1. Introduction

In order to cope with global environmental pollution and the increasingly tense fuel supply and demand contradiction, countries regard the development of new energy vehicles as a national strategy and regard it as the development direction of the global automotive industry. They accelerate the research and industrialization of technology, and actively develop and apply energy-saving technologies for automobiles. The energy-saving of new energy vehicles and the power battery system, as key components, directly affect the performance of the vehicle's power system and have become important strategic plans for achieving sustainable development in the automotive industry. Consumers have increasingly high demands for the power performance, reliability, environmental adaptability, and safety of new energy vehicles. Therefore, in the development process of new energy vehicles, it is particularly important to comprehensively test and evaluate the capabilities of power battery systems and provide safe and reliable power battery systems. Countries and automobile manufacturers should strengthen cooperation, jointly promote the research and development of power battery systems, formulate corresponding testing and evaluation standards and methods to ensure the reliability and safety of new energy vehicles, and further promote innovation and development of new energy vehicle technology.

2. Construction of a testing and evaluation system for power batteries

2.1. Determine testing indicators and key parameters

As an important evaluation indicator of the power battery system, battery capacity directly affects the energy storage and release capacity of the battery, and is also one of the key factors in the range of new energy vehicles. Evaluating battery capacity requires conducting charge and discharge tests under specific conditions to accurately measure the battery's energy storage capacity. Charging and discharging performance refers to the performance of a battery during the charging and discharging process, including the charging efficiency, discharging efficiency, and stability at different charging and discharging powers [1]. By conducting charge and discharge performance tests, the energy conversion efficiency and power response capability of batteries can be evaluated, providing important references for the utilization of electrical energy in battery systems. Cycle life assessment aims to simulate the performance degradation of a battery after multiple charge and discharge cycles, in order to predict the battery's service life and performance changes. By conducting cyclic charge and discharge tests on batteries and analyzing their performance changes with the number of cycles, important basis can be provided for battery life management and maintenance. The temperature characteristic test aims to evaluate the performance and safety characteristics of batteries in different temperature environments. Due to the significant impact of temperature on the performance and safety of batteries, conducting charge and discharge tests under different temperature conditions can provide a more comprehensive understanding of the working characteristics and safety boundaries of batteries, thereby providing scientific basis for the design and use of battery systems. Therefore, for a comprehensive evaluation of the power battery system, it is not only necessary to consider the above indicators, but also to fully demonstrate the design of the testing plan and data analysis to ensure the scientificity and reliability of the evaluation results.

2.2. Establish corresponding testing methods and standards

Capacity testing is an important method for evaluating the energy storage capacity of power batteries, usually using standardized charge and discharge cycles for testing to accurately measure the actual energy storage capacity of the battery. In capacity testing, the battery is charged and discharged in cycles according to the specified charging and discharging currents, and then the actual capacity of the battery is calculated through precise voltage and current monitoring, in order to understand the energy storage performance and actual available energy of the battery. The charging and discharging performance test aims to simulate the charging and discharging process under real working conditions, observe the response and efficiency of the battery under various working conditions. By simulating the charging and discharging processes at different powers and rates, the energy conversion efficiency, power output response, and cycling stability of the battery can be evaluated in real usage scenarios, providing reference for the practical application of the battery. Cycle life testing simulates the performance changes of a battery after multiple uses through continuous charge and discharge cycles. By conducting multiple cycles of charge and discharge tests on the battery, the cycle life, capacity retention rate, and changes in internal chemical reactions can be evaluated, providing important data for battery life prediction and management. Temperature characteristic testing is a charge and discharge test conducted under different temperature conditions to evaluate the performance and safety of the battery in different temperature environments. Temperature has a significant impact on the capacity, charging and discharging efficiency, and safety of batteries. Therefore, by simulating the charging and discharging process under different temperature conditions, the temperature response characteristics of batteries can be comprehensively understood, providing scientific basis for thermal management and safety design of batteries. The above testing methods play a crucial role in the evaluation system of power battery systems. Through scientific and accurate testing and analysis, the performance and reliability of battery systems can be comprehensively evaluated, providing important support for the research and application of new energy vehicles.

