1. Introduction

Over the past few decades, the development of noise reduction technology for ship propellers has been a focal point of maritime research institutions. It not only pertains to the stealth performance of vessels but also significantly influences the comfort of ships. This article reviews the recent advancements in ship propeller noise reduction technology, primarily analyzing two aspects: the structural optimization design and material optimization design of propellers.

Structural optimization involves modifying the structural parameters of ship propellers, such as the number of blades, blade shape, pitch, disc loading, installation angle, etc., to achieve lower cavitation noise and mechanical noise underwater. There are two main approaches to the application of structural optimization in ship propeller noise reduction. The first is to use fewer blades, smaller disc loading, and larger pitch to reduce cavitation noise by minimizing the formation and collapse of cavities in water.

Material technology aims to improve the material properties of ship propellers, enhancing their strength, stiffness, wear resistance, and corrosion resistance, thereby reducing vibration and noise underwater. There are two primary applications of material technology in ship propeller noise reduction. Firstly, high-strength and high-stiffness materials such as aluminum alloys and stainless steel can be used to increase the propeller’s stiffness, reducing deformation and vibration in water.

In summary, ship propeller noise reduction technology involves interdisciplinary knowledge and methods, making it a comprehensive research topic. The purpose of this article is to provide a review of the current status and development trends of ship propeller noise reduction technology, with the aim of offering reference and inspiration to relevant researchers and engineers and driving future advancements in maritime development.

2. Ship Propeller Geometric Structure Design and Optimization.

2.1. Propeller Blades

(1) Number of Blades

The number of blades on ship propellers typically ranges from 3 to 6, with 4, 5, and 6 being the most common. Some fishing vessels and tugboats even employ a 3-blade design [1]. Submersible propellers typically have 2 to 7 blades, with 7 being more common [2]. In submarines, the design with an odd number of blades, especially in the presence of cruciform control surfaces (rudders and fins), is more critical.

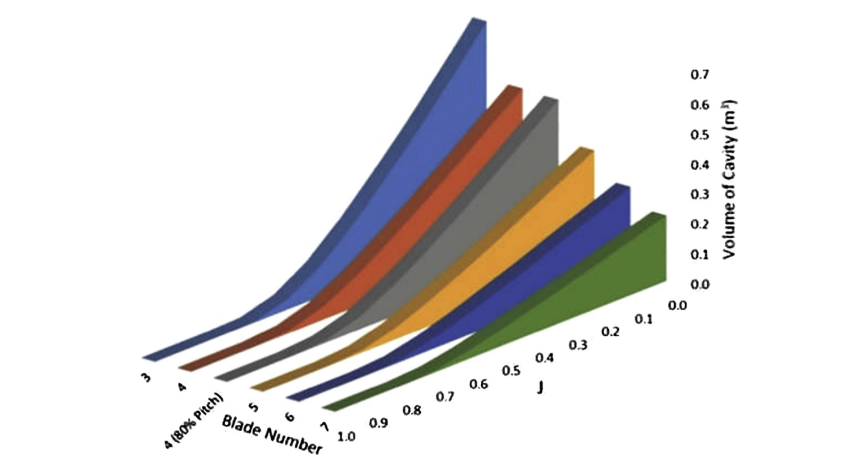

For even-numbered blades, there is a risk of efficiency fluctuations due to the symmetrical placement of blades on the control surface during each rotation, causing abrupt changes in fluid velocity. Therefore, increasing the number of blades can enlarge the propeller’s swept area, reduce the pressure difference between the back and front of the blades, thereby reducing cavitation volume. Research results in Figure 1 indicate that choosing the number of propeller blades between 5 and 7 is highly suitable, as it can significantly reduce cavitation volume. However, it should be noted that increasing the number of blades may result in a heavier and less overall efficient propeller [4]. Therefore, in military vessels, especially when noise reduction is more crucial than fluid dynamic efficiency, a propeller design with 5-7 blades is recommended.

