1. Introduction

The global construction industry is at a crossroads of innovation and sustainability, facing a huge challenge to reduce its environmental impact while meeting the growing demand for infrastructure and housing. As the world struggles to cope with pressing issues such as climate change, resource depletion and rapid urbanization, the need for sustainable building practices is becoming ever more urgent. This background sets the stage for the integration of building information modeling (BIM) and prefabricated construction (PC) technologies as a potential paradigm shift towards more sustainable, efficient and cost-effective construction methods. BIM is a digital representation of the physical and functional characteristics of a facility, providing an unparalleled opportunity to optimize project design, construction and operations. Meanwhile, PC, which involves manufacturing building parts in a factory environment and then assembling them on site, offers a way to significantly reduce construction waste and increase efficiency. This paper aims to explore how the synergies between BIM and PC technologies can be leveraged to align the construction industry with the United Nations Sustainable Development Goals (SDGS). By examining the intersections of these innovative technologies and the global sustainability agenda, the study aims to contribute to the discussion on sustainable urban development and the role of the construction industry in achieving sustainability [1]. The adoption of BIM and PC is seen not only as a technological evolution, but also as a strategic imperative to ensure that the construction sector contributes to sustainable development, highlighting the role of these technologies in advancing Sustainable Development Goals 9, 11, 12, 13, and 7.

2. Process Optimization with BIM and PC Integration

2.1. Streamlining Design and Construction Phases

The convergence of building Information Modeling (BIM) and prefabricated construction (PC) has brought about a paradigm shift in the transition of construction projects from design to actual construction. Traditionally, the design and construction phases have been separate, often resulting in significant differences between building design and actual construction capabilities. With its comprehensive digital representation of physical and functional characteristics, BIM enables detailed dynamic visualizations of projects covering architectural, mechanical, electrical and plumbing (MEP) systems in collaborative environments. This integrated approach is further enhanced by PC, which emphasizes off-site manufacturing of building components, ensuring that the design is not only sound in theory, but also feasible in practice and optimized for prefabrication. The advanced simulation and 3D visualization capabilities inherent in BIM software help identify potential problems early. For example, conflict detection tools in BIM can identify overlapping elements or conflicts between different models (structures, MEPs, etc.), which is critical to resolving this issue before manufacturing prefabricated components. This pre-emptive approach greatly reduces the need for rework and modifications during the construction phase, directly impacting the project schedule and cost efficiency [2]. In addition, integration makes the construction process more agile, and design changes can be quickly reflected in the prefabricated components while minimizing disruption to the overall project schedule.

Quantitative analysis supports the effectiveness of this integration, showing in several case studies that project times have been reduced by up to 30% due to reduced rework rates and more streamlined communication between design and construction teams, as shown in Table 1. It is supported by a mathematical model that predicts project timelines based on various integration levels of BIM and PC, taking into account variables such as project complexity, level of prefabrication, and BIM technical team expertise [3].

Table 1. Efficiency Gains in Construction Projects Through Integration of BIM and Prefabricated Construction

Project | Complexity Level | Prefabrication Level | BIM Expertise Level | Projected Timeline (months) | Actual Timeline (months) | Timeline Reduction (%) |

Skyline Tower | High | High | High | 24 | 18 | 25 |

Riverfront Residences | Medium | High | Medium | 18 | 14 | 22 |

Greenfield School | Low | Medium | High | 12 | 10 | 17 |

Urban Renewal Initiative | Medium | Low | Medium | 15 | 14 | 7 |

Tech Hub Expansion | High | Medium | Low | 20 | 18 | 10 |

2.2. Enhancing Quality Control

Traditionally, quality control of construction projects has been challenging because physical labor and site-specific conditions can lead to changes in the final product. The integration of BIM and PC can significantly mitigate these challenges. BIM’s accurate model provides a detailed blueprint for prefabricated components, ensuring that each component is manufactured to exact specifications. This level of accuracy is achieved through the PC’s inherently controlled manufacturing environment, where variables such as temperature, humidity, and material consistency can be closely monitored and adjusted. This controlled environment is in stark contrast to the variability of traditional construction sites, where external factors can lead to inconsistencies in the final product. By minimizing on-site errors and material waste, integration directly contributes to the sustainability goals of the construction industry [4]. For example, waste reduction indicators can be quantitatively measured, and studies have shown that material waste can be reduced by up to 40% when using PCS with BIM technology. These indicators not only demonstrate the environmental benefits of this approach, but also translate into cost savings through reduced material procurement and waste disposal costs.

