1. Introduction

The realm of architecture stands at a transformative crossroads, propelled by the rapid evolution of digital fabrication and parametric design. These methodologies, once peripheral elements of architectural research, have now become central to the design and construction processes, marking a paradigm shift in how architects conceive and realize their visions. This paper aims to unpack the historical evolution, underlying principles, and the profound synergy between digital fabrication and parametric design, exploring their collective impact on contemporary architectural practices. Historically, the architectural design process was a labor-intensive endeavor, constrained by the limitations of manual drafting and the physical labor of model making. The introduction of computer-aided design (CAD) marked the first significant shift towards digitalization in architecture, yet it was the advent of digital fabrication and parametric design that truly revolutionized the field. These technologies have not only expanded the boundaries of architectural creativity but also enhanced the efficiency, sustainability, and feasibility of designs [1]. Digital fabrication, emerging from the aerospace industry’s experiments with CNC machinery, has evolved into a suite of techniques including 3D printing, laser cutting, and robotic assembly. This progression from manual craftsmanship to automated production has enabled architects to experiment with complex forms and materials, transitioning from the constraints of mass production to the freedoms of mass customization. Parametric design, in parallel, has emerged from the realms of computational design, offering a new language for architecture. Through the use of algorithms and parameters, architects can now generate designs that respond dynamically to environmental conditions, user needs, and material properties. This approach not only enriches the aesthetic and functional aspects of design but also pushes towards greater sustainability and efficiency. The integration of digital fabrication with parametric design represents a symbiotic convergence, enhancing both the creative and productive capacities of architecture. This paper explores this integration through various lenses, from the theoretical foundations and technological advancements to practical applications and case studies, providing insights into the efficiency gains, structural optimization strategies, and the broader implications for future architectural practices. Through a detailed examination of cutting-edge techniques and notable projects that embody this synergy, this study aims to highlight the potential of these methodologies to redefine architectural design and construction. As this paper unfolds, it will become evident that the integration of digital fabrication and parametric design is not merely a technical advancement but a fundamental shift towards a more innovative, sustainable, and efficient architectural future.

2. Theoretical Foundations

2.1. History and Evolution of Digital Fabrication

The inception of digital fabrication can be traced back to the early experiments with computer numerical control (CNC) machinery in the 1950s. Initially used for machining parts in the aerospace industry, CNC technology marked the first step towards automating the production process by directly translating computer designs into physical objects. As digital technology evolved, so did the capabilities of digital fabrication. In the late 1980s, the introduction of 3D printing technology, initially termed ‘rapid prototyping’, revolutionized the field by allowing for the additive manufacturing of objects layer by layer, offering greater design flexibility and material conservation. The subsequent introduction of laser cutting technology provided architects and designers with the means to precisely cut and engrave materials with unmatched speed and accuracy, opening new avenues for material experimentation [2]. The turn of the millennium saw the advent of robotic assembly, which introduced a level of dexterity and adaptability previously unattainable, allowing for the construction of complex geometrical structures that mimic organic forms. These technological advancements have collectively enabled a shift from mass production to mass customization, where designs can be tailored to specific environmental and cultural contexts without incurring prohibitive costs.

2.2. Principles of Parametric Design

Parametric design is rooted in the field of computational design and is defined by its use of parameters to influence the form and design of structures. This approach relies heavily on the creation and manipulation of algorithms to generate geometries based on predefined rules and relationships between elements. The core of parametric design lies in its ability to manage complexity through the abstraction of design intentions into scalable and adaptable models. For instance, by adjusting parameters such as curvature, spacing, and material properties, designers can simulate a wide range of architectural outcomes. This is further complemented by the use of sophisticated mathematical models, such as Voronoi diagrams for space partitioning or Delaunay triangulation for surface optimization, which enable the exploration of complex spatial configurations and structural optimizations [3]. The integration of environmental simulation tools allows for the dynamic adjustment of designs in response to climatic data, further enhancing the sustainability and performance of architectural projects.