2.3. Implementation of experimental verification

Designing standardized testing procedures is a crucial component of the power battery evaluation system. Firstly, it is necessary to determine the testing parameters, testing equipment, and testing conditions to ensure the repeatability and comparability of the testing process. Corresponding testing plans need to be developed for different models and specifications of power batteries, and corresponding testing parameters and procedures need to be developed for each model to ensure the scientific and reliable testing results. During the testing process, it is necessary to accurately record the test data, including key parameters such as voltage, current, temperature, etc. during the charging and discharging process. At the same time, it is necessary to record the number of charging and discharging cycles and the energy changes during charging and discharging. These test data are crucial for subsequent analysis and comparison, providing experimental basis for the establishment of evaluation system and detailed data support for the performance characteristics of power batteries. For different models and specifications of power batteries, multiple tests and data analysis can be conducted to compare and analyze the performance characteristics and differences of different batteries. Through these analyses, we can gain a deeper understanding of the performance differences of different models and specifications of power batteries, as well as their performance under different testing conditions, providing important references for optimizing the evaluation system [2]. Finally, it is crucial to verify the feasibility and effectiveness of the testing and evaluation system. By comprehensively evaluating the test data and analysis results, it can be verified whether the evaluation system can comprehensively and objectively evaluate the performance of different models and specifications of power batteries. Meanwhile, based on the verification results, the evaluation system can be adjusted and improved to further enhance its feasibility and effectiveness. By following standardized testing procedures, recording accurate test data and conducting thorough analysis and comparison, as well as verifying the feasibility and effectiveness of the testing evaluation system, scientific basis and technical support can be provided for the comprehensive evaluation of power batteries, thereby promoting the development and application of new energy vehicle technology.

