect of acetic acid, pH and ethanol on intracellular pH of fermenting yeast. Applied Microbiology and Biotechnology, 31(5), 547-550.

[37]. Modig, T., Lidén, G., & Taherzadeh, M. J. (2002). Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J, 363(Pt 3), 769-776.

[38]. Zhang, J., Geng, A., Yao, C., Lu, Y., & Li, Q. (2012). Effects of lignin-derived phenolic compounds on xylitol production and key enzyme activities by a xylose utilizing yeast Candida athensensis SB18. Bioresource Technology, 121, 369-378.

[39]. Zhang, Y., Wang, L., & Chen, H. (2013). Formation Kinetics of Potential Fermentation Inhibitors in a Steam Explosion Process of Corn Straw. Applied Biochemistry & Biotechnology, 169(2), 359-367.

[40]. Zhang, B., Li, H., Chen, L., Fu, T., Tang, B., Hao, Y., Li, J., Li, Z., Zhang, B., Chen, Q., et al. (2022). Recent Advances in the Bioconversion of Waste Straw Biomass with Steam Explosion Technique: A Comprehensive Review. Processes, 10(10), 1959.

[41]. Nie, D., Zhang, Z., Zhao, C., & Li, Y. (2021). Research Progress on Steam Explosion Technology in Feed Utilization of Corn Straw. China Animal Husbandry & Veterinary Medicine.

[42]. Sulzenbacher, D., Atzmüller, D., Hawe, F., Richter, M., & Cristobal-Sarramian, A., Zwirzitz, A. (2023). Optimization of steam explosion parameters for improved biotechnological use of wheat straw. Biomass Conversion and Biorefinery, 13(2), 1035-1046.

[43]. Chen, X.-J., Lin, Q.-M., Rizwan, M., Zhao, X.-R., & Li, G.-T. (2019). Steam explosion of crop straws improves the characteristics of biochar as a soil amendment. Journal of Integrative Agriculture, 18(7), 1486-1495.

[44]. Figueroa-Torres, L. A., Lizardi-Jiménez, M. A., López-Ramírez, N., Varela-Santos, E. C., Hernández-Rosas, F., Favela-Torres, E., & Hernández-Martínez, R. (2020). Saccharification of water hyacinth biomass by a combination of steam explosion with enzymatic technologies for bioethanol production. 3 Biotech, 10(10), 432.

[45]. Gaworski, M., Jabłoński, S., Pawlaczyk-Graja, I., Ziewiecki, R., Rutkowski, P., Wieczyńska, A., Gancarz, R., & Łukaszewicz, M. (2017). Enhancing biogas plant production using pig manure and corn silage by adding wheat straw processed with liquid hot water and steam explosion. Biotechnology for Biofuels, 10(1), 259.

[46]. Semwal, S., Sivagurunathan, P., Satlewal, A., Kumar, R., Gupta, R. P., Christopher, J., & Kumar, R. (2023). An Efficient and Cost- Effective Pretreatment of Rice Straw Using Steam Explosion: A Pilot Scale Experience. Waste and Biomass Valorization.

[47]. Cui, L., Liu, Z., Si, C., Hui, L., & Zhao, T. (2012). Influence of steam explosion pretreatment on the composition and structure of wheat straw. Bioresources, 7(3), 4202-4213.

[48]. Bajpai, P. (2021). Developments in Bioethanol. Green Energy and Technology.

[49]. Smichi, N., Messaoudi, Y., Allaf, K., & Gargouri, M. (2020). Steam explosion (SE) and instant controlled pressure drop (DIC) as thermo-hydro-mechanical pretreatment methods for bioethanol production. Bioprocess and Biosystems Engineering, 43(6), 945-957.

Cite this article

Li,Z.;Cheng,X. (2024). Progress in the preparation of biomass energy from steam-exploded lignocellulose. Advances in Engineering Innovation,9,47-56.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Malico, I., Nepomuceno Pereira, R., Gonçalves, A. C., & Sousa, A. M. O. (2019). Current status and future perspectives for energy production from solid biomass in the European industry. Renewable and Sustainable Energy Reviews, 112, 960-977.

