1. Introduction

The robotics industry has undergone many significant changes as a result of the growing need for robots in our lives, including automated production, extraterrestrial missions, unmanned rescue vehicles, disaster rescue operations, socially supported robots at home and in education, self-driving cars, and therapeutic robots used in health, Mars surveys, or seabed analysis [1]. In addition to these mentioned robots, characterized by the rapid development of technology and the surging demand for efficiency, the integration of robots into warehouse management is also of great significance. Autonomous warehouse robots can complete a variety of tasks, such as accurate navigation and complex operations, and are the cornerstone for improving warehouse operations, reducing labor-intensive tasks, and improving overall productivity. Mobile robots can be divided into two categories: autonomous mobile robots and non-autonomous mobile robots. In either a known or unknown area, autonomous mobile robots can independently explore; Guidance systems can be used by non-autonomous mobile robots to navigate their environment [2]. In this paper, the autonomous mobile robot is adopted.

The robot model designed includes a six-degree-of-freedom robotic arm to handle a variety of manipulation tasks and a differential-drive base for comprehensive navigation. This study is also focused on an 8mm by 8mm camera sensor for object recognition, which is essential for manipulation tasks and navigation. This paper aims to scrutinize the robot's performance in a simulated warehouse environment, focusing on its navigation and manipulation capabilities.

This paper commences with the design and optimization process of the robot model, discussing the utilization of URDF, Xacro, and MoveIt for this purpose. The subsequent section expounds on the construction of a simulated warehouse environment in Gazebo, detailing the inclusion of static elements, dynamic elements, and manipulable objects to mimic real-world conditions. Following this, the paper delves into path planning and navigation, applying the move_base package for global path planning and executing local real-time planning. The final sections of the paper provide a comprehensive evaluation of the system, demonstrating experimental results, an analytical discussion comparing this study with previous research, and concluding thoughts encapsulating the study's key findings and recommendations for future research.

2. Methodology

2.1. Design and optimization of the robot model

The first step is the design and modeling of the robot. This is achieved by using the capabilities of the model-created Universal Robot Description Format (URDF) and XML macros for file management optimization (Xacro). The URDF provides a standard way to describe robot models in Robot Operating System (ROS). In the URDF file, each component of the robot (links, joints, sensors, etc.) is described, specifying physical properties, visual appearance, and their relative relationships. Incorporating the results of the kinematic analysis into the design at this stage ensures efficient functioning of the robotic arm. The dynamic restrictions on the model, the simulation's environmental circumstances, and other elements are used to calculate this configuration space. This study first needs to build a dynamic model based on a particular CAD 3-d model in order to do this motion planning [3]. However, due to the complexity of the robot, the corresponding URDF files become large and difficult to manage. So Xacro is needed. Xacro is short for XML macros, through which parts of a robot model, such as links and joints, can be defined as macros. These macros are then used in URDF files to make them more efficient and less error-prone.

This six-degree of freedom robotic arm has a complex structure. Six single-axis revolute joints are used to articulate the robotic arm: one for each of the gripper open-close, gripper radial-ulnar, wrist flexion-extension, shoulder abduction-adduction, elbow flexion-extension, and wrist flexion-extension. [4]. Therefore, before using URDF designs, it is necessary to understand the principles of robot movement and possible limitations, especially for six-degree-of-freedom robotic arms. Therefore, forward and inverse kinematics analyses were performed to estimate the motion dynamics of the arm. Forward kinematics analysis requires determining the position and orientation of the robot's end effector based on known input joint angles. This allows a comprehensive mapping between the joint space (input joint Angle) and the Cartesian space (position and orientation of the end effector). On the other hand, the inverse kinematics process requires the calculation of the joint Angle of the robot arm to achieve the desired position and orientation of the end effector. From these analyses, the arm's behaviours can be accurately predicted as a basis for its URDF design.

The six-degree-of-freedom arm's control is realized using the MoveIt! motion planning framework. After integrating the kinematic model, a MoveIt! configuration package is created for the robot. MoveIt! is a development of ROS's arm_ navigation program. The robot arms' arm navigation packages were created to facilitate motion planning, trajectory development, and environment monitoring [5]. The package contained the robot's URDF description, established the robot’s semantic description (including planning groups, end effector, and passive joints), and defined the robot model interface. Through the MoveIt! Setup Assistant, it is possible to visually confirm the arm's movement range and ensure its full functionality.

