1. Introduction

The mixed nitrate ester (DEGDN) propellant is characterized by high energy and good rheology [1-2], which can be well used in body-barrel weapons. Today’s large-caliber artillery development goal is to obtain a higher muzzle velocity, longer range and greater power, large size DEGDN propellant as a high-performance propellant charge, to fully meet the high muzzle velocity [3], low chamber pressure of large-caliber artillery indicators. For the large size propellant in the combustion process of combustion velocity [4], pressure and other combustion performance, is an important factor to highlight the performance of the firing charge. When the arc thickness of the propellant changes, its combustion properties and mechanical properties within the body tube weapon also change [5].

In this paper, combustion and mechanical properties of DEGDN propellants under four different aperture conditions are investigated to provide a basis for subsequent research on various aspects of large arc-thickness propellants [6-7].

2. Materials and Method

2.1. Experimental instruments and materials

Materials: ZY-11 pellets; Instrument: closed bomb structure, Self-made by Nanjing University of Science and Technology; Single-column hydraulic press, Tianjin Second Forging & Pressing Machine Tool Factory; Pendulum Impact Tester, CHANG CHUN INTELLIGENT APPARATUS CO., LTD.

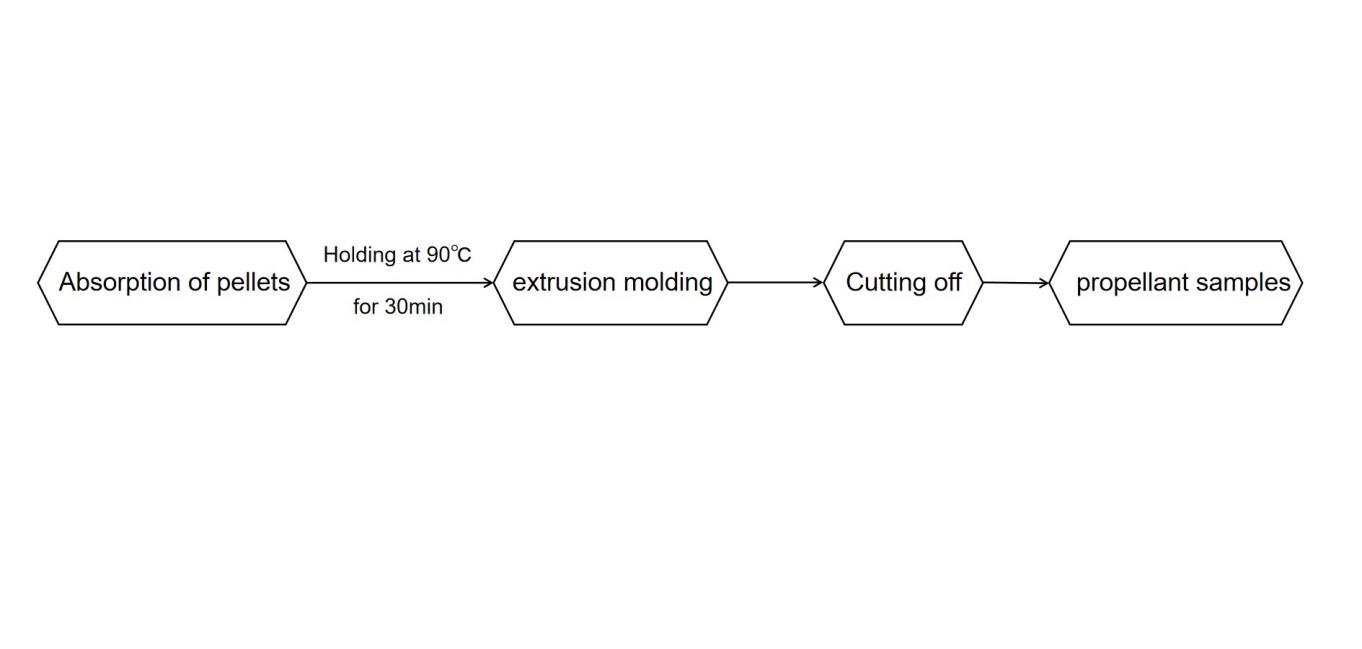

2.2. Preparation of propellants with different pore sizes

The preparation flow chart is shown in figure 1. Firstly, take appropriate amount of ZY-11 pellets and put them into the 90℃ drug cylinder to keep warm for 30 minutes. Put the 45/1 size mold used in this experiment into the designated position of the hydraulic press., start the hydraulic press to press molding, and Samples of propellants with different pore sizes were obtained, Cut into 4cm and 6cm strips for use [8].

