1. Introduction

For China today, environmental protection has become one of China's basic national policies, which means that China is vigorously supporting sustainable development for the well-being of all China and even all mankind [1]. However, as a major manufacturing country [2], the pollutant gas emissions and energy consumption caused by the manufacturing process will cause almost irreversible environmental degradation [3]. To alleviate this situation, a variety of methods have been used in different domains, such as waste heat recovery has been fully developed in energy reuse [3].

“Heat recovery term refers to an air-to-air heat or energy recovery system which is defined as the process of recovering energy (heat/mass) from a stream at a high temperature to a low temperature stream that is effective and economical to run [4].”

Waste heat recovery is the use of various methods to recover energy that is wasted in industrial production or lost in the environment and not used, and use this method to reduce energy consumption and environmental pollution [5]. Recovery for waste thermal energy, as a method of reducing energy consumption by reusing waste heat, has now been fully utilized in many fields. Waste heat recovery in energy-consuming industries is A significant aspect of the approach to mitigate alterations in climatic conditions [6]. By reusing energy, less fossil fuel can be consumed when consuming the same amount of energy. This means less pollution caused by mining and burning, and the resulting lower pressure of the earth's environmental self-regulation capacity. As a member of the earth's environment, human beings need to use resources rationally and adhere to the principle of protecting the environment in the process of industrial, scientific and technological and social development, because many non-renewable resources have no substitutes. Therefore, more efficient reuse of energy by improving waste heat recovery is extremely important for the environment.

However, in today's Chinese steel industry, compared with the international advanced level, waste heat recovery is still not highly efficient [3]. Compared with China's internal industrial system, in 2020, China's steel industry, as an energy-intensive industry, represented 11% of the country's aggregate energy usage, and carbon emissions exceeded 50% of the global steel industry's carbon emissions [7]. Therefore, it will continue to hinder the sustainable development in steel industry on the basis of existing energy problems [7]. Therefore, improvement of waste heat recovery is particularly significant, because it is not merely a conservation of energy worldwide, but also a stumbling block to the advancement of China's national strength and manufacturing industry as well.

In response to this situation, this article explains some existing innovative solutions for waste heat recovery in the literature review. In the discussion, in terms of economy, the current status of China's existing steel metallurgical sector shows that it has a relatively low waste heat recovery efficiency compared to its output and a strong regional imbalance, that is, the economic factors that are bound to affect the waste heat recovery capacity cannot be balanced in different regions of China. In terms of production technology, low-temperature waste heat recovery and equipment renewal issues have always been the main difficulties in waste heat recovery. The focus of this dissertation is to further explain and analyze China's existing waste heat recovery methods and difficulties, and compare them with different existing methods to enhance the efficiency of waste heat and find a feasible and optimal solution suitable for China's current economy.

2. Literature review

2.1. Current situation of waste heat recovery

Since the publication of the "Medium- and Long-term Special Plan for Energy Conservation" in 2004 [8], the Chinese government has begun to vigorously promote and support waste heat recovery in industries such as steel to reduce energy consumption, including but not limited to increasing capital investment and setting rigid requirements [8]. Behind this measure is China's abundant waste heat resources and its inefficient recovery methods [8]. In the recovery for waste heat of the steel manufacturing, exploitation of waste thermal energy with high temperature is the most common and has the highest recovery rate, but the quantity of low-temperature waste heat recovery is beneath 1% [9].

The utilization rate of waste heat resources in the steel manufacturing, which accounts for 15% of China's overall energy consumption, is extremely low compared to advanced enterprises in other developed countries, with a gap of 6-7% [3]. Based on China's large-scale steel and metallurgical industry, the large gap in utilization rate with developed countries makes the utilization of resources very large and further aggravates pollution. For different types of air pollutants, the emissions caused by industry account for at least 70% of the share [3]. Although the data is not satisfactory, it also reflects the amazing potential that China's steel industry can show in the future [8].

2.2. Principle of waste heat recovery

China's State Administration for Market Regulation states in the Industrial surplus energy resources evaluation methods that the official definition of waste heat is the usable heat energy output by industrial production process systems after consuming input energy, and provides a calculation formula for the surplus energy utilization rate, namely:

As shown in Equation (1), in this formula,

2.3. Methods of waste heat recovery

In the whole process of recovery of waste thermal energy, the existing innovations mainly include the following devices which are used for utilization of waste heat energy and energy exchange: economiser, waste heat boilers, regenerators, plate heat exchangers, heat pipe systems, Organic Rankine cycle and Kalina cycle, heat pumps [5]. Some of these technological innovations will be explained in the following paragraphs.

2.3.1. Packed bed

2.3.1.1. Working principle of packed bed reactor

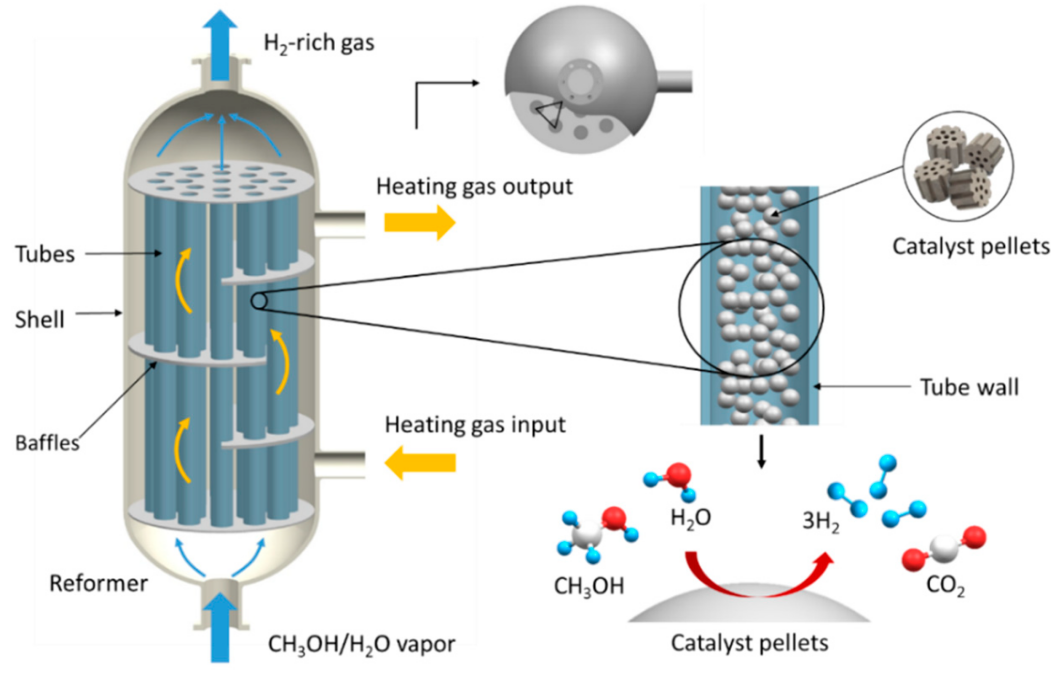

A packed bed reactor is a cylindrical device with a convex head that is commonly used in catalytic processes [12].

As shown in Figure 1, the core constituents of a packed bed reactor include liquid distributors, support plates and demisters [12, 14]. According to different needs, such as countercurrent or cocurrent of liquids, different types of liquid distributors are selected, such as nozzle distributors, extraction distributors or slotted distributors, etc. [14]. In its fundamental procedures, the reactants ingress from its top, fully contact and react with the catalyst while falling under gravity, and the products after the reaction leave from its bottom [12]. The catalyst used in this device is usually granular, and its effective life for the cycle operation time of the packed bed is considered when selecting it [12].

