1. Introduction

The current global energy demand and the urgent need to combat the emissions responsible for climate change have spurred a quest for alternative and sustainable energy sources. Conventional fossil fuels have long been the primary energy source, but their utilization has led to detrimental environmental repercussions such as air pollution and the exacerbation of the greenhouse effect. For example, Sulfur Dioxide (SO2) emissions, which results from burning coals, contributes to acid rain and public health [1]. As a result, scientists have started to investigate several forms of renewable energy, including solar, wind, biomass, and hydrogen.

The use of hydrogen, hailed as a flexible and sustainable energy source, has grown significantly. Its combustion yields only water, rendering it as an attractive candidate for carbon emission reduction. However, conventional ways of producing hydrogen, such as steam methane reforming (SMR), rely on the combustion of fossil fuels and produce carbon dioxide (CO2) emissions [2], undermining the very premise of clean hydrogen generation.

The combustion reaction is formulated as following: \( C{H_{4}}+2{O_{2}}→C{O_{2}}+{H_{2}}O+ΔE \)

In pursuit of genuinely sustainable hydrogen production, the focus has turned toward biohydrogen, with an emphasis on algae-based systems. Compared to alternative sources of biomass, photosynthetic microorganisms like algae offer a number of benefits. They are particularly intriguing candidates for sustainable hydrogen production due to their adeptness in absorbing solar energy and carbon dioxide through photosynthesis [3].

This process can be represented as: \( 2{H_{2}}O→2{H_{2}}+{O_{2}} \)

The biohydrogen production mechanism aligns with environmental virtues. It is not only valued as renewable resources but also operates on the principle of carbon neutrality. This arises since the carbon dioxide emissions from hydrogen production are offset by the carbon dioxide that algae capture during photosynthesis. However, it also presents significant challenges that need to be overcome. The efficiency of biohydrogen production via algae-based systems remains a focal point of investigation. Addressing questions of adaptability, the technological prowess of bioreactors and the optimization of those remain as an obstacle to paramount [4]. Aligned with the central aim of the research, an evaluation of the techno-economic and environmental viability is imperative.

2. Methods of Hydrogen Production

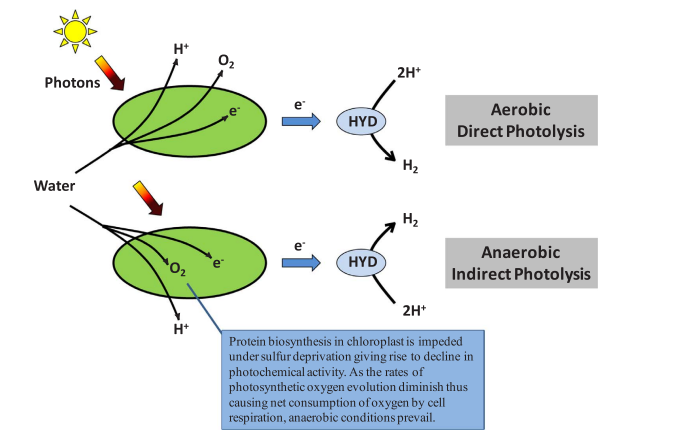

Biohydrogen is produced by a process known as biophotolysis, the dissociation of water molecules to form hydrogen and oxygen under solar radiation. There are two types of biophotolysis: direct and indirect.

2.1. Direct Biophotolysis

Direct biophotolysis generates electrons equivalents from splitting of water under aerobic conditions. It goes through two main steps: Photosynthesis (Equation (1)) and Hydrogen Production (Equation (2)). Photosynthesis splits up the water molecule and hydrogen production produces biohydrogen catalyzed by hydrogenases from green algae.

\( Photosynthesis: {{2H_{2}}O→4{H^{+}}+4{e^{-}}+{O_{2}}_{}}\ \ \ (1) \)

\( Hydrogen Production : 4{H^{+}}+4{e^{-}}→2{{H_{2}}^{}}\ \ \ (2) \)

Direct biophotolysis uses specialized photosynthetic microorganisms, such as algae and cyanobacteria, to directly create hydrogen gas from water while harnessing the power of sunlight. Photosystem II (PSII), a special portion of these microbes, uses the energy of sunlight to split water molecules. By splitting the water, high-energy electrons and oxygen are produced. Then, through a network of molecules known as an electron transport chain, these high-energy electrons are transferred within the bacteria. These electrons eventually arrive at hydrogenase, a component of the bacteria. The enzyme hydrogenase aids in the transformation of hydrogen ions into hydrogen gas. As water molecules split, they produce both oxygen and hydrogen ions. The presence of hydrogen ions helps create a gradient, which is a difference in concentration across a membrane. Oxygen gas is also produced as a result of the water-splitting process.

