1. Introduction

In the new era, new energy vehicles are developing rapidly, with companies such as Tesla, BYD, Xiaomi, etc. breaking through the encirclement and occupying a large proportion in the market. New energy vehicles are beginning to usher in greater development opportunities. To further improve new energy vehicles, it is necessary to explore key technologies for their power batteries, solve related problems in the application and recycling of power batteries, and maintain a good development trend.

2. Overview of power batteries for new energy vehicles

The power battery is the power source of new energy vehicles and an indispensable component for ensuring their stable and long-term operation. It also exhibits differential effects in different types of new energy vehicles, such as fuel hybrid new energy vehicles, which show good performance advantages in fuel economy and reducing exhaust emissions [1]. When evaluating power batteries, their performance should be evaluated from different aspects, including but not limited to: environmental friendliness, self discharge rate, reliability and stability, lifespan, power utilization density, economy, etc. The performance advantages and disadvantages of various types of power batteries should be analyzed in conjunction with Table 1. Based on the data in Table 1, the following conclusion can be drawn: compared with other types of batteries, lithium-ion vehicle power batteries have better comprehensive performance, manifested in environmentally friendly application, high power, ability to achieve cyclic charging, and long service life. Therefore, it is recommended that future research directions for new energy vehicle power batteries should be determined, and in-depth exploration should be carried out to maximize the efficiency of power batteries.

Table 1. Comparison of performance parameters of various batteries

Performance parameter | Lithium ion power battery | Ni-MH | Nickel-cadmium battery | Lead acid battery |

Specific energy (W · h/Kg) | 500 | 70~80 | 45~65 | 35~45 |

Specific power (W/kg) | 315 | 160~235 | ≥190 | 60 |

Volume specific energy (W · h/L) | 210-300 | 70~170 | 140 | 70 |

Unit voltage (V) | 3.7 | 1.2 | 1.2 | 2 |

Working temperature (℃) | -10~60 | 10~50 | -20~50 | -20~45 |

Monthly self discharge rate (%) | 0-4 | 30~35 | 20~30 | 3.5~5 |

Cycle life (times) | ≥2000 | ≥500 | 300-700 | 200-300 |

Memory effect | little or no | not have | have | not have |

Advantage | High number of cycles; small self discharge | Good safety performance; high stability | Good high rate discharge performance | Low price; wide adaptability |

Disadvantage | High cost | Low energy density and charging efficiency | Occupying up space and having a large battery weight | Short cycle life and severe environmental pollution |

3. Research status of power batteries for 3 new energy vehicles

As a product of the modern era, power batteries have gradually achieved widespread application in the field of new energy. However, further exploration is still needed in the automotive industry, and there is significant room for improvement in related technologies. A relatively complete development system has not yet been formed. Analyze the main aspects of the current development of new energy vehicles, including power performance, economy, and driving range, among which power issues to some extent determine the car's climbing ability, acceleration ability, top speed, etc. [2]. Therefore, it is necessary to combine the overall architecture of new energy vehicles with suitable power batteries, including nickel cadmium batteries, nickel hydrogen batteries, etc. Currently, there are still many problems with power batteries, manifested in battery pack matching, charging, environmental protection, and other aspects, which need to be flexibly solved by adopting relevant technologies.

4. Development paths of key technologies for new energy vehicle power batteries

Based on the current research status of power batteries for new energy vehicles, explore their key technologies, grasp their basic development path, determine their key development points, and lay a solid foundation for the development of new energy vehicles.

4.1. Performance testing technology for power batteries

Using power battery performance testing technology to clarify battery performance characteristics, in order to ensure that the battery meets application standards, pay attention to the following points:

4.1.1. Determine performance testing targets

Power batteries convert electrical energy through electrochemical reactions between positive and negative electrodes. When testing their performance, the main focus is on battery capacity, which refers to the ability of the battery to store electrical energy; Voltage, used to reflect the potential difference of the battery; Internal resistance to a certain extent determines the energy transfer efficiency of the battery; Cycle life, indicating battery stability and lifespan; Temperature has an impact on battery safety and working condition.

4.1.2. Test device design

• Maintain the safety of the testing equipment and install safety devices such as electrical isolation, explosion prevention, fire prevention, etc; The performance of power batteries is affected by voltage, current, temperature, etc. Therefore, the testing device should be able to maintain a stable and controllable working environment, strictly control parameters such as voltage, current, temperature, etc., keep them within safe thresholds, and obtain reproducible and accurate test results [3].