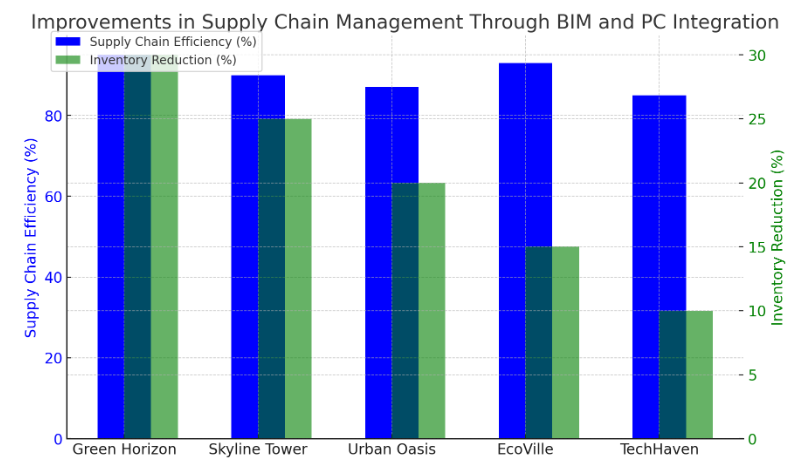

2.3. Improving Supply Chain Management

Figure 1. Improvements in Supply Chain Management Through BIM and PC Integration

The integration of BIM and PC has profoundly impacted supply chain management in the construction industry. BIM provides a detailed dynamic overview of the project, including the precise specifications of each component and the expected timeline for when those components will be needed on site. This level of detail optimizes the supply chain for timely delivery of prefabricated components, minimizing the need for on-site storage and reducing inventory costs. In addition, the predictability provided by PCS (components are manufactured to precise specifications and schedules) facilitates smoother supply chain operations [5]. This predictability, combined with BIM’s scheduling capabilities, allows for more efficient coordination of deliveries, ensuring components arrive exactly when they are needed, reducing the risk of project delays due to supply chain disruptions. Mathematical models have been developed to simulate supply chain logistics in construction projects, taking into account variables such as lead times, manufacturing speeds, and synchronization between supply chain components and construction schedules. These models have proven to help optimize supply chain operations, further improve project efficiency and reduce waste. As shown in Figure 1.

3. Sustainability Metrics and Environmental Impact

3.1. Carbon Footprint Reduction

Quantitative analysis and mathematical modeling provide a compelling case for the integration of Building Information Modeling (BIM) and Prefabricated Construction (PC) as a strategy for reducing the carbon footprint of construction projects. The application of BIM facilitates the precise planning and optimization of materials and components, while PC enables the efficient production and assembly of these components with minimal waste. This synergistic approach significantly lowers the volume of wasted resources, consequently reducing the emissions associated with material production and transportation.

A mathematical model to estimate CO2 savings from the integration of BIM and PC is as follows:

\( {C{O_{2}}_{savings}}=({M_{traditional}}-{M_{BIM-PC}})×{E_{production}}+({T_{traditional}}-{T_{BIM-PC}})×{E_{transport}} \ \ \ (1) \)

\( {C{O_{2}}_{savings}} \) represents the carbon dioxide savings in metric tons. \( {M_{traditional}} \) and \( {M_{BIM-PC}} \) denote the material used in traditional construction methods and construction utilizing BIM and PC integration, respectively, measured in metric tons. \( {E_{production}} \) is the CO2 emission factor for material production, measured in metric tons of CO2 per metric ton of material. \( {T_{traditional}} \) and \( {T_{BIM-PC}} \) represent the transportation required for traditional and BIM-PC integrated projects, respectively, measured in ton-kilometers. \( {E_{transport}} \) is the CO2 emission factor for transportation, measured in metric tons of CO2 per ton-kilometer [6].

By leveraging BIM for detailed planning and simulation, the construction process can minimize unnecessary procurement and use of materials, significantly reducing the emissions from material production. Similarly, PC’s efficient logistics and assembly processes decrease the need for extensive transportation, further lowering CO2 emissions.

3.2. Resource Efficiency

The integration of BIM and PC not only optimizes the use of materials but also ensures that the resources are utilized to their maximum efficiency, thereby reducing waste and enhancing the sustainability of construction projects. Through the precise and detailed modeling capabilities of BIM, combined with the controlled manufacturing environment of PC, construction projects can achieve a significant reduction in resource wastage. The quantitative analysis supporting the improvement in resource efficiency includes an evaluation of material savings, which can be calculated as follows:

\( {Material_{savings}}={M_{traditional}}-{M_{BIM-PC}} \ \ \ (2) \)

Where \( {Material_{savings}} \) indicates the reduction in materials used, measured in metric tons. \( {M_{traditional}} \) and \( {M_{BIM-PC}} \) represent the amount of materials utilized in traditional construction methods and in projects integrating BIM and PC, respectively [7].