However, there's a challenge in the process due to the production of oxygen. These microorganisms naturally produce oxygen alongside hydrogen. Unfortunately, oxygen can interfere with and slow down the production of hydrogen gas.

2.2. Indirect Biophotolysis

Indirect biophotolysis is another approach that harnesses the capabilities of photosynthetic microorganisms like algae and cyanobacteria for hydrogen production, but through a different process. Instead of directly splitting water to generate hydrogen, indirect biophotolysis involves two main stages: biomass production and subsequent hydrogen extraction.

In the first stage, these microorganisms capture sunlight and convert carbon dioxide into biomass, typically in the form of sugars. This process resembles traditional photosynthesis, where the absorbed light energy is transformed into chemical energy stored in the biomass. This biomass serves as a reservoir of energy for the subsequent hydrogen production.

The second stage involves processing the biomass to extract hydrogen gas. Depending on the microorganism and the desired outcome, different methods can be used. One common approach is through fermentation, where the biomass is subjected to specific conditions to encourage the production of hydrogen gas as a byproduct. Another method is gasification, where the biomass is transformed into a mixture of gases including hydrogen under high-temperature conditions.

Unlike direct biophotolysis, which focuses on directly converting sunlight into hydrogen gas, indirect biophotolysis has an intermediate step involving biomass production. This extra step can have advantages, such as allowing for the storage of energy in the biomass, which can be processed into hydrogen at a later time. However, it can also introduce additional complexities and potentially lower the overall efficiency of the process.

Figure 1. Schematic visualization of comparison between Direct Photolysis and Indirect Photolysis [5]

3. Technical developments of Bioreactors

Even though the theories and studies manifested that biophotolysis and biohydrogen have shown potential as efficient renewable biofuel, it has still not been made in practical use due to its dubious development of technologies. One main problem is the efficiency of bioreactors. Bioreactors are necessary in order to provide an optimal environment for hydrogen-producing microorganisms. However, Sanjay Kumar Gupta et al., professors from Durban University of Technology acknowledge that current biohydrogen production technologies face two major challenges of low-yield and high production cost, not adequately accomplishing the primary purpose of a bioreactor [6].

To optimize biophotolysis, there are many factors to consider; this section, however, will mainly discuss bioreactor design and engineering. Acknowledge that there are still efforts necessary in maintenance, monitoring, simulation, genetic engineering, etc.

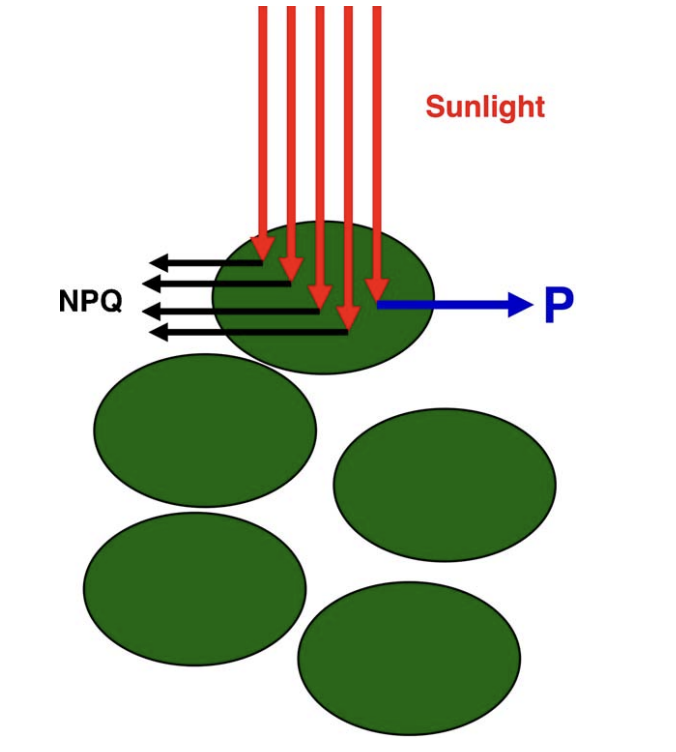

3.1. Efficient Photosynthetic Activity

3.1.1. Biological Renovations. Researchers suggest that truncation of chlorophyll antennae in photosystems will improve the efficiency of the plants’ photosynthesis. Antennae pigments play the role of collecting light energy from the sun and transferring it to the reaction center. According to Anastasios Melis, associated with Plant and Microbial Biology department in UC Berkeley, claims that truncation of antennae size “would minimize light absorption of each individual cells” and “permit greater transmittance” which would enable “more cells to contribute to useful photosynthesis and cultural productivity” [7].