Table 1. Geometric information of the initial propeller (DTNSRDC 4381) [4].

r/R | c/D | P/D | hs | xs/D | tmax/c | fmax/c |

0.2 | 0.174 | 1.332 | 0 | 0 | 0.0434 | 0.0351 |

0.25 | 0.202 | 1.338 | 0 | 0 | 0.0396 | 0.0369 |

0.3 | 0.229 | 1.345 | 0 | 0 | 0.0358 | 0.0368 |

0.4 | 0.275 | 1.358 | 0 | 0 | 0.0294 | 0.0348 |

0.5 | 0.312 | 1.336 | 0 | 0 | 0.0240 | 0.0307 |

0.6 | 0.337 | 1.280 | 0 | 0 | 0.0191 | 0.0245 |

0.7 | 0.347 | 1.210 | 0 | 0 | 0.0146 | 0.0191 |

0.8 | 0.334 | 1.137 | 0 | 0 | 0.0105 | 0.0148 |

0.9 | 0.280 | 1.066 | 0 | 0 | 0.0067 | 0.0123 |

0.95 | 0.210 | 1.031 | 0 | 0 | 0.0048 | 0.0128 |

1.0 | 0 | 0.995 | 0 | 0 | 0.0029 | – |

Number of blades: 5

Hub diameter ratio: 0.2

Expanded area ratio: 0.725

Section mean line: NACA08

Section thickness distribution: NACA66-MOD

Design advance coefficient: 0.889

Figure 1. Effect of the number of propeller blades on cavitation at r ¼ 0:15 [4].

