1. Introduction

Conventional sensors are generally composed of solid elements such as semiconductors, dielectrics, magnetic materials, and others. This type of sensor does not have good flexibility and stretchability. Flexible sensors overcome the disadvantage of rigidity found in conventional sensors and can be affixed to human skin or tissues. Additionally, they can simulate the tactile sensing capabilities of human skin to detect numerous stimuli [1]. These characteristics make sensors possible to directly and continuously monitor the human body's physiological signals including body temperature, heart rate, breathing, etc., and the surrounding environmental factors such as temperature and humidity, and to respond in time by outputting the corresponding visualization signals. Sensors are widely used in the fields of health monitoring, motion surveillance, biomedicine, interactive robots, environmental monitoring, and aerospace [2-4].

The acoustic, optical, electrical, and thermal properties of nanomaterials take on new characteristics. Nanomaterials tend to have excellent specific surface area. This property allows for efficient detection of the target analyte. This feature renders the sensor highly responsive to external environmental changes, with the sensitivity of the sensor fully maximized. Thus, nanomaterials have many significant advantages in the field of flexible wearable sensors [5].

Carbon is ubiquitous in nature and closely linked to the human experience, being one of the most prevalent elements. Due to the various electron orbitals, carbon materials have a wide range of properties and can be formed into substances with completely different structures and properties. New carbon nanomaterials have emerged during the past three decades, beginning with the zero-dimensional fullerenes found in 1895 and progressing to one-dimensional carbon nanotubes and two-dimensional graphene. Delocalized π-bonds bring high strength and modulus to carbon nanomaterials, and sp2 hybridization also brings good electrical conductivity. Carbon nanomaterials offer distinctive benefits with regard to their diversity in structure, thermal stability, and flexibility. Various studies on the structure of carbon nanomaterials have emerged in recent years, making carbon nanomaterials an important electronic component in wearable sensing devices. At present, with the rapid development of nanotechnology, carbon nanotubes, graphene, and other carbon nanomaterials are widely used in the field of flexible wearable sensors due to their excellent physicochemical properties. It is also possible to use composites created from a variety of nanomaterials to improve the performance of the sensors.

This paper introduces the structure and properties of different carbon nanomaterials and their preparation methods, summarizes the related research on carbon nanotubes, graphene, and MXene as sensing materials for the preparation of sensors, and discusses the current problems of carbon nanomaterials in the field of flexible wearable sensors as well as the future development trend.

2. Carbon nanomaterials

Carbon materials have a wide variety of properties. Common carbon-based nanomaterials in use today include carbon nanotubes, graphene, and MXene.

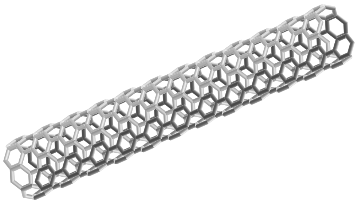

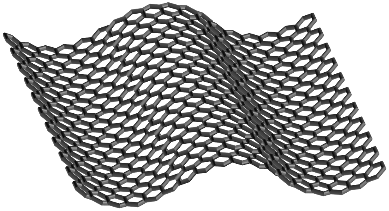

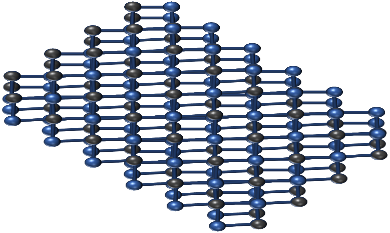

(a) (b) (c)

Figure 1. Schematic structure of (a) carbon nanotubes, (b) graphene, (c) MXene

2.1. Carbon nanotubes

The size of carbon nanotubes in the radial direction is only on the order of nanometers, but in the axial direction the size can be on the order of tens of centimeters, so carbon nanotubes are typical one-dimensional nanomaterials (Figure 1). Hexagonal carbon rings are formed between carbon atoms, connecting them into honeycomb-shaped one-dimensional nanohollow tubes, which are arranged in a spiral around the concentric tubes. Depending on the number of layers of curled graphite sheets, they can be categorized into single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs).