Figure 1. Preparation process of DEGDN propellant

2.3. Combustion Performance Test Methods

closed bomb device is shown in figure 2. The volume of the device used is 100 ml; Charge density is 0.2 g/ml; Nitrocellulose as an ignition charge, 1g per ignition charge packet [9-10]. Each sample was subjected to one experiment at high, low, and normal temperatures.

Figure 2. Schematic diagram of closed bomb structure

3. Results & Discussion

3.1. Combustion Performance Analysis

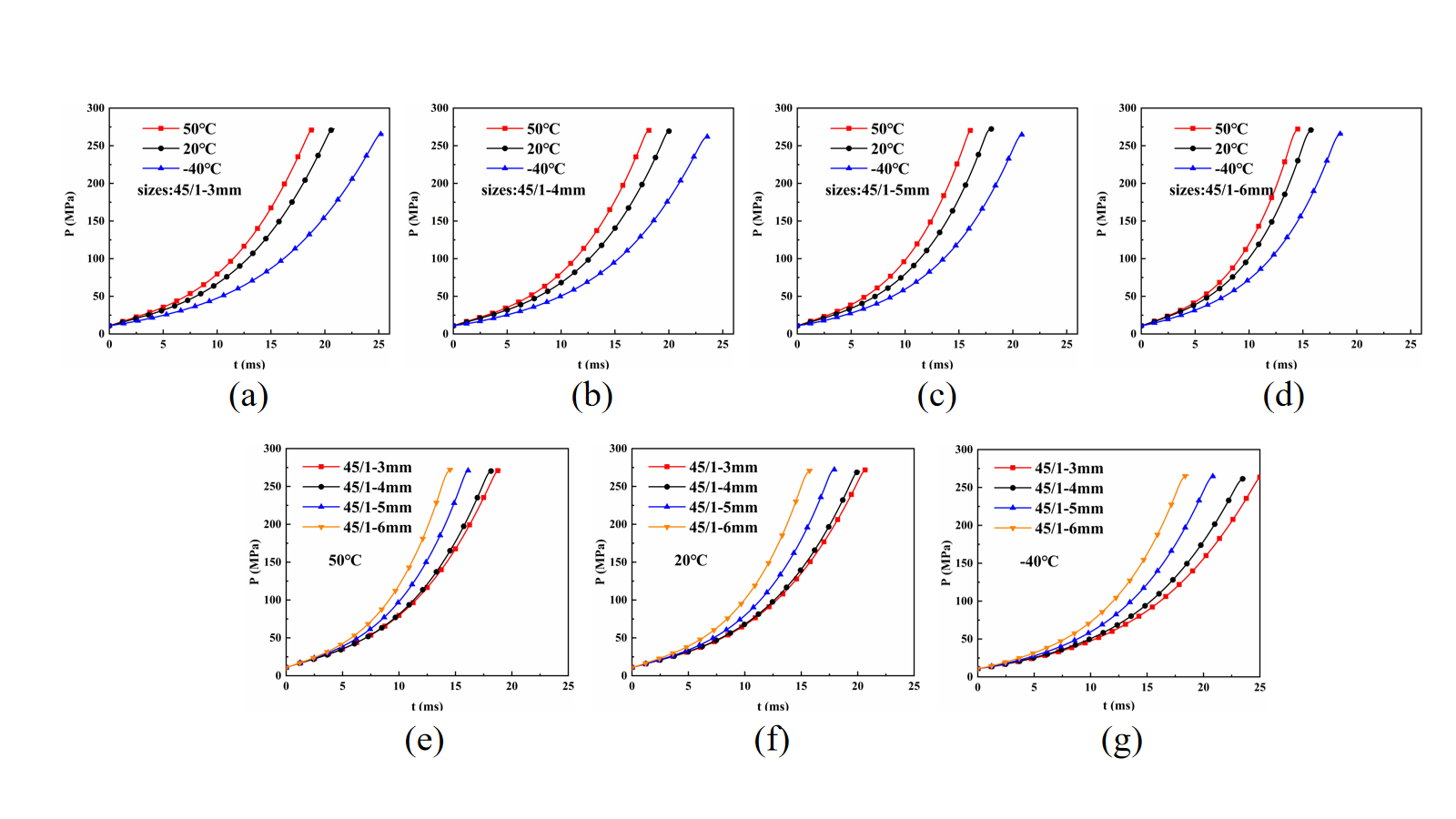

For this experiment, four single-hole molds with different hole diameters were used, with an arc thickness of 4.5 mm, denoted as 45/1. Figure 3 shows the pressure (p)-time (t) curve for large arc-thick propellants.

Figure 3. p-t curves for propellants with different pore sizes

In figure 3, figure 3(a)-figure 3(d) show the p-t curves of the propellants with four different hole diameters, and figure 3(e)-figure 3(g) show the p-t curves of the propellants at high temperature (50°C), room temperature (20°C), and low temperature (-40°C), respectively.

As can be seen in figure 3, under the same conditions of the drug type, with the increase of temperature, As the temperature increases, the pressure of the propellants grows faster, and the whole combustion process is completed more rapidly. The combustion performance parameters of the four different aperture propellants are shown in Table 1, where \( {p_{m}} \) and \( {t_{m}} \) are the maximum combustion pressure and combustion time, respectively. Combining figure 4 with Table 1, it can be seen that at the same temperature, the larger the hole diameters, the faster the pressure growth rate and the shorter the combustion time. Always satisfy \( {t_{m}} \) (45/1-6mm) < \( {t_{m}} \) (45/1-5mm) < \( {t_{m}} \) (45/1-4mm) < \( {t_{m}} \) (45/1-3mm); Because the smaller the aperture, the larger the arc thickness, the arc thickness becomes larger, the combustion time is prolonged so that the heat loss increases.

Table 1. Combustion performance parameters of propellants.