(2) Propeller Disk Loading

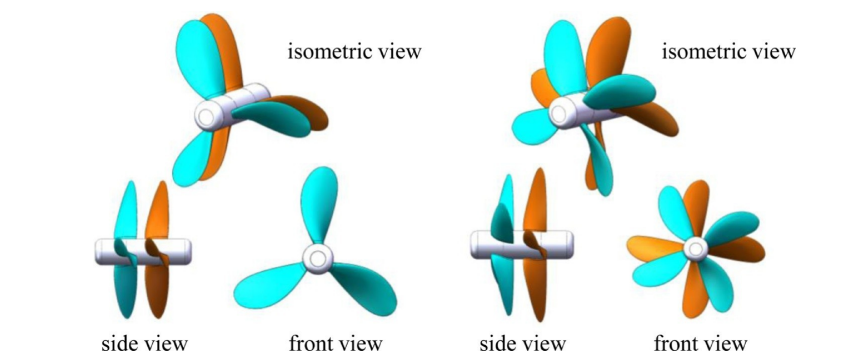

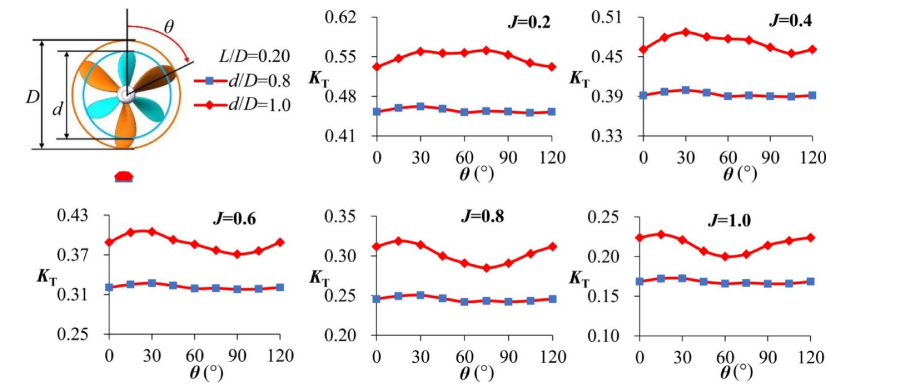

The disk loading of a ship propeller is one of the crucial parameters influencing both the aerodynamic performance and noise, and it is associated with the tip Mach number, load noise, thickness noise, and other factors. Song et al. [5], based on the Hanson noise model, proposed a multi-objective optimization design problem for propeller aerodynamics and noise, approximating it to a marine propeller using a medium substitution method for analysis. The design employed a combination of RANS method and the Hanson model to predict noise, utilizing a Kriging surrogate model and genetic algorithm for optimization search. Sun et al. [6] introduced the geometric shape of a tandem propeller with three combined parameters in 1983, determining the hydrodynamic performance. As shown in Figure 2, the diameters of the front and rear propellers are denoted by D and D’, respectively, and their ratio is D/D’; the axial distance between the front and rear propellers is expressed by L/D, where L is the axial distance and D is the diameter of the front propeller; the phase difference between the rear propeller and the front propeller is represented by θ. Yao et al. [7] proposed an innovative tandem propeller structure as shown in Figure 3, significantly reducing the disc area and number of blades on each plane by distributing the blades originally in one plane onto two different planes. This design not only improves efficiency but also retains the advantages of traditional propellers with multiple blades and a high disc loading. Despite the drawbacks such as increased shaft length, structural weight, and manufacturing costs, the tandem propeller successfully reduces the vibration in the tail structure induced by propeller-induced pressure, providing a new perspective for performance improvement.

Figure 2. Geometry of the traditional tandem propeller CLAU3-30-1-10-20-0 (left) and CLB4-55-1-10-21-23.7 (right) [6].

Figure 3. Comparison of thrust coefficient (KT) of the new tandem propeller with the traditional tandem propeller consisting of two AU3-30 propellers, L/D=0.20 [7].

This study compared the open-water performance of traditional tandem propellers and a novel tandem propeller with different phase angles under two conditions: d/D=1.0 and d/D=0.8, with L/D=0.20. The tandem propeller consists of two B4-55 propellers, corresponding to a numerical result with L/D=0.21. It is evident that, regardless of variations in the phase angle, the thrust of the novel tandem propeller is consistently smaller.

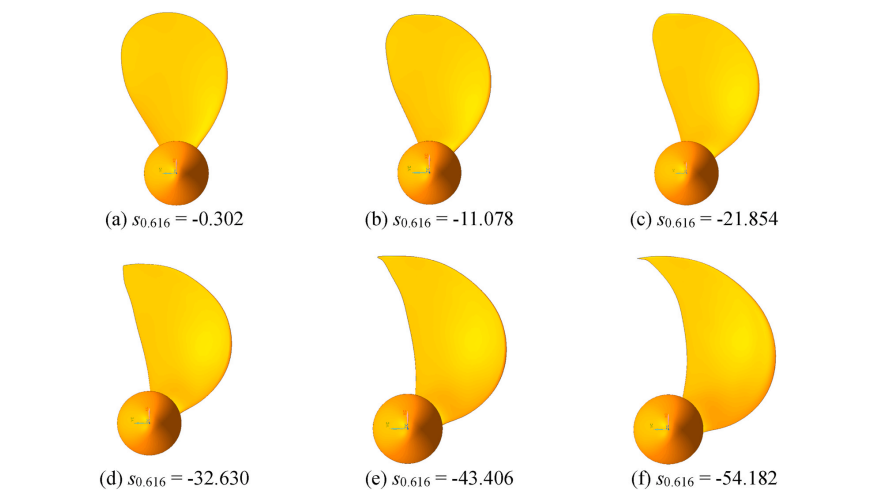

2.2. Propeller Skew Angle

Moderate skew angle design of a propeller [8] can effectively reduce underwater noise, improve fluid dynamic characteristics, decrease vibration and pressure pulsation, thereby enhancing propulsion efficiency. Careful consideration is required in selecting the skew angle during actual design to avoid excessively large or inappropriate angles. This is crucial for a balanced consideration of factors such as resistance, power consumption, and ultimately achieving noise control and performance balance. Qing [9] verified the prediction of the open-water characteristics of heavily skewed propellers throughout the entire range of advance ratios using the RANS method. The computational results exhibited good consistency with experimental data across various advance ratios, particularly with differences less than 3% under non-design loads. However, a critical analysis of the prediction of T-type and K values was conducted, discussing potential shortcomings in existing RANS methods. Further optimization was undertaken for the noise reduction direction of propeller skew angles.Hu [10] and colleagues, by reducing grid size to accurately capture the tip vortex region, studied the rolling-up and backflow of tip vortices for propellers. They observed that with an increase in skew angle, the rolling-up of cavitation tip vortices in the propeller was enhanced, as shown in Figure 4. At advance coefficients J=0.71 and 0.77, an increased skew angle improved the cavitation phenomenon, leading to the formation of a cavitation-free zone near the leading edge. This indicates that larger skew angles are advantageous in reducing overall cavitation in the propeller, thereby achieving the goal of noise reduction. However, when cavitation is low, increasing the propeller skew angle does not necessarily improve its performance. The skew angle of a propeller needs to be adapted in conjunction with other parameters to achieve optimal noise reduction effects.

