1. Introduction

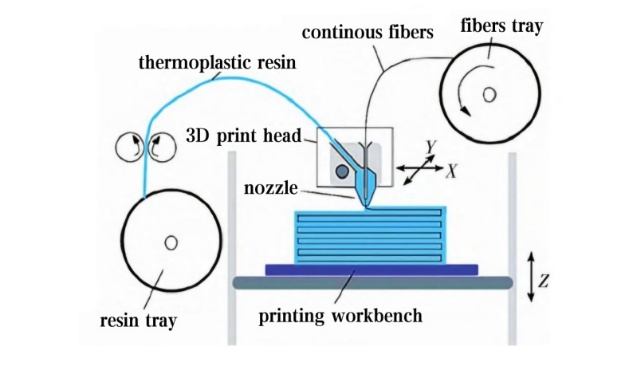

Continuous carbon fiber reinforced composites are advanced materials with unique benefits that make them stand out in applications where high performance and lightweight are required. Not only does it provide high strength and rigidity so that items are less likely to be deformed or damaged, but it is also abrasion- and temperature-resistant and able to maintain stable performance under extreme conditions. In addition, the lightweight properties of continuous carbon fiber reinforced composites make them ideal for aerospace, automotive, and other fields where mass reduction is required [1-3]. Additive manufacturing technology, also known as 3D printing technology, is a layer-by-layer printing technology based on digital files of a three-dimensional model using an adhesively bondable joining material such as metals or plastics [4-5]. The use of 3D printing technology has revolutionized the preparation of continuous carbon fiber reinforced composites. This technology dramatically improves preparation efficiency, reduces production costs, achieves high material utilization, and reduces waste [4]. Through 3D printing technology, continuous carbon fiber reinforced composites of various shapes and sizes can be flexibly produced to meet the needs of different applications. The application potential of this technology is enormous and opens a new path for developing continuous carbon fiber-reinforced composites. Fused deposition molding (FDM) is currently the most widely used process for preparing continuous fiber-reinforced composites, and the method is characterized by low cost, fast printing speed, and a wide range of wire options [6]. The printing process is mainly for the matrix resin wire, and continuous fibers are introduced into the print head; the resin is melted in the heated cavity inside the head to impregnate the continuous fibers, and then the resin and continuous fibers are extruded from the nozzle to achieve layer-by-layer printing, and then the continuous fiber reinforced parts are obtained after cooling [7].

The base resin materials commonly used for 3D printing of continuous carbon fiber reinforced composites are thermoplastic resins. However, not all thermoplastic resins meet the printing requirements. Widely used thermoplastic resins include polylactic acid (PLA), nylon (PA), and polyether ether ketone (PEEK). Moreover, continuous carbon fiber reinforced composites exhibit excellent mechanical properties, significantly improving over pure resin materials.

In thermoplastic technology and 3D printing, there have been many related research and applications at home and abroad. For example, Markforged in the United States launched a Mark Two printer [8]; the device can combine carbon fiber, glass fiber, and other continuous fibers during 3D printing. This technology is widely used in aerospace, automotive manufacturing, medical equipment, and other fields, as well as in the composite application of thermoplastic resin and continuous fiber. Impossible Objects developed the CBAM (Composite Additive Manufacturing) technology [9], which combines continuous fibers with thermoplastic materials for the large-scale production of high-performance composites, especially for lightweight and high-strength industrial components. Stratasys offers FDM (Fused Deposition Modeling) and FDM Carbon Fiber technology [10], which are mainly used in the aerospace and automobile industries. In China, Zhejiang University has conducted thorough research on 3D printing technology of continuous fiber reinforced composite, a specially developed 3D printing method with high performance by combining thermoplastic materials, carbon fiber, and glass fiber. The research team of Huazhong University of Science and Technology has carried out a lot of experimental work in this field, mainly studying the mechanical properties, heat treatment process, and printing quality control of continuous fiber-reinforced composites. Changchun University of Science and Technology focuses on the application research of 3D printing technology for carbon fiber composites. It has made significant progress in the components' strength, stiffness, and weight control. Markforged, the technologies developed by Impossible Objects and other commercial companies have been well used in 3D printing of composite materials, but. However, the printed composite materials have low fiber content and high resin content, and there is little research on 3D printed continuous fiber reinforced thermoplastic composites with high fiber content. To fill this gap, this paper studies the printing process and performance of continuous fiber 3D printing composite corrugated sandwich structures, aiming to understand their behavior and manufacturing optimization deeply.