2.3.1.2. Advantages and disadvantages of packed bed reactors

The advantage of packed bed reactors is that they are easy to build and low-cost, caused by their increasing popularity [12]. Moreover, compared with other types of reactors, the reactants in packed bed reactors are in more complete contact with the catalyst with a higher conversion rate, which means more products can be formed and less raw materials are wasted [12]. However, the difficulty of replacing the catalyst, the possibility of side reactions and the difficulty in controlling the temperature have become the disadvantages of packed bed reactors [12].

2.3.1.3. Innovation of packed bed reactors

Steel slag, which is solid and has low-cost properties, can play the role of energy storage substance for thermal use in Thermal Energy Storage (TES) systems [15]. Using this as a theoretical basis, a system was designed to convert the discontinuous heat supply which was caused by the intermittent operation of steel furnaces into a continuous heat supply [15]. The researchers also pointed out that this method is suitable for the development and research of recovery for waste heat with extremely high temperature systems to serve the purpose of low cost and high efficiency [15]. To this end, the importance of packed bed design and its impact on ultimate efficiency has been repeatedly emphasized [15].

The difficulties caused by large amounts of powder transported by hot exhaust gas in packed bed TES systems (primarily powder retention and pressure drop) may be solved by changing the heat transfer fluid to a gas-powder two-phase exhaust gas [6]. Experimental observations found that using gas-powder two-phase waste as the thermal transfer medium can effectively avoid the powder retention phenomenon which is the powder deposited within the packed bed that contaminates the clean air emitting polybrominated biphenyls [6]. At the same time, after analyzing the impact of changes in fluid mass flux on the pressure drop trend, the study concluded that in order to enhance the productivity of packed bed TES systems, a power supply with high charging power should be the first choice to reduce the impact of powder retention on pressure drop [6].

2.3.2. Heat exchanger

2.3.2.1. Working principle of heat exchanger

A heat exchanger is an apparatus designed to transfer heat from one fluid medium to another, while preventing any intermixing or physical contact between the two fluids [16]. Common heat exchangers are divided into two types: plate/fin heat exchangers and shell and tube exchanger [16]. Shell and tube exchangers are usually cheaper than plate/fin heat exchangers.

![Figure 2. Structure of a shell and tube heat exchanger [16]](https://file.ewadirect.com/press/media/markdown/document-image2_eBaqjAZ.png)

As shown in the Figure 2, this is a simplified architectural Schematic of the working principle of a shell and tube exchanger. During its operation, the flow direction of the hotter fluid (i.e., red fluid) and the colder fluid (i.e., blue fluid) is not restricted, which means the two fluids can flow in parallel, countercurrent, or crosscurrent [16]. When the hotter fluid and the colder fluid flow, the hot fluid is chilled and the cold fluid is heated which is a process in which only thermal energy is transferred without transferring media [16].

![Figure 3. The structure of a plate/fin heat exchanger [16]](https://file.ewadirect.com/press/media/markdown/document-image3_M6L4MiC.png)

As shown in the Figure 3, this is a simplified schematic diagram of the working principle of a plate/fin heat exchanger [16]. It has a significant quantity of thin metal plates or fins featuring large exposure surfaces to increase the rate of heat exchange [16]. Its hot fluid (i.e., red fluid) and cold fluid (blue fluid) flow in a crossflow manner, that is, at right angles to the flow direction [16].

![Figure 4. The structure of a heat pipe heat exchanger [17]](https://file.ewadirect.com/press/media/markdown/document-image4_F7qSCD1.jpeg)

heat pipe heat exchangers belong to the direct contact type of direct-contact indirect-contact heat exchangers classified by contact [18]. As depicted in Figure 4, a heat pipe heat exchanger is comprised of an evaporation section and a condensation section with hot and cold media, respectively, separated and sealed by a partition, with a heat pipe bundle running through it [19].

2.3.2.2. Advantages and disadvantages of heat exchangers

The advantages of heat exchangers are easy disassembly, easy maintenance (with low cost), small size and can work in elevated temperature and pressure environment [20]. However, the disadvantages of heat exchangers cannot be ignored: leakage and pressure drop in the system need to be paid attention to first, followed by technical requirements for operators during disassembly and assembly: the pressure in the cooler will increase due to overtightening clamping bolts [20]. The high initial cost and inability to increase capacity brought by expensive titanium plates are also disadvantages in plate exchangers and tube exchangers respectively [20].

2.3.2.3. Innovation of heat exchanger

The study on system for waste heat utilization based on flat-plate heat pipe exchanger theory pointed out that compared with traditional cylindrical heat pipe methodology, the advantage of flat heat pipe is that it can maximize the radiation absorption area through its flat evaporator surface [21]. The main application conditions of the innovative heat exchanger system include waste heat recovery temperatures above 500 ℃ is pointed out [21]. In terms of design, a stainless steel plate immobilized at the rear of the evaporator to expand the overall heat conducting area was emphasized [21]. The device designed during the experimental procedure is depicted in the Figure 5.

![Figure 5. The innovative system about flat plate heat exchanger [21]](https://file.ewadirect.com/press/media/markdown/document-image5_n4D0SV1.jpeg)

A new system for waste thermal energy recovery that uses endothermic heat instead of sensible heat to transform heat energy into chemical potential energy by combining endothermic reactions with high-temperature waste heat has been proposed [22]. This recovery system uses methane-steam reforming reaction (i.e. CH₄+H₂O→CO+3H₂) as a typical example to reuse waste thermal energy with high temperature from exhaust gas and slag [22]. In the area of waste gas, endothermic reactions are necessary, especially when facing high-temperature waste gas above 1,300 K, because the waste gas cooled by the steam method will waste a lot of energy [22]. For this reason, the researchers proposed the use of a high-temperature phase change ball that can change from solid to liquid [22].

With the rapid advancement of information technique, the demand for data centers has greatly increased, which means that data centers have a large quantity of waste thermal energy that can be recovered for regional heating networks, agriculture and industrial production, etc. [23]. Two direct-to-chip cooling heat exchanger systems are designed to recover this heat for building heating [23].

In 2018, the theory that a heat pump is suitable for extraction of residual low-temperature heat was proposed [18].

2.3.3. Steam power cycle

2.3.3.1. Working principle of steam power cycle

Working fluid is an important medium used in thermodynamic cycles which is used to improve the productivity of the cycle according to the different attributes of different types of fluids [24]. Common steam power cycles include Rankine cycle, organic Rankine cycle, Carnot cycle, etc. [25].

![Figure 6. The structure of Rankine cycle [26]](https://file.ewadirect.com/press/media/markdown/document-image6_wuSSbE0.jpeg)

As shown in the Figure 6, the steam Rankine cycle is one of the main power generation cycles. It obtains heat from fossil fuel combustion, solar energy or nuclear energy to drive this cycle. It includes four main devices: boiler, turbine, condenser and pump (boiler and condenser are both heat exchangers) [26]. Saturated liquid water is heated to overheated steam in the boiler and then enters the turbine [26]. After converting thermal energy into mechanical energy, it loses energy and flows into the condenser to be chilled again to water in saturated liquid state and then pumped into the boiler to repeat the cycle [26]. The quality of water does not change in this process [26].

2.3.3.2. Innovation of steam power cycle

Working fluid is the medium used in fluid transmission and control systems, including liquids and gases (mainly compressed air) [25]. Working fluids with excellent performance in the organic Rankine cycle were studied to better utilize the flue gas at low temperature exhausted by the sintering waste heat boiler as a thermal energy supplier for alkaline organic Rankine cycle power generation, and founded upon literature and experiments, it was concluded that R236ea, R245fa and R601a have better net power generation of the system and efficiency of thermal energy utilization [27]. For different research goals, there are different insights on the key to the identification of the working medium of the organic Rankine cycle: the characteristics of heat suppliers operating at low and high pressure and the constraints on the system for recovery, or high latent heat of boiling for greater unit work output [28, 29].