The design of the mobile chassis resembled a small car and featured differential wheels, offering seamless movement in any direction. By varying the speed of each wheel, the robot could move forward, backward, or rotate in place, allowing for efficient navigation in the intricate warehouse environment [6]. The differential wheel algorithm is shown as:

\( ω=\frac{Vr-Vl}{d} \) | (1) |

where ω is the angular velocity of the whole robot, \( Vr \) is the velocity of the right wheel, \( Vl \) is the velocity of the left wheel. It is crucial in calculating the required speed for each wheel given the desired linear and angular velocity of the robot.

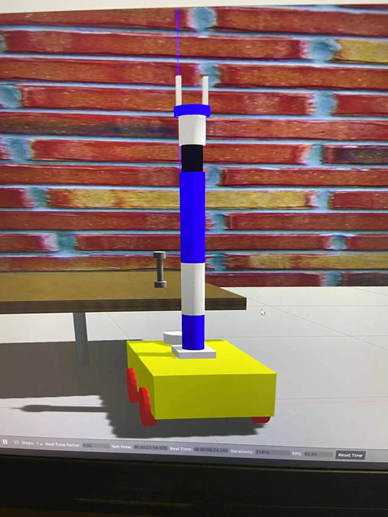

With the robotic arm and base fully operational, the next step is their seamless integration. For this, the transform (TF) package in ROS can be used to establish a tree of coordinate frames at runtime. This TF tree tracked the relative transformations between different parts of the robot, essentially linking the manipulator arm's motion with the differential drive base. This means that even when the base is on the move, the robotic arm can accurately track and interact with objects, thus enhancing the efficiency of operations within the warehouse. The 6-DOF robotic arm and the differential drive base are shown in Figure 1.

|

Figure 1. The 6-DOF robotic arm and the differential drive base. |

2.2. Path planning and navigation

The move_base package in ROS constitutes a significant tool for autonomous robot navigation, allowing the robot to move between its current location and a predefined target. This package integrates data from multiple sources such as odometry, sensors, and a predefined map to compute an achievable global path [7]. In the field of warehouse automation, the employment of the move_base package facilitates the robot's navigation through an extensive network of aisles, transferring goods and pallets from one location to another. This package uses the costmap_2d package to generate two costmaps, one for global and another for local navigation, offering a real-time representation of the environment around the robot. Obstacles register as costs on these maps. The global planner utilizes this costmap to plot an optimized path from the robot's current location to its goal, accounting for static obstacles [8].

The global path provides the main navigation framework. Dynamic window method (DWA) and Timing Elastic band method (TEB) are two effective algorithms for circumnavigating obstacles [9]. The DWA is a local planner that calculates multiple possible trajectories from the robot's current position and speed, determines the cost of each trajectory, and selects the most cost-effective trajectory. Its computational speed makes it particularly suitable for scenarios where robots need to react quickly to dynamic obstacles [10]. At the same time, taking the robot's kinematic constraints and dynamic obstacles into account, TEB can optimize the entire trajectory, making it more suitable for situations where accuracy is critical. These two methods can be used in different situations depending on the specific needs. Construction of the Simulated Warehouse in Gazebo.

Simulated environment construction represents a pivotal step in verifying the efficacy of the mobile robot's navigation algorithms. Gazebo, an open-source 3D robotics simulator, offers realism and compatibility with ROS, making it an ideal choice for simulation. Static elements, such as walls and immovable obstacles, form a part of the Gazebo environment to replicate a realistic warehouse layout. Dynamic elements, simulated using mobile cylinders, model the challenges of a live warehouse scenario that the robot may need to navigate.

Inclusion of manipulable objects of varying dimensions and properties enriches the complexity and realism of the simulation environment. These objects function as simulated goods that the robot may have to pick, carry, and place at different locations. This simulated environment, designed to mirror real-world conditions, allows for the refinement of navigation algorithms and robot design, thereby enhancing the robot's operational performance in real-world warehouse settings.

2.3. Construction of the simulated warehouse in Gazebo

Simulated environment construction represents a pivotal step in verifying the efficacy of the mobile robot's navigation algorithms. Gazebo, an open-source 3D robotics simulator, offers realism and compatibility with ROS, making it an ideal choice for simulation. Static elements, such as walls and immovable obstacles, form a part of the Gazebo environment to replicate a realistic warehouse layout. Dynamic elements, simulated using mobile cylinders, model the challenges of a live warehouse scenario that the robot may need to navigate.