[2]. Awasthi, M. K., Sarsaiya, S., Patel, A., Juneja, A., Singh, R. P., Yan, B., Awasthi, S. K., Jain, A., Liu, T., Duan, Y., et al. (2020). Refining biomass residues for sustainable energy and bio-products: An assessment of technology, its importance, and strategic applications in circular bio-economy. Renewable and Sustainable Energy Reviews, 127, 109876.

[3]. Zhou, X., & Xu, Y. (2019). Integrative process for sugarcane bagasse biorefinery to co-produce xylooligosaccharides and gluconic acid. Bioresource Technology, 282, 81-87.

[4]. Yin, X., Wei, L., Pan, X., Liu, C., Jiang, J., & Wang, K. (2021). The Pretreatment of Lignocelluloses With Green Solvent as Biorefinery Preprocess: A Minor Review. Frontiers in Plant Science, 12.

[5]. Zhou, Z., Lei, F., Li, P., & Jiang, J. (2018). Lignocellulosic biomass to biofuels and biochemicals: A comprehensive review with a focus on ethanol organosolv pretreatment technology. Biotechnology and Bioengineering, 115(11), 2683-2702.

[6]. Zhang, J., Wang, Y., Du, X., & Qu, Y. (2020). Selective removal of lignin to enhance the process of preparing fermentable sugars and platform chemicals from lignocellulosic biomass. Bioresource Technology, 303, 122846.

[7]. Zabed, H. M., Akter, S., Yun, J., Zhang, G., Awad, F. N., Qi, X., & Sahu, J. N. (2019). Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renewable and Sustainable Energy Reviews, 105, 105-128.

[8]. Chen, H., Liu, J., Chang, X., Chen, D., Xue, Y., Liu, P., Lin, H., & Han, S. (2017). A review on the pretreatment of lignocellulose for high-value chemicals. Fuel Processing Technology, 160, 196-206.

[9]. Yu, Y., Wu, J., Ren, X., Lau, A., Rezaei, H., Takada, M., Bi, X., & Sokhansanj, S. (2022). Steam explosion of lignocellulosic biomass for multiple advanced bioenergy processes: A review. Renewable and Sustainable Energy Reviews, 154(C), S1364032121011382.

[10]. Zhang, L., Shi, L., Wang, T., et al. (2008). Conversion of wheat stalk lignocellulose during the process of steam explosion. Transactions of the CSAE, 24(10), 195-199.

[11]. Li, D., Wei, N., Zhang, H., Shen, N., Li, F., & Wu, G. (2023). Effect of high temperature hydrothermal pretreatment on lignocellulose and its enzymatic hydrolysis: A review. Renewable Energy Resources, 41(08), 1001-1007.

[12]. Zhang, Y., & Chen, H. (2012). Multiscale modeling of biomass pretreatment for optimization of steam explosion conditions. Chemical Engineering Science, 75, 177-182.

[13]. Baral, N. R., & Shah, A. (2017). Comparative techno-economic analysis of steam explosion, dilute sulfuric acid, ammonia fiber explosion and biological pretreatments of corn stover. Bioresource Technology, 232, 331-343.

[14]. Horn, S. J., Estevez, M. M., Nielsen, H. K., Linjordet, R., & Eijsink, V. G. H. (2011). Biogas production and saccharification of Salix pretreated at different steam explosion conditions. Bioresource Technology, 102(17), 7932-7936.

[15]. Vivekanand, V., Olsen, E. F., Eijsink, V. G. H., & Horn, S. J. (2013). Effect of different steam explosion conditions on methane potential and enzymatic saccharification of birch. Bioresource Technology, 127, 343-349.

[16]. Pielhop, T., Larrazábal, G. O., Studer, M. H., Brethauer, S., Seidel, C.-M., & Rudolf von Rohr, P. (2015). Lignin repolymerisation in spruce autohydrolysis pretreatment increases cellulase deactivation. Green Chemistry, 17(6), 3521-3532.

[17]. Börjesson, J., Peterson, R., & Tjerneld, F. (2007). Enhanced enzymatic conversion of softwood lignocellulose by poly(ethylene glycol) addition. Enzyme and Microbial Technology, 40(4), 754-762.

[18]. Kim, Y., Kreke, T., Ko, J. K., & Ladisch, M. R. (2015). Hydrolysis-determining substrate characteristics in liquid hot water pretreated hardwood. Biotechnology and Bioengineering, 112(4), 677-687.