Lightweight sandwich structure is currently the most widely used energy-absorbing protective structure in engineering protection, which is usually composed of two high-strength panels above and below and a lightweight core layer in the middle, the composition of which gives the structure high specific strength, high specific stiffness, and excellent energy-absorbing properties [11, 12], which make the lightweight sandwich structure effectively reduce the deformation and deflection when it is subjected to an impact load [13]. In addition, compared to solid panels of the same mass, lightweight sandwich structures exhibit superior blast and impact resistance [14].Therefore, lightweight sandwich structures are widely used in naval ships [15, 16], transportation [17, 18], aerospace and structural engineering protection [19].

Corrugated sandwich structures can be designed in various geometrical shapes such as triangular, trapezoidal, sinusoidal, and hexagonal honeycomb shapes. Among them, carbon fiber trapezoidal corrugated sandwich structures excel in static performance with high specific strength, lightweight, fatigue resistance, vibration and noise reduction, and corrosion resistance [20], and their fatigue resistance accounts for about 80% of their static tensile strength, whereas the fatigue resistance of general metallic materials only accounts for about 50% of their static tensile strength. At the same time, these corrugated sandwich structures have superior vibration-damping capabilities and bending resistance and are used in integrated protection systems for aerospace and ocean engineering. For example, the sandwich structures involved in aerospace use corrugated laminated core sandwich panel structures, which are mainly used to make spacecraft hulls, but also in areas such as high-speed train floors.

The main objective of this study is to design and fabricate 3D-printed continuous fiber-reinforced corrugated sandwich structures and to study their performance in complex mechanical environments in depth, especially optimizing the printing process. Specifically, the research will focus on the optimal 3D printing process applicable to continuous carbon fiber-reinforced thermoplastic composite corrugated sandwich structures and investigate their compressive mechanical properties through theoretical analysis and experimental testing. The research results are expected to provide theoretical support and technical guidance for the optimization of these structures in the aerospace sector.

2. 3D printing continuous fiber reinforced thermoplastic composites corrugated sandwich structure principles and experimental designs

2.1. Experimental materials

In this thesis, a composite material combining continuous dry fibers and thermoplastic resin is selected as the experimental material. This high-performance material shows apparent advantages in being lightweight, strong, and durable.

The main difference between continuous fiber-reinforced thermoplastic composites and traditional thermoplastic composites is that the fibers in the former are constant in the whole material system. In contrast, the fibers in the latter are discontinuous, so the mechanical properties of continuous fiber-reinforced thermoplastic composites are superior to those of non-continuous fiber-reinforced thermoplastic composites. The tensile strength and modulus are excellent, and the rigidity of the composites improved, while the thermoplastic resin, as the matrix material, not only possesses exceptional toughness and processability but also strengthens the interfacial bonding between the fibers and the resin, which comprehensively optimizes the mechanical properties of the materials [21]. In addition, this composite material has good fatigue resistance and impact resistance. It can maintain long-term stability in complex mechanical environments, adapting to high-intensity working conditions and repetitive load demand. Compared to traditional short fiber or particle-reinforced composites, the monolithic nature of the continuous fibers makes this material more reliable and durable under high loading conditions, which meets the more demanding application requirements [22].

2.2. Experimental principles

The real-time impregnation process is an innovative manufacturing method that combines continuous dry fibers (the full name is "continuous carbon fiber reinforced nylon composite prepreg") with thermoplastic resins precisely controlled for efficient composite production, as shown in Figure 1. There are three common types of impregnation of continuous fiber-reinforced thermoplastic composites including melt impregnation, solution impregnation, and powder impregnation. Among them, melt impregnation is a method of impregnating fiber bundles or fabrics into molten thermoplastic resins. In this process, the molten resin penetrates the voids of the fiber tows. The advantages of melt impregnation include the simplicity of the process, high productivity, and the ability to maintain fiber integrity and continuity.

This experiment uses the 3D printing in-nozzle impregnation method, which means that the carbon fiber filaments complete the impregnation in the nozzle during the printing process. In this process, continuous carbon fibers are converted through a specific conduit to the 3D printing head, where they are impregnated in real-time with a thermoplastic resin heated to a molten state. The resin fully encapsulates the fibers under thrust. It is extruded through the nozzle to form composite filaments, which are deposited layer by layer to ultimately form a three-dimensional structure with high strength and lightweight characteristics.