Organic Rankine Cycle and Supercritical Rankine Cycle are suitable for low temperature (lower than 200 degrees Celsius), medium temperature (between 200 to 500 degrees Celsius) and high temperature (higher than 500 degrees Celsius) waste heat recovery respectively [30, 31]. The working medium of the organic Rankine cycle adopts organic fluids or hydrocarbons including wet fluids, isentropic fluids and dry fluids instead of water resources with high thermal conductivity, safety and easy access, which are mostly used in ordinary Rankine cycles [30]. Since organic fluids tend to boil at lower temperatures than water, the organic Rankine cycle can operate at lower temperatures [31]. This directly leads to one of its three major application areas, including low-grade heat extraction [31]. Supercritical carbon dioxide has recently been widely studied in the Supercritical Brayton Cycle [31]. This has also been pointed out by researchers such as Matteo Biondi that the supercritical carbon dioxide closed-loop system may be an effective substitute to the traditional organic Rankine cycle in the field of waste thermal energy recovery in small and medium-sized companies, especially when the temperature exceeds 400 degrees Celsius, because supercritical carbon dioxide is non-flammable and has stable chemical properties [32].

Three different organic Rankine cycles and three different Kalina cycles can be used for comparative analysis to improve their efficiency [33]. Different from the conclusions drawn by Jafari et al., Davood et al. believed that the organic Rankine cycle is suitable for medium-temperature heat suppliers, while the Kalina cycle shows the best performance in waste thermal energy recovery at low temperature [33].

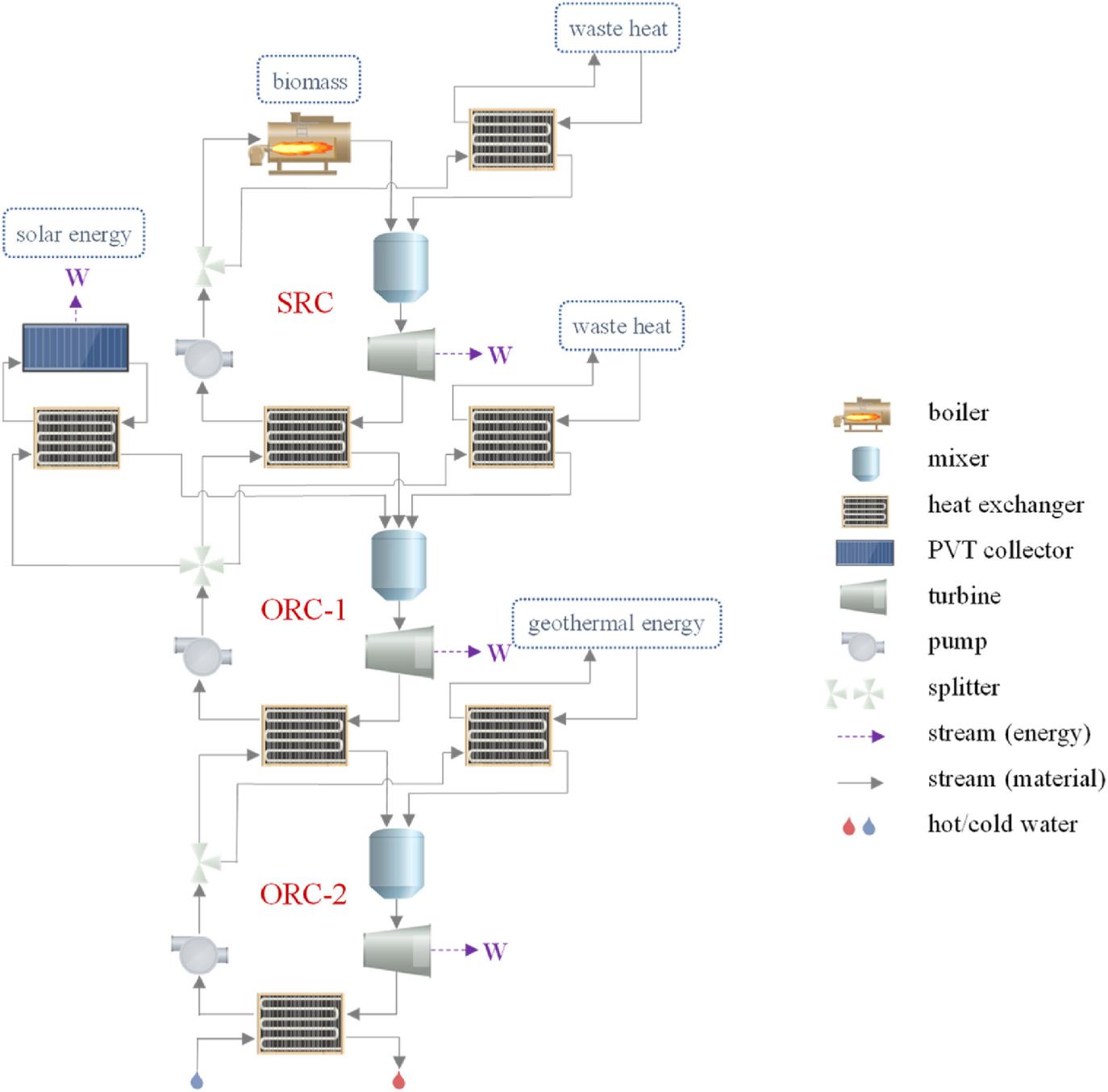

Cascading different organic Rankine cycles with the conventional steam Rankine cycle can theoretically produce a complex cycle system capable of recovering high, medium, low and temperature heat sources, which is used in many cases such as aluminum production, solar energy, geothermal energy, etc. [34]. In this complex steam-organic Rankine cycle system, a steam Rankine cycle for recovering high-temperature heat sources is designed, and two organic Rankine cycle systems for recovering medium-temperature and low-temperature heat sources are arranged in a cascade manner [34]. The composite cycle is shown in Figure 7.

3. Discussion

3.1. Current status of waste heat recovery in China's steel industry

3.1.1. Recovery efficiency and distribution range

As shown in Equation (2), according to the formula mentioned in the literature review, in China, even high-temperature waste heat, which has the highest recovery efficiency among different types of waste heat, has a current recovery rate of only 44.4% [35]. The extraction efficiency of medium-range waste heat is only 30.2%, and the extraction efficiency of low-grade waste thermal energy, which has the lowest recovery rate, is less than 2% [35]. Compared with the data in 2019, the recovery rates of the three types of waste heat increased by less than 1% year-on-year [36]. Compared with the growth of China's annual crude steel output, which increased from 995.4189 million metric tons in 2019 to 1,019.081 million metric tons in 2023, a growth rate of 2.4%, it seems to be slow [37]. The comparison of these data clearly shows that the steel industry failed to balance production and environmental protection during its rapid development, and indirectly reflects two possibilities: China's current technology for recovering waste heat in steel manufacturing has not achieved a major technical breakthrough, or the breakthrough technology has not been promoted nationwide.