• When designing testing equipment, reference should be made to corresponding specifications and standards to ensure that the design architecture of the testing equipment meets industry and national requirements, including testing parameters, testing environment, testing methods, etc., in order to improve the accuracy and comparability of testing results; Considering the simplicity and ease of operation of the testing device, simplifying the testing process, and providing a broader space and platform for daily maintenance and repair.

4.1.3. Selection and calibration of testing instruments

The specifications and types of the selected testing instruments should meet basic testing requirements, including the following: BT-3561A Capacity Tester, LCR Resistance Tester, FL601 Temperature Control Device, etc.; All types of testing instruments should highlight characteristics such as reliability, high stability, and high precision, and be able to provide relatively accurate and rich testing data. Technical personnel should be arranged to conduct experimental verification and trial operation before formal use, in order to avoid failure problems during formal testing and affect the progress of normal testing.

4.1.4. Choose multiple testing methods

With the support of testing instruments, choose multiple testing methods to improve detection performance, including:

• Dynamic characteristic testing method: objectively evaluate the dynamic performance of the battery under differentiated working conditions and loads. The testing items include power output testing, charging characteristic testing, discharging characteristic testing, etc. In the testing, simulate the application scenario of the battery, determine whether there are any abnormal problems, and evaluate its performance in energy efficiency, power transmission, response speed, etc. [4].

• Temperature characteristic testing method: Evaluate the performance of batteries in differentiated temperature environments, including temperature limit testing, constant temperature testing, cycle testing, etc., in order to comprehensively evaluate the role of batteries in thermal management, thermal stability, and clarify the overall characteristics of the battery. To ensure controllable and accurate testing, temperature control equipment can be introduced to record the temperature changes of the battery at each stage, presented in the form of charts. For example, when a lithium battery loses thermal control, its temperature changes are shown in Table 2.

• Life cycle testing method: Evaluate the performance degradation law of batteries during repetitive charge and discharge cycles, simulate the process of charge and discharge cycles in virtual reality, reduce interference from other factors, evaluate the battery cycle life and lifespan, record the number of test cycles, eliminate data that is not of reference value, clarify capacity degradation, and analyze the test results based on this.

Table 2. Battery temperature change table

Serial Number | Stage | Temperature/℃ |

1 | High temperature induced stage | 60-100 |

2 | Thermal runaway development stage | 100-150 |

3 | Explosive stage | >150 |

4.1.5. Test control and data acquisition

Prepare BT-3561A precision digital multimeter, LCR data acquisition system, Huber Ministat 125 LabVIEW software to support data acquisition and control process, collect changes in various parameters during testing, and verify the accuracy of test results using multiple devices.

4.2. Matching technology for power battery pack

Considering the various problems in the matching technology of new energy vehicle power battery packs, the application process of this technology should be optimized to maximize its effectiveness. The key is:

4.2.1. Topology optimization of power battery system

Achieving topology optimization can effectively improve battery utilization and new energy vehicle performance, starting from the following two points:

• Following the design standards of "standardization and modularization", individual batteries are combined into several standardized module units, and the module voltage, power characteristics, capacity, etc. are designed in a consistent and predictable pattern to simplify the overall assembly process of the battery pack and provide convenience for subsequent maintenance and upkeep. In addition, the modular layout method leverages its topology advantages by directly replacing faulty units in the event of battery performance failures, thereby reducing maintenance costs, expenses, and enhancing the flexibility of the battery pack. The modular structure is also conducive to redundant design, ensuring the safety and reliability of the battery system, and has a wide applicability, which can be directly introduced into other vehicle models [5].

• Battery management system integration: Utilizing an intelligent battery management system to monitor and display battery status, such as temperature, current, voltage, etc., automatically adjust the charging and discharging process of the battery at different stages, balance the status between individual batteries, and increase service life.

4.2.2. Optimization of battery pack state estimation algorithm

• Selecting appropriate model algorithms: Based on the overall structure of the battery pack, select appropriate battery modules such as support vector machine models, neural network models, equivalent circuit models, etc., and use these advanced models to accurately describe the battery's action process, life characteristics, dynamic response, electrochemical features, etc., ensuring stable and accurate state estimation, reflecting the battery state, and steadily improving battery management effectiveness [6].