Figure 4. Propeller under different skews [10].

2.3. Propeller Blade Shape

Altering the blade shape of a propeller can indeed reduce tip vortices, thereby achieving the goal of lowering noise. Hua et al. [11] studied the vibration reduction and noise characteristics of a serrated-tip propeller using vortex dynamics principles. They found that the serrated-tip propeller could reduce periodic harmonic vibration and noise while improving rotational efficiency under high loads. Shu et al. [12] investigated the use of twisted blades to enhance propeller blade shape, aiming to improve the fluid flow around the blades as the propeller rotates underwater. Their results showed better hydrodynamic characteristics within a certain angle range. Properly reducing the angle in this region and conducting precise numerical simulations could lead to an ideal propeller blade shape. Additionally, foreign scholars proposed a three-dimensional flow separation model, applying the flat plate method to blunt-edged propellers. They improved the hydrodynamic performance of the Voith-Schneider propulsion system by adding flaps to the trailing edge of the blades, testing three different types of flap motions. These examples highlight the significant potential of blade shape in propeller optimization design.

2.4. Future Directions and Innovations in Propeller Geometry Design

In the design and optimization process of ship propellers, noise reduction technology, machine learning, and neural networks can play crucial roles. For instance, machine learning algorithms can optimize propeller design parameters, such as pitch, diameter, and rotational speed, to achieve the best noise reduction effects [5]. Additionally, neural networks can be utilized to simulate and predict the noise performance of propellers under different conditions, allowing for the anticipation and avoidance of situations where excessive noise might occur during the design phase [13].

Regarding the use of a circumferential friction-based generator [14], it can be employed for real-time monitoring of propeller bearings. The friction nanogenerator is a device that converts mechanical energy into electrical energy. By detecting the vibrations and noise generated during the operation of the bearings, it can provide real-time monitoring of the bearing’s working condition. If anomalies in the bearing occur, such as overheating or wear, the vibration and noise patterns it generates will change. The friction nanogenerator can detect these changes, enabling early warning of bearing faults [14 15]. This technology not only enhances the safety of ships but also allows for the extraction of linear relationships between variables such as noise, surface roughness, speed, etc., from detected current signal changes for better analysis.