At present, the distribution of crude steel output among China's steel enterprises and provinces is uneven. Steel enterprises are mainly concentrated in the southeast, especially in Shandong Province, Tianjin and Jiangsu Province [38]. Hebei Province and Jiangsu Province, situated in northern and eastern regions of China respectively, are the only two provincial administrative regions with crude steel output exceeding 100 million tonnes, and the raw steel output of most provinces is concentrated between 20 million and 30 million tonnes, and the raw steel output of the least province is less than 1 million tonnes [37]. Unbalanced steel output means uneven distribution of steel waste heat suppliers, that is, the waste heat suppliers in the eastern coastal areas of China will be much greater than those in the west. This may lead to differences in the waste heat recovery methods applicable to different regions, and even the importance of waste heat recovery, which in turn may lead to resistance to the promotion of waste heat recovery in areas with low steel production capacity.

In addition, as China's economy is developing rapidly, there is a phenomenon of regional imbalance. For example, China's economic center is primarily concentrated along the coastlines of Eastern and Southern China [37]. In regions with more developed economies and larger steel production, technological innovation and promotion can be subject to fewer financial constraints, that is, the feasibility of innovative technologies can be improved. It is observable that when the funds for waste heat recovery technology innovation are limited, the focus of both waste heat recovery technology innovation and technology promotion should be placed first in eastern China, and then gradually promoted nationwide after certain results are achieved.

3.1.2. Existing standards and technologies

According to the Guidelines for comprehensive cascade utilization of industrial waste heat jointly issued by the State General Administration of the People's Republic of China for Quality Supervision and Inspection and Quarantine and the Standardization Administration of the P.R.C., China divides the measures for industrial waste heat recovery into four types: reuse, substitution, quality improvement and conversion, that is, re-inputting waste heat into the original energy-consuming equipment or equipment system, improving the grade of waste heat and converting the form of energy [10]. Specifically, among these four types of measures, reuse and substitution use similar logic, that is, while minimizing the loss of waste heat during recovery, it is re-invested in the production process to lower the amount of input heat to fulfill the ultimate target of environmental protection and conservation. The difference between the two is that reuse emphasizes returning waste heat to the original equipment, while substitution tends to return waste heat to the working system where the original equipment is located. Among the other two measures, quality improvement refers to improving the grade of waste heat energy (i.e. increasing the temperature) to meet heat demand, and conversion refers to converting the energy storage form from thermal energy to other forms, such as mechanical energy.

At the same time, as one of China's major intensive industries, the steel industry has been given a general idea of waste heat utilization for reference and use by major enterprises, and different types of technologies have been classified in detail according to different steps of steelmaking, pointing out that it is necessary to comprehensively utilize different technical measures such as "reuse, substitution, quality improvement, and conversion" to maximize regional energy utilization in different steelmaking steps [10]. When such technologies are applied to the case analysis of waste heat recovery in the steel manufacturing, their primary objective is obviously concentrated on waste thermal energy with medium and low temperature, which has abundant waste heat resources but is more difficult to use and has a significantly lower utilization rate [10].

It can be seen that the Chinese government can discover the disadvantages and difficulties faced by low-grade waste heat recovery in the current steel industry and take active actions, which deliberately emphasizes and guides the industry to devote attention on the huge potential of waste heat of medium and low grade when formulating the standards for utilization of waste thermal energy, and gives specific examples of its recovery procedures for reference for the purpose of obtaining technological innovation and industrial upgrading. However, China's waste heat with medium and low temperature recovery rate has not shown a clear upward trend in the four years since the standard was released in 2020, indicating that there remains potential for advancement in terms of technological innovation and popularization and market incentive mechanisms. It can be seen that although this guidance is impeccable in guiding the industry to recover waste heat, its publicity capacity still has room for improvement to make the waste heat recovery method more widely used in companies in the steel industry. In addition, China's steel mills vary greatly in size, and this guidance should add items on the average market price required for different methods to adapt to the economic capabilities of factories of different sizes.

3.2. Dilemma of waste heat recovery

3.2.1. Impact of technology

In the past, most enterprises implemented relatively simple and traditional methods to recover the exploited waste heat [39]. The equipment that has been used until it is aged and worn due to cost has aggravated the consequences of this phenomenon [39]. In addition to aging and wear, the equipment used in the waste heat recovery process also has problems such as backwardness and dependence on imported technology [39]. Simultaneously, compared with high-temperature waste heat that can be basically recovered, the recovery and application of low-grade waste heat is still waiting to be further deepened and expanded, and has become a key node for the further development of waste heat recovery [40].

In terms of technology, China's current steel and metallurgical industry has not taken a proactive attitude towards and solved the problem of waste heat recovery, and still focuses on high-temperature waste heat [41]. The value of recycling low-temperature waste heat is ignored by many companies [41]. In addition to the considerable quantity of waste heat resources being wasted, the main problems caused by this include the inconsistency of waste heat recovery system technology, which will cause difficulties for the subsequent overall technical optimization [41]. The narrow range and types of energy utilization still bother researchers in the current steel industry [42]. In addition, part of the reason why the equipment dedicated to recover waste heat in the steel manufacturing has not been able to keep pace with the technological updates needs to be attributed to the difficulty of importing internationally advanced patented technologies [41]. It is evident that waste heat recovery in China's steel manufacturing still depends heavily on patents from developed countries, and no major breakthroughs have been made in independent research. In terms of technology improvement, since the patents involved may be used in the research process, this problem may make it difficult for China to conduct research on waste heat recovery. If this situation continues for a long time, it may cause the gap between China's waste heat recovery technology and that of developed countries to widen and become difficult to catch up.

Compared with the past, the technical difficulties faced by waste heat recovery are almost the same: they are all concentrated on equipment problems and recovery of low-grade waste heat. It is significant to mention that with the strong financial and technical support of the government, the problems of equipment aging and wear that were prevalent in the past have been improved to guarantee that the waste heat recovery rate is maintained within the highest possible range to promote the technological progress of waste heat recovery and implement the concept of sustainable development. However, in terms of equipment selection and technical patents, China's steel companies have not yet achieved independence and self-sufficiency, and since this situation has persisted for a considerable period of time, the possibility of this situation continuing in the future cannot be ignored, in other words, it must be assumed. Patent issues not only involve low-temperature waste heat with a low current recovery rate, but also advanced methodologies for harnessing high-temperature waste thermal energy with better recycling and utilization conditions. That is, patent issues involve a wide range. China's steel companies should deeply and clearly recognize that the steel industry, as the pillar of the country's manufacturing industry, cannot be controlled by others in terms of technology, and continue to independently and in-depth research on China's own methods used for waste heat recovery. In addition, although the importance of low-temperature waste heat recovery has long been proposed, it is still at a disadvantage in waste heat recovery to this day. Improving the recovery ratio of low-grade waste heat is crucial to environmental protection and energy conservation in the steel industry.

3.2.2. Economic impact

In addition to technical issues, waste heat recovery in China has always faced difficulties due to economic or other factors. This dilemma has changed over the past decade, from insufficient understanding of waste heat recovery and the economic crisis faced by the entire steel industry to the lack of timely equipment updates and the technical disparity caused by the scale gap between manufacturers.

In the past, the economic difficulties faced by waste heat recovery mainly focused on the low utilization rate of recovered heat energy (i.e., the waste heat that has been successfully recovered but not fully utilized constitutes a high proportion of the aggregate amount of recovered waste heat) and the energy loss caused by the long transportation route [40]. At the same time, from 2011 to 2012, due to the imbalance of market supply and demand caused by the rapid advancement of production capacity and the high production costs, the situation of the steel industry sustained a downward trend : the sales profit margin was only 2.42% and 0.04% respectively; steel companies in China achieved a profit of 1.58 billion yuan in 2012, an annual decline of 98.2% [43, 44]. This situation can greatly affect the waste heat recovery in the steel manufacturing: low sales profit margins may make enterprises unable to afford the financial expenditure for upgrading waste heat recovery equipment; but since the high production costs are largely responsible for the low profit margins, some enterprises with spare capacity may also respond to the national call to reduce costs and increase profits by energy conservation and emission reduction or waste heat recovery.