Inclusion of manipulable objects of varying dimensions and properties enriches the complexity and realism of the simulation environment. These objects function as simulated goods that the robot may have to pick, carry, and place at different locations. This simulated environment, designed to mirror real-world conditions, allows for the refinement of navigation algorithms and robot design, thereby enhancing the robot's operational performance in real-world warehouse settings.

3. Experimental result and analysis

3.1. Design and optimization of the robot model

Building ROS and Gazebo simulation environments is standard for emulating real-world warehouse scenarios. The warehouse model in Gazebo uses basic geometric shapes to assemble elements such as shelves, goods, static obstacles, and moving obstacles. The shelves are organized in an orderly manner, simulating the actual warehouse infrastructure, while goods are randomly placed on the shelves. Static obstacles are set up to simulate immovable structures such as columns and walls, while moving obstacles represented by moving cylinders are introduced to simulate dynamic entities such as other warehouse workers or machinery. Finally, a mobile handling robot equipped with a six-degree-of-freedom arm and a differentially driven mobile base is introduced into the simulation world to create a complex test environment.

Setting up the ROS environment involves configuring the necessary ROS packages and nodes for the simulation. The robot model described in the URDF starts in the ROS environment and connects to Gazebo via the "gazebo_ros" plugin. This makes it possible for robots to communicate and control in Gazebo simulations. In addition, a visualization tool, RViz, is set up to observe the robot's performance in real time. Through the comprehensive setting of ROS and Gazebo environment, the simulation provides an accurate and reliable platform for the performance test of mobile handling robots.

A series of tests were designed to evaluate the performance of mobile handling robots in various tasks. The experiment run consists of two distinct phases: navigation and operation. For the navigation phase, the initial position and destination of the robot are predefined. A set of predefined waypoints is then established on the map, and the robot's task is to navigate to these waypoints from the starting point while avoiding static and dynamic obstacles, and finally to the destination. The ability of path planning and obstacle detection is tested. This phase utilizes the move_base package in ROS to perform global and local path planning. In addition, the robot must adapt to changes in the environment, such as the unexpected introduction of moving obstacles.

Gazebo interface |

RViz interface |

Figure 2. Path planning and navigation test. (a) is the Gazebo interface; (b) is the RViz interface. | |