[19]. Mackie, K. L., Brownell, H. H., West, K. L., & Saddler, J. N. (1985). Effect of Sulphur Dioxide and Sulphuric Acid on Steam Explosion of Aspenwood. Journal of Wood Chemistry and Technology, 5(3), 405-425.

[20]. López-Linares, J. C., Cara, C., Moya, M., Ruiz, E., Castro, E., & Romero, I. (2013). Fermentable sugar production from rapeseed straw by dilute phosphoric acid pretreatment. Industrial Crops and Products, 50, 525-531.

[21]. Chang, J., Cheng, W., Yin, Q., Zuo, R., Song, A., Zheng, Q., Wang, P., Wang, X., & Liu, J. (2012). Effect of steam explosion and microbial fermentation on cellulose and lignin degradation of corn stover. Bioresource Technology, 104, 587-592.

[22]. Shukla, A., Kumar, D., Girdhar, M., Kumar, A., Goyal, A., Malik, T., & Mohan, A. (2023). Strategies of pretreatment of feedstocks for optimized bioethanol production: distinct and integrated approaches. Biotechnology for Biofuels and Bioproducts, 16(1), 44.

[23]. Fan, X., Cheng, G., Zhang, H., Li, M., Wang, S., & Yuan, Q. (2014). Effects of acid impregnated steam explosion process on xylose recovery and enzymatic conversion of cellulose in corncob. Carbohydrate Polymers, 114, 21-26.

[24]. Gao, H., Wang, Y., Yang, Q., Peng, H., Li, Y., Zhan, D., Wei, H., Lu, H., Bakr, M. M. A., El-Sheekh, M. M., et al. (2021). Combined steam explosion and optimized green-liquor pretreatments are effective for complete saccharification to maximize bioethanol production by reducing lignocellulose recalcitrance in one-year-old bamboo. Renewable Energy, 175, 1069-1079.

[25]. Banoth, C., Sunkar, B., Tondamanati, P. R., & Bhukya, B. (2017). Improved physicochemical pretreatment and enzymatic hydrolysis of rice straw for bioethanol production by yeast fermentation. 3 Biotech, 7(5), 334.

[26]. Nasir, A., Chen, H. Z., & Wang, L. (2020). Novel Single-step Pretreatment of Steam Explosion and Choline Chloride to De-lignify Corn Stover for Enhancing Enzymatic Edibility. Process Biochemistry, 94, 273-281.

[27]. Iroba, K. L., Baik, O.-D., & Tabil, L. G. (2017). Torrefaction of biomass from municipal solid waste fractions II: Grindability characteristics, higher heating value, pelletability and moisture adsorption. Biomass and Bioenergy, 106, 8-20.

[28]. He, X., Wang, L., & Lau, A. (2020). Investigation of Steam Treatment on the Sorption Behavior of Rice Straw Pellets. Energies, 13(20), 5401.

[29]. Onyenwoke, C., Tabil, L. G., Dumonceaux, T., Cree, D., Mupondwa, E., Adapa, P., & Karunakaran, C. (2022). Investigation of Steam Explosion Pretreatment of Sawdust and Oat Straw to Improve Their Quality as Biofuel Pellets. Energies, 15(19), 7168.

[30]. Adapa, P. K., Tabil, L. G., Schoenau, G. J., Canam, T., & Dumonceaux, T. (2011). Quantitative Analysis of Lignocellulosic Components of Non-Treated and Steam Exploded Barley, Canola, Oat and Wheat Straw Using Fourier Transform Infrared Spectroscopy. Agricultural science and technology: B, 1(2), 177-188.

[31]. Auxenfans, T., Crônier, D., Chabbert, B., & Paës, G. (2017). Understanding the structural and chemical changes of plant biomass following steam explosion pretreatment. Biotechnology for Biofuels, 10(1), 36.

[32]. Steinbach, D., Wüst, D., Zielonka, S., Krümpel, J., Munder, S., Pagel, M., & Kruse, A. (2019). Steam Explosion Conditions Highly Influence the Biogas Yield of Rice Straw. Molecules, 24(19), 3492.

[33]. Overend, R., Chornet, E., & Gascoigne, J. A. (1987). Fractionation of Lignocellulosics by Steam-Aqueous Pretreatments [and Discussion]. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences.