Figure 2. Schematic representation of sunlight absorption of fully pigmented microalgae (left) and truncated microalgae (right) [7].

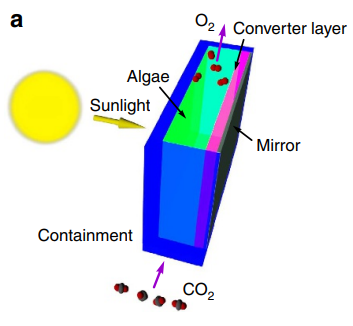

3.1.2. Development of Bioreactors. Bioreactor designs need to maximize light exposure while ensuring efficient gas exchange, temperature control, and nutrient availability. Primarily, it needs to capture as much solar energy as possible, since the growth of photosynthetic microorganisms, like algae and cyanobacteria, relies on their ability to capture light energy for photosynthesis. Bioreactor designs should aim to expose the maximum surface area of microorganisms to light while avoiding shading or light attenuation caused by self-shading [8]. This can involve designing transparent or translucent walls, tubes, or other structures that allow light to penetrate and reach the microorganisms effectively.

For example, Lothar Wondraczek and teammates designed photoluminescent converter of type \( C{a_{0.59}}S{r_{0.40}}E{u_{0.01}}S \) shown in Figure 3, which enables “enables efficient conversion of the green part of the incoming spectrum into red light to better match the \( {Q_{y}} \) peak of chlorophyll b,” which would significantly increase photosynthetic activity, resulting in higher algae reproduction rate [9].

Figure 3. Flat Panel algae reactor combined with a solar spectral converter in backlight geometry

Another concern would be maintaining a consistent and appropriate temperature range. Temperature plays a significant role in the growth and metabolic activity of microorganisms, so temperature control is essential to ensure optimal hydrogen production rates and prevent temperature stress that could denature the microorganism. To regulate the bioreactor’s temperature, bioreactors may incorporate heaters, coolers, or heat exchangers. Researchers predict the temperature range to be approximately 25°C to 40°C [10]; however, researchers introduced that most appropriate temperature control equipment depends on heat load, or specific internal energy, which is a challenge that should be discovered in the future [11].

3.2. Conversion to Biomass and Electricity

Researchers have delved deeper in order to discover a way to coexist the two prominent renewable energies: biomass and photovoltaic. As such, more efficient conversion technology between two energies is needed.

Not sufficient research is done in the area to prove that their conversion is fully maximized. However, there are some suggestions about what technical implications could be made. For example, David Parlevliet and Navid Reza Moheimani propose that the major challenge of converting biomass to usable electricity is that both microalgae and photovoltaic devices compete for the same sunlight resource. However, some microalgae groups only need specific parts of the solar spectrum (blue and red light) for photosynthesis, while photovoltaic devices can absorb a broader range of visible light. To address this, Parlevliet and Moheimani suggest using a filter above the algae culture to modify the light spectrum reaching the algae. This modified spectrum can then be used to generate electricity, which can power additional systems or provide extra illumination for microalgae growth. Modeling suggests that this approach can improve the productivity of light-limited microalgae systems by at least 4% [12].

Overall, there are still more technological developments needed to commercialize the use of bioreactors. If these factors are incorporated into bioreactors, biohydrogen would be accessible as renewable energy in the near future.

4. Economic Analysis

The U.S. Department of Energy (DOE) stated that their cost goal of hydrogen energy is $2.60/kg, while its production hasn’t reached yet after continuous funding [13]. This raised the question of whether to continue the economical support towards biohydrogen production, which required analysis of biohydrogen’s future cost.

4.1. Short-term Economics

In the short term, the development of biohydrogen technology requires substantial initial investments in research, engineering, and equipment. These upfront costs can impact the technology's economic feasibility during its early stages. The short-term financial concerns also include operational costs, such as labor, maintenance, and energy consumption.

Biohydrogen production requires a bioreactor that was discussed in Section 3, and previous studies demonstrated that the cost of the reactor significantly impacted the cost of the hydrogen produced. The complex the reactor gets, requires more advanced materials, resulting in higher price. While the cost of reactors may vary, the study from US Department of Energy assumes approximately in cost of $100/ \( {m^{2}} \) , shown in Table 1, the bioreactor culminates in the most efficient hydrogen production [13].