3. Propeller External Material Design

3.1. Selection of Propeller Materials

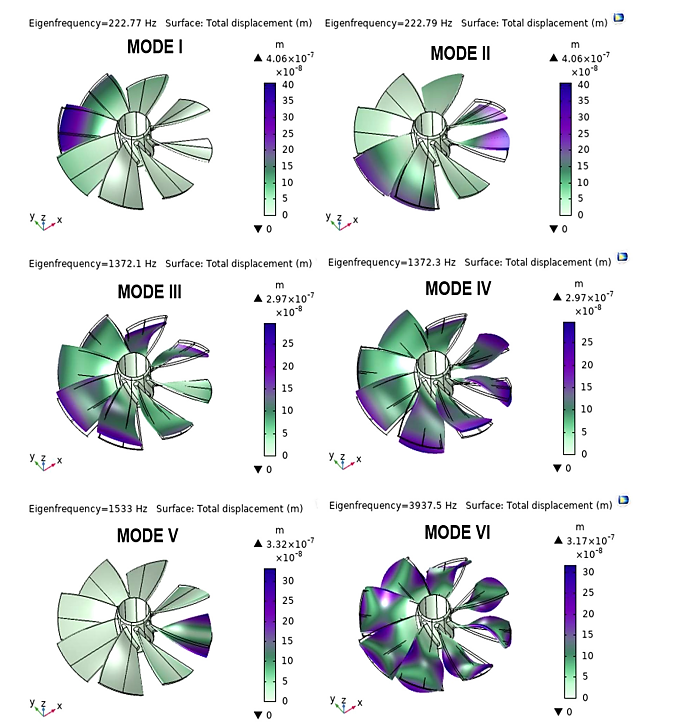

The selection of materials for propellers typically needs to meet various requirements, including strength, corrosion resistance, high damping characteristics, among others. Joshi J et al. [16] initially created a grid model of the propeller using CAD. Subsequently, they used COMSOL to compare the vibration frequencies of materials such as aluminum alloy, stainless steel, and titanium alloy. The characteristic frequency values for aluminum alloy materials, as shown in Figure 5 (six vibration modes of aluminum alloy propellers), were obtained. Ultimately, it was concluded that aluminum alloy is the most ideal material for propeller design.

Figure 5. Mode shapes for aluminium alloy Propeller [16].

The use of composite materials in propeller blade manufacturing has become increasingly popular in recent years.. These composite material blades consist of multiple layers of woven fibers and a foam core, providing characteristics such as lightweight, corrosion resistance, low vibration, and reduced noise. The use of composite materials in propeller manufacturing endows them with greater flexibility, significantly improving hydrodynamic efficiency. These materials are composed of carbon fiber, Kevlar synthetic fiber, glass fiber, and epoxy resin. They make the propeller lighter, and by improving the hydroelasticity, they can enhance the propulsion efficiency and reduce the noise of the propeller. This hydroelastic design not only increases the flexibility of the propeller, reducing the potential for vibration transmission but also helps maintain a low noise level during underwater operations. In summary, innovative manufacturing methods using composite materials provide a sustainable solution for improving performance, reducing weight, and minimizing noise.

3.2. Optimization Design of Propeller Surface Coatings

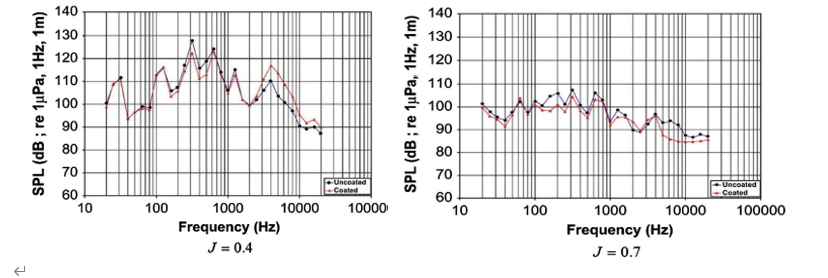

The use of coatings [24] can increase propeller efficiency by 6%. During the operation of ships, coatings enhance propeller efficiency by reducing the adhesion of fouling [17]. The first study on the impact of coatings on propeller noise was conducted by Atlar in 2012. In this study, a four-layer standard color coating (Intersleek 900) was applied to a three-bladed propeller model of a commercial ship. Tests were conducted in a cavitation tunnel under different conditions. The results indicated that coatings could only achieve effective noise reduction at high advance ratios. It is noteworthy that the advance ratio is defined as \( J=VA/n.D \) , where n is the rotational speed, and D is the propeller diameter. Figure 6 [18] illustrates the main research findings for two advance ratios.

Figure 6. Effects of the blade coating on the propeller noise [18]

3.3. Design of Ducted Propellers

In 2014, Ghadimi et al. [19] investigated the noise generated by a B-series 5-blade propeller in a duct. The results revealed that the duct not only altered the flow characteristics around the propeller, but also effectively prevented cavitation and thrust fluctuations, thereby significantly reducing noise. This finding provides a new perspective for understanding and controlling propeller noise. Stefano Gaggero [20] and his team used a commercial RANS solver combined with the Schnerr-Sauer cavitation model to predict the tip and tip leakage vortex cavitation capabilities of conventional propellers and ducted propellers. They compared the performance of the two and found that the cavitation tip vortex generated by the leading edge of the ducted propeller was more stable than that of the conventional propeller, which resulted in more effective noise reduction. In addition, Mirzazadeh [21] and others at the Marine Engineering Research Center of Sharif University of Technology used computational fluid dynamics and experimental methods to study the performance of a model of a fishing boat’s ducted five-blade propeller.