Carbon nanotubes possess light-transmissive and flexible properties due to their flawless hexagonal structure, resulting in robust stability, and superior mechanical and electrical properties. Carbon nanotubes have ultra-high tensile strength and can be stretched continuously many times without fracture, and their fatigue limit is better than that of current engineering materials [6]. Carbon nanotubes possess a notable capacity for current-carrying, as every layer of their walls can be utilized to conduct current, while their substantial surface area allows for high conductivity. This quality enables carbon nanotubes to carry more current. The properties of carbon nanotubes can be modulated by creating defects on their surface, which usually contain a large number of various defects due to the limitations of the carbon nanotube manufacturing process.

Carbon nanotubes can be synthesized using different methods such as the electric arc discharge method (EAD), laser ablation method, and chemical vapor deposition (CVD). EAD is the most used approach and was the first technique utilized to create carbon nanotubes. At a certain pressure, in a vacuum vessel filled with inert gas, graphite is used as the anode, and carbon nanotubes are deposited on the cathode of the electrode during the arc discharge. Laser ablation involves the use of a laser beam in a heated vessel to irradiate a graphite target, evaporating it to produce gaseous carbon, which is deposited as carbon nanotubes in the presence of a catalyst. CVD is a flow of hydrocarbons (benzene, methane, etc.) that are catalyzed and decomposed at high temperatures to form carbon nanotubes.

2.2. Graphene

Graphene is connected by sp2 hybridized covalent bonds, forming a honeycomb-like lamellar structure between carbon atoms, which is tightly stacked into a stable ortho-hexagonal crystal structure (Figure 1). Graphene is believed to be a constituent of the graphite crystal structure.

Graphene is the lightest mass and thinnest two-dimensional planar material ever discovered with exceptional mechanical and electrical properties. Graphene is so strong and stable that it is difficult to be damaged by external influences, and is theoretically 100 times stronger than steel, with a modulus of 1.0 TPa. It responds to environmental stimuli like light, gas, and temperature and is incredibly translucent and sensitive to changes in the environment. At room temperature, graphene is the best conducting material because to its extremely high electron mobility, low resistance, and energy efficiency. Nanographene is highly malleable and can form various microstructures, and its own stacking mechanism and quantum nano-tunneling effect also make it ultra-highly sensitive. Graphene's unique properties make it a strong candidate for flexible electronics [7].

Redox techniques and mechanical exfoliation can be used to create graphene. Mechanical exfoliation is a method of exfoliating single or few layers of graphene from graphite as raw material by the action of mechanical or certain chemical reagents. The redox method describes how graphite reacts with potent acids and potent oxidizers to produce graphite oxide, which is then separated using ultrasound and reduced with a reducing agent to eliminate any leftover oxygen-containing functional groups to produce reduced graphene oxide (rGO).

2.3. MXene

MXene is a broad category of two-dimensional carbon-nitrides, nitrides, and carbides of transition metals. With the rapid development of MXene, it has evolved from a single transition metal system to dual transition metals and even multiple transition metals (Figure 1). MXene materials are obtained by etching MAX-phase materials, which is a collective term for a class of ternary layered compounds. MAX phase crystals are lamellar hexagonal. The layers of M and A atoms are arranged alternately, with the X atom occupying the center position, and when the A atom is etched, the remaining M and X atomic layers form a two-dimensional Mn+1Xn atomic crystal.

MXene stands out among many two-dimensional materials due to its excellent mechanical properties, strong electrical conductivity, high specific surface area, and excellent hydrophilicity. The Young's modulus of MXene is lower than that of graphene, but the flexural stiffness is higher than that of graphene, which is 3-130 times higher than that of graphene, and the flexibility of MXene decreases with the increase of layer thickness. MXene, as a polyatomic composition material, each part has an effect on the electrical conductivity, while MXene defects also cause changes in the electrical conductivity. The presence of functional groups on the surface brings MXene a tunable structure and a wealth of surface physicochemical properties.

MXene can be made by etching MAX phase materials, mainly by hydrofluoric acid etching and electrochemical etching. The MAX phase material was etched using hydrofluoric acid, and the etched multilayer accordion structure of MXene. The electrochemical etching method for the preparation of MXene utilizes the MAX phase as an electrode to produce an etching effect at the anode. The etched multilayer was again stripped using an intercalator under an applied voltage to obtain a single layer of MXene nanosheets.