The bond between the resin and the fibers in this process is very important to the final formed structure. When the resin penetrates the carbon fiber through real-time impregnation, ensuring material homogeneity and strength is critical, which significantly improving the composite's mechanical properties. The process reduces the multiple steps required in traditional composite production, such as impregnation, curing, and lamination, and reduces manual intervention, further enhancing productivity.

There are several crucial technological control factors in the 3D printing process. In addition to high-performance composites mentioned above, controlling the correct temperature is a key factor in ensuring successful 3D printing. Materials that are too hot or too cold can lead to print failures. In addition, the temperature must remain stable throughout the 3D printing process to avoid distortion or warpage caused by uneven temperature. The third is the layer thickness factor. If the layer thickness of the print is too large, it will decrease precision, while a thin layer thickness will lead to slower printing speed or printing failure. To solve this problem, you can use the automatic layer thickness adjustment function to control layer thickness. Fourth, the ambient temperature and humidity factors, the temperature and humidity can affect the quality of the print object. If the temperature and humidity in the air are too high, then the 3D-printed object will be prone to defects, such as splitting or distortion. To avoid this, you can place your 3D printer in a relatively constant environment and try to avoid areas of high humidity by using heaters and humidity-absorbing devices.

In summary, this process in 3D printing uses advanced materials technology and complicated control techniques to create composites with superior performance and a high level of customization, providing a great deal of flexibility in manufacturing structures with complex geometries, enabling the realization of design requirements that are difficult to accomplish with traditional manufacturing methods. Due to its high efficiency and repeatability, the real-time impregnation process has been widely used in many high-end fields such as aerospace, automotive, sporting goods, etc.. It has become one of the most critical technologies that drive the development of the modern manufacturing industry.

Figure 1. 3D schematic diagram of the printing equipment [23]

2.3. Experimental steps

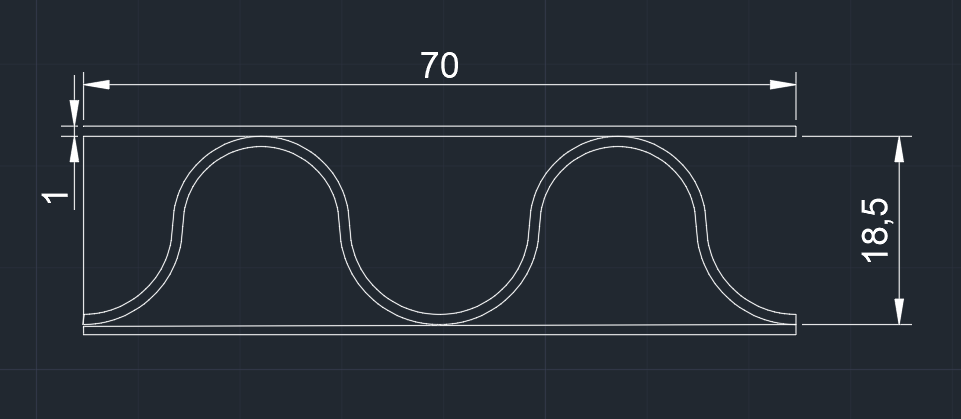

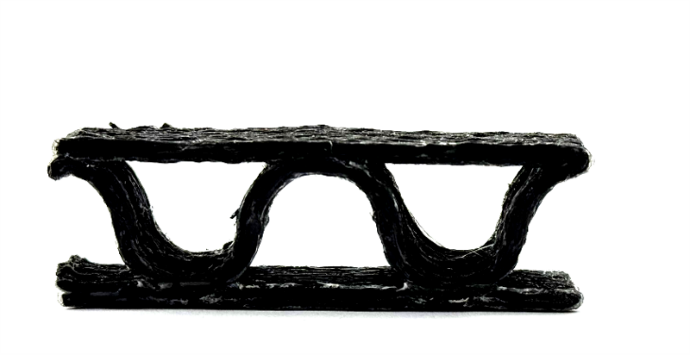

The 2D drawing software CAD was used to draw a continuous fiber thermoplastic resin composite arc sandwich structure with dimensions of 70mm * 20.5mm * 12mm (Figure 2). The core radius of the middle sandwich structure is 9.25mm, and the fiber spacing is 1 mm. The graphic fibers are printed twice to ensure stability. When painting the circular arc, it should be approximated as multiple line segments.