3. Specific components of the system testing and evaluation system

3.1. Architecture

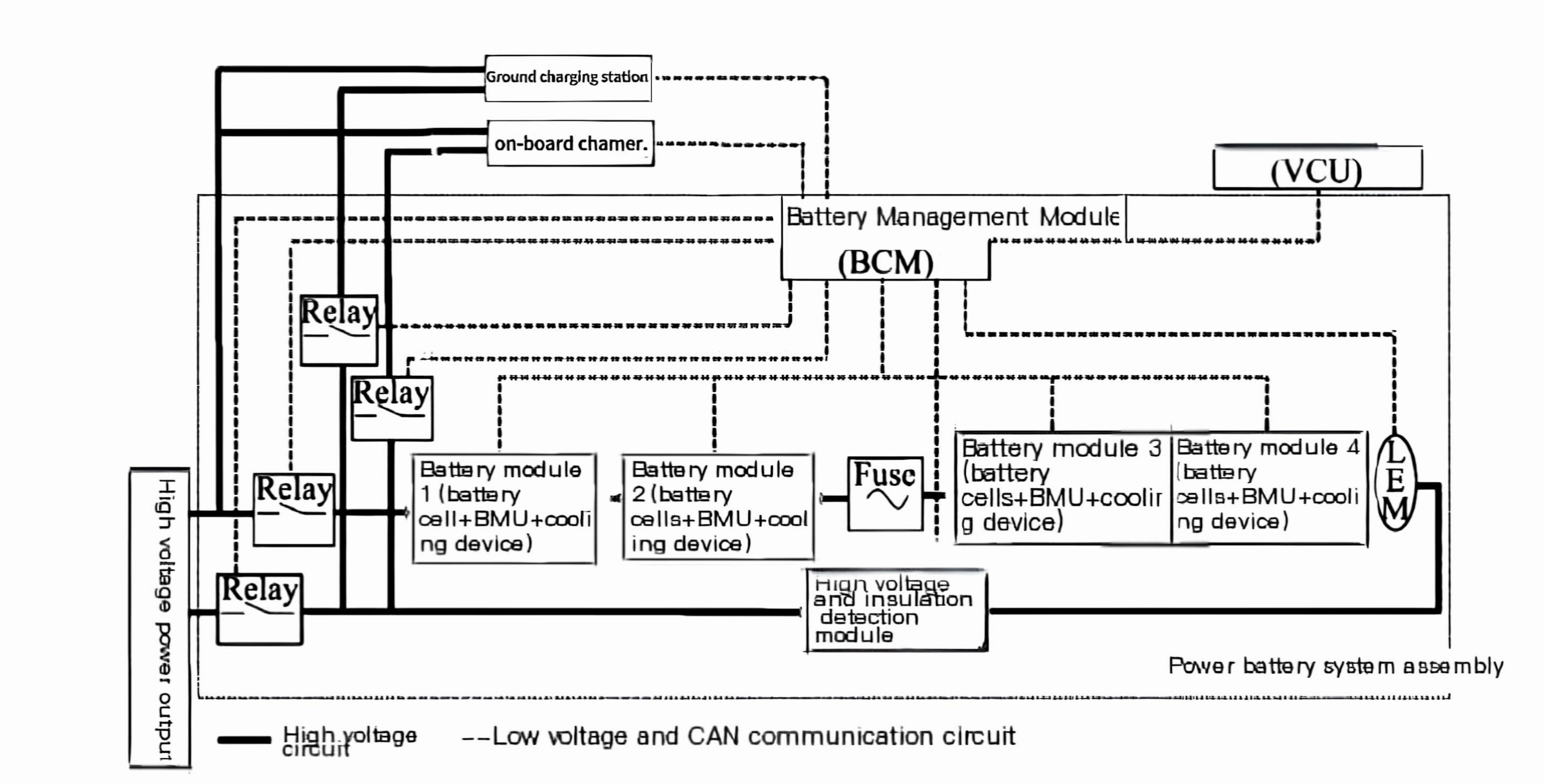

From Figure 1, it can be seen that the system is an important component of new energy electric vehicles, and its internal subsystems mainly include battery cells, management systems, thermal management systems, high and low voltage electrical components, etc. During work, by dissipating heat from the lithium-ion battery, it is kept in a suitable working temperature range, thereby improving its service life and safety.

Figure 1. Structure diagram of power battery system

To ensure that the performance indicators of new energy electric vehicles, including power, machinery, safety, and reliability, meet national and enterprise standards, multiple performance indicators such as environmental adaptability, electromagnetic compatibility, power, machinery, safety, and reliability are tested and evaluated. Due to the complex structure of the battery system, it is necessary for personnel to conduct a comprehensive analysis of the work requirements of each part of the system during performance testing, and independently verify the important subsystems and components in the system. Nowadays, when evaluating the performance of power battery systems, the entire system is generally divided into three levels: the first level is the battery module, and the second level is the battery cell. In addition, the entire system also involves multiple types of electronic devices such as relays and controllers, which require relevant tests to verify their performance.

3.2. Battery system assembly

This level is an independent unit in the energy storage equipment of new energy vehicles, with a clear control system and management objectives. By connecting the battery to the entire vehicle through communication and simulating the vehicle's operating environment, precise verification of its performance can be achieved, reducing the complexity of experimental evaluation. The focus of actual testing work can be seen from the basic requirements and performance analysis of the entire vehicle.

The first heat dissipation effect. Its research content includes: whether the battery system can operate normally in special environments; Can the system structure, shell materials, etc. meet the usage requirements; Can it resist fatigue caused by external environment; Can the internal management function ensure that the battery operates at a suitable working temperature.

Second environmental performance. The focus is on the ability of the powertrain to withstand external conditions. Especially the sealing performance of the shell material is significantly different from traditional automotive parts, requiring a certain degree of fire resistance to prevent water from seeping into the system, causing short circuits and insulation failures. At the same time, the content and requirements of environmental performance testing are closely related to the installation location of the battery system assembly. Staff need to conduct corresponding tests according to different installation locations, including smoke tests, dust tests, waterproof tests, etc.