The widespread application of ducted propellers in the field of ships has a significant impact on ship noise. The design aims to effectively reduce underwater noise levels [23], by changing the shape of the propeller, adding ducts, and optimizing the way water flows. This achieves effects such as noise reduction, control of vortices and turbulence, reduction of cavitation noise [22], and control of vibrations. These technological improvements help to enhance the environmental performance of ships, reduce interference with marine ecosystems, and also comply with environmental standards, providing beneficial solutions for ship design and operation.

4. Future prospects

Optimize the structural design of the propeller, improve the efficiency and cavitation performance of the propeller, and reduce the cavitation noise. For example, by increasing the number of blades and using ducts, the blade load distribution can be improved, the tip vortex intensity can be reduced, and thus the cavitation noise can be reduced. Moreover, by designing low bubble and semi-uniform flow propellers, the noise propagation of the propulsion system can be reduced.

Improve the surface characteristics of the propeller, reduce the friction resistance and biofouling of the propeller, and reduce the erosion. For example, by using attachment-release type antifouling coatings, the binding force between the organisms and the solid surface can be weakened by using their low surface energy characteristics, and the biofouling layer can be peeled off at a certain flow rate, which can also reduce the surface roughness and the resistance. In addition, by setting a small number of holes on the propeller blades, the tip vortex cavitation of the propeller can be reduced, and the increase of these pressure relief holes will make the operation of the ship propeller quieter.

Use new materials and technologies to improve the strength and corrosion resistance of the propeller, extend the service life of the propeller, and reduce the maintenance cost. For example, by using composite materials, ceramic materials, metal matrix composite materials, etc., the impact resistance and wear resistance of the propeller can be improved, and the weight of the propeller can be reduced and the efficiency can be increased. Furthermore, by using ultrasonic, laser, electromagnetic and other technologies, the surface of the propeller can be cleaned, repaired, modified, etc., to restore or improve the performance of the propeller.

5. Conclusion

This article elucidates the research progress in the field of ship propeller noise reduction design, delving into multiple key technical aspects and providing comprehensive insights into optimizing propeller performance and decreasing noise. In terms of blade configuration, the significance of an odd number of blades, particularly in submarines with cruciform control surfaces, is highlighted. Disk loading and tandem propeller design have been proven to be crucial parameters, influencing cavitation volume and overall efficiency. Moderate propeller skew angle design contributes to effectively reducing underwater noise. Altering blade shape, such as serrated-tip or twisted blades, demonstrates the potential to decrease tip vortices and noise. In material selection, the gradual shift towards composite materials offers characteristics like lightweight, corrosion resistance, low vibration, and noise reduction. Additionally, ducted propellers and coating technologies show substantial potential in noise reduction. Future directions underscore the application of machine learning, neural networks, and circumferential friction-based generators in propeller design, as well as ongoing research in ducted propellers and coating technologies. These research findings provide guidance for the future development of ship propeller design, fostering the continuous emergence of more intelligent, efficient, and environmentally friendly propeller technologies.

References

[1]. Carlton J. Marine propellers and propulsion. Butterworth-Heinemann; 2012

[2]. Renilson M. Hydro-acoustic performance. In: Submarine hydrodynamics. Springer; 2015. . 147–50.

[3]. Ghose J. Basic ship propulsion. Allied Publishers; 2004.

[4]. Aristotelis O, Asimakopoulos A, Kaklis P. Effects of propeller geometry on cavitation; 2016.

[5]. SONG Xiang, YU Peixun, BAI Junqiang, HAN Xiao, PENG Jiahui. Aerodynamic and Aeroacoustic Optimization of Propeller Based on Hanson Noise Model [J]. Journal of Northwestern Polytechnical University, 2020, 38(4): 685-694.

[6]. Sun, 0., Gu, Y.D., Zheng, S.Z., 1983. Tandem Propeller and its Design Method. The people’s communication publishing company, China.