samples | T/℃ | Pm/MPa | tm/ms | um/cms-1 |

45/1-3mm | 50 | 271.76 | 18.96 | 26.93 |

20 | 272.47 | 20.84 | 25.42 | |

-40 | 265.99 | 25.38 | 22.09 | |

45/1-4mm | 50 | 270.75 | 18.28 | 28.03 |

20 | 269.99 | 20.16 | 26.11 | |

-40 | 262.20 | 23.69 | 22.92 | |

45/1-5mm | 50 | 271.38 | 16.25 | 28.30 |

20 | 272.36 | 18.01 | 26.64 | |

-40 | 265.16 | 20.98 | 23.02 | |

45/1-6mm | 50 | 272.86 | 14.72 | 27.15 |

20 | 271.79 | 15.95 | 25.21 | |

-40 | 266.39 | 18.64 | 22.37 |

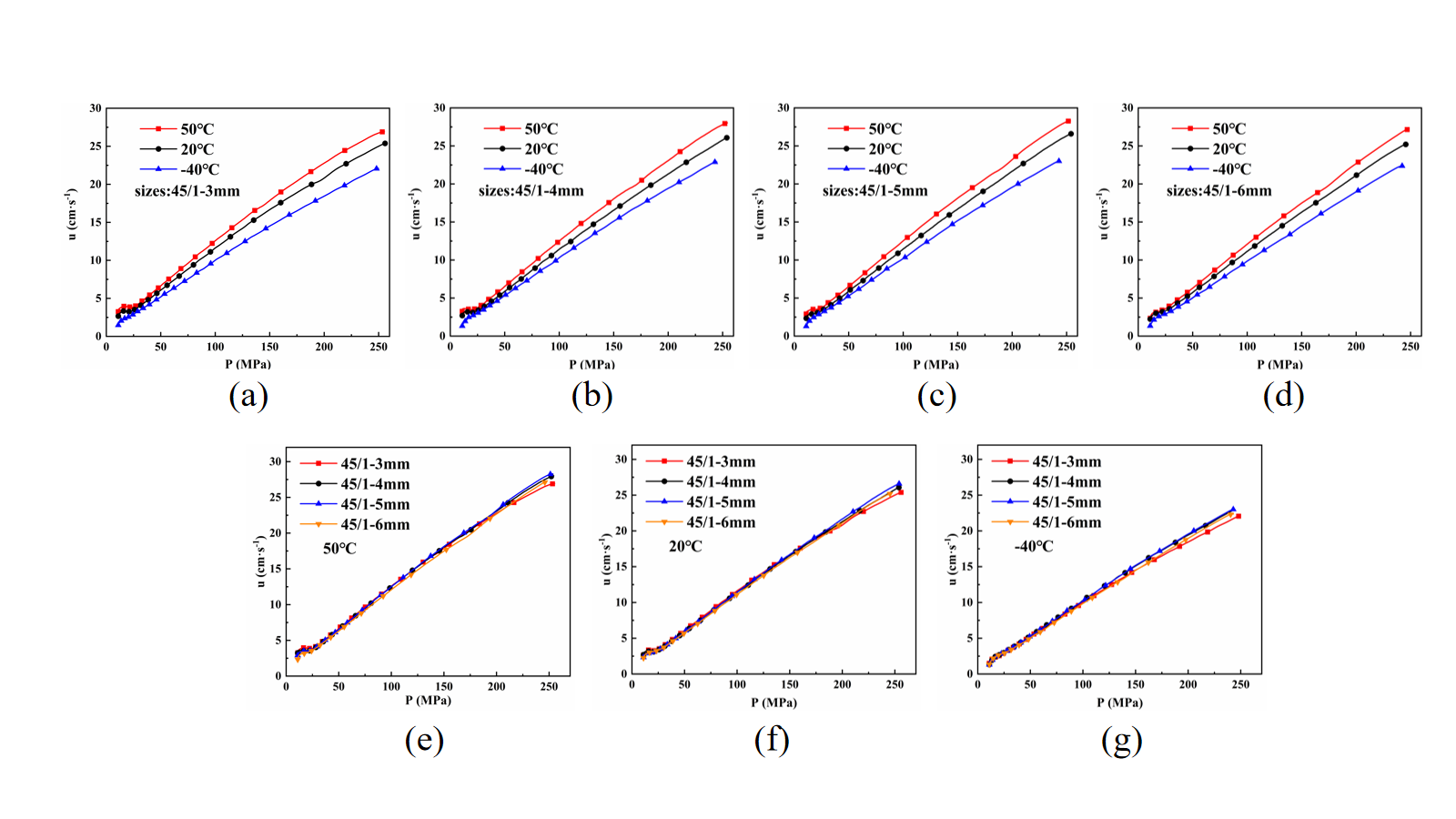

Figure 4 shows the burn rate (u)-pressure (p) curve for for the propellants with different pore sizes.

Figure 4. u-p curves for propellants with different pore sizes

In figure 4, figure 4(a)-figure 4(d) show the u-p curves of the propellants with four different hole diameters, and figure 4(e)-figure 4(g) show the u-p curves of the propellants at high temperature (50°C), room temperature (20°C), and low temperature (-40°C), respectively.

As can be seen from figure 4 that as the temperature increases, The rate of ignition of the propellants at the same pressure is consequently increased. In addition, the burning speed of the propellant increases steadily throughout the combustion process, and the size of the burning speed does not change significantly with the change in arc thickness due to changes in the aperture. Combined with Table 1, it can be obtained: under the same conditions of the drug type, the higher the temperature, the greater the maximum burning speed of the propellant can achieve.