The third mechanics. The focus is on inspecting the composition strength, internal devices, etc. of the battery system to determine whether it can work normally under specific conditions and whether it has failed due to insufficient strength, fatigue, and other reasons. This is very different from traditional part inspection, as the volume and mass of battery systems are much larger. If conventional inspection methods are used, it is likely to cause system failure, resulting in unnecessary time and cost. At present, multiple technical standards have been tested and verified in China, including random vibration cycle test, modal test, vibration thermal cycle test, etc. [3].

Fourth, electromagnetic compatibility performance. Due to the presence of multiple temperature and voltage sampling circuits as well as independent controllers in battery system components, the design of the system needs to meet the basic requirements of electromagnetic compatibility. At the same time, due to the complex electromagnetic environment in which the system operates, it needs to be subject to certain anti-interference measures to prevent electromagnetic radiation from interfering with other system components and posing a threat to the personal safety of personnel. The experimental content is shown in Table 1.

Table 1. Electromagnetic anti-interference test items

Electromagneticanti -interference test | Frequency domain testing | Radiation immunity | High current injection method (BIC) |

ALSE method | |||

Msgegtio field inte rference | |||

Time domain testing | Transient conducted immunity of power lines | ||

Transient conducted immunity of signal/control lines | |||

Electrical Fast Transient Pulse Swarm lmmunity | |||

Electrostatic Discharge | |||

Fifth, high voltage design. The power battery system assembly requires a working voltage higher than 300 V. Therefore, in actual evaluation work, comprehensive consideration should be given to the voltage requirements, combining leakage current detection with high voltage resistance testing, and combining leakage current detection with high voltage resistance testing to conduct functional tests on battery system components.

Sixth, the controller. The power supply for this part comes from the 12 V or 24 V power supply of the entire vehicle, so it is necessary to meet the performance requirements of the vehicle for the parts. The specific testing is mainly reflected in two aspects: low-voltage power supply and electrical performance. From the perspective of practical application, performance testing of low-voltage power supplies includes detection of power supply voltage, voltage fluctuations, static current, and voltage range; Electrical performance tests include tests on reverse voltage, discontinuous voltage, and load rejection of the power supply.

Seventh, electrochemical performance. This type of characteristic test is fundamentally different from the performance requirements of conventional vehicle components. For new energy electric vehicles, their electrochemical performance is directly related to the overall power performance of the vehicle. Therefore, the focus is on testing and evaluating their capacity, power output, feedback capability, etc. under specific conditions, including constant power discharge performance, static capacity, energy output, etc.

Eighth, cycle life. This performance test aims to test whether the number of charging/discharging cycles and the total energy output throughout the entire lifecycle meet the requirements for vehicle use. Usually, staff use cycle life flowcharts to test and validate the accuracy and thermal management capabilities of battery management systems, as shown in Figure 2. Due to longer testing cycles in certain areas, separate inspections and analyses are required. This project aims to establish a mathematical model based on battery life test data to assist staff in accurately calculating and analyzing its service life, which is of great significance for the research and design of new energy electric vehicles in China. To better test the performance of the battery system, some people suggest saving testing and other aspects. This not only strengthens the technical requirements for the battery system assembly, but also fully reflects the usage status of the car [4].

Figure 2. Flow chart of cycle life detection

3.3. Cell testing

The battery is the basic unit that makes up the battery system, and its actual performance directly affects the safety level, reference power, and usage time of the entire system. When conducting experimental verification, in addition to considering the impact of temperature factors on battery performance, it is also necessary to compare and analyze the test results of the battery under different conditions. The battery safety performance test is a direct reflection of the chemical characteristics and protective measures of the battery, which is of great help to the safe operation of the battery system. Therefore, it is necessary to strengthen the experimental research on the battery and adjust the specific plan based on the final results. As shown in Figure 2.