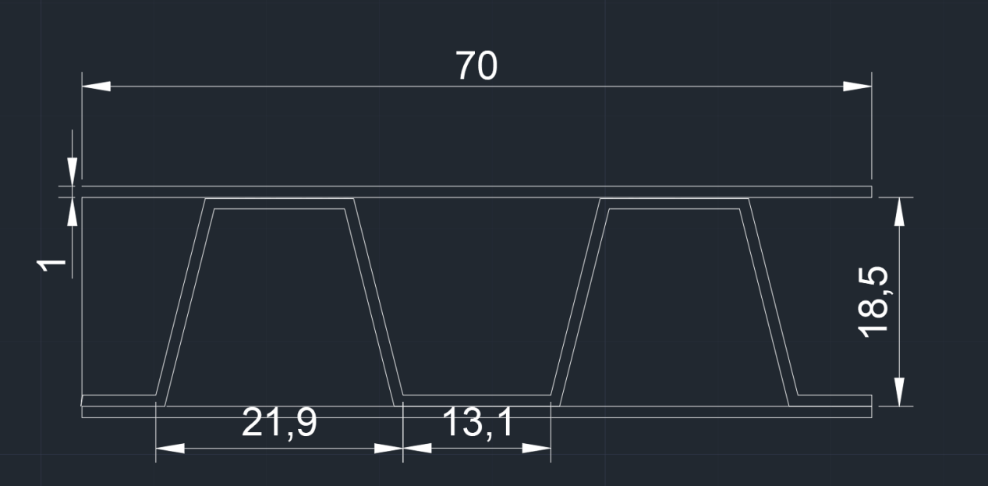

The CAD drew a trapezoidal sandwich structure with continuous dimensions of 70mm * 20.5mm * 12mm (Figure 3). The spacing of the interlayer structures was 18.5mm, the fiber spacing was 1mm, and the graphic fibers were printed twice to ensure their stability. When painting the circular arc, it should be approximated as multiple line segments to draw.

Figure 2. Arc sandwich structures of continuous fiber thermoplastic resin composites

Figure 3. The trapezoidal sandwich structures of continuous fiber thermoplastic resin composite materials

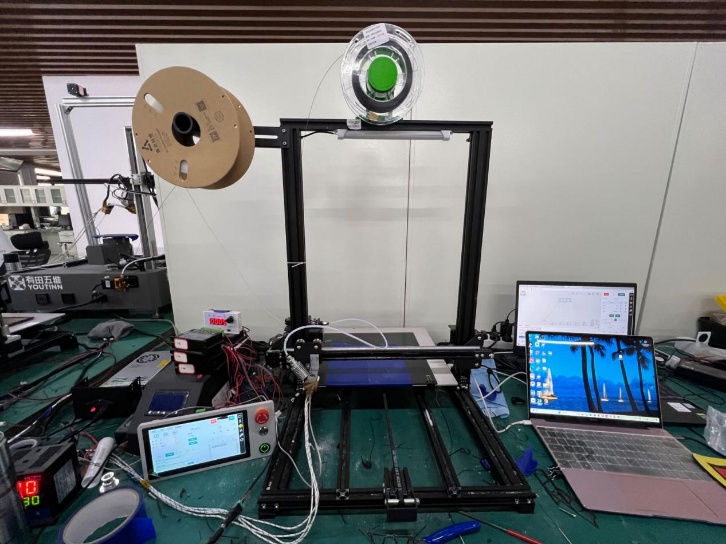

After the drawing was finished, the endpoint coordinates of the different segments were recorded in a document format. The file was imported to the 3D printing platform for printing (Figure 4). Before printing, the temperature was set to around 270 degrees Celsius to ensure proper resin melting. The filaments are impregnated with resin at the nozzle to form continuous fiber thermoplastic structures on the platform at the bottom of the 3D printer (Figure 5&6).