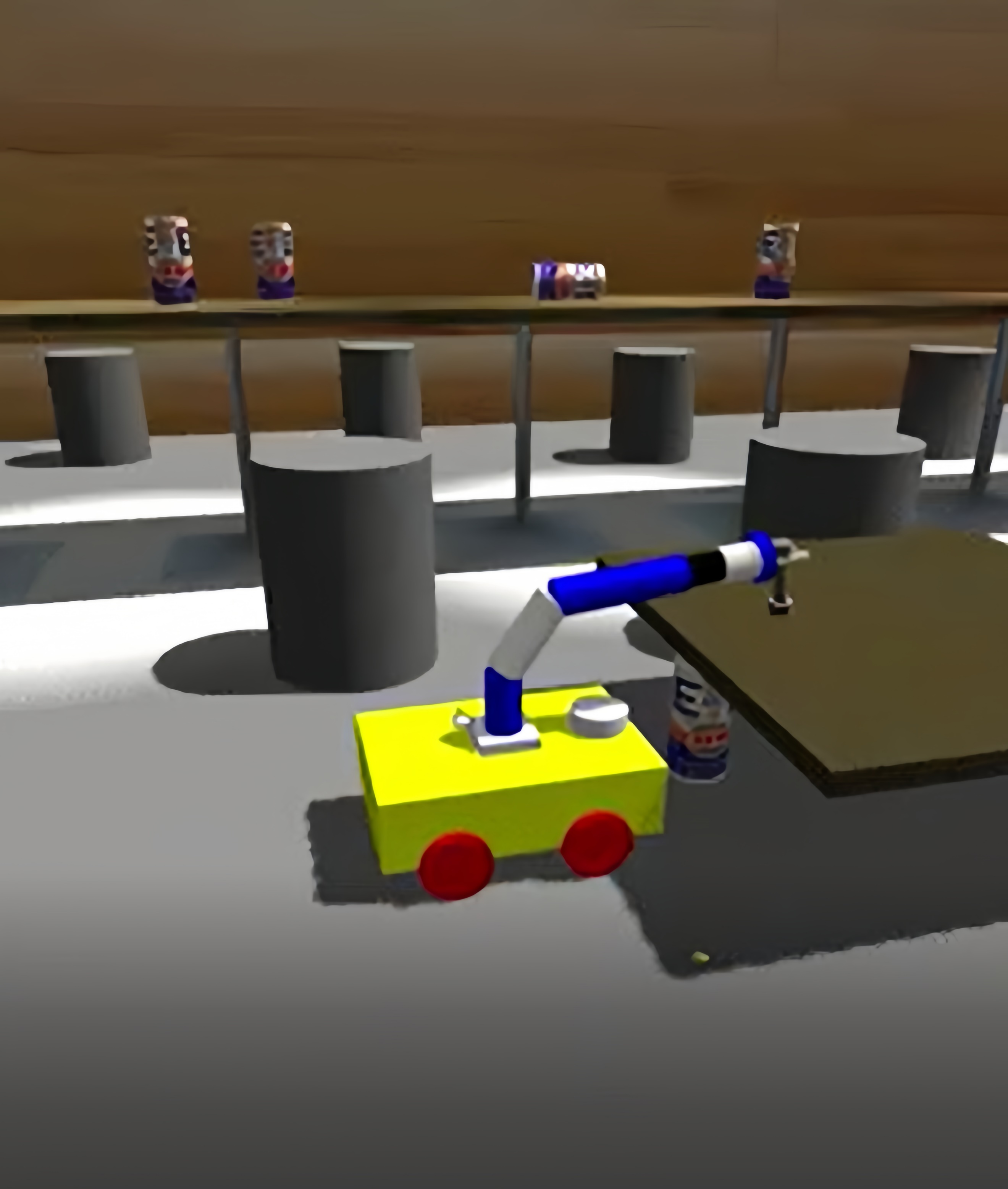

During the operation phase, operable objects are placed in random locations, and the robot is tasked with identifying, picking up, and placing these objects in predefined locations. The robot must correctly identify and manipulate the cargo. The shelves are filled with goods of all shapes and sizes. The robot is ordered to retrieve a specific item from a specified location.

|

Figure 3. The grasping test. |

3.2. Experimental evaluation criteria

The performance of autonomous mobile handling robot in warehouse environment needs to be tested with different indexes. Each indicator has been carefully designed to cover both quantitative and qualitative aspects of the robot's navigation capabilities. The first metric is path efficiency, which outlines the robot's ability to navigate a warehouse environment. To calculate this, the length of the path the robot takes from the starting point to the destination is compared to the shortest possible path. Calculate the ratio of the actual travel distance to the optimal path length and use this as a measure of efficiency. A lower ratio indicates that the robot's navigation strategy and route planning ability are more efficient, while a higher ratio indicates that the robot's navigation strategy and route planning ability are less efficient. The second metric is the task completion time. This duration is calculated from the moment the robot begins to perform the task until it successfully completes the task. This is an important measure in warehouse operations where efficiency and speed are critical. Shorter completion times mean superior performance, and the ideal autonomous robot can quickly complete tasks without compromising accuracy or safety. The third metric is collision count, which is originally designed to record the number of collisions a robot encounters while performing a task. However, because of the design of the robot used in this study, it does not physically collide with any obstacles due to the efficient obstacle avoidance mechanism implemented. Instead, this metric has been adjusted to count the number of times the robot has to change its path due to the detection of an obstacle. The lower the count, the more effective the detection mechanism is and the smaller the deviation from the planned path. The final metric is the operational stability. The operational stability measure is a qualitative measure to evaluate the operational stability of a robot during motion. Evaluate by observing the movement pattern of the robot, looking for smooth and stable operation. In a real-world environment, any erratic or sudden movement can lead to potential damage, which may mean the need to recalibrate or adjust the control system.

The ROS 3D visualization tool RViz can be used to monitor these performance metrics in real time. The tool can visualize the robot's path and 3D data from the sensors. RViz provides immediate feedback for rapid performance evaluation and system tuning. The tool is also invaluable for diagnosing system problems and providing a visual context for the robot's sensor readings and its interaction with the warehouse environment.

In order to evaluate the robot's ability in object manipulation, a series of performance indicators are implemented. These metrics cover different aspects of a robot's interaction with its environment, focusing specifically on its operational tasks in a warehouse environment. The first metric is operational accuracy, which measures the robot's accuracy in identifying, reaching, grasping, and placing objects in designated locations. This is assessed by looking at the difference between the robot's expected and actual movements. If the robot is able to accurately grasp the specified object and place it in the correct position, the operational task is considered successful. Second, "grasp success rate" refers to the percentage of successful grabs by the robot. When the robot firmly grasps the object during transportation without dropping it, it is considered a successful grasp. This metric is especially important in a warehouse environment, where falling objects can cause damage and operational delays. However, it is not known whether grabbing items will drop in Gazebo's simulated environment, as the capture success rate was one hundred percent in all the tests. Finally, "Speed of operation" evaluates the time it takes the robot to complete the operational task, from the moment it receives the command to the time the object is precisely placed at its destination. Similar to task completion times in navigation performance metrics, shorter durations are advantageous because they mean faster operations and higher productivity in warehouse tasks.