• Perform parameter identification and select calibration mode: Adjust the battery pack state estimation algorithm, use professional techniques to accurately identify and calibrate the battery model parameters, such as adaptive filtering algorithms, optimization algorithms, and other parameter identification techniques. Then integrate the measured data generated in each stage, input the battery parameters into the model, ensure the reliability of the state estimation process, and obtain relatively accurate detection results.

4.3. Power battery charging technology

4.3.1. Constant current and constant voltage charging technology

During the charging process, the voltage and current are kept constant, and the charging ends when the preset state of charge and cut-off voltage are reached. For example, when charging a lithium iron phosphate battery, when the voltage of a single battery is less than 3.2V, it is charged in a constant current manner, and when the voltage of a single battery reaches 3.2V, it is converted to constant voltage charging to improve charging safety.

When charging, attention should also be paid to the impact from the following aspects:

• Maximum acceptable current: In the face of excessive charging current, lithium ions directly combine with electrons to exert their effect, reducing and forming dendritic metallic lithium on the negative electrode surface of the battery cell. The continuous growth of lithium dendrites will cause electrolyte and electrode fluctuations during battery cycling, resulting in continuous loss of electrolyte and irreversible precipitation of metallic lithium, affecting the coulombic efficiency of the battery. In addition, lithium dendrites may puncture the separator, causing a short circuit in the power battery, and in severe cases, leading to thermal runaway of the battery and causing combustion and explosion of new energy vehicles [7].

• Temperature: The charging characteristics of batteries are greatly affected by temperature, especially in low-temperature environments, where the number of lithium ions participating in the reaction decreases, the electrochemical reaction rate decreases, the charging internal resistance increases, the charging capacity decreases, and in severe cases, lithium dendrites and battery short circuits may occur. Therefore, the lithium battery should be heated to a suitable temperature before charging to avoid uncontrolled charging.

4.3.2. Wireless charging technology

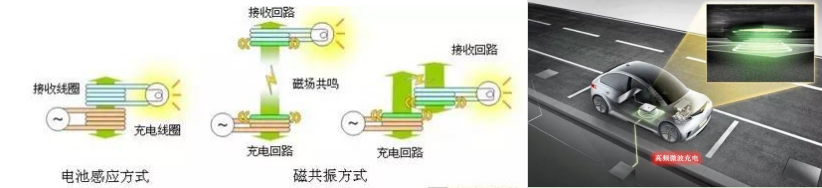

Wireless charging technology refers to the use of wireless energy transmission devices buried underground in parking spaces to transmit electrical energy to wireless energy reception devices under the chassis of new energy vehicles, including three charging modes, as shown in Figure 1 for detailed analysis:

• Electromagnetic induction charging: The charging coil forms an alternating magnetic field through alternating current, which induces an electromotive force in the receiving coil and outputs current to the new energy vehicle. The transmission distance is up to 1.2m, with high efficiency and simple structure, suitable for static wireless charging.

• Magnetic resonance charging: The magnetic resonance between the charging device and the receiving device increases the current transmission distance and reduces impedance, with a transmission distance of up to several meters. It does not require precise docking and can achieve synchronous charging of multiple cars [8].

• High frequency microwave charging: using high-frequency microwaves to transmit electrical energy, with a transmission distance of up to several meters. Although the transmission distance is long, it will also consume more electrical energy.

Figure 1. Wireless charging technology diagram

4.3.3. Battery swapping technology

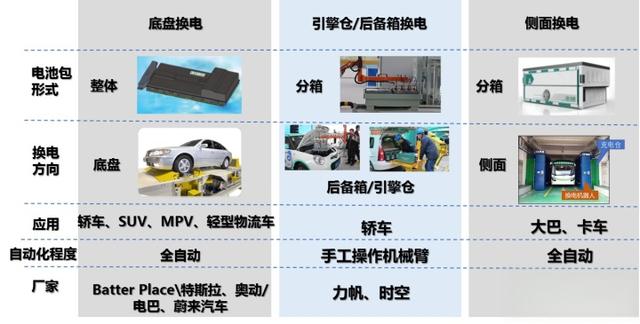

Battery swapping technology includes the method shown in Figure 2 for detailed analysis:

• Chassis Battery Replacement: Disassemble the power battery from the lower part of the car chassis and replace it with a new battery pack. It is commonly used in light vehicles such as MPVs, SUVs, and sedans, such as Tesla, NIO, and BAIC. This method has a high degree of intelligence and short battery replacement time, but requires the construction of a battery replacement station, which requires high investment.