Figure 4. 3D printer with impregnated filaments and resin as printing material

Figure 5. A curved sandwich physical piece

Figure 6. Trapezoid sandwich physical parts

3. Results and the analysis

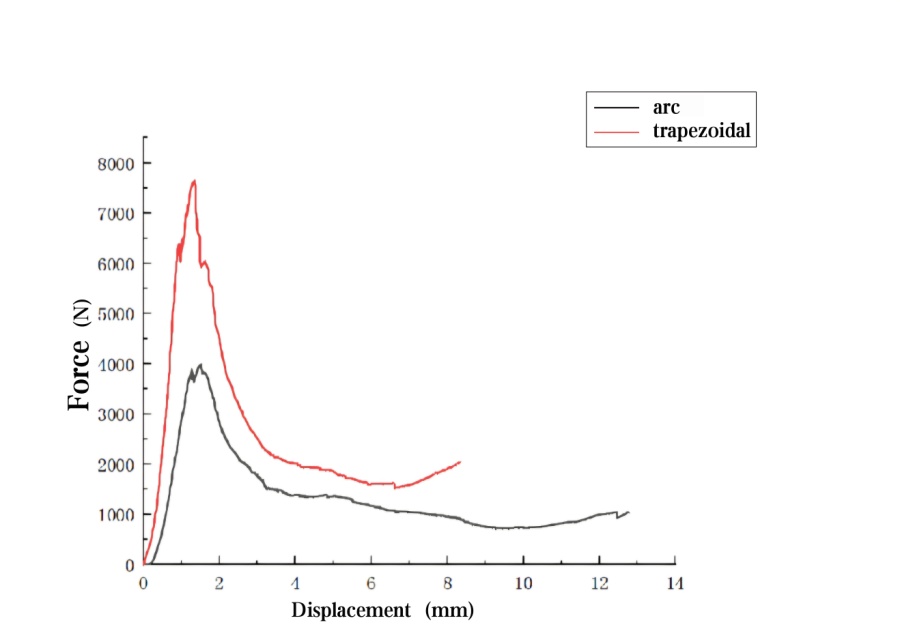

Quasi-static axial compression tests were conducted using a WDM-100E universal test machine with a maximum load capacity of 100 kN (Figure 7). The 2 mm/min loading speed is designed to ensure the consistent strain rate of the corrugated sandwich structures, avoiding the influence of the strain rate difference on mechanical properties. The collected load-displacement data were used to analyze the compressive mechanical properties of two corrugated sandwich structures (Figure 8).

Figure 7. The WDM-100E equipment

Figure 8. The sandwich's physical piece after the compression test

Figure 9. Load-displacement data statistics chart

From the force-displacement data graph (Figure 9), it can be seen that when the moving indenter starts to contact with the test piece, the axial compressive load starts from zero and increases approximately linearly with the axial compressive displacement, during which there is a drop (about 1.6 mm), but the overall rise.When the displacement reaches about 1.8mm, the peak compressive test force data for the continuous fiber thermoplastic resin composite arc sandwich structure is 3998N, and the peak compressive test force data for the continuous fiber thermoplastic resin composite trapezoidal core structure is 7,650N.The load reaches the peak compressive load, and then there is a sudden drop in the load, which fluctuates up and down in a range (0 to 8,000 N) with a large amplitude of fluctuations.The load then increases again very slowly and fluctuates up and down within a certain range (approximately 1,000-2,000N).The experiment found that under the same displacement amount, the test force of the trapezoidal sandwich structure demonstrated a higher load-bearing capacity than that of the arc structure.

The compressive strength represents the critical strength of the corrugated sandwich structure under compression loading. The specific formula is expressed as follows:

\( σ=\frac{{F_{ip}}}{S} \) (1)

Where Fip is the limit load of the elastic section of the load-displacement curve, S is the cross-sectional area of the outer direction of the loading corrugated sandwich structure panel, and the value is the product of length and thickness.

Table 1. Evaluation parameters for the compressive mechanical Performance of corrugated sandwich structures (peak data)

Experimental force/N | Compressive strengthσ/MPa | |

Arc | 3,998 | 4.76 |

Trapezoidal | 7,650 | 9.11 |

According to the calculation (Table 1), the peak compressive strength of the trapezoidal sandwich structure is 9.11MPa, compared to 4.76MPa for the arc sandwich structure. The compressive strength of the trapezoidal sandwich structure is greater than that of the arc sandwich structure. It can be concluded that the compression resistance of the continuous fiber thermoplastic resin with composite trapezoidal sandwich structure is stronger than that of the arc structure in constant conditions.