[7]. Huilan Yao, Yong Liu, Huaixin Zhang, Qin Zhang,Comparative study on hydrodynamic performance and induced pressure of new canard tandem propellers and conventional propellers,Ocean Engineering,Volume221, 2021, 108566, ISSN 0029-8018.

[8]. Ramakrishna V, Rao D A, Rao C S, et al. Noise Control of a Marine Propeller by Modifying the Skew Angle [M]. 2021.

[9]. Da-Qing L (2006) Validation of rans predictions of open water performance of a highly skewed propeller with experiments. In: Conference of global Chinese scholars on hydrodynamics

[10]. Hu J, Zhang W, Wang C, et al. Impact of skew on propeller tip vortex cavitation [J]. Ocean Engineering, 2021, 220:108479.

[11]. Hua, H., & Jin, K. (2002). Experimental Study on Hydrodynamics and Vibration Reduction Characteristics of Serrated Blade Propeller under High Load. Journal of Vibration and Shock, 21(4).

[12]. Shu, J., Kang, L., Long, B., et al. (2011). Blade Shape Improvement of Propeller Based on Fluent Software. Energy Saving Technology, 29(1).

[13]. Hou, X., Zhou, X., & Huang, X. (2023). Reconstruction of Ship Propeller Wake Field Based on Physical Information Neural Network (Online First). Journal of Shanghai Jiao Tong University. doi: 10.16183/j.cnki.jsjtu.2023.101.

[14]. Li, C.; Wang, Z.; Shu, S.; Tang, W. A Self-Powered Vector Angle/Displacement Sensor Based on Triboelectric Nanogenerator. Micromachines 2021, 12 (3), 231

[15]. Li, C.; Wang, Z.; Shu, S.; Tang, W. A Self-Powered Vector Angle/Displacement Sensor Based on Triboelectric Nanogenerator. Nano Energy 2021, 91, 105991

[16]. Joshi J, Manral A R, Arya N M, et al. Robust material of propeller blade for its Eigen frequency [J]. Materials Today:Proceedings, 2021, 44(5).

[17]. Korkut E, Atlar M. An experimental investigation of the effect of foul release coating application on performance, noise and cavitation characteristics of marine propellers. Ocean Eng 2012;41:1–12.

[18]. Atlar M, Glover E, Candries M, Mutton R, Anderson C. The effect of a foul release coating on propeller performance. International conference on Marine Science and Technology for Environmental Sustainability (ENSUS 2002). University of Newcastle upon Tyne; 2002.

[19]. Feizi Chekab MA, Ghadimi P, Nourozi H. Investigation on the effects of increasing the number of blades and using ducts to reducing noise of noncavitating propellers. J Iran Soc Acoust 2014;1(2).

[20]. Stefano Gaggero et al. A study on the numerical prediction of propellers cavitating tip vortex [J]. Ocean Engineering, 2014, 92:137-161.

[21]. Mirzazadeh S. Design and construction of an optimized section for improvement of propulsion system efficiency (Master of Science). Mechanical Engineering, Sharif University of Technology; 2013.

[22]. Pan Y-C, Zhang H-X. Numerical prediction of marine propeller noise in nonuniform inflow. China Ocean Eng 2013;27(1):33–42.

[23]. Davaie Markazi AH, Nazarahari M. Application of DWT for ship’s acoustic signal identification using feature extraction methods and ensemble learning.

[24]. Bagheri MR, Seif MS, Mehdigholi H. An experimental study on the effect of IS700 coating on the cavitation inception and development, and noise reduction of a marine propeller. J Appl Mech Eng.

Cite this article

Zhang,Z. (2024). Research on ship propeller noise reduction: Advanced materials and innovative geometric design. Applied and Computational Engineering,61,222-230.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Carlton J. Marine propellers and propulsion. Butterworth-Heinemann; 2012

[2]. Renilson M. Hydro-acoustic performance. In: Submarine hydrodynamics. Springer; 2015. . 147–50.

[3]. Ghose J. Basic ship propulsion. Allied Publishers; 2004.