Table 1. Retail Cost of Transparent & Translucent Materials [13]

Materials | Cost ($/ \( {m^{2}} \) ) |

Glass | $51.61 |

Plexiglas | $15.47 |

Clear PVC | $5.56 |

Blue Tarp | $0.46 |

4 mil polyethylene | $0.19 |

1 mil polyethylene | $0.05 |

Table 2 shows the total capital costs in the process of algal hydrogen production. It requires a minimum of 3.07 million dollars for equipment and 5.16 million dollars for total capital investment. Therefore, in the short term, it is true that hydrogen production is not very cost-efficient, compared to the practicality of the product.

Table 2. Algal Hydrogen Production Capital Costs [13]

Algae Ponds | $1,100,000 |

PSA Compressor | $359,000 |

PSA Unit | $121,000 |

Storage Compressor | $578,000 |

High-Pressure Storage | $913,000 |

Total Equipment Cost | $3,071,000 |

Engineering & Construction | $1,423,000 |

Contractor Fees & Contingency | $674,000 |

Total Capital Investment | $5,168,000 |

4.2. Long-term Economics

In contrast, over the long term, the economic landscape of biohydrogen technology shows high potential. As the technology matures and scales up, economies of scale can lead to reductions in production costs per unit of hydrogen. The growth of biohydrogen technology can contribute to job creation in research, development, manufacturing, and operations, resulting in local economic growth and diversification.

Competition with other energy sources, both fossil fuels and alternative renewable energies, becomes increasingly relevant in the long term. As economies transition towards cleaner energy, the attractiveness of biohydrogen can grow due to its environmental benefits. The positive impact on the environment, including reduced greenhouse gas emissions and improved air quality, can lead to long-term economic benefits by mitigating climate change and lowering health-related expenses.

The global energy landscape and market dynamics also significantly influence long-term economic effects. As renewable energy becomes more mainstream, the demand for hydrogen as an energy carrier can rise, positively impacting the economic viability of biohydrogen technology.

Continued research and development efforts can result in significant cost reductions over the long term. Efficiency improvements, genetic engineering breakthroughs, and optimized bioreactor designs contribute to lowering production costs.

5. Environmental Viability

Despite its imperfect efficiency, Biohydrogen continues to be uplifted due to establishments of major environmental advantages. On account of fossil fuels’ high carbon dioxide emission, experts sought for an innovative environmentally-friendly energy, and hydrogen has risen up as a leading alternative since. Hydrogen is considered as a potential energy source due to its clean energy source and high energy density [14]. It also has a high level of versatility, which increases its application to a variety of technical fields.

Even though hydrogen possesses significant benefits, it was highly criticized by its production. For example, the conventional method of hydrogen production, the steam methane reforming (SMR), is considered to be not environmental because of its immense carbon dioxide emission. The Hydrogen Newsletter states that SMR produces about 8 to 10 kilograms of carbon dioxide per 1 kilogram of hydrogen, which is highly pollutive [15]. These studies started to question the true “greenness” of hydrogen, which seemed to dissociate hydrogen from renewable energy.

However, hydrogen has returned to the debate after the discovery of its environmental production, biohydrogen. Biohydrogen production procedure uses the fermentation or photosynthesis abilities of specific microorganisms, such as specific types of bacteria or algae, to transform organic resources like biomass, agricultural waste, wastewater, or these materials into hydrogen gas. When using renewable feedstocks, biohydrogen production is carbon-neutral since it doesn't release carbon dioxide during hydrogen generation, in contrast to conventional hydrogen production methods that may require carbon-intensive procedures. It also has the potential to be quite effective, as some microbes are capable of turning a sizable amount of the energy content of the organic material into hydrogen. This strategy not only results in a clean-burning fuel but also aids in resource recovery and waste remediation.

