1. Introduction

With the advancement of the “Healthy China” strategy and the growing consumer demand for functional foods, the innovative upgrading of traditional medicinal diets has become a research focus in the field of food science. Bazhen Cake, a classic spleen-strengthening medicinal diet, is formulated with eight herbal ingredients including Poria and lotus seeds, exhibiting significant qi-tonifying and spleen-strengthening effects. However, the traditional dosage forms suffer from coarse texture, poor portability, and low utilization efficiency of active components, which limit their market promotion [1]. Existing glutinous rice cake products, such as Rosa roxburghii glutinous rice cake [2] and dandelion glutinous rice cake [3], have improved portability but still face shortcomings including insufficient functional components and overly pronounced herbal taste. Therefore, this study developed a Bazhen glutinous rice cake with both efficacy and palatability, based on the traditional Bazhen formula and combined with freeze-drying technology, β-cyclodextrin inclusion, and response surface methodology. By establishing a multi-dimensional evaluation system integrating “process-sensory-functional efficacy,” this study aims to overcome the limitations of traditional processing and provide technical support for the industrialization of medicinal food homologues.

2. Materials and methods

2.1. Materials and equipment

Materials: Poria, Codonopsis pilosula, Atractylodes macrocephala, Coix seed, Chinese yam, Euryale seeds, white hyacinth bean, and lotus seed kernels (Zhang Zhongjing Pharmacy, Henan Province, China); wet-milled glutinous rice flour (Changfengpo Foods, Jingmen City, China); β-cyclodextrin (analytical grade, Sigma-Aldrich); rose essential oil (food grade, Baihua Flavors, Guangzhou, China); other auxiliary materials, including granulated sugar and butter, were commercially available food-grade ingredients.

Equipment: Pulverizer (Rongshida RS-FS1401), induction cooker (Midea C22-RT2240), electronic balance (Leqi LQ-C5001), high-pressure steam sterilizer (Tuoyan Technology YX-280), Huajida steamer (HJD-A44-304).

2.2. Experimental methods

2.2.1. Process flow

Pre-treatment of raw and auxiliary materials → preparation of freeze-dried yam fragments → β-cyclodextrin inclusion of rose essential oil particles → filling preparation → steaming → glutinous rice dough preparation → stuffing and shaping → final product.

2.2.2. Key process parameters

Pre-treatment of raw and auxiliary materials: The processed eight herbal ingredients were separately ground through a No. 7 sieve (aperture 0.15 mm), then proportionally mixed and kneaded into a fine powder.

Preparation of freeze-dried yam: Fresh yam slices were soaked in a color-protecting solution (0.5% citric acid + 0.1% ascorbic acid) for 3 h, pre-frozen at −30 °C for 12 h, and subjected to vacuum microwave drying (power 400 W, 6 h) until the moisture content reached 0.12 g/g.

β-Cyclodextrin inclusion of rose essential oil: Rose essential oil was extracted using 7.5% NaCl solution, then mixed with β-cyclodextrin solution (15%) at an oil-to-carrier ratio of 1:10, stirred magnetically at 60 °C for 2 h, centrifuged (4000 rpm, 15 min), and finally spray-dried (inlet temperature 160 °C, outlet temperature 80 °C).

2.2.3. Orthogonal experimental design

Based on the results of single-factor experiments, water addition (A: 115, 125, 135 g), syrup addition (B: 85, 87.5, 90 g), and the ratio of herbal slices to syrup (C: 13:1, 14:1, 15:1) were selected as variables and optimized according to an L9(3⁴) orthogonal array (Table 1).

|

Level |

A The proportion of traditional Chinese medicine decoction pieces added |

B Addition amount of syrup(g) |

C Water addition(g) |

|

1 |

13:1 |

85 |

115 |

|

2 |

14:1 |

87.5 |

125 |

|

3 |

15:1 |

90 |

135 |

2.3. Evaluation methods

Sensory Evaluation: The method was adapted from GB 7099-2015. Sixteen panelists (equal gender distribution) scored five indicators, including color and hardness, on a 100-point scale (Table 2; note that standards and descriptions were inconsistent). After removing extreme values, the mean score was calculated.