4. Conclusion and outlook

The test results show that the trapezoidal sandwich structures of continuous fiber thermoplastic resin composites have significant advantages over the arc sandwich structures. These provide valuable insights for the structure design and material selection of high-pressure resistance in engineering and are relevant to related research. From the perspective of mechanical properties, the shape of the trapezoidal sandwich structure is more likely to disperse when the stress is compressed, the stiffness is greater, the material deformation is more minor under the action of external force, and the stability and reliability are better. On the other hand, although the arc sandwich structure can be easily used for some purposes, it may affect its performance due to excessive stress points or bending in the face of a sizeable compressive load.

In addition, in terms of the manufacturing process and application adaptability, the geometric design of trapezoidal sandwich structures, with more substantial carrying capacity, may be easier to adapt to other engineering structures so that the structure has more significant application potential and practical value in aerospace, automobile manufacturing, construction engineering, and other fields.

The limitations of this study are as follows. Firstly, corrugated sandwich structures can be classified into various types based on the shape of the core layer, such as rectangular, triangular, trapezoidal, circular, and sinusoidal cores. This paper only compares trapezoidal and arc shapes. Secondly, the sandwich structures studied in this experiment were subjected to quasi-static and low-speed impact loads for mechanical performance analysis. Experimental studies under high-speed impact and explosion loads have not been conducted. Thirdly, this paper focuses solely on single-layer sandwich structures and does not investigate trapezoidal corrugated sandwich structures' energy absorption performance and efficiency under impact loads when additional layers are added, panel thickness is increased, core wall angles are reduced, or core height is increased.

In the future, we can further study other geometric sandwich structures to explore more possible structure forms and performance characteristics, increase the long-term durability and fatigue performance of material tests, evaluate reliability and stability in practical engineering applications, and explore the application of the technology in other fields, such as medical devices and sporting equipment.

References

[1]. [1] Shan, Z. D., Fan, C. Z., & Sun, Q. L. (2020). Research on additive manufacturing technology and equipment for fiber-reinforced resin matrix composites. China Mechanical Engineering, 31(2), 221–226.

[2]. Harris, M., Potgieter, J., & Archer, R. (2019). Effect of material and process-specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials, 12(10), 1664. https://doi.org/10.3390/ma12101664

[3]. Liu, X. J., Li, F., & Jiao, Z. W. (2017). Research progress in 3D printing of fiber-reinforced composites. Plastics, 46(6), 61–66.

[4]. Park, S., Shou, W., & Makatura, L. (2022). 3D printing of polymer composites: Materials, processes, and applications. Matter, 5(1), 43–76. https://doi.org/10.1016/j.matt.2021.11.020

[5]. Parandoush, P., & Lin, D. (2017). A review on additive manufacturing of polymer-fiber composites. Composite Structures, 182, 36–53. https://doi.org/10.1016/j.compstruct.2017.08.088

[6]. Quan, C., Han, B., & Hou, Z. H. (2020). 3D printed continuous fiber reinforced composite auxetic honeycomb structures. Composites Part B: Engineering, 187, 107858. https://doi.org/10.1016/j.compositesb.2020.107858

[7]. Fu, Y. T., & Yao, X. F. (2021). Multi-scale analysis for 3D printed continuous fiber reinforced thermoplastic composites. Composites Science and Technology, 216, 109065. https://doi.org/10.1016/j.compscitech.2021.109065

[8]. Liu, G., Xiong, Y., & Zhou, L. (2021). Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Composites Communications, 27, 100907. https://doi.org/10.1016/j.coco.2021.100907

[9]. Meng, Y., Zhou, G., Cai, D., & Zhang, N. (2024). Study on the forming defects and process optimization methods of continuous aramid fiber reinforced PLA composite materials 3D printing technology. Composite Materials Science & Engineering, 0(1), 98–104.

[10]. Yu , L., Nie , X., & Luo , C. (2023). Progress in 3D Printing of Continuous Fiber Reinforced Composites Based on Fused Deposition Modeling. Aero Weaponry, 30(02), 42–52. https://doi.org/10.12132/ISSN.1673-5048.2022.0217

[11]. Yan, L., Zhu, K., & Chen, N. (2021). Energy-absorption characteristics of tube-reinforced absorbent honeycomb sandwich structure. Composite Structures, 255, 112946. https://doi.org/10.1016/j.compstruct.2020.112946

[12]. Lu, G., & Yu, T. (2003). Energy absorption of structures and materials. Elsevier.