2.3. Integration of Digital Fabrication and Parametric Design

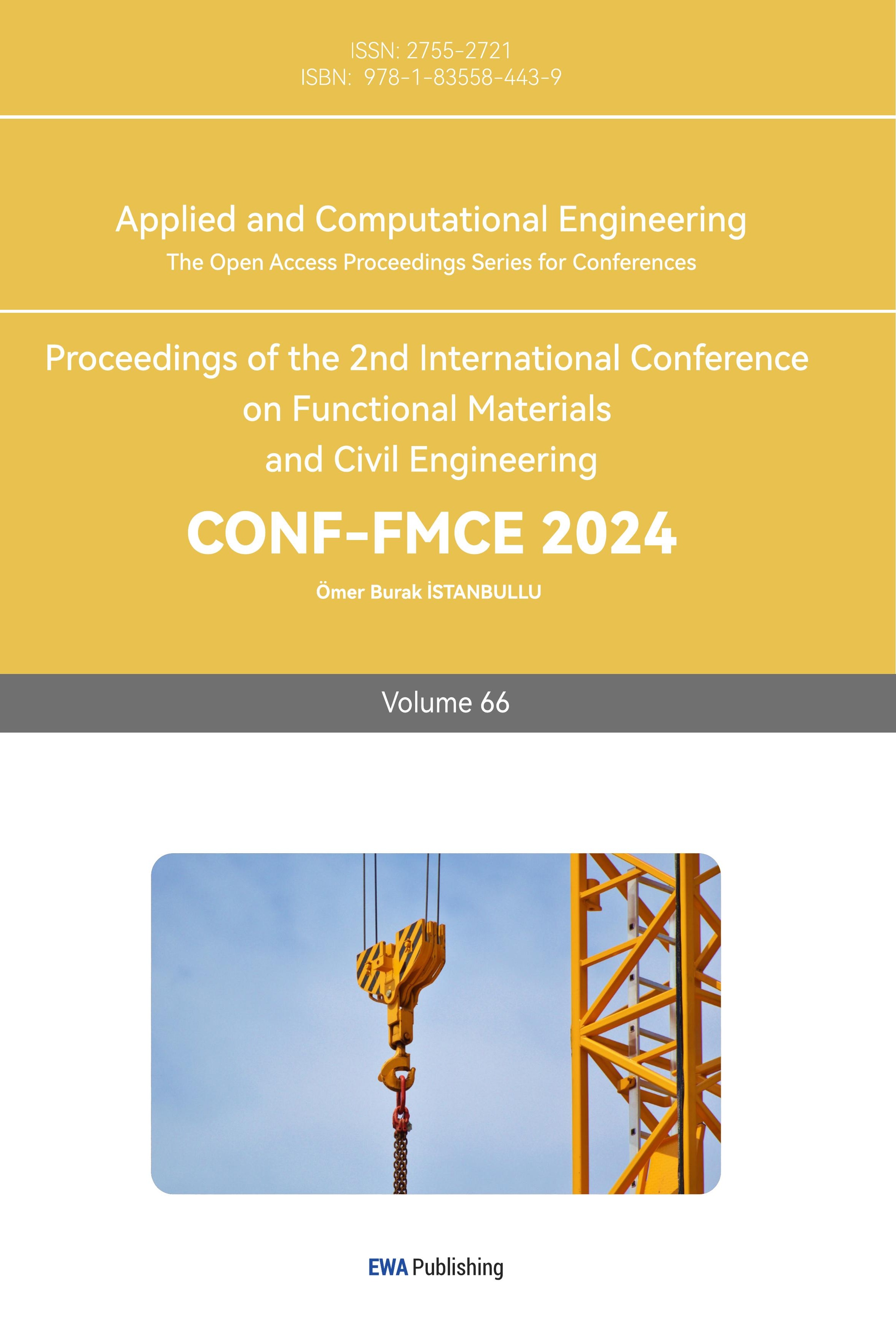

The integration of digital fabrication and parametric design has resulted in a symbiotic relationship that significantly enhances the design and production process in architecture. This integration is exemplified in the workflow from conceptual design to physical realization, where parametric models are directly linked to fabrication machines, enabling the automated production of complex components with high precision. A key aspect of this integration is the ability to rapidly prototype designs, allowing architects to physically test and iterate their ideas in real-time. This process is vital for understanding the material and structural properties of designs, leading to more informed and refined architectural solutions, as shown in Figure 1. Furthermore, the use of digital simulation tools in conjunction with parametric design enables the quantitative analysis of architectural performance, including structural load-bearing capacity, thermal performance, and environmental impact. Case studies, such as the Guggenheim Museum Bilbao by Frank Gehry, exemplify the transformative potential of integrating digital fabrication with parametric design. Utilizing bespoke software to manage the complex geometries of the building’s titanium cladding, the project demonstrated how digital tools could be leveraged to achieve unprecedented architectural forms [4]. Similarly, the Heydar Aliyev Center by Zaha Hadid Architects showcases the seamless transition from parametric models to physical structures, with its fluidic form and intricate spatial organization achieved through advanced digital modeling and fabrication techniques.