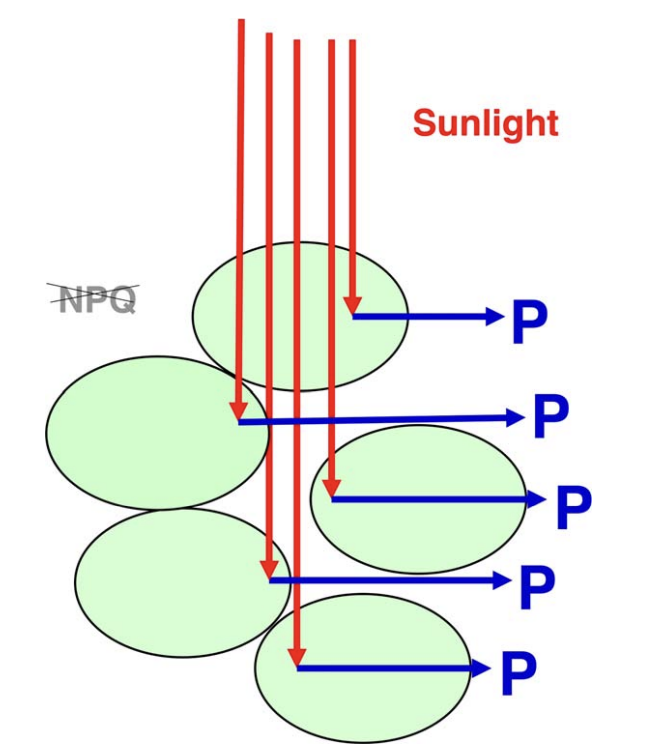

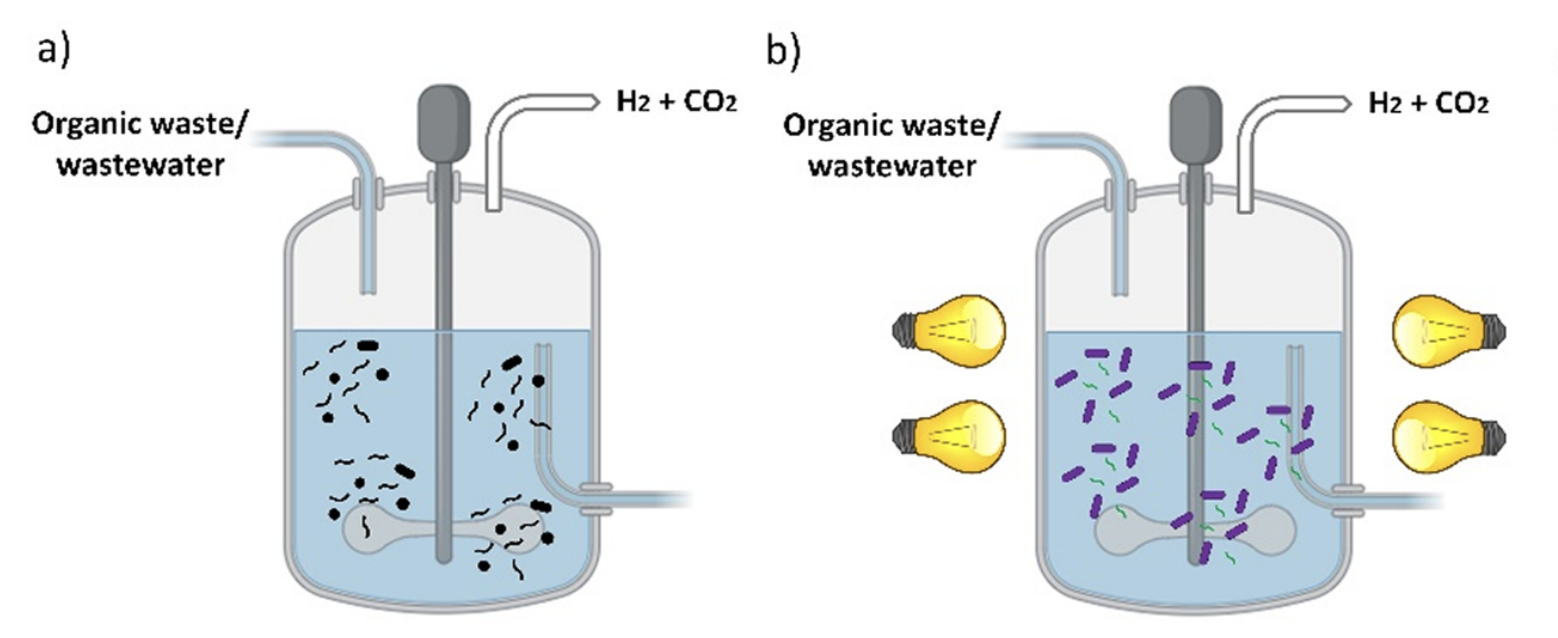

Moreover, Hailin Tian and his colleagues have claimed another innovative practice: producing biohydrogen from organic wastes. This process also goes through biological fermentation; however, they require an additional step of decomposers that could break down the organic wastes into main byproducts needed in the process (reference Section 2). There are various types of fermentation process, but mainly it is classified as two: dark fermentation and photo fermentation. Dark fermentation takes place in a dark and anaerobic environment, and hydrogen is produced by the reduction of protons. Photo fermentation has access to sunlight and produces hydrogen by photosynthetic reaction. Both are proven to be efficient production, and they are capable of facilitating with organic wastes, which shows the high potential of hydrogen energy [16].