3.2. Mechanical properties analysis

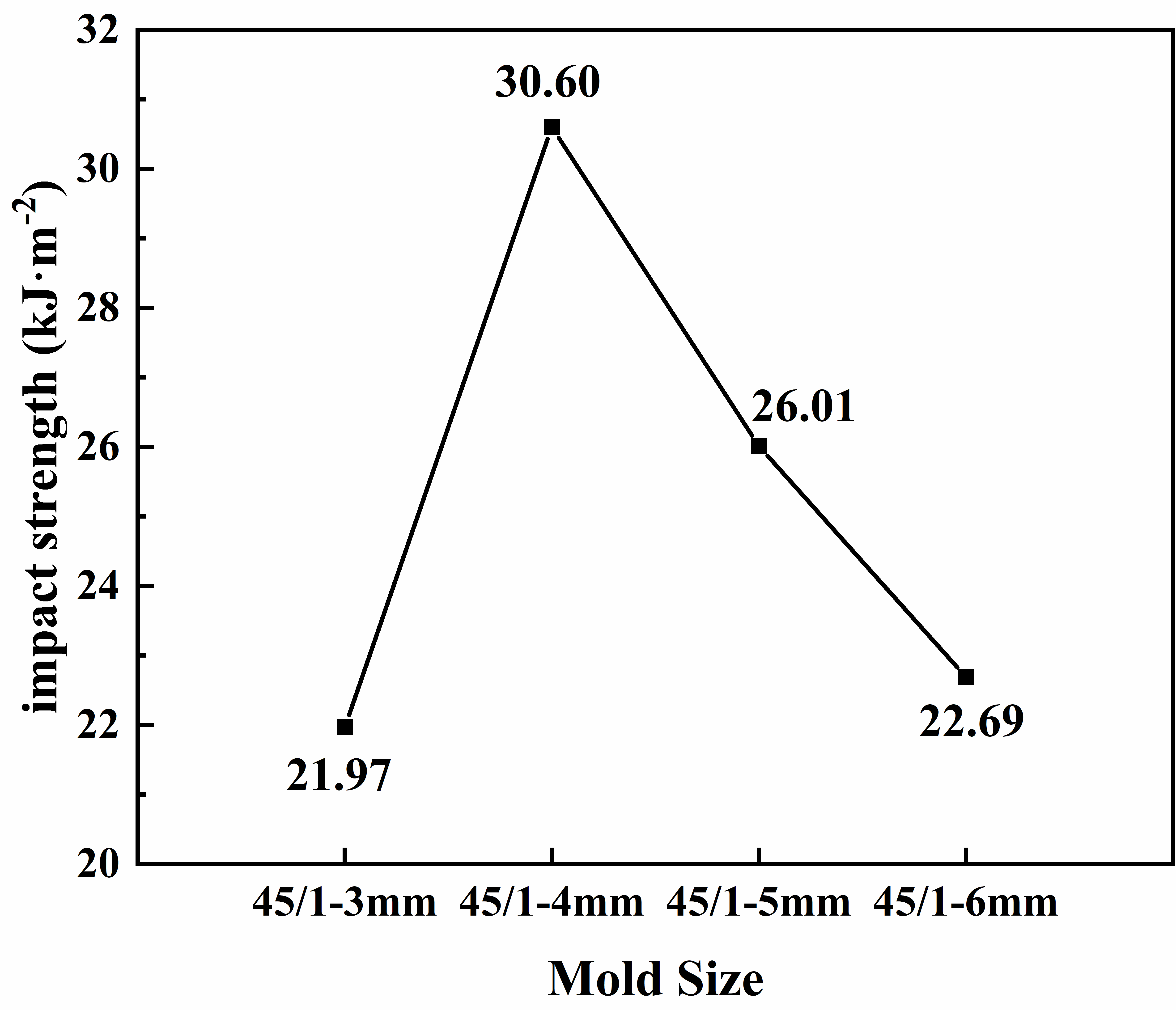

Pendulum impact test was used to test the impact resistance of the propellant with different pore sizes, and figure 5 shows the results of the impact strength of the propellants with different aperture diameters. Each sample is tested 5 times and the average value is taken.