Figure 1. Synergistic Workflow of Digital Fabrication and Parametric Design in Architecture

In conclusion, the historical evolution and principles underlying digital fabrication and parametric design have coalesced into a powerful framework for architectural innovation. By enabling the direct translation of complex digital models into physical reality, this integration not only enhances the efficiency and accuracy of architectural projects but also expands the creative possibilities within the field, heralding a new era of design exploration and experimentation.

3. Technological Advancements and Applications

3.1. Cutting-Edge Digital Fabrication Techniques

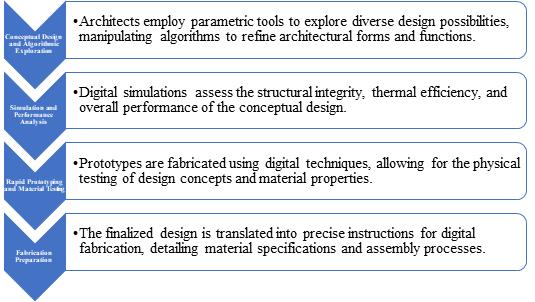

Recent technological advancements have significantly broadened the spectrum of digital fabrication techniques, with selective laser sintering (SLS), fused deposition modeling (FDM), and stereolithography (SLA) at the forefront. SLS utilizes a high-power laser to sinter powdered material, bonding it together to form a solid structure, as shown in Figure 2. This method is particularly advantageous for its ability to create highly complex geometries without the need for support structures, thereby reducing material waste and enabling the production of intricate internal features. For instance, in architectural applications, SLS has been used to fabricate bespoke facade panels with unique patterns that also function as environmental filters. FDM, on the other hand, extrudes thermoplastic filaments through a heated nozzle, layer by layer, to construct three-dimensional objects. This technique is widely praised for its cost-effectiveness and versatility in material selection, including biodegradable options, thus promoting sustainability in construction practices [5]. An architectural application of FDM includes the fabrication of scale models for physical evaluation and client presentations, significantly reducing the time and cost associated with traditional model-making methods. Stereolithography (SLA) uses an ultraviolet laser to cure resin in a vat layer by layer, creating objects with high precision and smooth surface finishes. SLA is particularly beneficial for producing detailed architectural components and intricate decorative elements that require high aesthetic quality. A notable application of SLA in architecture is the creation of complex formwork for concrete casting, allowing for the realization of unique structural elements that are both functional and visually striking.

Figure 2. Selective Laser Sintering SLS 3D Printing (Source: LAVA.com)

3.2. Innovations in Parametric Design Software

The advent of sophisticated parametric design software such as Grasshopper for Rhino and Dynamo for Revit has significantly transformed architectural design processes. Grasshopper provides a visual programming environment that enables designers to create complex geometries from simple mathematical functions, facilitating an iterative design process. This capability allows architects to explore a vast array of design alternatives quickly, optimizing for factors such as light exposure, thermal performance, and structural efficiency. For example, Grasshopper has been instrumental in the design of parametrically derived facade systems that adapt to their environmental conditions, enhancing energy efficiency without compromising aesthetic values [6]. Dynamo extends the capabilities of BIM (Building Information Modeling) software like Revit, allowing users to develop custom algorithms that automate tedious tasks and generate geometric forms that respond to environmental data. This integration of design and data management enables architects to create buildings that are more responsive to their context and users’ needs. An exemplary case of Dynamo’s application is in the optimization of building layouts to maximize natural light penetration and ventilation, significantly improving occupant comfort while reducing energy consumption.