Figure 4. Diagram of types of biological fermentation: (a) dark fermentation and (b) photo fermentation [16]

6. Challenges and Prospects

6.1. Challenges

Biohydrogen production holds promise as a clean and sustainable energy source, but it faces several technical challenges. First, it can be difficult to use microorganisms to produce hydrogen at large yields and rates. The sensitivity of many bacteria that produce hydrogen to environmental factors, including pH, temperature, and substrate concentration might hinder their productivity [16]. Researchers are actively working on optimizing these conditions to maximize biohydrogen production.

Second, the economics of biohydrogen production are a major hurdle. The production cost of biohydrogen is often higher than that of hydrogen produced from fossil fuels. This is due to factors such as the relatively low conversion efficiencies of biological processes and the cost of feedstock materials. A study in "Renewable and Sustainable Energy Reviews" in 2020 highlighted the need for cost-effective feedstock solutions and efficient bioprocessing techniques to make biohydrogen economically competitive [17]. Additionally, scaling up biohydrogen production to meet commercial demands presents engineering and logistical challenges that must be addressed to make it a viable option in the energy market.

6.2. Prospects

Despite the challenges, biohydrogen has several prospects that make it an attractive option for a sustainable energy future. Firstly, its environmental benefits are undeniable. Biohydrogen production is a carbon-neutral process when using renewable feedstocks, which can significantly reduce greenhouse gas emissions compared to fossil fuel-derived hydrogen. This also aligns with global efforts to mitigate climate change.

Secondly, ongoing advancements in biotechnology, including genetic engineering and synthetic biology, offer the potential to enhance the efficiency and productivity of hydrogen-producing microorganisms. Researchers are exploring genetic modifications to improve the robustness and performance of these organisms and engineered microorganisms are exhibiting increased hydrogen production capabilities.

In conclusion, while biohydrogen production faces technical and economic challenges, its prospects are promising. The ongoing research into optimizing microbial processes, reducing production costs, and increasing scalability, coupled with its environmental benefits, position biohydrogen as a valuable component of the transition to a more sustainable and clean energy future.

7. Conclusion

In conclusion, the exploration of algae-based hydrogen energy presented in this paper underscores the significant potential of biohydrogen as a sustainable and environmentally friendly energy source. The urgent need to address climate change and reduce carbon emissions has stimulated the search for alternative energy solutions, and biohydrogen offers a promising pathway forward.

The paper has delved into various aspects of biohydrogen production, from the biological mechanisms of photosynthesis and biophotolysis to the technical developments in bioreactor design and engineering. It has highlighted both the challenges and prospects of this technology, recognizing that while there are obstacles to overcome, there are also remarkable opportunities for advancement.

The analysis of economics shows that in the short-term, biohydrogen production may face initial hurdles due to upfront costs. Nevertheless, the long-term outlook is positive, with potential for cost reductions, job creation, and positive environmental impacts. Furthermore, the environmental viability of biohydrogen cannot be overstated. Its carbon-neutral production process, when utilizing environmental feedstocks, contributes to greenhouse gas reduction and aligns with global efforts to combat climate change.

In conclusion, the future of biohydrogen appears promising, despite obstacles to economic viability and technology optimization. Biohydrogen is expected to play a big role in the switch to a more sustainable and clean energy future because of ongoing research and development activities and developments in biotechnology. Algae-based hydrogen energy is a gleam of hope and an ode to human ingenuity in the search for a greener tomorrow as the world struggles with a more serious environmental crisis.

References

[1]. Epstein, P. R., J. J. Buonocore, K. Eckerle, M. Hendryx, B. M. Stout III, R. Heinberg, R. W. Clapp, B. May, N. L. Reinhart, M. M. Ahern, S. K. Doshi, and L. Glustrom. 2011. Full cost accounting for the life cycle of coal in “Ecological Economics Reviews.” Ann. N.Y. Acad. Sci. 1219: 73–98.