[13]. Hasebe, R. S., & Sun, C. T. (2000). Performance of Sandwich Structures with Composite Reinforced Core. Journal of Sandwich Structures and Materials, 2(1), 75–100. https://doi.org/10.1106/b861-va45-gu4d-11pl

[14]. Liu, H., Cao, Z. K., Yao, G. C., Luo, H. J., & Zu, G. Y. (2013). Performance of aluminum foam–steel panel sandwich composites subjected to blast loading. Materials & Design, 47, 483–488. https://doi.org/10.1016/j.matdes.2012.12.003

[15]. Gargano, A., Das, R., & Moritz, A. P. (2022). Comparative experimental study into the explosive blast response of sandwich structures used in naval ships. Composites Communications, 30, 101072. https://doi.org/10.1016/j.coco.2022.101072

[16]. Luc St-Pierre, Deshpande, V. S., & Fleck, N. A. (2015). The low velocity impact response of sandwich beams with a corrugated core or a Y-frame core. International Journal of Mechanical Sciences, 91, 71–80. https://doi.org/10.1016/j.ijmecsci.2014.02.014

[17]. Belingardi, G., Cavatorta, M. P., & Duella, R. (2003). Material characterization of a composite–foam sandwich for the front structure of a high speed train. Composite Structures, 61(1-2), 13–25. https://doi.org/10.1016/s0263-8223(03)00028-x

[18]. Ning, H., Janowski, G. M., Vaidya, U. K., & Husman, G. (2007). Thermoplastic sandwich structure design and manufacturing for the body panel of mass transit vehicle. Composite Structures, 80(1), 82–91. https://doi.org/10.1016/j.compstruct.2006.04.090

[19]. Rejab, M. R. M., & Cantwell, W. J. (2013). The mechanical behaviour of corrugated-core sandwich panels. Composites Part B: Engineering, 47, 267–277. https://doi.org/10.1016/j.compositesb.2012.10.031

[20]. Zhou R., Yue Z., Xu X., Wang J. & Zhang Q.(2024) The resistance to strong dynamic impact characteristics of multi-stage metal corrugated sandwich structures. Explosion and Shock, 44(11),90-103.

[21]. Zhao Y. & Liu H.(2020). Preparation and Application of Continuous Fiber Reinforced High-performance Thermoplastic Resin Matrix Composites. Materials Engineering,48(08),49-61.

[22]. Zhang J. & Zhai G.(2021). Research on Continuous Fiber Composite Lattice Materials Prepared by Spatial Weaving Method and Their Compressive Properties. Composite materials science and engineering, (3), 45-50. Doi: 10.19936 / j.carol carroll nki. 2096-8000.20210328.007.

[23]. Sugiyama, K., Matsuzaki, R., Ueda, M., Todoroki, A., & Hirano, Y. (2018). 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Composites Part A: Applied Science and Manufacturing, 113, 114–121. https://doi.org/10.1016/j.compositesa.2018.07.029

Cite this article

Dong,J. (2025). Process validation and performance evaluation of 3D printing continuous fiber reinforced thermoplastic composite corrugated sandwich structure. Advances in Engineering Innovation,16(5),36-43.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. [1] Shan, Z. D., Fan, C. Z., & Sun, Q. L. (2020). Research on additive manufacturing technology and equipment for fiber-reinforced resin matrix composites. China Mechanical Engineering, 31(2), 221–226.

[2]. Harris, M., Potgieter, J., & Archer, R. (2019). Effect of material and process-specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials, 12(10), 1664. https://doi.org/10.3390/ma12101664

[3]. Liu, X. J., Li, F., & Jiao, Z. W. (2017). Research progress in 3D printing of fiber-reinforced composites. Plastics, 46(6), 61–66.

[4]. Park, S., Shou, W., & Makatura, L. (2022). 3D printing of polymer composites: Materials, processes, and applications. Matter, 5(1), 43–76. https://doi.org/10.1016/j.matt.2021.11.020

[5]. Parandoush, P., & Lin, D. (2017). A review on additive manufacturing of polymer-fiber composites. Composite Structures, 182, 36–53. https://doi.org/10.1016/j.compstruct.2017.08.088

[6]. Quan, C., Han, B., & Hou, Z. H. (2020). 3D printed continuous fiber reinforced composite auxetic honeycomb structures. Composites Part B: Engineering, 187, 107858. https://doi.org/10.1016/j.compositesb.2020.107858