|

Figure 5. Impact strength of propellants with different pore sizes |

As can be seen in figure 5, The impact strength of the propellant was the highest at 4 mm pore size, reaching 30.60KJm-2, Followed by a propellant with a bore diameter of 5 mm, When the hole diameter of 3mm and 6mm impact strength is relatively smallest, and the difference between the two less than 5%, 45/1-4mm compared to the two strengths increased by about 40%. This is because the hole diameter of 4mm is smaller than the arc thickness of 45/1-3mm, resulting in a denser internal component, and therefore enhanced impact strength. When the hole diameter reaches 5mm, although the components are more dense than 45/1-4mm, the further reduction of arc thickness leads to not enough volume to withstand the same impact force, resulting in less impact strength than 45/1-4mm, But at this point, it is still stronger than the impact strength of 45/1-3mm. When the hole diameter is 6mm, the arc thickness decreases even further, showing the densest but smallest arc thickness, at which point it reaches equilibrium with the relatively undense but maximum arc thickness of 45/1-3mm, and so exhibits almost the same impact strength.

4. Conclusion

1. DEGDN propellants pressure in the combustion process is an exponential rapid growth, and the higher the temperature, the faster the growth rate; Larger apertures result in smaller arc thicknesses and thus shorter combustion times resulting in reduced heat loss. In addition, the burning rate of the propellant during combustion does not vary with the orifice diameter.

2. At a pore size of 4 mm, the impact strength of the propellant is the greatest, increasing by about 40% over the 45/1-3 mm and 45/1-6 mm, which have the relatively smallest strengths.

References

[1]. Tian, Y., Wang, Y.B., He, W.D., Dong, J. (2019) Effects of TMETN Content and NC Nitrogen Content on the Mechanical Properties of TMETN/NG Mixed Nitrate Propellants. J. Chinese Journal of Explosives & Propellants., 42(02): 175-179. DOI:10.14077/ j.issn.1007-7812.2019.02.012.

[2]. Liu, W.X., Liu, Y., Gao, F.L., Wang, W., Wang, Y.L. (2023) Application of microreactor in synthesis and quality improvement of energetic materials. J. Chemical Industry and Engineering Progress., 42(07): 3349-3364. DOI:10.16085/j.issn.1000-6613.2023-0329.

[3]. Wang, Y.B., Jiang, L.M., He, W.D. (2020) Three-dimensional network structure nitramine gun propellant with nitrated bacterial cellulose. J. Journal of Materials Research and Technology., 9(6): 15094-15101. https://doi.org/10.1016/j.jmrt.2020.10.097.

[4]. Li, B., Li, Y., Liao, X. (2016) Experimental Study on the Enhancement Effect of the Combustion Performance of Solid Powder with Plasma. J. Chinese Journal of Explosives & Propellants., 39(04): 87-91. DOI:10.14077/j.issn.1007-7812.2016.04.017.

[5]. Dong, X.L., Rui, X.T., Li, C. (2023) Interior ballistic two-phase flow model and its calculation for a mixed charge structure. J. International Communications in Heat and Mass Transfer., 144: 106788. https://doi.org/10.1016/j.icheatmasstransfer.2023.106788.

[6]. Li, W., Gu, Q., Song, Q., Xiang, L., Wu, J.H. (2015) Research progress of thermoplastic elastomer propellant abroad. J. Chemical Propellants & Polymeric Materials., 13(06): 8-13. DOI:10.16572/j.issn1672-2191.201506002.

[7]. Yuan, H., Ma, Z.L., Zhang, S.L., Shi, W.W., Kang, R.Y. Chen, C.L. (2023) Numerical simulation of internal ballistic performance of different layered variable burning rate propellant. J. New Chemical Materials., 51(03): 185-190. DOI:10.19817/j.cnki.issn1006-3536.2023.03.033.

[8]. Cao, R.D., Zhang, X.B. (2019) Design optimization for a launching system with novel structure. J. Defence Technology., 15(05): 680-689. https://doi.org/10.1016/j.dt.201908005.