Determination of Functional Components: The content of astragaloside IV was measured by HPLC (C18 column, acetonitrile–water gradient elution, flow rate 1.0 mL/min, detection wavelength 203 nm).

Texture Analysis: Texture properties, including hardness, elasticity, and chewiness, were measured using a texture analyzer (probe P/5, compression ratio 50%).

|

Evaluating indicator |

Score value |

High |

Middle |

Poor |

|

Humidity |

20 |

Moderate humidity has good agglomeration 17~20 |

Invagination is wet or dry12~17 |

Moist not agglomerated or dry chapped less than 12 points |

|

Plasticity degree |

15 |

Perfect shape17~20 |

Partial collapse12~17 |

Serious collapse less than 12 points |

|

Taste |

20 |

The taste is well combined 17~20 |

The taste of the medicine is slightly abrupt12~17 |

The taste is weirdless than 12 points |

|

Odour |

10 |

Sweet aroma 17~20 |

Slightly astringent12~17 |

Puckeryless than 12 points |

|

Appearance |

10 |

Beautiful appearance17~20 |

Ordinary appearance 12~17 |

Ugly appearanceless than 12 points |

|

Holistic scoring |

10 |

Complete acceptance85~100 |

Generally accepted 60~85 |

Not-acceptable Under 60 points |

3. Results and analysis

3.1. Single-factor experimental results

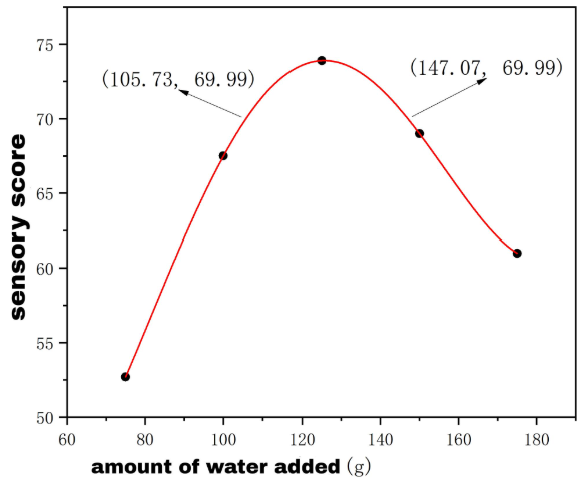

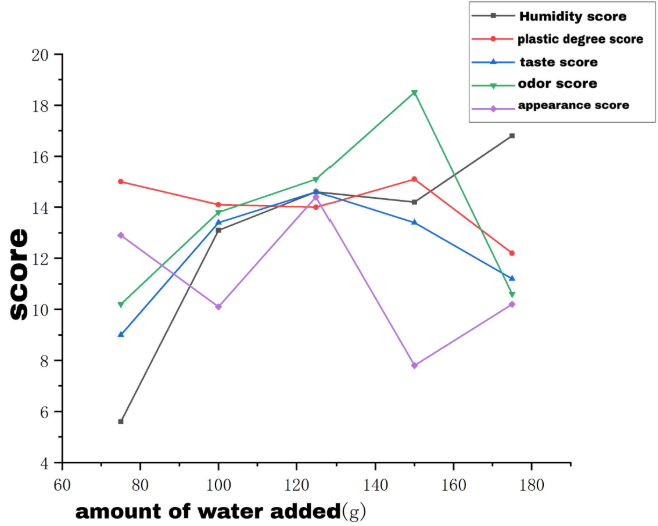

3.1.1. Water addition

When the water addition was 125 g, the sensory score reached its peak (82 points). At this level, the product exhibited a pleasant aroma, agreeable taste, and uniform texture (Figure 1).