At present, in addition to the limitations of existing technology levels, the scale of the metallurgical industrial system, including the steel industry, varies greatly among different enterprises [41]. Therefore, the waste heat recovery technologies used by steel plants of different sizes vary greatly, greatly affecting the average efficiency of waste heat recovery [41]. Simultaneously, the hardware facilities utilized for waste heat recovery in the production process of enterprises have not been able to keep pace with the rapid update of technology and the limitations of the technical team for corresponding technology research and development. The emergence of this situation is primarily considering the high cost of replacing mechanical equipment in terms of economy [41].

Compared with the past, due to the advancement of the steel metallurgical industry, the situation of recovery of waste heat in the manufacturing has improved in two aspects. First, enterprises have clearer goals for waste heat recovery, focusing on the proportion of energy that can be truly reused. Second, large enterprises have established specialized technical teams and started to independently research and develop ways to recover waste heat. However, this phenomenon also means that the current problems and difficulties make it more difficult for the government to use simple methods such as improving corporate awareness and calling for waste heat recovery to make companies really start to pay attention to waste heat recovery. Instead, it needs to rely more on providing sufficient economic support to enterprises with small and medium size that lack adequate capacity to upgrade their equipment and technology, and other practical actions to narrow the gap in the level of technology used by steel companies of different sizes.

3.3. Solutions for waste heat recovery

As a dilemma that has plagued China's steel industry for an extended period, low-temperature waste heat recovery needs to find measures appropriate for the market. After excluding the impact of economy and cost, the following innovative methods for recovery of waste heat with low temperature can be considered as options.

Organic Rankine cycle and Kalina cycle. Both cycles are used to produce electrical power using recovered heat. In comparison with the traditional Rankine cycle, the organic Rankine cycle has a lower applicable temperature range, but when compared with the Kalina cycle, the applicable temperature range of the basic Kalina cycle and other cycle systems based on it is lower and more limited [33]. These two basic cycle power generation technologies are also mentioned in the Guidelines for industrial waste heat comprehensive cascade utilization and have become the only two methods designated for recovery of waste thermal energy with low temperature [10]. When further studying the organic Rankine cycle and adjusting the details in depth, the conclusions of the following completed studies are helpful to improve efficiency or reduce costs: desuperheating is considered more practical in comparison with the full condensation method due to higher recovery rate and lower loss rate [29]; the regenerative organic Rankine cycle with refrigerant R236ea shows good energy-saving effect when applied to reuse waste heat from flue gas with low temperature, and the flue gas waste thermal energy recovery rate reaches more than 65% [27]. In addition, since China's recovery methods of waste heat with high and low temperature need to be unified to prepare for future technological innovation and equipment upgrades, the cascade Rankine cycle designed based on multiple heat sources can be used as a reference [34]. In the cascade Rankine cycle, steam and the organic Rankine cycle work together as a whole to simultaneously capture and utilaze waste heat at three different temperature levels: high, medium and low [34].

It can be concluded that the steam power cycle used in China's steel metallurgical manufacturing can be improved by: using the desuperheating method instead of the full condensation method; using the refrigerant R236ea as a heat transfer fluid in the regenerative organic Rankine cycle; using the cascade Rankine cycle. The technical feasibility and economic feasibility of the above three methods will be evaluated separately below.

3.4. Evaluation of the technical feasibility of the scheme

In the comparative experiment of organic Rankine cycle and Kalina cycle power generation technology, the complex Kalina cycle with preheater is considered to have the highest efficiency at an ammonia concentration of 0.9, but in practical applications, the Kalina cycle cannot show satisfactory recovery efficiency in the medium and high temperature range [33]. It must be mentioned that in Davood Atashbozorg's experiment, the two types of waste heat used came from the rolling section and the electric arc furnace respectively, and because the temperature of the two types of waste heat did not exceed the maximum limit of waste thermal energy with low temperature stipulated in the Guidelines for industrial waste heat comprehensive cascade utilization, in China's industrial system, the two types of waste heat used by Davood Atashbozorg can only be considered as two types of low-temperature waste heat with different temperatures [33]. In the scenario where the waste heat temperature adapted by the Kalina cycle is more limited than that of the organic Rankine cycle, the problem that arises is that the Kalina cycle power generation technology may be suspected of being incapable of recovery of waste heat with low temperature waste heat recovery, resulting in resistance to its promotion in steel companies.

In recent years, there have been endless studies on the working media in the organic Rankine cycle, including the comparison of the economic performance and system thermal efficiency of mixed working fluids and pure working fluids. However, mixed working fluids are not necessarily superior to pure working fluids under special circumstances, and the results are not universal [45]. Under the premise that the Chinese government has recommended that steel companies use the organic Rankine cycle for recovery of waste thermal energy with low temperature, the refrigerant R236ea, i.e. hexafluoropropane, is currently extensively employed in refrigeration systems such as air conditioners. As a refrigerant, R236ea has the characteristics of not being easy to pyrolyze, long service life, and environmental protection and energy conservation. It fits the current problems of serious greenhouse gas emissions and low waste heat recovery efficiency in China's steel manufacturing. It can be employed as one of the options when companies consider using the organic Rankine cycle to reuse waste heat. But the problem is that this fluid has not been used in waste heat recovery in the steel industry, which means it is unknown whether it can perform as well in the complex environment of the steel industry with many interference factors as in laboratories or air conditioning systems. It may be questioned by manufacturers whether it is worth their initial investment costs.

However, although the above measures may be able to promote the development of recovery of waste heat in China's steel industry to a certain extent, the problem of "being controlled by others in technology" has not been avoided, that is, China's steel companies still tackle the challenge of having to import patents from developed countries. The research and technology that have been completed in developed countries can help China avoid more mistakes in technological development, and their high technological barriers can also become a barrier to further development of waste thermal energy recovery and further implementation of environmental protection concepts. High patent fees may even become a problem encountered by the R&D team during the research process and even in subsequent technology updates. In response to this situation, on the one hand, the Chinese government needs to attach importance to waste heat recovery and actually encourage and guide the independent innovation of steel companies by creating a good market environment. On the other hand, companies should increase their financial investment in R&D teams and enhance their own innovation capabilities in order to break through the technological blockade.

4. Conclusion

At present, in the research on enhancing the waste heat recovery efficiency, the research on steam power cycle is more extensive. Part of the conclusions of these studies focus on the fluids used, such as using refrigerants with better thermal efficiency to replace existing heat transfer fluids. Another part of the research is dedicated to the scope of application of different types of cycles and different combinations to apply to waste heat energy at different temperature levels.

In China, the difficulties faced by waste heat recovery in the steel industry are divided into two parts, past and present, for comparative research to find changes: the recovery efficiency is lower than that of developed countries and is greatly affected by the local economy; over the past few years, China's recovery and utilization of waste heat faces the problem of patent thresholds, and there has been no breakthrough in low-temperature waste heat recovery technology, which means that the efficiency of low-temperature waste heat recovery has not been significantly improved. In response to the above problems, this article proposes two methods: using the refrigerant hexafluoropropane R236ea as an option in the steam power cycle; using the Kalina cycle to replace the organic Rankine cycle when recovering ultra-low-temperature waste heat energy. The analysis process is as follows.

This study practices the concept of sustainable development under socialism with Chinese characteristics. The conclusions obtained can provide theoretical help to improve China's waste heat recovery efficiency to a certain extent, thereby reducing the abuse of energy, mining and waste of waste heat to the environment. When applied to the steel industry, it can reduce the sustained energy expenses and help China's steel manufacturing achieve higher profit margins.