3. Flexible sensors

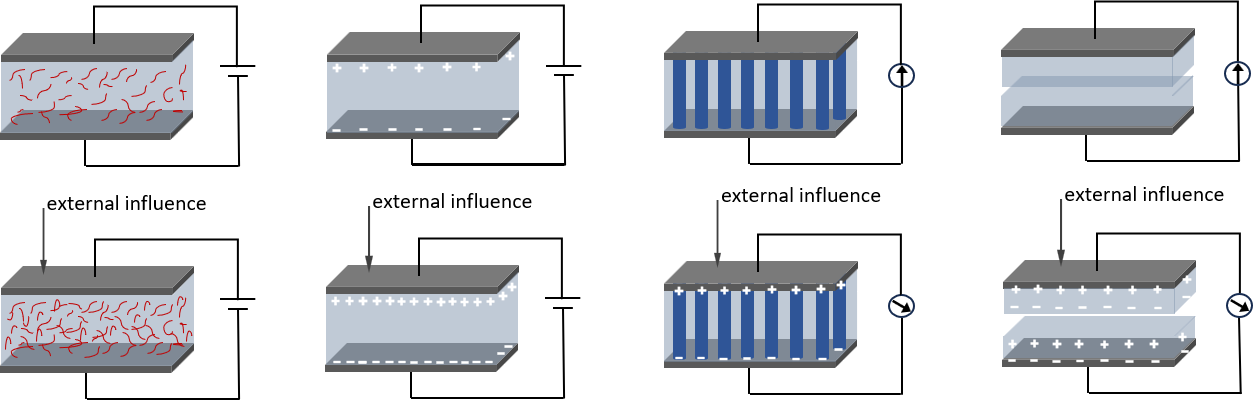

Flexible sensors are objects or ornaments that sense a measurement and transform it into an output signal that can be used in accordance with a predetermined pattern. The form of flexible sensors is flexible and various, and they have good flexibility and ductility. They can even be easily twisted or folded. According to the sensing mechanism, flexible sensors can be categorized into flexible piezoresistive sensors, flexible capacitive sensors, flexible piezoelectric sensors, friction electric sensors and so on (Figure 2).

(a) (b) (c) (d)

Figure 2. Sensing mechanisms of (a) piezoresistive sensors, (b) capacitive sensors, (c) piezoelectric sensors, (d) friction electric sensors

Flexible piezoresistive sensors deform the active material when detecting actuation, indirectly changing the distribution and contact state of the internal conductive material, causing the conductive substance in the sensor's resistance to change. A common configuration involves coupling two rough conductive surfaces together, allowing for a variable number of electrical contacts and thus an effective increase or decrease in resistivity between the electrodes [8]. Flexible capacitive sensors comprise two parallel conductive electrodes and a compliant dielectric layer sandwiched between them. The sensors function through electrostatic capacitance, which results in the accumulation or release of charge and a change in capacitance. However, the sensor's sensitivity is constrained by the fact that the alteration in the dielectric layer is typically restricted [9]. The piezoelectric material of the flexible piezoelectric sensor is subjected to a fixed direction of the external action, the internal electrode will produce the phenomenon of polarization, at the same time in the two surfaces of the opposite sign of the charge; when the action is withdrawn, and then return to the uncharged state. When two different materials come into contact through applied force, the frictional charge is produced over the surface due to electrification of the contact. Friction electric sensors based on contact electricity and electrostatic induction can push forward the development of self-actuated sensors that do not require an external energy supply by converting a mechanical stimulus into an electrical signal output [10].

Flexible sensors can be categorized into flexible pressure sensors, flexible gas sensors, and flexible temperature sensors according to their applications. The application of carbon nanomaterials in flexible sensors, which are more mature and widely used, is now introduced [11].

3.1. Flexible pressure sensors

Flexible pressure sensors that detect changes in electrical impulses brought on by stress can assess deformation or pressure stimuli. Pressure sensors are mainly categorized into piezoresistive pressure sensors and capacitive pressure sensors. The microstructure of the sensor has a strong influence on its mechanical properties since it is the nature of the sensor structure that is mainly changed by the measurement. It has enormous potential as a tool for tracking physiological signals like pulse, heart rate, and respiration rate as well as human movement like joint and muscle action. Carbon nanomaterials can be used for flexible pressure sensors as the resistance of the carbon nanomaterials allows on-off action in response to changes in external force.