• Front/rear battery replacement: Open the trunk or front hood, remove the old battery, and replace it with a new power battery. It is commonly used in the sedan field, such as Time Space Electric, Lifan, etc. It does not require the construction of a battery replacement device and can be manually operated by a robotic arm to complete the battery replacement operation. The cost is low, but it requires two people to operate, resulting in low efficiency [9].

• Side panel battery replacement: Remove the battery pack from the side panel and replace it with a new power battery, which is commonly used in electric trucks and buses. Although the battery layout is relatively reasonable, it needs to be opened on the side panel, which reduces the appearance of the vehicle.

Figure 2. Battery swapping technology diagram

4.4. Thermal management technology for power batteries

When new energy vehicles run for a long time, the battery temperature will continue to rise. When the temperature exceeds 40 ℃, the chemical substances in the battery will become more active, undergo strong electrochemical reactions, consume more electrolyte, and cause metal accumulation, which will damage the overall uniformity of the battery module. Introduce thermal management technology to solve such problems, and adopt the following methods to address them:

4.4.1. Air cooling technology

• Leave ventilation ducts inside the power battery. If the requirements for heat dissipation and cooling performance are low, air can be transported to the battery module through a blower to reduce the battery temperature; If there is a high demand for heat dissipation, use an air conditioning system to cool the ambient air and deliver low-temperature air to the inside of the battery module to improve the cooling effect.

• Air cooling channel structure layout: Comparing and analyzing the application effects of "Z" - shaped and "U" - shaped channel structures, the shape of the channel will affect the uniformity of battery temperature. According to the "Z" - shaped structure layout, air can be inserted and evenly circulated between different battery cells, thereby inserting ripples between the cooling plates of the battery pack, maintaining uniform air flow on the battery surface, and improving the cooling efficiency of the channel.

4.4.2. Indirect liquid cooling technology

Compared with air cooling technology, liquid cooling technology has higher specific heat capacity and heat transfer efficiency. To maximize the efficiency of liquid cooling technology, suitable cooling liquids such as water, oil (silicone oil, white oil, mineral oil), alcohols (propylene glycol, ethylene glycol, ethanol), etc. Although water is cheap and has high heat transfer efficiency, it has a high freezing point and strong corrosiveness, which is not conducive to large-scale applications. Propylene glycol is low toxicity but can corrode aluminum materials. Other types of cooling liquids have various defects and deficiencies. The final choice is the ethylene glycol aqueous solution, which has advantages in all aspects and is composed of ethylene glycol, ionized water, additives, etc. Although the dosage of additives is ≤ 5%, their effects cannot be ignored, including:

• Corrosion inhibitor: used to prevent metal corrosion perforation of liquid cooled plates and reduce coolant loss. There are two types: organic and inorganic. The former has the advantages of low conductivity and low environmental pollution. Commonly used ones include aromatic acid salts, p-chlorobenzoic acid, hydroxybenzoic acid, etc; The latter mainly promotes metal oxidation to form a protective film on the surface of liquid cooled plates, commonly including molybdates, nitrites, silicates, etc., which can be selected as needed [10].

• Defoamer: It is used to reduce the foam tendency, reduce corrosion and improve the heat dissipation effect when the coolant is recycled. Common defoamers include silicone, polyether and non silicone. Organic silicone defoamers have high activity and low solubility in oil and water, highlighting their strong defoaming ability, stable chemical properties, non toxicity, and low volatility; Polyether defoamers have high temperature resistance and strong foam inhibition ability, but their low toxicity and low foam breaking rate affect their sustainable use; Non silicone defoamers, commonly used including fatty acid esters, alcohols, etc., have low cost and easy production, but their applicability is poor and their defoaming efficiency needs to be improved.

4.4.3. Direct contact liquid cooling technology

Direct contact liquid cooling technology also known as submerged liquid cooling technology, immerses the heating period directly in the coolant and reduces heat through the circulation of the coolant, including two forms of cooling:

• Two phase liquid cooling form: The cooling liquid reduces heat due to phase change vaporization during circulation, and when the gaseous cooling liquid enters the relevant equipment, it will be converted into liquid form due to condensation, resulting in high heat dissipation efficiency. Subsequently, there will be escape when converted into gas, so its container should be sealed.