[34]. Montané, D., Overend, R. P., & Chornet, E. (1998). Kinetic models for non-homogeneous complex systems with a time-dependent rate constant. The Canadian Journal of Chemical Engineering, 76(1), 58-68.

[35]. Zheng, R., Zhang, H., Zhao, J., Lei, M., & Huang, H. (2011). Direct and simultaneous determination of representative byproducts in a lignocellulosic hydrolysate of corn stover via gas chromatography–mass spectrometry with a Deans switch. Journal of Chromatography A, 1218(31), 5319-5327.

[36]. Pampulha, M. E., & Loureiro-Dias, M. C. (1989). Combined effect of acetic acid, pH and ethanol on intracellular pH of fermenting yeast. Applied Microbiology and Biotechnology, 31(5), 547-550.

[37]. Modig, T., Lidén, G., & Taherzadeh, M. J. (2002). Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem J, 363(Pt 3), 769-776.

[38]. Zhang, J., Geng, A., Yao, C., Lu, Y., & Li, Q. (2012). Effects of lignin-derived phenolic compounds on xylitol production and key enzyme activities by a xylose utilizing yeast Candida athensensis SB18. Bioresource Technology, 121, 369-378.

[39]. Zhang, Y., Wang, L., & Chen, H. (2013). Formation Kinetics of Potential Fermentation Inhibitors in a Steam Explosion Process of Corn Straw. Applied Biochemistry & Biotechnology, 169(2), 359-367.

[40]. Zhang, B., Li, H., Chen, L., Fu, T., Tang, B., Hao, Y., Li, J., Li, Z., Zhang, B., Chen, Q., et al. (2022). Recent Advances in the Bioconversion of Waste Straw Biomass with Steam Explosion Technique: A Comprehensive Review. Processes, 10(10), 1959.

[41]. Nie, D., Zhang, Z., Zhao, C., & Li, Y. (2021). Research Progress on Steam Explosion Technology in Feed Utilization of Corn Straw. China Animal Husbandry & Veterinary Medicine.

[42]. Sulzenbacher, D., Atzmüller, D., Hawe, F., Richter, M., & Cristobal-Sarramian, A., Zwirzitz, A. (2023). Optimization of steam explosion parameters for improved biotechnological use of wheat straw. Biomass Conversion and Biorefinery, 13(2), 1035-1046.

[43]. Chen, X.-J., Lin, Q.-M., Rizwan, M., Zhao, X.-R., & Li, G.-T. (2019). Steam explosion of crop straws improves the characteristics of biochar as a soil amendment. Journal of Integrative Agriculture, 18(7), 1486-1495.

[44]. Figueroa-Torres, L. A., Lizardi-Jiménez, M. A., López-Ramírez, N., Varela-Santos, E. C., Hernández-Rosas, F., Favela-Torres, E., & Hernández-Martínez, R. (2020). Saccharification of water hyacinth biomass by a combination of steam explosion with enzymatic technologies for bioethanol production. 3 Biotech, 10(10), 432.

[45]. Gaworski, M., Jabłoński, S., Pawlaczyk-Graja, I., Ziewiecki, R., Rutkowski, P., Wieczyńska, A., Gancarz, R., & Łukaszewicz, M. (2017). Enhancing biogas plant production using pig manure and corn silage by adding wheat straw processed with liquid hot water and steam explosion. Biotechnology for Biofuels, 10(1), 259.

[46]. Semwal, S., Sivagurunathan, P., Satlewal, A., Kumar, R., Gupta, R. P., Christopher, J., & Kumar, R. (2023). An Efficient and Cost- Effective Pretreatment of Rice Straw Using Steam Explosion: A Pilot Scale Experience. Waste and Biomass Valorization.

[47]. Cui, L., Liu, Z., Si, C., Hui, L., & Zhao, T. (2012). Influence of steam explosion pretreatment on the composition and structure of wheat straw. Bioresources, 7(3), 4202-4213.

[48]. Bajpai, P. (2021). Developments in Bioethanol. Green Energy and Technology.

[49]. Smichi, N., Messaoudi, Y., Allaf, K., & Gargouri, M. (2020). Steam explosion (SE) and instant controlled pressure drop (DIC) as thermo-hydro-mechanical pretreatment methods for bioethanol production. Bioprocess and Biosystems Engineering, 43(6), 945-957.