[4]. Aristotelis O, Asimakopoulos A, Kaklis P. Effects of propeller geometry on cavitation; 2016.

[5]. SONG Xiang, YU Peixun, BAI Junqiang, HAN Xiao, PENG Jiahui. Aerodynamic and Aeroacoustic Optimization of Propeller Based on Hanson Noise Model [J]. Journal of Northwestern Polytechnical University, 2020, 38(4): 685-694.

[6]. Sun, 0., Gu, Y.D., Zheng, S.Z., 1983. Tandem Propeller and its Design Method. The people’s communication publishing company, China.

[7]. Huilan Yao, Yong Liu, Huaixin Zhang, Qin Zhang,Comparative study on hydrodynamic performance and induced pressure of new canard tandem propellers and conventional propellers,Ocean Engineering,Volume221, 2021, 108566, ISSN 0029-8018.

[8]. Ramakrishna V, Rao D A, Rao C S, et al. Noise Control of a Marine Propeller by Modifying the Skew Angle [M]. 2021.

[9]. Da-Qing L (2006) Validation of rans predictions of open water performance of a highly skewed propeller with experiments. In: Conference of global Chinese scholars on hydrodynamics

[10]. Hu J, Zhang W, Wang C, et al. Impact of skew on propeller tip vortex cavitation [J]. Ocean Engineering, 2021, 220:108479.

[11]. Hua, H., & Jin, K. (2002). Experimental Study on Hydrodynamics and Vibration Reduction Characteristics of Serrated Blade Propeller under High Load. Journal of Vibration and Shock, 21(4).

[12]. Shu, J., Kang, L., Long, B., et al. (2011). Blade Shape Improvement of Propeller Based on Fluent Software. Energy Saving Technology, 29(1).

[13]. Hou, X., Zhou, X., & Huang, X. (2023). Reconstruction of Ship Propeller Wake Field Based on Physical Information Neural Network (Online First). Journal of Shanghai Jiao Tong University. doi: 10.16183/j.cnki.jsjtu.2023.101.

[14]. Li, C.; Wang, Z.; Shu, S.; Tang, W. A Self-Powered Vector Angle/Displacement Sensor Based on Triboelectric Nanogenerator. Micromachines 2021, 12 (3), 231

[15]. Li, C.; Wang, Z.; Shu, S.; Tang, W. A Self-Powered Vector Angle/Displacement Sensor Based on Triboelectric Nanogenerator. Nano Energy 2021, 91, 105991

[16]. Joshi J, Manral A R, Arya N M, et al. Robust material of propeller blade for its Eigen frequency [J]. Materials Today:Proceedings, 2021, 44(5).

[17]. Korkut E, Atlar M. An experimental investigation of the effect of foul release coating application on performance, noise and cavitation characteristics of marine propellers. Ocean Eng 2012;41:1–12.

[18]. Atlar M, Glover E, Candries M, Mutton R, Anderson C. The effect of a foul release coating on propeller performance. International conference on Marine Science and Technology for Environmental Sustainability (ENSUS 2002). University of Newcastle upon Tyne; 2002.

[19]. Feizi Chekab MA, Ghadimi P, Nourozi H. Investigation on the effects of increasing the number of blades and using ducts to reducing noise of noncavitating propellers. J Iran Soc Acoust 2014;1(2).

[20]. Stefano Gaggero et al. A study on the numerical prediction of propellers cavitating tip vortex [J]. Ocean Engineering, 2014, 92:137-161.

[21]. Mirzazadeh S. Design and construction of an optimized section for improvement of propulsion system efficiency (Master of Science). Mechanical Engineering, Sharif University of Technology; 2013.

[22]. Pan Y-C, Zhang H-X. Numerical prediction of marine propeller noise in nonuniform inflow. China Ocean Eng 2013;27(1):33–42.

[23]. Davaie Markazi AH, Nazarahari M. Application of DWT for ship’s acoustic signal identification using feature extraction methods and ensemble learning.

[24]. Bagheri MR, Seif MS, Mehdigholi H. An experimental study on the effect of IS700 coating on the cavitation inception and development, and noise reduction of a marine propeller. J Appl Mech Eng.