3.3. Simulation Results

In the simulation environment, a comprehensive set of indicators is used to evaluate the effectiveness of autonomous mobile handling robots. The robot's performance in "task completion time" was measured by timing the time it took to move from its initial position, pick up a specific object, and transport it to a designated location. Across a sample of 50 tasks, the mean task completion time was 4.21 minutes and the standard deviation was 0.48 minutes, illustrating reliable and consistent performance. In terms of "path efficiency," the robot scored an average of 87.62% compared to the theoretical shortest path in an accessible environment. The robot's ability to find efficient paths demonstrates its strong navigation skills and adaptability to dynamic warehouse layouts. The "path adjustment frequency", that is, the number of times the robot has to modify the path due to unexpected obstacles, is significantly lower, indicating that the robot's obstacle detection and obstacle avoidance ability is strong. In terms of "operational stability," the robot demonstrated consistent stability throughout the simulation, with minimal interruptions during task execution and stable end-effector motion. In terms of operational performance, the robot scored highly for "operational accuracy" with an average of 96.00%, indicating that it has a strong ability to identify, reach and accurately place objects. The "grab success rate" is 100%, which means that the robot has never failed to safely grasp the specified object and has not had any drop incidents during transport. "Operating speed," the average time it takes to complete an operational task, was recorded as 1.71 minutes, which means an efficient operating process.

In summary, autonomous mobile handling robots show high proficiency in both navigation and operational tasks, which is expected to significantly improve the efficiency of warehouse management. The robot's ability to smoothly integrate these two core operations demonstrates its potential in real-world warehouse environments.

Table 1. Summary of the test result.

task completion time (min) | the standard deviation of task completion time (min) | path efficiency | operational accuracy | grab success rate | Operating speed (min) |

4.21 | 0.48 | 87.62% | 96.00% | 100% | 1.71 |

4. Discussion

The experimental results highlight the potential of autonomous mobile manipulators with integrated six-degree of freedom arms to perform complex tasks in warehouse environments. A mobile robotic arm is able to navigate efficiently along a specified path and successfully identify and interact with objects in its operating environment. The precision of these custom robot functions is due to the implementation of enhanced path planning algorithms and improved control methods.

Compared to the research referenced, this study advances previous research on warehouse automation by integrating a 6-DOF robotic arm into a mobile base. This additional component allows the robot to handle more complex tasks, including object manipulation. In addition, the implementation of the differential drive model, as well as the use of PID controllers, provides superior navigation and operation capabilities for mobile manipulators. These combined capabilities exceed the performance of older models that rely on traditional path planning techniques.

5. Conclusion

The research validates effectively that an autonomous mobile manipulator equipped with an integrated 6-DOF arm can successfully perform diversified tasks in a warehouse setting. These activities include navigating efficiently within the warehouse, accurately identifying objects, and manipulating the identified objects with precision. The accomplishment of these tasks is due to the successful application of the enhanced path planning algorithm, accurate differential drive model, and a robust PID controller, as demonstrated by the experimental results.

Future research might delve into enhancing the object recognition capabilities of the robot by integrating advanced machine learning algorithms. Additionally, the design of the 6-DOF robotic arm can be further improved to adapt to objects of various shapes and sizes, thereby increasing its utility in warehouse environments. Another area worth exploring is the development of multi-robot systems for improving task allocation efficiency in large-scale warehouse operations.

This study lays a solid foundation for those seeking warehouse automation. It illustrates the application of improved path planning and control techniques in successfully operating an autonomous mobile manipulator equipped with an integrated 6-DOF arm. The successful outcomes of this research present promising avenues for enhancing warehouse efficiency and productivity.

References

[1]. F. H. Ajeil, I. K. Ibraheem, M. A. Sahib, and A. J. Humaidi, “Multi-objective path planning of an autonomous mobile robot using hybrid PSO-MFB optimization algorithm,” Applied Soft Computing, vol. 89, Article ID 106076, 2020.

[2]. R. Siegwart, I. R. Nourbakhsh, and D. Scaramuzza, Introduction to Autonomous Mobile Robots, Massachusetts Institute of Technology, Cambridge, MA USA, 2011.