[2]. Cho, H. H., Strezov, V., & Evans, T. J. (2022, October 20). Environmental impact assessment of hydrogen production via steam methane reforming based on emissions data. Energy Reports. https://doi.org/10.1016/j.egyr.2022.10.053

[3]. Putatunda, C., Behl, M., Sharma, S., & Solanki, P. (2022, October 27). Current challenges and future technology in photofermentation-driven biohydrogen production by utilizing algae and bacteria. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2022.10.042

[4]. Ahmed, S. F., Rafa, N., Mofijur, M., Badruddin, I. A., Inayat, A., Ali, M. S., Farrok, O., & Yunus Khan, T. M. (2021, August 27). Biohydrogen production from biomass sources: Metabolic pathways and Economic Analysis. Frontiers. https://doi.org/10.3389/fenrg.2021.753878

[5]. Show, K.-Y., Yan, Y., Ling, M., Ye, G., Li, T., & Lee, D.-J. (2018). Hydrogen production from algal biomass – advances, challenges and prospects. Bioresource Technology, 257, 290–300. https://doi.org/10.1016/j.biortech.2018.02.105

[6]. Kumar Gupta, S., Kumari, S., Reddy, K., & Bux, F. (2013). Trends in biohydrogen production: Major challenges and state-of-the-art developments. Environmental Technology, 34(13–14), 1653–1670. https://doi.org/10.1080/09593330.2013.822022

[7]. Melis, A. (2009). Solar energy conversion efficiencies in photosynthesis: Minimizing the chlorophyll antennae to maximize efficiency. Plant Science, 177(4), 272–280. https://doi.org/10.1016/j.plantsci.2009.06.005

[8]. Janssen, M., Tramper, J., Mur, L. R., & Wijffels, R. H. (2002). Enclosed outdoor photobioreactors: Light regime, photosynthetic efficiency, scale-up, and future prospects. Biotechnology and Bioengineering, 81(2), 193–210. https://doi.org/10.1002/bit.10468

[9]. Wondraczek, L., Batentschuk, M., Schmidt, M. A., Borchardt, R., Scheiner, S., Seemann, B., Schweizer, P., & Brabec, C. J. (2013). Solar spectral conversion for improving the photosynthetic activity in algae reactors. Nature Communications, 4(1). https://doi.org/10.1038/ncomms3047

[10]. Wasanasathian, A., & Peng, C.-A. (2022). Photobioreactor. Photobioreactor - an overview | ScienceDirect Topics. https://www.sciencedirect.com/topics/immunology-and-microbiology/photobioreactor

[11]. Pratt, S. (2010). Understanding Temperature Control in Bioreactor Systems. Thermo Fisher Scientific. https://assets.thermofisher.com/TFS-Assets/LED/Application-Notes/D00154~.pdf

[12]. Parlevliet, D., & Moheimani, N. (2014). Efficient conversion of solar energy to biomass and electricity. Aquatic Biosystems, 10(1), 4. https://doi.org/10.1186/2046-9063-10-4

[13]. Amos, W. A. (2003). Updated Cost Analysis of Photobiological Hydrogen Production From Chlamydomonas Reinhardtii Green Algae. Milestone Report for the U.S. Department of Energy’s HCFIT Program Analysis Task. https://doi.org/http://www.osti.gov/bridge

[14]. U.S. Department of Energy. (n.d.). Hydrogen benefits and considerations. Alternative Fuels Data Center: Hydrogen Benefits and Considerations. https://afdc.energy.gov/fuels/hydrogen_benefits.html

[15]. Editor. (2023, January 17). Gh2 facts: CO2 emissions per kg of hydrogen depending on the method of production. Hydrogen Newsletter. https://www.hydrogennewsletter.com/gh2-facts/#:~:text=Steam%20Methane%20Reforming%20(SMR)%20is,per%20kg%20of%20hydrogen%20produced.

[16]. Tian, H., Li, J., Yan, M., Tong, Y. W., Wang, C.-H., & Wang, X. (2019). Organic waste to biohydrogen: A critical review from Technological Development and Environmental Impact Analysis Perspective. Applied Energy, 256, 113961. https://doi.org/10.1016/j.apenergy.2019.113961

[17]. Sebestyén, V. (2021). Renewable and Sustainable Energy Reviews: Environmental Impact Networks of Renewable Energy Power Plants. Renewable and Sustainable Energy Reviews, 151, 111626. https://doi.org/10.1016/j.rser.2021.111626

Cite this article

Park,S. (2024). Techno-economic and environmental viability assessments of algae-based hydrogen energy. Applied and Computational Engineering,84,46-54.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Epstein, P. R., J. J. Buonocore, K. Eckerle, M. Hendryx, B. M. Stout III, R. Heinberg, R. W. Clapp, B. May, N. L. Reinhart, M. M. Ahern, S. K. Doshi, and L. Glustrom. 2011. Full cost accounting for the life cycle of coal in “Ecological Economics Reviews.” Ann. N.Y. Acad. Sci. 1219: 73–98.