Introducing wrinkling in films made of carbon nanotube enhances its elasticity and sensitivity. When two crumpled electrodes are connected, the resistivity changes due to altered electrical contact points upon activation. Park et al [12]. used a spray gun deposition method to deposit carbon nanotube films onto polystyrene (PS) substrates, and when PS was externally stimulated, PS contracted back to its original shape, resulting in the carbon nanotube films bending and forming highly self-similar folded structures. Not only did pleats relieve strain, they also increased pressure sensitivity by a factor of 12,800 with a response time of less than 20 milliseconds. The increased sensitivity was due to the surface roughness of the pleat.

Not only is it possible to enhance the efficacy of pressure sensors by implementing folds, but producing porous structures can also greatly improve their performance. 3D porous structures exhibit exceptional pressure sensing capabilities. Flexible sensors with graphene as the conductive material are the most widely studied pressure sensors. By compressing honeycomb rGO foams and mechanically compressing them into polydimethylsiloxane through unidirectional freeze-drying, Zheng et al. created nanocomposite strain sensors. The sensing sensitivity of nanocomposite sensors was greatly increased by compressing aligned rGO foams into thinner films since this increased the number of conducting routes. The sensor demonstrated remarkable stretchability of over 120%, a broad linear sensing range from 0-110%, and a high sensitivity for strain sensing of around 7.2 in the transverse direction [13].

The most direct way to construct sensors with higher flexibility is to load MXene onto flexible substrates by spinning, dip-coating, and deposition to improve the overall performance of the sensors by taking advantage of the good ductility and low hardness of flexible substrates. The technique of sandwiching biodegradable polylactic acid (PLA) flakes and finger electrode-coated PLA flakes between porous MXene-impregnated paper and PLA flakes was used to create a highly sensitive, flexible, and biodegradable pressure sensor [14]. This pressure sensor has a quick reaction time of 11 ms, excellent degradability, and outstanding reproducibility over 10,000 cycles.

3.2. Flexible gas sensors

Gas sensors can be used to detect the presence or absence of specific gases and measure the concentration of gas components within a certain environmental area, and convert information about the gas type and its concentration into an electrical signal. Resistive and capacitive gas sensors are the two basic varieties. Because of their flexible substrate, flexible gas sensors are light, flexible, and bendable, among other qualities. and have great potential for development in the fields of health monitoring, humidity detection, and environmental detection. According to the sensitivity of the resistance of carbon nanomaterials to the nature and concentration of various chemical gases, various gas-sensitive detectors can be made to classify, or quantitatively detect and monitor various gases and their mixtures.

The ability of certain metal oxides to sensitize gases can be significantly enhanced by carbon nanotubes. Aleksanyan et al. deposited MWCNT:SnO2 films on flexible polyimide substrates using electron beam deposition [15]. The material exhibited reliable tensile properties, and its sensor response remains consistent even after multiple bends. Additionally, it displayed favorable gas-sensitive properties, with an excellent linear response to hydrogen at concentrations ranging from 25 to 3000 ppm.

In gas sensing, graphene has an exceptional advantage. After the defect density is regulated, the target gas may be efficiently adsorbed by the graphene flaws, which considerably speeds up the reaction time of graphene sensors. By adjusting the density and size of the defects in graphene using ion irradiation and H2 etching to increase the response performance, a faulty graphene-based gas sensor that generates more efficient adsorption sites was created [16]. This gas sensor performed 13 times better than the original graphene-based gas sensor, with a response of up to 248% at 100 ppm NO2.

MXene is often considered a flexible gas sensor, and the composite materials of MXene enhance the interlayer spacing and specific surface area, which increases the number of gas adsorption active sites and improves gas sensitivity performance [17]. The in situ precipitation technique may be used to successfully produce formaldehyde (HCHO) sensing materials based on MXene/NiO composites. MXene/NiO chemoresistive sensors benefit from the good characteristics of MXene and the heterogeneous structure generated between MXene and NiO, resulting in ultra-high sensing characteristics for HCHO. In comparison to pure MXene and NiO, the MXene/NiO-P2 sensor has a response of 8.8 for 50 ppm HCHO gas.

3.3. Flexible temperature sensors

A temperature sensor is a sensor that detects temperature and transforms the data into an output signal that may be used. Most flexible temperature sensors operate on the basis of a change in resistance, usually utilizing the positive temperature effect of the conductive filler. When the temperature rises near the melting point, the resistance increases rapidly by several orders of magnitude, and when the temperature drops back to room temperature, the resistance returns to its initial value. It can be applied in circuits to automatically adjust the output power for temperature visualization. Flexible temperature sensors have great application prospects in plant physiological monitoring and body temperature monitoring.