• Single phase liquid cooling mode: In this mode, there is no phase change when the coolant continues to circulate and dissipate heat. The coolant cools down again after heating up and flowing to other locations, achieving closed-loop circulation. Compared to the above forms, this mode has higher requirements for the boiling point of the coolant, but does not require repeated replacement or replenishment of the coolant. It can be stored in a regular container, but the heat dissipation efficiency is relatively low and needs attention.

4.5. Power battery system control technology

The power battery system consists of a battery pack, battery management system, battery module, etc. It controls the battery system to enhance the safety and reliability of the power battery. Pay attention to the following points:

4.5.1. Application of Power Battery Control Algorithm

Using modeling to control the overall state of the power battery, increase battery life, and improve utilization rate. The algorithm operates according to the following process: using monitoring equipment and sensors to collect various data in the battery system online, such as SOC, temperature, voltage, current, etc. Based on this, a mathematical model of the battery is built, covering battery power characteristics, corresponding characteristics, internal conditions, and other information. State estimation algorithms are introduced to control the battery state, such as health status, SOC status, etc. Combining with battery optimization goals and specific requirements, the algorithm application process is determined; Analyze the application conditions of various algorithms such as genetic algorithm, model predictive control, dynamic programming, etc., consider influencing factors such as temperature conditions, power standards, capacitor capacity, etc., and select the optimal battery operation plan. Using optimization algorithms to obtain operational strategies, integrating them into the battery management system, and combining the algorithm output results to achieve rational allocation of power, voltage, charging and discharging current, etc., to achieve optimal control effects.

4.5.2. Charge and discharge power management technology

• Power allocation technology: Based on the status and operational requirements of new energy batteries, the charging and discharging power allocation ratio is set to guide the charging and discharging process. During charging, the charging power is strictly controlled to prevent overcharging from affecting the lifespan of the power battery; When discharging, the discharge power is set based on the available power of the power battery, power operation requirements, etc., to support the normal and stable operation of the vehicle.

• Peak power management technology: When new energy vehicles need to output a certain instantaneous high power, strictly control the peak power output value of the battery, adjust the temperature control device, strictly control the discharge speed, provide a good operating environment, and ensure that the battery pack provides corresponding support when facing high power demands to prevent various unpredictable problems caused by power overload.

• Power balance technology: For systems composed of multiple battery cells or modules, balance management is carried out to achieve temperature balance and charge state balance among different modules in the power battery system, in order to prevent damage to battery life caused by thermal imbalance, capacity differences, and other factors.

4.6. Pollution control technologies

4.6.1. Waste gas treatment technology

• Organic waste gas compression: Install a gas collection hood on the compression device, and then combine it with an exhaust pipe and a secondary activated carbon adsorption device to collect the waste gas.

• Alkali washing tower treatment: used to remove and separate fluorides from gases, converting them into harmless gases.

• Activated carbon adsorption: It can treat exhaust gas through porous solid adsorbents, utilizing molecular gravity, chemical bonding forces, etc. to adsorb harmful gases. It is suitable for the treatment of exhaust gas at room temperature, without viscous substances, low concentration, and high air volume.

• Combustion method: including catalytic combustion, thermal combustion, and direct combustion, which converts harmful substances in exhaust gas into direct emissions such as water vapor and carbon dioxide.

• Condensation method: Based on the different properties of organic waste gas and other saturated vapor pressures at different temperatures, volatile organic compounds that are easy to condense and separate are separated.

4.6.2. Power battery recycling technology

• Disassembly and sorting: Using professional equipment to disassemble and sort various types of power batteries, separating them from other components, and then classifying them based on battery type, structure, status, etc.

• Material recycling: After dismantling, various materials such as cobalt, manganese, nickel and other metals are recycled for the production of recycled materials; Recycling organic solvents and electrolytes to achieve harmless treatment.

• Reuse: Combining the characteristics of recycled materials to produce new power batteries and other products, alleviating raw material pressure and reducing negative environmental impact.

• Attention: When recycling batteries, pay attention to safety, avoid battery short circuits, fire accidents, etc., and recycle them after professional training to improve the recycling rate; Comply with relevant national policies, laws and regulations, involving obtaining licenses, hazardous waste disposal, and other aspects; Resource depletion refers to the loss of corresponding amounts of water and energy resources when recycling power batteries, and energy-saving measures should be taken.