[3]. P. Vyavahare, S. Jayaprakash and K. Bharatia, "Construction of URDF model based on open source robot dog using Gazebo and ROS," 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 2019, pp. 1-5, doi: 10.1109/ICASET.2019.8714265.

[4]. S. Kumra, R. Saxena and S. Mehta, "Design and development of 6-DOF robotic arm controlled by Man Machine Interface," 2012 IEEE International Conference on Computational Intelligence and Computing Research, Coimbatore, India, 2012, pp. 1-5.

[5]. Chitta, Sachin & Sucan, Ioan & Cousins, Steve. (2012). Moveit![ROS topics]. IEEE Robotics & Automation Magazine - IEEE ROBOT AUTOMAT. 19. 18-19. 10.1109/MRA.2011.2181749.

[6]. Ho-Huu, V., Nguyen-Thoi, T., Truong-Khac, T. et al. An improved differential evolution based on roulette wheel selection for shape and size optimization of truss structures with frequency constraints. Neural Comput & Applic 29, 167–185 (2018).

[7]. Zhang H-y, Lin W-m, Chen A-x. Path Planning for the Mobile Robot: A Review. Symmetry. 2018; 10(10):450.

[8]. Ren, G., Liu, P., & He, Z.. A global path planning algorithm based on the feature map. IET Cyber-Systems and Robotics, 4(1), 15-24. (2022).

[9]. Montani M, Ronchi L, Capitani R, Annicchiarico C. A Hierarchical Autonomous Driver for a Racing Car: Real-Time Planning and Tracking of the Trajectory. Energies. 2021; 14(19):6008.

[10]. Park, SO., Lee, M.C. & Kim, J. Trajectory Planning with Collision Avoidance for Redundant Robots Using Jacobian and Artificial Potential Field-based Real-time Inverse Kinematics. Int. J. Control Autom. Syst. 18, 2095–2107 (2020).

Cite this article

Pan,Q. (2024). Design and analysis of an autonomous warehouse robot system with 6-DOF manipulator. Applied and Computational Engineering,34,114-121.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2023 International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. F. H. Ajeil, I. K. Ibraheem, M. A. Sahib, and A. J. Humaidi, “Multi-objective path planning of an autonomous mobile robot using hybrid PSO-MFB optimization algorithm,” Applied Soft Computing, vol. 89, Article ID 106076, 2020.

[2]. R. Siegwart, I. R. Nourbakhsh, and D. Scaramuzza, Introduction to Autonomous Mobile Robots, Massachusetts Institute of Technology, Cambridge, MA USA, 2011.

[3]. P. Vyavahare, S. Jayaprakash and K. Bharatia, "Construction of URDF model based on open source robot dog using Gazebo and ROS," 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 2019, pp. 1-5, doi: 10.1109/ICASET.2019.8714265.

[4]. S. Kumra, R. Saxena and S. Mehta, "Design and development of 6-DOF robotic arm controlled by Man Machine Interface," 2012 IEEE International Conference on Computational Intelligence and Computing Research, Coimbatore, India, 2012, pp. 1-5.

[5]. Chitta, Sachin & Sucan, Ioan & Cousins, Steve. (2012). Moveit![ROS topics]. IEEE Robotics & Automation Magazine - IEEE ROBOT AUTOMAT. 19. 18-19. 10.1109/MRA.2011.2181749.

[6]. Ho-Huu, V., Nguyen-Thoi, T., Truong-Khac, T. et al. An improved differential evolution based on roulette wheel selection for shape and size optimization of truss structures with frequency constraints. Neural Comput & Applic 29, 167–185 (2018).

[7]. Zhang H-y, Lin W-m, Chen A-x. Path Planning for the Mobile Robot: A Review. Symmetry. 2018; 10(10):450.

[8]. Ren, G., Liu, P., & He, Z.. A global path planning algorithm based on the feature map. IET Cyber-Systems and Robotics, 4(1), 15-24. (2022).

[9]. Montani M, Ronchi L, Capitani R, Annicchiarico C. A Hierarchical Autonomous Driver for a Racing Car: Real-Time Planning and Tracking of the Trajectory. Energies. 2021; 14(19):6008.

[10]. Park, SO., Lee, M.C. & Kim, J. Trajectory Planning with Collision Avoidance for Redundant Robots Using Jacobian and Artificial Potential Field-based Real-time Inverse Kinematics. Int. J. Control Autom. Syst. 18, 2095–2107 (2020).