This model highlights the potential for substantial material savings, directly correlating with a decrease in the environmental impact associated with material extraction, processing, and disposal. Furthermore, the streamlined process reduces the likelihood of overordering and excess inventory, thereby lowering the carbon footprint associated with the lifecycle of construction materials.

3.3. Energy Efficiency in Construction and Operation

The utilization of BIM-PC integration extends beyond the construction phase, offering benefits throughout the building’s lifecycle, particularly in terms of energy efficiency. By incorporating energy simulation tools within BIM software, stakeholders can make informed decisions during the design phase that optimize the building’s energy consumption patterns for heating, cooling, lighting, and other operational needs.

The following equation represents the potential energy savings during the operational phase of a building designed and constructed with BIM and PC technologies:

\( {Energy_{savings}}={E_{traditional}}-{E_{BIM-PC}} \ \ \ (3) \)

Where \( {Energy_{savings}} \) denotes the reduction in energy consumption, measured in kilowatt-hours (kWh). \( {E_{traditional}} \) and \( {E_{BIM-PC}} \) are the estimated energy consumption of buildings constructed through traditional methods and those utilizing BIM-PC integration, respectively. These savings arise from the strategic placement of windows for natural lighting, optimized building orientation for passive solar heating and cooling, and the incorporation of energy-efficient materials and systems identified through BIM’s analytical tools [8]. Consequently, buildings designed with these methodologies not only require less energy for daily operations but also contribute to a reduction in the overall demand for fossil fuels, thus lowering greenhouse gas emissions associated with energy production.

4. Future Trends and Research Directions

4.1. Advancements in Technology

With the advent of artificial intelligence (AI) and the Internet of Things (IoT), the integration of prefabricated building (PC) and building information modeling (BIM) technologies promises transformative advances. The convergence of AI with BIM and PC will revolutionize the construction industry by enhancing predictive analytics, automating design processes, and improving project management and execution. AI algorithms can analyze massive data sets from BIM to predict project outcomes, optimize construction sequence, and identify potential design conflicts before they occur, significantly reducing costs and project timelines. For example, machine learning models can be trained on historical BIM data to predict the structural integrity of prefabricated components, adjusting designs in real time to ensure compliance with safety standards. In addition, the role of IoT in this integration facilitates real-time data collection and monitoring of construction sites and prefabricated components, enabling a dynamic feedback loop between the physical construction process and the digital BIM model [9]. IoT sensors embedded in prefabricated components monitor the condition of materials during transportation and construction, ensuring that any deviations from planned specifications are addressed immediately. In addition, IoT devices can track the usage and performance of buildings after construction, feed the data back into BIM models to inform future projects and form a closed loop between the design, construction and operational phases. This symbiotic relationship between AI, IoT, BIM and PC not only increases efficiency and reduces waste, but also drives the construction industry towards fully automated and intelligent construction processes.

4.2. Global Adoption and Customization

The potential for global adoption of BIM and PC technologies presents multiple challenges and opportunities. Depending on economic, cultural and regulatory factors, the readiness and enthusiasm for building technology integration varies from region to region. For example, in developed countries with high labor costs and stringent environmental regulations, BIM and PC adoption is driven by the need for efficiency, cost reduction and sustainability. In contrast, developing countries are likely to prioritize the technology’s ability to quickly address housing shortages and infrastructure development needs. Customizing BIM and PC technologies to suit local conditions is essential for their widespread adoption. This involves adapting these technologies to meet local building codes, materials, and construction practices, as well as addressing the specific environmental and social challenges of each region. In addition, developing flexible and scalable BIM and PC platforms that can be easily customized by local engineers and architects without significant retraining or significant up-front investment is critical to driving global adoption. Cross-border collaboration and knowledge sharing between countries with advanced BIM and PC capabilities and those in the early stages of adoption can accelerate this process, enabling the global construction industry to benefit from these technologies [10].

5. Conclusion

The integration of building Information Modelling (BIM) and prefabricated building (PC) offers a compelling way for the construction industry to contribute to the United Nations Sustainable Development Goals (SDGS). This paper shows that by strategically adopting BIM and PC, the construction industry can significantly improve efficiency, reduce its environmental footprint, and play a key role in promoting sustainable urbanization. The synergies between these technologies not only benefit resource optimization and waste reduction, but also create energy-efficient buildings that contribute to climate change mitigation and advancing the global Sustainable Development Goals. In addition, enhanced collaboration and information sharing are key components of BIM, helping to ensure that construction projects meet community needs and environmental considerations. However, to realize the full potential of BIM and PC integration, challenges related to technology adoption will need to be overcome, including initial costs, the need for stakeholder education, and the development of standardized practices. Future research and development efforts should therefore focus on addressing these challenges, promoting global adoption, and continuously advancing these technologies to meet local and global sustainability needs. As the construction industry moves towards a more digital and sustainable future, the strategic integration of BIM and PC technologies is critical to shaping sustainable cities and communities for future generations.