[7]. Fu, Y. T., & Yao, X. F. (2021). Multi-scale analysis for 3D printed continuous fiber reinforced thermoplastic composites. Composites Science and Technology, 216, 109065. https://doi.org/10.1016/j.compscitech.2021.109065

[8]. Liu, G., Xiong, Y., & Zhou, L. (2021). Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Composites Communications, 27, 100907. https://doi.org/10.1016/j.coco.2021.100907

[9]. Meng, Y., Zhou, G., Cai, D., & Zhang, N. (2024). Study on the forming defects and process optimization methods of continuous aramid fiber reinforced PLA composite materials 3D printing technology. Composite Materials Science & Engineering, 0(1), 98–104.

[10]. Yu , L., Nie , X., & Luo , C. (2023). Progress in 3D Printing of Continuous Fiber Reinforced Composites Based on Fused Deposition Modeling. Aero Weaponry, 30(02), 42–52. https://doi.org/10.12132/ISSN.1673-5048.2022.0217

[11]. Yan, L., Zhu, K., & Chen, N. (2021). Energy-absorption characteristics of tube-reinforced absorbent honeycomb sandwich structure. Composite Structures, 255, 112946. https://doi.org/10.1016/j.compstruct.2020.112946

[12]. Lu, G., & Yu, T. (2003). Energy absorption of structures and materials. Elsevier.

[13]. Hasebe, R. S., & Sun, C. T. (2000). Performance of Sandwich Structures with Composite Reinforced Core. Journal of Sandwich Structures and Materials, 2(1), 75–100. https://doi.org/10.1106/b861-va45-gu4d-11pl

[14]. Liu, H., Cao, Z. K., Yao, G. C., Luo, H. J., & Zu, G. Y. (2013). Performance of aluminum foam–steel panel sandwich composites subjected to blast loading. Materials & Design, 47, 483–488. https://doi.org/10.1016/j.matdes.2012.12.003

[15]. Gargano, A., Das, R., & Moritz, A. P. (2022). Comparative experimental study into the explosive blast response of sandwich structures used in naval ships. Composites Communications, 30, 101072. https://doi.org/10.1016/j.coco.2022.101072

[16]. Luc St-Pierre, Deshpande, V. S., & Fleck, N. A. (2015). The low velocity impact response of sandwich beams with a corrugated core or a Y-frame core. International Journal of Mechanical Sciences, 91, 71–80. https://doi.org/10.1016/j.ijmecsci.2014.02.014

[17]. Belingardi, G., Cavatorta, M. P., & Duella, R. (2003). Material characterization of a composite–foam sandwich for the front structure of a high speed train. Composite Structures, 61(1-2), 13–25. https://doi.org/10.1016/s0263-8223(03)00028-x

[18]. Ning, H., Janowski, G. M., Vaidya, U. K., & Husman, G. (2007). Thermoplastic sandwich structure design and manufacturing for the body panel of mass transit vehicle. Composite Structures, 80(1), 82–91. https://doi.org/10.1016/j.compstruct.2006.04.090

[19]. Rejab, M. R. M., & Cantwell, W. J. (2013). The mechanical behaviour of corrugated-core sandwich panels. Composites Part B: Engineering, 47, 267–277. https://doi.org/10.1016/j.compositesb.2012.10.031

[20]. Zhou R., Yue Z., Xu X., Wang J. & Zhang Q.(2024) The resistance to strong dynamic impact characteristics of multi-stage metal corrugated sandwich structures. Explosion and Shock, 44(11),90-103.

[21]. Zhao Y. & Liu H.(2020). Preparation and Application of Continuous Fiber Reinforced High-performance Thermoplastic Resin Matrix Composites. Materials Engineering,48(08),49-61.

[22]. Zhang J. & Zhai G.(2021). Research on Continuous Fiber Composite Lattice Materials Prepared by Spatial Weaving Method and Their Compressive Properties. Composite materials science and engineering, (3), 45-50. Doi: 10.19936 / j.carol carroll nki. 2096-8000.20210328.007.

[23]. Sugiyama, K., Matsuzaki, R., Ueda, M., Todoroki, A., & Hirano, Y. (2018). 3D printing of composite sandwich structures using continuous carbon fiber and fiber tension. Composites Part A: Applied Science and Manufacturing, 113, 114–121. https://doi.org/10.1016/j.compositesa.2018.07.029