Figure 1. Effect of water addition on the sensory score of bazhen glutinous rice cake

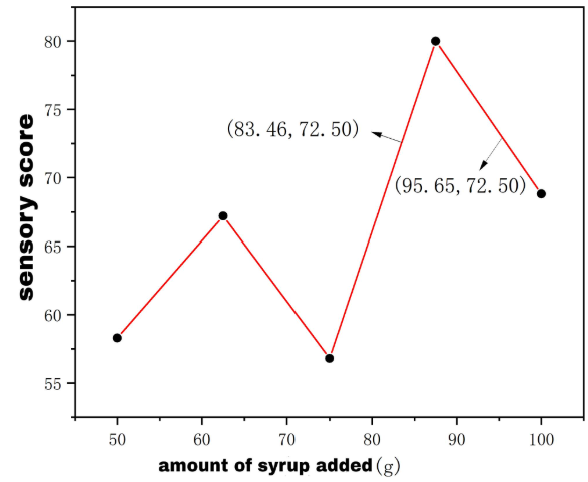

3.1.2. Syrup addition

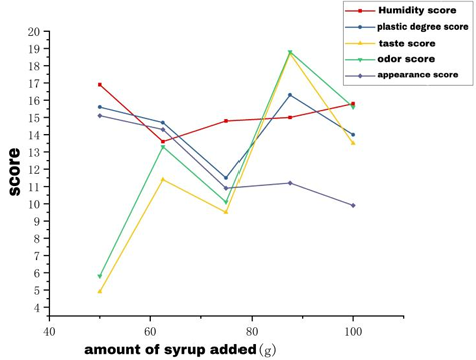

When the syrup addition was 87.5 g, the flavor and shaping scores reached their optimum (80 points). Excess syrup led to a sticky texture (Figure 2).

Figure 2. Effect of syrup addition on the sensory score of Bazhen glutinous rice cake

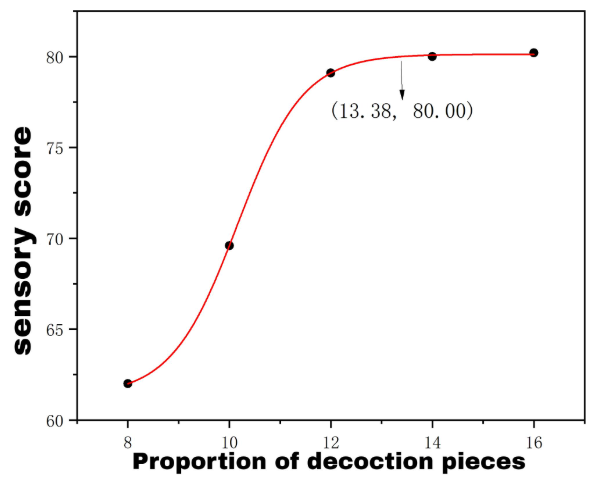

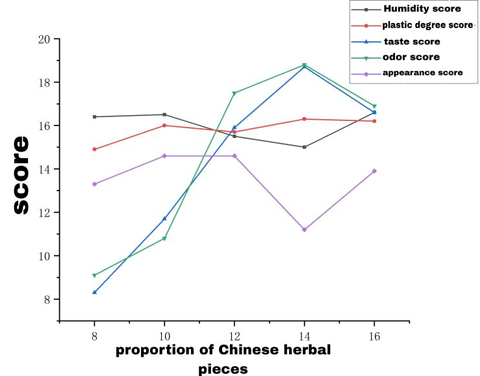

3.1.3. Ratio of herbal slices to syrup

When the ratio of herbal slices to syrup was 14:1, the harmony between herbal aroma and sweetness reached its optimum (overall score 82 points) (Figure 3).

Figure 3. Effect of the ratio of herbal slices to syrup on the sensory score of Bazhen glutinous rice cake

3.2. Orthogonal experimental results and analysis

As shown in Table 3 and the analysis of variance (Table 4), water addition (p < 0.05) had a significant effect on the overall score. The optimal combination was A2B1C2 (herbal slices-to-syrup ratio 14:1, syrup 85 g, water 125 g).