References

[1]. Henderson, Kirsten, and Michel Loreau. “A model of Sustainable Development Goals: Challenges and opportunities in promoting human well-being and environmental sustainability.” Ecological modelling 475 (2023): 110164.

[2]. Leal Filho, Walter, Amanda Lange Salvia, and João Henrique Paulino Pires Eustachio. “An overview of the engagement of higher education institutions in the implementation of the UN Sustainable Development Goals.” Journal of Cleaner Production 386 (2023): 135694.

[3]. Kwilinski, Aleksy, Oleksii Lyulyov, and Tetyana Pimonenko. “Environmental sustainability within attaining sustainable development goals: The role of digitalization and the transport sector.” Sustainability 15.14 (2023): 11282.

[4]. Waqar, Ahsan, Abdul Hannan Qureshi, and Wesam Salah Alaloul. “Barriers to building information modeling (BIM) deployment in small construction projects: Malaysian construction industry.” Sustainability 15.3 (2023): 2477.

[5]. Babalola, Ayotunde, et al. “A bibliometric review of advances in building information modeling (BIM) research.” Journal of Engineering, Design and Technology 21.3 (2023): 690-710.

[6]. Patel, Kartik, and Rajeev Ruparathna. “Life cycle sustainability assessment of road infrastructure: a building information modeling-(BIM) based approach.” International Journal of Construction Management 23.11 (2023): 1837-1846.

[7]. Anukaenyi, Victor, et al. “Enhancing Offsite Construction for UK SMEs through Building Information Modelling: A Comprehensive Analysis.” Thirty-Ninth Annual Conference. 2023.

[8]. Fagbenro, Rasaki Kolawole, et al. “Influence of prefabricated construction on the mental health of workers: systematic review.” European journal of investigation in health, psychology and education 13.2 (2023): 345-363.

[9]. Tatari, Ali. “Simulating Cost Risks for Prefabricated Construction in Developing Countries Using Bayesian Networks.” Journal of Construction Engineering and Management 149.6 (2023): 04023037.

[10]. Anaç, Merve, Gulden Gumusburun Ayalp, and Kamil Erdayandi. “Prefabricated construction risks: A holistic exploration through advanced bibliometric tool and content analysis.” Sustainability 15.15 (2023): 11916.

Cite this article

Mi,Z.;Deng,Q. (2024). Aligning building information modeling and prefabricated construction with sustainable development goals: A framework for sustainable urbanization. Applied and Computational Engineering,70,48-53.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Henderson, Kirsten, and Michel Loreau. “A model of Sustainable Development Goals: Challenges and opportunities in promoting human well-being and environmental sustainability.” Ecological modelling 475 (2023): 110164.

[2]. Leal Filho, Walter, Amanda Lange Salvia, and João Henrique Paulino Pires Eustachio. “An overview of the engagement of higher education institutions in the implementation of the UN Sustainable Development Goals.” Journal of Cleaner Production 386 (2023): 135694.

[3]. Kwilinski, Aleksy, Oleksii Lyulyov, and Tetyana Pimonenko. “Environmental sustainability within attaining sustainable development goals: The role of digitalization and the transport sector.” Sustainability 15.14 (2023): 11282.

[4]. Waqar, Ahsan, Abdul Hannan Qureshi, and Wesam Salah Alaloul. “Barriers to building information modeling (BIM) deployment in small construction projects: Malaysian construction industry.” Sustainability 15.3 (2023): 2477.

[5]. Babalola, Ayotunde, et al. “A bibliometric review of advances in building information modeling (BIM) research.” Journal of Engineering, Design and Technology 21.3 (2023): 690-710.

[6]. Patel, Kartik, and Rajeev Ruparathna. “Life cycle sustainability assessment of road infrastructure: a building information modeling-(BIM) based approach.” International Journal of Construction Management 23.11 (2023): 1837-1846.

[7]. Anukaenyi, Victor, et al. “Enhancing Offsite Construction for UK SMEs through Building Information Modelling: A Comprehensive Analysis.” Thirty-Ninth Annual Conference. 2023.

[8]. Fagbenro, Rasaki Kolawole, et al. “Influence of prefabricated construction on the mental health of workers: systematic review.” European journal of investigation in health, psychology and education 13.2 (2023): 345-363.

[9]. Tatari, Ali. “Simulating Cost Risks for Prefabricated Construction in Developing Countries Using Bayesian Networks.” Journal of Construction Engineering and Management 149.6 (2023): 04023037.

[10]. Anaç, Merve, Gulden Gumusburun Ayalp, and Kamil Erdayandi. “Prefabricated construction risks: A holistic exploration through advanced bibliometric tool and content analysis.” Sustainability 15.15 (2023): 11916.