3.4. Result evaluation

Through the analysis of the evaluation contents of the three testing items mentioned above, it can be seen that the performance testing and evaluation of the battery system assembly, battery components, and battery cells are carried out from two perspectives. One is safety. This type of detection is conducted in specific situations, and the specific evaluation method is based on the degree of danger. For example, if there is no change, it means the function is normal. Passive protection devices require maintenance. If there is a fire, there will be no explosion. If there is an explosion, the battery will be completely disassembled. On the other hand, it has nothing to do with security. Classify the battery condition during and after the experiment, and combine it with various domestic technical standards to determine more parameters of the power battery, such as electromagnetic compatibility, environmental climate, electrochemistry, mechanical, etc.

4. New energy vehicle battery system management

4.1. System composition

Nowadays, the battery management system of new energy electric vehicles has adopted advanced technology, including temperature regulation and voltage control circuits. These circuits are equipped with thermometers inside to monitor the temperature of the battery, and adjust the temperature and collect voltage information by connecting external fan control circuits and voltage acquisition modules. In working mode, this system can directly analyze basic information such as remaining battery capacity, battery usage temperature, and usage time, helping staff quickly judge the performance of the battery. From the perspective of the long-term development of new energy vehicles, the importance of battery management systems is self-evident. It can accurately determine the working status of the overall battery system, and adjust and implement strategies based on specific status control to ensure the safe and stable operation of the battery system. According to the structural diagram of the battery management system (Figure 3), it can be seen that it also has multiple functions such as data acquisition, status detection, balance control, and safety protection [5].

Figure 3. Management structure of battery system

Firstly, taking data collection as an example, the battery management system provides technical support for the charging control module and discharging control module. Through data collection, the system can monitor the charge status and voltage of the battery to maintain the normal operation of the battery management system, avoid unnecessary problems, and ensure the safe operation of the battery system. Secondly, state detection is another important function of battery management systems. The system can perform comprehensive status monitoring of the battery pack, including monitoring of parameters such as charge state, voltage deviation, and internal resistance. Through real-time monitoring and analysis, the system can promptly detect potential battery issues such as capacity decay, imbalance, and faults, provide timely alarms and maintenance guidance, and avoid safety risks and performance degradation caused by battery problems [6]. Thirdly, balanced control is designed to address the issue of imbalance between individual cells in a battery pack. Due to the different characteristics and usage of each individual cell in the battery pack, it can lead to uneven charge distribution among the cells. In this way, it is easy to cause unstable performance of the battery pack, and even lead to overcharging or overdischarging phenomena. To solve this problem, the battery management system can adjust the charge distribution between each individual cell in the battery pack through balanced control technology, ensuring the overall performance and lifespan of the battery pack [7].

4.2. Implementation strategy

Firstly, for data collection, it is necessary to ensure that the system can accurately collect and record key data during the battery charging and discharging process. It involves technical issues such as the selection and layout of sensors, and the stability of data transmission. At the same time, it is necessary to establish a sound data storage and management mechanism to ensure the accuracy and traceability of data. Secondly, in terms of state detection, it is necessary to establish a comprehensive state monitoring system, including battery parameter monitoring, fault diagnosis, and real-time alarm functions. It is necessary to develop comprehensive monitoring indicators and fault diagnosis algorithms, and ensure the reliability and stability of monitoring equipment. Thirdly, in terms of balance control, it is necessary to develop corresponding balance schemes for different types of battery packs, including the selection of dynamic balance and static balance technologies, as well as the optimization of balance control strategies. In addition, it is necessary to consider the impact of balanced control on battery life and performance, develop reasonable control strategies, and balance performance and life [8]. Fourthly, in the process of system design and installation, it is necessary to strictly follow relevant standards and specifications to ensure the security and stability of the system. In addition, it is necessary to improve the overall quality management level from the aspects of supply chain management, quality control, etc., to ensure the reliability and stability of the system. Finally, by introducing advanced technologies such as artificial intelligence and big data analysis, intelligent optimization and predictive analysis of battery management systems can be achieved. This requires the establishment of a comprehensive data analysis platform and algorithm model to achieve real-time monitoring and predictive analysis of battery system status and performance, providing more accurate support for operation management and maintenance.