[9]. Zhao, Y.H., Xiao, Z.G., Yan, W.R., Yan, G. H., Liang, L. (2020) Interior Ballistic Performance Prediction of Gun Propellant Charge Based on Closed-bomb Test. J. Chinese Journal of Explosives & Propellants., 43(01): 81-84+89. https://doi.org/10.14077/j.issn1007-7812. 201901010.

[10]. Zheng, W., Wang, J.N., Xie, B., Song, X.D., Tian, J., Yuan, Z.F. (2011) Properties of Composite Modified Double-based Propellant Containing CL-20. J. Chinese Journal of Energetic Materials., 19(03): 272-275. https://doi.org/10.3969/j.issn1006-9941.201103007.

Cite this article

Zhang,J.;Zhu,J.;Zhao,L.;Liu,Z. (2024). Combustion and impact performance of DEGDN propellants under different size conditions. Applied and Computational Engineering,66,8-12.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Tian, Y., Wang, Y.B., He, W.D., Dong, J. (2019) Effects of TMETN Content and NC Nitrogen Content on the Mechanical Properties of TMETN/NG Mixed Nitrate Propellants. J. Chinese Journal of Explosives & Propellants., 42(02): 175-179. DOI:10.14077/ j.issn.1007-7812.2019.02.012.

[2]. Liu, W.X., Liu, Y., Gao, F.L., Wang, W., Wang, Y.L. (2023) Application of microreactor in synthesis and quality improvement of energetic materials. J. Chemical Industry and Engineering Progress., 42(07): 3349-3364. DOI:10.16085/j.issn.1000-6613.2023-0329.

[3]. Wang, Y.B., Jiang, L.M., He, W.D. (2020) Three-dimensional network structure nitramine gun propellant with nitrated bacterial cellulose. J. Journal of Materials Research and Technology., 9(6): 15094-15101. https://doi.org/10.1016/j.jmrt.2020.10.097.

[4]. Li, B., Li, Y., Liao, X. (2016) Experimental Study on the Enhancement Effect of the Combustion Performance of Solid Powder with Plasma. J. Chinese Journal of Explosives & Propellants., 39(04): 87-91. DOI:10.14077/j.issn.1007-7812.2016.04.017.

[5]. Dong, X.L., Rui, X.T., Li, C. (2023) Interior ballistic two-phase flow model and its calculation for a mixed charge structure. J. International Communications in Heat and Mass Transfer., 144: 106788. https://doi.org/10.1016/j.icheatmasstransfer.2023.106788.

[6]. Li, W., Gu, Q., Song, Q., Xiang, L., Wu, J.H. (2015) Research progress of thermoplastic elastomer propellant abroad. J. Chemical Propellants & Polymeric Materials., 13(06): 8-13. DOI:10.16572/j.issn1672-2191.201506002.

[7]. Yuan, H., Ma, Z.L., Zhang, S.L., Shi, W.W., Kang, R.Y. Chen, C.L. (2023) Numerical simulation of internal ballistic performance of different layered variable burning rate propellant. J. New Chemical Materials., 51(03): 185-190. DOI:10.19817/j.cnki.issn1006-3536.2023.03.033.

[8]. Cao, R.D., Zhang, X.B. (2019) Design optimization for a launching system with novel structure. J. Defence Technology., 15(05): 680-689. https://doi.org/10.1016/j.dt.201908005.

[9]. Zhao, Y.H., Xiao, Z.G., Yan, W.R., Yan, G. H., Liang, L. (2020) Interior Ballistic Performance Prediction of Gun Propellant Charge Based on Closed-bomb Test. J. Chinese Journal of Explosives & Propellants., 43(01): 81-84+89. https://doi.org/10.14077/j.issn1007-7812. 201901010.

[10]. Zheng, W., Wang, J.N., Xie, B., Song, X.D., Tian, J., Yuan, Z.F. (2011) Properties of Composite Modified Double-based Propellant Containing CL-20. J. Chinese Journal of Energetic Materials., 19(03): 272-275. https://doi.org/10.3969/j.issn1006-9941.201103007.