In future work, waste heat recovery technology should adapt to the current state of Chinese steel industry and prepare for the large-scale promotion of waste thermal energy recovery. In China, the distribution density of steel mills in different regions is different. Similarly, the economic dependence of different provinces or regions on the economic benefits brought by the steel and metallurgical industry is also different. Therefore, according to the different economic conditions and needs of different provinces, exclusive methods for improving waste heat recovery efficiency should be formulated. For example, for provinces with poor economic conditions and low dependence on the economic benefits brought by steel mills, methods with relatively low recovery efficiency but lower cost should be found for waste heat recovery. At the same time, attention should be paid to the characteristics of the leading industries in these provinces. For example, for provinces with tourism as the main industry, the environmental pollution caused by high-efficiency waste heat recovery should also be evaluated. Such measures can maximize the protection of the industrial structure in different provinces while improving the efficiency of waste heat recovery of the steel industry. Due to the large gap in the industrial structure in different provinces, the implement of different waste thermal energy recovery methods in different regions will be more likely to be accepted by steel mills. At the same time, the large disparity in the size of steel mills in China may also become an obstacle to the promotion of methods used for recovery and utilization of waste thermal energy. In China, the definition of steel mill size is unclear, and there is a large economic gap between steel mills of different sizes. The costs that these steel mills can afford to update the methods employed for recovery of waste thermal energy and the scale of waste heat that needs to be recovered are different. This is a huge challenge for further actions that need to be taken in the future, including statistics on steel mills of different sizes in China and the costs they can afford for technology updates, as well as further in-depth research on waste heat recovery technology to meet the above needs.

Future work of this dissertation can promote the optimization of China's overall energy structure. This efficient and circular use of waste heat energy will help the sustainable development of the local economy and the national economy. This energy structure optimization caused by waste heat recovery can directly benefit people's livelihood. The reduction in fossil fuel consumption caused by waste heat energy recovery will help reduce greenhouse gas output, mitigate the greenhouse effect, and help improve the living environment of citizens.

References

[1]. State Council Information Office (2023). China’s Green Development in the New Era.

[2]. Wang, Z. and Liu, W. (2024). My country’s Overall Manufacturing Scale Has Remained the world’s Largest for 14 Consecutive Years. People’s Daily. 22 Jan.

[3]. State Council of the PRC (2015). Made in China 2025.

[4]. Mardiana-Idayu, A. and Riffat, S.B. (2012). Review on Heat Recovery Technologies for Building Applications.Renewable and Sustainable Energy Reviews, 16(2), pp.1241–1255. https: //doi.org/10.1016/j.rser.2011.09.026.

[5]. Jouhara, H., Khordehgah, N., Almahmoud, S., Delpech, B., Chauhan, A. and Tassau, S. (2018).Waste heat recovery technologies and applications. June 2018, 6, pp.268–289.

[6]. Schwarzmayr, P., Birkelbach, F., Walter, H., Javernik, F., Schwaiger, M. and Hofmann, R. (2023). Packed bed thermal energy storage for waste heat recovery in the iron and steel industry: An experimental study on powder hold-up and pressure drop. arXiv (Cornell University), 75(109735). https: //doi.org/10.1016/j.est.2023.109735.

[7]. Metallurgical Industry Planning and Research Institute (2020). China’s Iron and Steel Industry Energy Saving and Low-Carbon Development Report (2020).

[8]. National Development and Reform Commission (2004). Medium- and Long-Term Special Plan for Energy Conservation.

[9]. Zhang, M. (2015). Application of Waste Heat Recovery Technology in the Iron and Steel Industry and Analysis of Energy Saving Potential - Baidu Library.

[10]. State General Administration of the People's Republic of China for Quality Supervision and Inspection and Quarantine and Standardization Administration of the P.R.C. (2018). Guidelines for Industrial Waste Heat Comprehensive Cascade Utilization.

[11]. Ma, G., Cai, J., Zeng, W. and Dong, H. (2012). Analytical Research on Waste Heat Recovery and Utilization of China’s Iron & Steel Industry. Energy Procedia, 14, pp.1022–1028. https: //doi.org/10.1016/j.egypro.2011.12.1049.

[12]. Catalano, S., Wozniak, A. and Kaplan, K. (2024). Packed Bed (PBR). In: Visual Encyclopedia of Chemical Engineering Equipment.

[13]. Zhu, J., Araya, S.S., Cui, X., Sahlin, S.L. and Kær, S.K. (2020). Modeling and Design of a Multi-Tubular Packed-Bed Reactor for Methanol Steam Reforming over a Cu/ZnO/Al2O3 Catalyst. Energies, 13(3), p.610. https: //doi.org/10.3390/en13030610.

[14]. Naik, S., Wesorick, S., Cotton, S., Plegue, T., Hoffman, N. and TerBeek, E. (2024). Absorbers. In: Visual Encyclopedia of Chemical Engineering Equipment.

[15]. Ortega-Fernández, I. and Rodríguez-Aseguinolaza, J. (2019). Thermal energy storage for waste heat recovery in the steelworks: The case study of the REslag project.Applied Energy, 237, pp.708–719. https: //doi.org/10.1016/j.apenergy.2019.01.007.

[16]. Woodford, C. (2023). Explain that Stuff.

[17]. Simplified Schematic Diagram of a Heat Pipe. (n.d.). global.dnp.

[18]. Farhat, O., Faraj, J., Hachem, F., Castelain, C. and Khaled, M. (2022). A recent review on waste heat recovery methodologies and applications: Comprehensive review, critical analysis and potential recommendations.Cleaner Engineering and Technology, 6(100387), p.100387. https: //doi.org/10.1016/j.clet.2021.100387.

[19]. Zhihu Column. (2017). Application of Heat Pipe Technology in Industrial Waste Heat Recovery. [online] Available at: https: //zhuanlan.zhihu.com/p/28469724 [Accessed 11 Mar. 2024].

[20]. Yousef (2023). 12 Different Types of Heat Exchangers & Their Application.

[21]. Jouhara, H., Almahmoud, S., Chauhan, A., Delpech, B., Nannou, T., Tassou, S.A., Llera, R., Lago, F. and Arribas, J.J. (2017). Experimental investigation on a flat heat pipe heat exchanger for waste heat recovery in steel industry.Energy Procedia, 123, pp.329–334. https: //doi.org/10.1016/j.egypro.2017.07.262.

[22]. Maruoka, N., Mizuochi, T., Purwanto, H. and Akiyama, T. (2004). Feasibility Study for Recovering Waste Heat in the Steelmaking Industry Using a Chemical Recuperator.ISIJ International, 44(2), pp.257–262. https: //doi.org/10.2355/isijinternational.44.257.

[23]. Lu, T., Lü, X., Välisuo, P., Zhang, Q. and Clements-Croome, D. (2024). Innovative approaches for deep decarbonization of data centers and building space heating networks: Modeling and comparison of novel waste heat recovery systems for liquid cooling systems.Applied Energy, [online] 357(122473), p.122473. https: //doi.org/10.1016/j.apenergy.2023.122473.

[24]. Nie, X., Zhao, L., Deng, S., Su, W. and Zhang, Y. (2018). A review of molecular simulation applied in vapor-liquid equilibria (VLE) estimation of thermodynamic cycles.Journal of Molecular Liquids, [online] 264, pp.652–674. Available at: https: //www.sciencedirect.com/science/article/abs/pii/S016773221832186X [Accessed 14 Nov. 2024].

[25]. baike.baidu. (2023). Desuperheater and Pressure Reducer.