5. Analysis of test research results

In the testing of new energy vehicle power battery systems, the testing of battery modules and cells is particularly important. In the process of developing the battery system for the entire vehicle, it is necessary to fully integrate the vehicle performance, automotive component testing requirements, and the characteristics of the battery itself to improve the testing methods and ensure the rationality and effectiveness of the testing plan. When analyzing the test results, the first step is to conduct safety performance testing. In this stage, the testing process should be completed in extreme environments to verify the safety performance of the battery system assembly, battery modules, and cells under extreme conditions [9]. This extreme environment includes high temperature, low temperature, high humidity, low pressure, etc. Conducting safety performance testing under these conditions can be more closely related to the various situations that batteries may encounter in actual use, thus constructing a comprehensive safety evaluation plan and improving the effectiveness of testing work. In the process of safety performance testing, it is necessary to evaluate the overall safety performance of the battery system, including testing of overcharge and over discharge protection, short circuit protection, over temperature protection, and other aspects of the battery. According to different levels of danger, batteries were evaluated to varying degrees, and SAND 2005-3123 classified them into 8 categories, as shown in Table 2 [10].

In addition, it is necessary to conduct in-depth evaluations of the safety performance of battery modules and cells to ensure that the battery can operate safely and reliably in various extreme situations. In addition to security performance testing, non-security performance testing is also crucial. In this stage, it is necessary to meet the requirements of vehicle development and conduct a comprehensive analysis based on the power system, capacity system, and service life standards. At the same time, it is necessary to test the performance of the battery system under different operating conditions, including considerations of power performance, cycle life, charge and discharge performance, etc. The detection of battery modules and cells is a crucial step in the testing of new energy vehicle power battery systems. During the testing process, it is necessary to fully consider the performance requirements of the entire vehicle, the testing needs of automotive components, and the characteristics of the battery itself to ensure the rationality and effectiveness of the testing plan. Through strict safety and non-safety performance testing, the safety and stability of battery systems can be effectively improved, ensuring the reliability and performance of new energy vehicle power battery systems.

Table 2. Hazardous levels and description

danger grade | description | Classification criteria and impact |

0 | unchanged | No changes, normal function |

1 | passive protection | No damage,no leakage, swelling, fire, ruptureor explosion occurred, no thermal runawayoccurred, passive protection device needs tobe repaired |

2 | damage | No leakage,swelling,fire, rupture, or explosion occurred,and no thermal runaway occurred, which can be repaired |

3 | Leakage (mass change<50%) | No swelling,fire,rupture,or explcsion occurred, and themass change was less than 50% of the electrolyteweight |

4 | Swelling and leakage (50% change inquality) | No fire,rupture,or explosion occurred, with a masschange greater than 50% of the electrolyte weight |

5 | Fire breaking out | No rupture or explosion occurred (no battery parts areallowed to fly out during the test) |

6 | break | No explosion occurred, and battery components wereallowed to fly out during the testing process |

7 | explosion | Explosion (complete disassembly of battery) |

6. Conclusions

Analyzing the testing status of the power battery system for new energy vehicles is an important step in ensuring the performance and safety of the battery system. For battery module and cell testing, the testing standards should be determined based on the overall vehicle development performance, and the testing methods should be improved in combination with the overall vehicle performance, automotive component testing requirements, and the characteristics of the battery itself to ensure the rationality of the testing plan. In terms of analysis of test results, both safety performance testing and non safety performance testing are key components. Safety performance testing needs to be completed in extreme environments, and a safety evaluation plan should be established to comprehensively evaluate the safety performance of the battery system's assemblies, modules, and cells, in order to improve the effectiveness of the testing work. Non safety performance testing should meet the needs of vehicle development, taking into account factors such as power system, capacity system, service life standards, as well as mechanical performance testing, to ensure the stability of battery system operation and the rationality of automotive component testing. Through effective detection and analysis, the safety, reliability, performance stability, and service life of new energy vehicle power battery systems can be ensured, thereby promoting the sustainable development of new energy vehicles. However, in practical applications, further research and standard development are needed to continuously improve the performance and safety of battery systems, and promote further breakthroughs and innovations in new energy vehicle technology.