|

Number |

A |

B |

C |

Comprehensive score |

|

1 |

1 |

1 |

1 |

64.4 |

|

2 |

1 |

2 |

2 |

80.6 |

|

3 |

1 |

3 |

3 |

66.6 |

|

4 |

2 |

1 |

2 |

82 |

|

5 |

2 |

2 |

3 |

74.6 |

|

6 |

2 |

3 |

1 |

61.8 |

|

7 |

3 |

1 |

3 |

75.8 |

|

8 |

3 |

2 |

1 |

58.2 |

|

9 |

3 |

3 |

2 |

79 |

|

K1 |

70.533 |

74.067 |

61.467 |

|

|

K2 |

72.800 |

71.133 |

80.533 |

|

|

K3 |

71.000 |

69.133 |

72.333 |

|

|

R |

2.267 |

4.934 |

19.066 |

|

Factor |

Sum of partial squares |

Degree of freedom |

F-ratio |

F critical value |

Significance |

|

A The ratio of Chinese herbal pieces to syrup |

8.596 |

2 |

0.303 |

19.000 |

|

|

B Addition amount of syrup |

36.942 |

2 |

1.302 |

19.000 |

|

|

C Water addition |

548.862 |

2 |

19.338 |

19.000 |

* |

|

Error |

28.38 |

2 |

Note: * indicates a significant difference (P < 0.05).

4. Discussion

4.1. Process innovation

Freeze-drying technology effectively preserved thermolabile components such as yam polyphenols, while the β-cyclodextrin inclusion process achieved an encapsulation rate of 92.3% for rose essential oil, significantly masking the bitterness of the herbal ingredients. Compared with the traditional steaming method, the retention rate of astragaloside IV increased by 56% (p < 0.01), and the sensory score was 12.3% higher than that of commercially available dandelion glutinous rice cake [3], indicating that the process improvement successfully balanced functionality and palatability.

4.2. Limitations

This study did not investigate the effect of long-term storage on texture, and subsequent shelf-life experiments are required. In addition, the β-cyclodextrin inclusion process is relatively costly and needs further optimization to reduce the difficulty of industrial application.

5. Conclusion

Under the optimized conditions of a herbal slices-to-syrup ratio of 14:1, syrup 85 g, and water 125 g, the content of astragaloside IV in Bazhen Glutinous Rice Cake was significantly increased, the sensory score improved by 18.6%, and the texture properties (hardness 120 ± 5 g/cm², elasticity coefficient 0.85) were superior to those of the traditional dosage form. This process provides a feasible approach for the functional enhancement of medicinal food homologues and demonstrates considerable potential for industrial application.

References

[1]. Xing, S., et al. (2021). Development of dandelion glutinous rice cake.Food Industry, 42(4), 119–124.

[2]. Wei, G. M., et al. (2018). Development of Rosa roxburghii glutinous rice cake.Food Research and Development, 39(1), 83–88.

[3]. Zhou, X. J. (2012). Clinical application of Bazhen cake.Inner Mongolia Journal of Traditional Chinese Medicine, 31(11), 66–67.

[4]. Li, Z. X., Xu, X. Y., Zhang, X. Z., et al. (2024). Development and quality analysis of green tea rice cake.Food Industry Science and Technology, 45(3), 171–178.

[5]. Yang, S. Y., Cai, Q., Wu, F. F., et al. (2019). Study on the production process of fermented brown rice cake.Journal of Food and Biotechnology, 38(4), 30–38.

Cite this article

Liu,Y.;Shi,C.;Chen,S. (2025). Study on the production process of Bazhen glutinous rice cake based on traditional formula. Journal of Food Science, Nutrition and Health,4(1),90-96.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Journal:Journal of Food Science, Nutrition and Health

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Xing, S., et al. (2021). Development of dandelion glutinous rice cake.Food Industry, 42(4), 119–124.

[2]. Wei, G. M., et al. (2018). Development of Rosa roxburghii glutinous rice cake.Food Research and Development, 39(1), 83–88.

[3]. Zhou, X. J. (2012). Clinical application of Bazhen cake.Inner Mongolia Journal of Traditional Chinese Medicine, 31(11), 66–67.

[4]. Li, Z. X., Xu, X. Y., Zhang, X. Z., et al. (2024). Development and quality analysis of green tea rice cake.Food Industry Science and Technology, 45(3), 171–178.

[5]. Yang, S. Y., Cai, Q., Wu, F. F., et al. (2019). Study on the production process of fermented brown rice cake.Journal of Food and Biotechnology, 38(4), 30–38.