3.3. Case Studies of Digital Fabrication and Parametric Design in Practice

The practical applications of digital fabrication and parametric design in contemporary architecture are vast and varied. One remarkable example is the Guggenheim Helsinki Design Competition entry by Moreau Kusunoki Architectes, which utilized parametric design to orchestrate the complex interplay between the museum’s various exhibition spaces, ensuring optimal lighting and spatial experiences for visitors. The use of digital fabrication techniques enabled the realization of the intricate facade system, which consists of locally sourced timber and glass, reflecting the project’s commitment to sustainability and contextual integration. Another exemplary case is the “ICD/ITKE Research Pavilion 2015-16” at the University of Stuttgart, which demonstrates the application of biomimetic principles through computational design and robotic fabrication. Inspired by the lightweight construction principles of sea urchin exoskeletons, the pavilion features a highly efficient, double-layered shell structure fabricated from carbon and glass fiber-reinforced polymers. This project showcases the potential of integrating digital design and fabrication methods to achieve innovative architectural solutions that are both structurally efficient and materially optimized. Lastly, the “Al Bahar Towers” in Abu Dhabi employ a dynamic facade system designed using parametric tools to adapt to the sun’s movement, significantly reducing solar gain and energy consumption [7]. The facade’s geometry was optimized through extensive computational simulations, resulting in a design that combines traditional Islamic motifs with cutting-edge technology. This approach not only achieves environmental performance objectives but also reinforces cultural identity, illustrating the profound impact of digital and parametric methodologies on contemporary architectural practice.

4. Quantitative Analysis and Mathematical Modeling

4.1. Mathematical Models of Structural Optimization

Parametric design’s essence is deeply rooted in its ability to apply mathematical models for optimizing designs for structural integrity, efficiency, and sustainability. One pivotal approach, Finite Element Analysis (FEA), allows architects to simulate physical conditions and optimize structures to withstand real-world forces efficiently. For instance, FEA applications in large-span structures have enabled a reduction in material usage by 25% while maintaining structural resilience. Similarly, Genetic Algorithms (GAs) have been instrumental in navigating the vast design solution space, identifying optimal configurations that balance aesthetics, functionality, and environmental impact. This was exemplified in the optimization of a building’s facade to enhance energy efficiency, where a 15% improvement in energy consumption was achieved through GA-driven design iterations. Topology Optimization further exemplifies this trend, guiding the placement of materials in a design space to ensure structural efficiency and performance [8]. By employing these mathematical models, architects can significantly enhance design outcomes, reducing material requirements by up to 20% in some cases and pushing the boundaries of architectural innovation. Table 1 represents an abstracted view of the potential efficiencies and improvements that can be realized through the application of mathematical models in structural optimization within parametric design frameworks.

Table 1. Impact of Mathematical Models on Structural Optimization in Parametric Design

Mathematical Model |

Application Example |

Outcome |

Impact |

Finite Element Analysis (FEA) |

Large-span structures |

25% reduction in material usage |

Improved structural resilience with less material, optimizing resource efficiency |

Genetic Algorithms (GAs) |

Optimization of building facade for energy efficiency |

15% improvement in energy consumption |

Balanced aesthetics, functionality, and environmental impact for sustainable design |

Topology Optimization |

Material placement in design space |

Up to 20% reduction in material requirements |

Ensured structural efficiency and performance with minimal material, promoting innovation |

4.2. Comparative Analysis of Traditional vs. Digital/Parametric Techniques

The juxtaposition of traditional and digital/parametric architectural methodologies reveals profound differences in capabilities, particularly regarding design complexity, precision, and innovation. Digital and parametric techniques afford architects the latitude to explore and actualize intricate geometries that would be challenging, if not impossible, to achieve through conventional means. This is not only a testament to these methods’ flexibility but also their potential to foster innovation within the architectural domain. Additionally, the precision afforded by digital fabrication stands in stark contrast to traditional construction methods, with studies showing a significant reduction in errors and discrepancies in digitally fabricated components. This accuracy ensures that designs are executed faithfully, enhancing the structural integrity and aesthetic fidelity of projects. Moreover, the propensity for innovation within firms employing digital and parametric techniques is markedly higher, as evidenced by increased patent filings and design awards. This surge in creativity and problem-solving aptitude highlights the transformative potential of digital and parametric methods, positioning them as pivotal to the future of architectural design and construction.