[26]. Ibrahim Dincer (2018). Comprehensive Energy Systems. S.L.: Elsevier.

[27]. Feng, J., Cheng, X., Yan, Y., Zhao, L. and Dong, H. (2023). Thermodynamic and thermo-economic analysis, performance comparison and parameter optimization of basic and regenerative organic Rankine cycles for waste heat recovery.Case Studies in Thermal Engineering, 52(103816), pp.103816–103816. https: //doi.org/10.1016/j.csite.2023.103816.

[28]. Reza Jaafari and Rahimi, A.B. (2021). Determination of optimum organic Rankine cycle parameters and configuration for utilizing waste heat in the steel industry as a driver of receive osmosis system.Energy Reports, 7, pp.4146–4171. https: //doi.org/10.1016/j.egyr.2021.06.065.

[29]. Asim, M., Khan, S., Abdul Wasy Zia, Farooq Riaz Siddiqui and Michael K.H. Leung (2024). Thermal Performance Enhancement of Novel Integrated Vapor Compression and Organic Rankine Cycle for Electricity Production: A Full-Condensing vs. Desuperheating Approach Comparison in Ultra-Low-Grade Waste Heat Recovery. e-Prime, 7(100493), pp.100493–100493. https: //doi.org/10.1016/j.prime.2024.100493.

[30]. Jafari, M., Muhammad Imran Khan, Al-Ghamdi, S.G., Jaworski, A.J. and Faisal Asfand (2023). Waste heat recovery in iron and steel industry using organic Rankine cycles.Chemical Engineering Journal, 477(146925), pp.146925–146925. https: //doi.org/10.1016/j.cej.2023.146925.

[31]. Chowdhury, A. and M. Monjurul Ehsan (2023). A Critical Overview of Working Fluids in Organic Rankine, Supercritical Rankine, and Supercritical Brayton Cycles Under Various Heat Grade Sources.International journal of thermofluids, 20(100426), pp.100426–100426. https: //doi.org/10.1016/j.ijft.2023.100426.

[32]. Biondi, M., Giovannelli, A., Di Lorenzo, G. and Salvini, C. (2020). Techno-economic analysis of a sCO2 power plant for waste heat recovery in steel industry.Energy Reports, 6, pp.298–304. https: //doi.org/10.1016/j.egyr.2020.11.147.

[33]. Davood Atashbozorg, A Mohseni Arasteh, Salehi, G. and Masoud Torabi Azad (2022). Analysis of Different Organic Rankine and Kalina Cycles for Waste Heat Recovery in the Iron and Steel Industry.ACS omega, 7(50), pp.46099–46117. https: //doi.org/10.1021/acsomega.2c03922.

[34]. Dokl, M., Rok Gomilšek, Petar Sabev Varbanov, Yee Van Fan, Zdravko Kravanja and Lidija Čuček (2023). Synthesis of Rankine cycle systems with cascade and separate configurations utilising multiple heat sources at different temperature levels.Energy, 284(128588), pp.128588–128588. https: //doi.org/10.1016/j.energy.2023.128588.

[35]. The Chinese Society for Metals (2024b). New Progress in Science and technology: Integrated Development of Key Technology Systems for cross-border Utilization of Distributed Waste Heat in Steel Processes. Csm.org.cn.

[36]. Shi, Z., Zhou, H., Tan, H. and Feng, Q. (2019). Research on the Current Status of Waste Heat Recovery Technology in Steel Industry.Technology Wind.

[37]. National Bureau of Statistics. (2020). National Data. [online] Available at: https: //data.stats.gov.cn/.

[38]. Wan, J. (2022). Panoramic Map of Big Data of Chinese Steel Industry Enterprises in 2022.Forward-the Economist.

[39]. Li, Q. (2014). Current Situation and Countermeasures of Insufficient Utilization of Waste Heat from Steel Smelting.Science and Technology.

[40]. Xiong, C. (2012). Utilization of Waste Heat and Energy in the Steel Industry Faces New Challenges. China Steel News.

[41]. Yu, H. (2020). Current Situation and Countermeasures of Insufficient Utilization of Waste Heat in the Iron and Steel Metallurgical Industry.Science and Technology.

[42]. Tang, W. (2019). Exploring the Shortcomings and Prospects of Waste Heat and Waste Energy Utilization in Iron and Steel Metallurgy Related Fields.Henan Electric Power.

[43]. The State Council of the People’s Republic of China. (2012). Analysis of the Operation of the Steel Industry in 2011 and Outlook for 2012.

[44]. The State Council of the People’s Republic of China. (2013). Analysis of the Operation of the Steel Industry in 2012 and Outlook for 2013.

[45]. Cao, J., Feng, X., Ji, X., Wu, H., Li, C. and Lu, X. (2022). Review of Studies on Organic Rankine Cycle with Zeotropic Mixtures.Thermal Power Generation, 51.

Cite this article

Hu,L. (2025). How to improve the efficiency of waste heat recovery in the steel industry in China?. Advances in Engineering Innovation,16(9),40-52.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. State Council Information Office (2023). China’s Green Development in the New Era.

[2]. Wang, Z. and Liu, W. (2024). My country’s Overall Manufacturing Scale Has Remained the world’s Largest for 14 Consecutive Years. People’s Daily. 22 Jan.

[3]. State Council of the PRC (2015). Made in China 2025.

[4]. Mardiana-Idayu, A. and Riffat, S.B. (2012). Review on Heat Recovery Technologies for Building Applications.Renewable and Sustainable Energy Reviews, 16(2), pp.1241–1255. https: //doi.org/10.1016/j.rser.2011.09.026.

[5]. Jouhara, H., Khordehgah, N., Almahmoud, S., Delpech, B., Chauhan, A. and Tassau, S. (2018).Waste heat recovery technologies and applications. June 2018, 6, pp.268–289.

[6]. Schwarzmayr, P., Birkelbach, F., Walter, H., Javernik, F., Schwaiger, M. and Hofmann, R. (2023). Packed bed thermal energy storage for waste heat recovery in the iron and steel industry: An experimental study on powder hold-up and pressure drop. arXiv (Cornell University), 75(109735). https: //doi.org/10.1016/j.est.2023.109735.

[7]. Metallurgical Industry Planning and Research Institute (2020). China’s Iron and Steel Industry Energy Saving and Low-Carbon Development Report (2020).

[8]. National Development and Reform Commission (2004). Medium- and Long-Term Special Plan for Energy Conservation.

[9]. Zhang, M. (2015). Application of Waste Heat Recovery Technology in the Iron and Steel Industry and Analysis of Energy Saving Potential - Baidu Library.

[10]. State General Administration of the People's Republic of China for Quality Supervision and Inspection and Quarantine and Standardization Administration of the P.R.C. (2018). Guidelines for Industrial Waste Heat Comprehensive Cascade Utilization.

[11]. Ma, G., Cai, J., Zeng, W. and Dong, H. (2012). Analytical Research on Waste Heat Recovery and Utilization of China’s Iron & Steel Industry. Energy Procedia, 14, pp.1022–1028. https: //doi.org/10.1016/j.egypro.2011.12.1049.

[12]. Catalano, S., Wozniak, A. and Kaplan, K. (2024). Packed Bed (PBR). In: Visual Encyclopedia of Chemical Engineering Equipment.

[13]. Zhu, J., Araya, S.S., Cui, X., Sahlin, S.L. and Kær, S.K. (2020). Modeling and Design of a Multi-Tubular Packed-Bed Reactor for Methanol Steam Reforming over a Cu/ZnO/Al2O3 Catalyst. Energies, 13(3), p.610. https: //doi.org/10.3390/en13030610.