References

[1]. Zhu, H. (2023). Research on Hardware Optimization Design of Power Battery Management System for New Energy Vehicles. Automotive Test Report, 7, 70-72.

[2]. Wu, S., & Lei, Z. (2023). Application Technology of Lithium ion Power Battery System for New Energy Vehicles. Special Purpose Vehicle, 9, 22-24.

[3]. Zu, Q. (2023). Maintenance and upkeep of power batteries for new energy vehicles. Special Purpose Vehicle, 8, 115-117.

[4]. Wang, S., Yu, X., & Wu, S. (2018). Research on the Testing and Evaluation System of New Energy Vehicle Power Battery System. Automotive and Driving Maintenance (Maintenance Edition), 5, 162.

[5]. Lü, D. (2024). Common Fault Analysis of Power Battery Management System for New Energy Vehicles. Automotive Maintenance and Repair, 2, 70-72.

[6]. Liu, L., Guo, S., & Wang, L. (2023). Research on Power Battery System and Structural Technology Based on Patent Analysis. Automotive Abstracts, 11, 22-28.

[7]. Diao, G. (2023). Optimization of Composite Electric Energy System Design for New Energy Vehicles. Automotive Test Report, 19, 59-61.

[8]. Wu, S., & Lei, Z. (2023). Application Technology of Lithium ion Power Battery System for New Energy Vehicles. Special Purpose Vehicles, 9, 22-24.

[9]. Wang, Z. (2023). Research on Control Technology of Power Battery System for New Energy Vehicles. Automotive Maintenance Technician, 8, 117-118.

[10]. Wen, Z., Lu, X., & Lu, S. (2023). Research on Electrical Performance Test of Power Battery System for New Energy Vehicles. Automotive Test Report, 7, 67-69.

Cite this article

Li,L.;Zhang,L.;Song,Y.;Wang,L.;Cheng,C.;Xi,L.;Yi,X. (2025). Research on the testing and evaluation system of power battery system for new energy vehicles. Advances in Engineering Innovation,16(5),20-27.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Advances in Engineering Innovation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhu, H. (2023). Research on Hardware Optimization Design of Power Battery Management System for New Energy Vehicles. Automotive Test Report, 7, 70-72.

[2]. Wu, S., & Lei, Z. (2023). Application Technology of Lithium ion Power Battery System for New Energy Vehicles. Special Purpose Vehicle, 9, 22-24.

[3]. Zu, Q. (2023). Maintenance and upkeep of power batteries for new energy vehicles. Special Purpose Vehicle, 8, 115-117.

[4]. Wang, S., Yu, X., & Wu, S. (2018). Research on the Testing and Evaluation System of New Energy Vehicle Power Battery System. Automotive and Driving Maintenance (Maintenance Edition), 5, 162.

[5]. Lü, D. (2024). Common Fault Analysis of Power Battery Management System for New Energy Vehicles. Automotive Maintenance and Repair, 2, 70-72.

[6]. Liu, L., Guo, S., & Wang, L. (2023). Research on Power Battery System and Structural Technology Based on Patent Analysis. Automotive Abstracts, 11, 22-28.

[7]. Diao, G. (2023). Optimization of Composite Electric Energy System Design for New Energy Vehicles. Automotive Test Report, 19, 59-61.

[8]. Wu, S., & Lei, Z. (2023). Application Technology of Lithium ion Power Battery System for New Energy Vehicles. Special Purpose Vehicles, 9, 22-24.

[9]. Wang, Z. (2023). Research on Control Technology of Power Battery System for New Energy Vehicles. Automotive Maintenance Technician, 8, 117-118.

[10]. Wen, Z., Lu, X., & Lu, S. (2023). Research on Electrical Performance Test of Power Battery System for New Energy Vehicles. Automotive Test Report, 7, 67-69.