5. Conclusion

In summary, the article comprehensively discusses and analyzes the key technologies of new energy vehicle power batteries. The various technical points proposed above have great feasibility and effectiveness in implementation. However, when introducing them into the development process, it is necessary to combine the application characteristics and development needs of different technologies, and adjust and optimize the application of relevant technologies based on the basic situation of new energy vehicles, so as to maximize their efficiency. In addition, it is necessary to correctly predict the development trend of new energy vehicles, pay attention to the advantages and disadvantages of different technological applications, and start from various aspects such as the basic architecture, market competition, and manufacturer production capacity of new energy vehicles to determine the direction of technological development and improve development efficiency.

References

[1]. Chen, Y. H., & He, L. J. (2023). Analysis of Thermal Management Technology for Power Batteries in New Energy Vehicles. Times Automotive, (19), 76-78.

[2]. Zhang, R. (2023). Research on Fault Diagnosis and Maintenance Technology of New Energy Vehicle Power Battery. Automotive Test Report, (5), 55-57.

[3]. Wang, Y. D. (2023). Challenges and Development Trends of Safety Management Technology for Power Batteries in New Energy Vehicles. Automotive and New Power, (5), 61-64.

[4]. Li, Z. Y., & Liu, T. Y. (2023). Exploration of Thermal Management Technology for Power Batteries in New Energy Vehicles. Automotive Test Report, (16), 38-40.

[5]. Li, Z. Y., & Liu, T. Y. (2023). Research on Cooling Technology of New Energy Vehicle Power Battery. Science and Innovation, (22), 34-36.

[6]. Fu, S. C. (2023). Research on Optimization of Temperature Control Technology for Power Batteries in New Energy Vehicles. Automotive Test Report, (11), 85-87.

[7]. Wang, Z. W. (2023). Research on Control Technology of Power Battery System for New Energy Vehicles. Automotive Maintenance Technician, (8), 117-118.

[8]. Wei, X. F., Lin, S., Zhu, K. B., & Yang, G. Z. (2023). Overview of Air Cooling Technology for Power Batteries in New Energy Vehicles. Volkswagen, (7), 145-147.

[9]. Wu, Q. F. (2023). Research on Optimization of Matching Technology for New Energy Vehicle Power Battery Pack. Automotive Test Report, (20), 61-63.

[10]. Gao, D. B., Ke, Y. W., & Mo, S. H. (2023). Research on Comprehensive Testing Technology for Power Batteries of New Energy Vehicles. Automotive Testing Report, (8), 43-45.

Cite this article

Zhang,J.;Zhou,T.;Xin,Z.;Cheng,C.;Wang,L.;Xi,L.;Yi,X. (2025). Analysis of key technologies for power batteries in new energy vehicles. Advances in Engineering Innovation,16(4),75-82.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Chen, Y. H., & He, L. J. (2023). Analysis of Thermal Management Technology for Power Batteries in New Energy Vehicles. Times Automotive, (19), 76-78.

[2]. Zhang, R. (2023). Research on Fault Diagnosis and Maintenance Technology of New Energy Vehicle Power Battery. Automotive Test Report, (5), 55-57.

[3]. Wang, Y. D. (2023). Challenges and Development Trends of Safety Management Technology for Power Batteries in New Energy Vehicles. Automotive and New Power, (5), 61-64.

[4]. Li, Z. Y., & Liu, T. Y. (2023). Exploration of Thermal Management Technology for Power Batteries in New Energy Vehicles. Automotive Test Report, (16), 38-40.

[5]. Li, Z. Y., & Liu, T. Y. (2023). Research on Cooling Technology of New Energy Vehicle Power Battery. Science and Innovation, (22), 34-36.

[6]. Fu, S. C. (2023). Research on Optimization of Temperature Control Technology for Power Batteries in New Energy Vehicles. Automotive Test Report, (11), 85-87.

[7]. Wang, Z. W. (2023). Research on Control Technology of Power Battery System for New Energy Vehicles. Automotive Maintenance Technician, (8), 117-118.

[8]. Wei, X. F., Lin, S., Zhu, K. B., & Yang, G. Z. (2023). Overview of Air Cooling Technology for Power Batteries in New Energy Vehicles. Volkswagen, (7), 145-147.

[9]. Wu, Q. F. (2023). Research on Optimization of Matching Technology for New Energy Vehicle Power Battery Pack. Automotive Test Report, (20), 61-63.

[10]. Gao, D. B., Ke, Y. W., & Mo, S. H. (2023). Research on Comprehensive Testing Technology for Power Batteries of New Energy Vehicles. Automotive Testing Report, (8), 43-45.