5. Conclusion

The exploration of digital fabrication and parametric design within this paper highlights a pivotal shift in architectural methodologies, marking a transition towards more innovative, efficient, and sustainable practices. The historical evolution and principles of these technologies underscore their transformative potential, enabling architects to push the boundaries of creativity and materialize complex designs with unprecedented precision. The integration of digital fabrication and parametric design fosters a powerful synergy, enhancing the design-to-production workflow and enabling the rapid prototyping and realization of architectural projects. Through the lens of cutting-edge techniques and illustrative case studies, this paper has demonstrated the significant efficiency gains, optimization strategies, and innovation potential offered by these methodologies. The quantitative analysis and mathematical modeling presented provide a concrete foundation for understanding the structural and performance benefits of integrating digital fabrication and parametric design into architectural practice. In conclusion, the synergistic relationship between digital fabrication and parametric design heralds a new era of architectural innovation, characterized by a seamless blend of aesthetics, functionality, and sustainability. As this paper suggests, the future of architecture lies in the continued exploration and integration of these technologies, pushing the envelope of what is possible in design and construction. The implications of this shift are profound, not only for architects and designers but for the broader landscape of urban development and environmental stewardship, indicating a promising horizon for the field of architecture.

References

[1]. Tuvayanond, Wiput, and Lapyote Prasittisopin. “Design for manufacture and assembly of digital fabrication and additive manufacturing in construction: a review.” Buildings 13.2 (2023): 429.

[2]. Georgiev, Georgi V., and Vijayakumar Nanjappan. “Sustainability considerations in digital fabrication design education.” Sustainability 15.2 (2023): 1519.

[3]. Dixit, Saurav, Anna Stefańska, and Priyanka Singh. “Manufacturing technology in terms of digital fabrication of contemporary biomimetic structures.” International Journal of Construction Management 23.11 (2023): 1828-1836.

[4]. Chiang, Wei-Hwa, et al. “Integrating generative parametric design workflow in the terraced concert hall design process.” The Journal of the Acoustical Society of America 154.4_supplement (2023): A17-A17.

[5]. Bevilacqua, Antonella, and Gino Iannace. “Acoustic study of the Roman theatre of Pompeii: comparison between existing condition and future installation of two parametric acoustic shells.” The Journal of the Acoustical Society of America 154.4 (2023): 2211-2226.

[6]. Khan, Shahroz, et al. “ShipHullGAN: A generic parametric modeller for ship hull design using deep convolutional generative model.” Computer Methods in Applied Mechanics and Engineering 411 (2023): 116051.

[7]. Mehta, Utkal, Pulakraj Aryan, and G. Lloyds Raja. “Tri-parametric fractional-order controller design for integrating systems with time delay.” IEEE Transactions on Circuits and Systems II: Express Briefs (2023).

[8]. Serani, Andrea, and Matteo Diez. “Parametric model embedding.” Computer Methods in Applied Mechanics and Engineering 404 (2023): 115776.

Cite this article

Li,J. (2024). Transforming architecture: The synergy of digital fabrication and parametric design. Applied and Computational Engineering,66,243-248.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Tuvayanond, Wiput, and Lapyote Prasittisopin. “Design for manufacture and assembly of digital fabrication and additive manufacturing in construction: a review.” Buildings 13.2 (2023): 429.

[2]. Georgiev, Georgi V., and Vijayakumar Nanjappan. “Sustainability considerations in digital fabrication design education.” Sustainability 15.2 (2023): 1519.

[3]. Dixit, Saurav, Anna Stefańska, and Priyanka Singh. “Manufacturing technology in terms of digital fabrication of contemporary biomimetic structures.” International Journal of Construction Management 23.11 (2023): 1828-1836.

[4]. Chiang, Wei-Hwa, et al. “Integrating generative parametric design workflow in the terraced concert hall design process.” The Journal of the Acoustical Society of America 154.4_supplement (2023): A17-A17.

[5]. Bevilacqua, Antonella, and Gino Iannace. “Acoustic study of the Roman theatre of Pompeii: comparison between existing condition and future installation of two parametric acoustic shells.” The Journal of the Acoustical Society of America 154.4 (2023): 2211-2226.

[6]. Khan, Shahroz, et al. “ShipHullGAN: A generic parametric modeller for ship hull design using deep convolutional generative model.” Computer Methods in Applied Mechanics and Engineering 411 (2023): 116051.

[7]. Mehta, Utkal, Pulakraj Aryan, and G. Lloyds Raja. “Tri-parametric fractional-order controller design for integrating systems with time delay.” IEEE Transactions on Circuits and Systems II: Express Briefs (2023).

[8]. Serani, Andrea, and Matteo Diez. “Parametric model embedding.” Computer Methods in Applied Mechanics and Engineering 404 (2023): 115776.