[2]. Cho, H. H., Strezov, V., & Evans, T. J. (2022, October 20). Environmental impact assessment of hydrogen production via steam methane reforming based on emissions data. Energy Reports. https://doi.org/10.1016/j.egyr.2022.10.053

[3]. Putatunda, C., Behl, M., Sharma, S., & Solanki, P. (2022, October 27). Current challenges and future technology in photofermentation-driven biohydrogen production by utilizing algae and bacteria. International Journal of Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2022.10.042

[4]. Ahmed, S. F., Rafa, N., Mofijur, M., Badruddin, I. A., Inayat, A., Ali, M. S., Farrok, O., & Yunus Khan, T. M. (2021, August 27). Biohydrogen production from biomass sources: Metabolic pathways and Economic Analysis. Frontiers. https://doi.org/10.3389/fenrg.2021.753878

[5]. Show, K.-Y., Yan, Y., Ling, M., Ye, G., Li, T., & Lee, D.-J. (2018). Hydrogen production from algal biomass – advances, challenges and prospects. Bioresource Technology, 257, 290–300. https://doi.org/10.1016/j.biortech.2018.02.105

[6]. Kumar Gupta, S., Kumari, S., Reddy, K., & Bux, F. (2013). Trends in biohydrogen production: Major challenges and state-of-the-art developments. Environmental Technology, 34(13–14), 1653–1670. https://doi.org/10.1080/09593330.2013.822022

[7]. Melis, A. (2009). Solar energy conversion efficiencies in photosynthesis: Minimizing the chlorophyll antennae to maximize efficiency. Plant Science, 177(4), 272–280. https://doi.org/10.1016/j.plantsci.2009.06.005

[8]. Janssen, M., Tramper, J., Mur, L. R., & Wijffels, R. H. (2002). Enclosed outdoor photobioreactors: Light regime, photosynthetic efficiency, scale-up, and future prospects. Biotechnology and Bioengineering, 81(2), 193–210. https://doi.org/10.1002/bit.10468

[9]. Wondraczek, L., Batentschuk, M., Schmidt, M. A., Borchardt, R., Scheiner, S., Seemann, B., Schweizer, P., & Brabec, C. J. (2013). Solar spectral conversion for improving the photosynthetic activity in algae reactors. Nature Communications, 4(1). https://doi.org/10.1038/ncomms3047

[10]. Wasanasathian, A., & Peng, C.-A. (2022). Photobioreactor. Photobioreactor - an overview | ScienceDirect Topics. https://www.sciencedirect.com/topics/immunology-and-microbiology/photobioreactor

[11]. Pratt, S. (2010). Understanding Temperature Control in Bioreactor Systems. Thermo Fisher Scientific. https://assets.thermofisher.com/TFS-Assets/LED/Application-Notes/D00154~.pdf

[12]. Parlevliet, D., & Moheimani, N. (2014). Efficient conversion of solar energy to biomass and electricity. Aquatic Biosystems, 10(1), 4. https://doi.org/10.1186/2046-9063-10-4

[13]. Amos, W. A. (2003). Updated Cost Analysis of Photobiological Hydrogen Production From Chlamydomonas Reinhardtii Green Algae. Milestone Report for the U.S. Department of Energy’s HCFIT Program Analysis Task. https://doi.org/http://www.osti.gov/bridge

[14]. U.S. Department of Energy. (n.d.). Hydrogen benefits and considerations. Alternative Fuels Data Center: Hydrogen Benefits and Considerations. https://afdc.energy.gov/fuels/hydrogen_benefits.html

[15]. Editor. (2023, January 17). Gh2 facts: CO2 emissions per kg of hydrogen depending on the method of production. Hydrogen Newsletter. https://www.hydrogennewsletter.com/gh2-facts/#:~:text=Steam%20Methane%20Reforming%20(SMR)%20is,per%20kg%20of%20hydrogen%20produced.

[16]. Tian, H., Li, J., Yan, M., Tong, Y. W., Wang, C.-H., & Wang, X. (2019). Organic waste to biohydrogen: A critical review from Technological Development and Environmental Impact Analysis Perspective. Applied Energy, 256, 113961. https://doi.org/10.1016/j.apenergy.2019.113961

[17]. Sebestyén, V. (2021). Renewable and Sustainable Energy Reviews: Environmental Impact Networks of Renewable Energy Power Plants. Renewable and Sustainable Energy Reviews, 151, 111626. https://doi.org/10.1016/j.rser.2021.111626