[14]. Naik, S., Wesorick, S., Cotton, S., Plegue, T., Hoffman, N. and TerBeek, E. (2024). Absorbers. In: Visual Encyclopedia of Chemical Engineering Equipment.

[15]. Ortega-Fernández, I. and Rodríguez-Aseguinolaza, J. (2019). Thermal energy storage for waste heat recovery in the steelworks: The case study of the REslag project.Applied Energy, 237, pp.708–719. https: //doi.org/10.1016/j.apenergy.2019.01.007.

[16]. Woodford, C. (2023). Explain that Stuff.

[17]. Simplified Schematic Diagram of a Heat Pipe. (n.d.). global.dnp.

[18]. Farhat, O., Faraj, J., Hachem, F., Castelain, C. and Khaled, M. (2022). A recent review on waste heat recovery methodologies and applications: Comprehensive review, critical analysis and potential recommendations.Cleaner Engineering and Technology, 6(100387), p.100387. https: //doi.org/10.1016/j.clet.2021.100387.

[19]. Zhihu Column. (2017). Application of Heat Pipe Technology in Industrial Waste Heat Recovery. [online] Available at: https: //zhuanlan.zhihu.com/p/28469724 [Accessed 11 Mar. 2024].

[20]. Yousef (2023). 12 Different Types of Heat Exchangers & Their Application.

[21]. Jouhara, H., Almahmoud, S., Chauhan, A., Delpech, B., Nannou, T., Tassou, S.A., Llera, R., Lago, F. and Arribas, J.J. (2017). Experimental investigation on a flat heat pipe heat exchanger for waste heat recovery in steel industry.Energy Procedia, 123, pp.329–334. https: //doi.org/10.1016/j.egypro.2017.07.262.

[22]. Maruoka, N., Mizuochi, T., Purwanto, H. and Akiyama, T. (2004). Feasibility Study for Recovering Waste Heat in the Steelmaking Industry Using a Chemical Recuperator.ISIJ International, 44(2), pp.257–262. https: //doi.org/10.2355/isijinternational.44.257.

[23]. Lu, T., Lü, X., Välisuo, P., Zhang, Q. and Clements-Croome, D. (2024). Innovative approaches for deep decarbonization of data centers and building space heating networks: Modeling and comparison of novel waste heat recovery systems for liquid cooling systems.Applied Energy, [online] 357(122473), p.122473. https: //doi.org/10.1016/j.apenergy.2023.122473.

[24]. Nie, X., Zhao, L., Deng, S., Su, W. and Zhang, Y. (2018). A review of molecular simulation applied in vapor-liquid equilibria (VLE) estimation of thermodynamic cycles.Journal of Molecular Liquids, [online] 264, pp.652–674. Available at: https: //www.sciencedirect.com/science/article/abs/pii/S016773221832186X [Accessed 14 Nov. 2024].

[25]. baike.baidu. (2023). Desuperheater and Pressure Reducer.

[26]. Ibrahim Dincer (2018). Comprehensive Energy Systems. S.L.: Elsevier.

[27]. Feng, J., Cheng, X., Yan, Y., Zhao, L. and Dong, H. (2023). Thermodynamic and thermo-economic analysis, performance comparison and parameter optimization of basic and regenerative organic Rankine cycles for waste heat recovery.Case Studies in Thermal Engineering, 52(103816), pp.103816–103816. https: //doi.org/10.1016/j.csite.2023.103816.

[28]. Reza Jaafari and Rahimi, A.B. (2021). Determination of optimum organic Rankine cycle parameters and configuration for utilizing waste heat in the steel industry as a driver of receive osmosis system.Energy Reports, 7, pp.4146–4171. https: //doi.org/10.1016/j.egyr.2021.06.065.

[29]. Asim, M., Khan, S., Abdul Wasy Zia, Farooq Riaz Siddiqui and Michael K.H. Leung (2024). Thermal Performance Enhancement of Novel Integrated Vapor Compression and Organic Rankine Cycle for Electricity Production: A Full-Condensing vs. Desuperheating Approach Comparison in Ultra-Low-Grade Waste Heat Recovery. e-Prime, 7(100493), pp.100493–100493. https: //doi.org/10.1016/j.prime.2024.100493.

[30]. Jafari, M., Muhammad Imran Khan, Al-Ghamdi, S.G., Jaworski, A.J. and Faisal Asfand (2023). Waste heat recovery in iron and steel industry using organic Rankine cycles.Chemical Engineering Journal, 477(146925), pp.146925–146925. https: //doi.org/10.1016/j.cej.2023.146925.

[31]. Chowdhury, A. and M. Monjurul Ehsan (2023). A Critical Overview of Working Fluids in Organic Rankine, Supercritical Rankine, and Supercritical Brayton Cycles Under Various Heat Grade Sources.International journal of thermofluids, 20(100426), pp.100426–100426. https: //doi.org/10.1016/j.ijft.2023.100426.

[32]. Biondi, M., Giovannelli, A., Di Lorenzo, G. and Salvini, C. (2020). Techno-economic analysis of a sCO2 power plant for waste heat recovery in steel industry.Energy Reports, 6, pp.298–304. https: //doi.org/10.1016/j.egyr.2020.11.147.

[33]. Davood Atashbozorg, A Mohseni Arasteh, Salehi, G. and Masoud Torabi Azad (2022). Analysis of Different Organic Rankine and Kalina Cycles for Waste Heat Recovery in the Iron and Steel Industry.ACS omega, 7(50), pp.46099–46117. https: //doi.org/10.1021/acsomega.2c03922.

[34]. Dokl, M., Rok Gomilšek, Petar Sabev Varbanov, Yee Van Fan, Zdravko Kravanja and Lidija Čuček (2023). Synthesis of Rankine cycle systems with cascade and separate configurations utilising multiple heat sources at different temperature levels.Energy, 284(128588), pp.128588–128588. https: //doi.org/10.1016/j.energy.2023.128588.

[35]. The Chinese Society for Metals (2024b). New Progress in Science and technology: Integrated Development of Key Technology Systems for cross-border Utilization of Distributed Waste Heat in Steel Processes. Csm.org.cn.

[36]. Shi, Z., Zhou, H., Tan, H. and Feng, Q. (2019). Research on the Current Status of Waste Heat Recovery Technology in Steel Industry.Technology Wind.

[37]. National Bureau of Statistics. (2020). National Data. [online] Available at: https: //data.stats.gov.cn/.

[38]. Wan, J. (2022). Panoramic Map of Big Data of Chinese Steel Industry Enterprises in 2022.Forward-the Economist.

[39]. Li, Q. (2014). Current Situation and Countermeasures of Insufficient Utilization of Waste Heat from Steel Smelting.Science and Technology.

[40]. Xiong, C. (2012). Utilization of Waste Heat and Energy in the Steel Industry Faces New Challenges. China Steel News.

[41]. Yu, H. (2020). Current Situation and Countermeasures of Insufficient Utilization of Waste Heat in the Iron and Steel Metallurgical Industry.Science and Technology.

[42]. Tang, W. (2019). Exploring the Shortcomings and Prospects of Waste Heat and Waste Energy Utilization in Iron and Steel Metallurgy Related Fields.Henan Electric Power.

[43]. The State Council of the People’s Republic of China. (2012). Analysis of the Operation of the Steel Industry in 2011 and Outlook for 2012.

[44]. The State Council of the People’s Republic of China. (2013). Analysis of the Operation of the Steel Industry in 2012 and Outlook for 2013.

[45]. Cao, J., Feng, X., Ji, X., Wu, H., Li, C. and Lu, X. (2022). Review of Studies on Organic Rankine Cycle with Zeotropic Mixtures.Thermal Power Generation, 51.