Excellent carrier mobility is exhibited by molybdenum disulfide (MoS2) and carbon nanotubes. The thermal stability of produced nanocomposites is greatly increased by the two-dimensional, layered MoS2 nanomaterial. Highly sensitive resistive temperature sensors based on MWCNT@MoS2 nanocomposite films were made by ultrasonically processing generated MoS2 nanoparticles and MWCNTs mixed in N-methylpyridine solution [18]. The MWCNT@MoS2 composite sensor exhibits a TCR of 0.62%/K and a hysteresis loss of 0.57% when tested in the high temperature range of 298-373 K. In the 298–173 K temperature range, the TCR multiplied to 2.07%/K while the hysteresis loss was 0.39%.

Graphene has excellent resistive temperature characteristics with ultra-high thermal conductivity, which basically returns to the initial resistance at room temperature after being stimulated by a step temperature. Utilizing a single-step solvent evaporation process, Chen et al. introduced a novel flexible sandwich-structured polydimethylsiloxane (PDMS)@graphene sensor that measures temperatures ranging from -40 to 300 degrees Celsius, and its maximum thermal index is 12015.86 K with a monitoring resolution of 0.5 °C [19]. It outperforms most flexible multimodal temperature sensors that have been extensively studied for the relatively limited monitored temperatures range from 0 to 100 °C.

MXene's electrical conductivity remains constant, while its thermal conductivity enhances as the temperature increases. Wan et al. introduced a temperature-sensitive material that is a hybrid of Ti3C2Tx (MXene) and zinc-octaethylporphyrin (ZnOEP) [20]. The MXene flakes are wrapped in a scaffolding structure made of the self-assembling ZnOEP fiber network, giving the substrate a leaf-like shape. The high temperature coefficient of the MXene and the low modulus of the ZnOEP network enable the flexible temperature sensor to achieve a sensitivity of 2.34%°C-1 and a low hysteresis rate of 3.58%.

4. Conclusion

This paper summarizes the unique electronic structure and properties of carbon nanomaterials, including carbon nanotubes, graphene, and MXene, and analyzes the response mechanism of the sensors and the research on the applications of carbon nanomaterials-based flexible sensors commonly used today.

Carbon nanomaterials are an important driver of scientific and technological development, with the dual advantages of high-end applications and composite applications, and can be applied to a variety of different situations. However, their surface energy is large, easy to be affected by the dispersion, and often used in the state of agglomeration, thus limiting the maximization of performance. Moreover, the preparation of carbon nanomaterials is complicated, and the production efficiency of material preparation is low. It is especially important to realize the rapid, quantitative, and correct characterization of carbon nanomaterial dispersions, which can be achieved by using the existing experimental conditions. At the same time, it is crucial to investigate how carbon nanoparticles and surfactants work in order to point the way toward the creation of effective surfactants.

Flexible wearable sensors are expected to help solve key challenges faced by humans, and they have a wide range of prospects for development. Challenges to the stability of flexible sensors usually stem from the materials used in their fabrication, and the current level of material preparation technology and processes for carbon nanomaterials used in flexible sensors is immature, with a lack of consistency in production and standardized material specifications difficult to achieve. The physicochemical properties of the material itself, as well as properties that change over time or in the environment, can easily affect the performance of flexible sensors. The most straightforward method is to increase the environmental stability of the sensor materials, which can be enhanced by employing inherently waterproof materials or by applying a protective layer to the sensitive material and the entire device. Flexible wearable sensors imply direct contact with the surface of the skin, and the most important consideration for such materials is biocompatibility. A specific biocompatibility issue is the immune response, which varies from person to person, depends on the position and time of contact between the device and tissue, and can be tested for toxicity or sensitization. In addition, flexible sensors face problems such as impermeability to moisture and air permeability, which affects wearable comfort. This can be solved by installing a waterproof and breathable membrane for the sensor device to continuously breathe to preserve the housing's internal and external pressure balance.

References

[1]. Han S, Kim J, Won S M, et al. 2018 Science translational medicine. 10 eaan4950

[2]. Bae C W, Toi P T, Kim B Y, et al. 2019 ACS Appl. Mater. Interfaces. 11 14567-14575

[3]. Kim J, de Araujo W R, Samek I A, et al. 2015 Electrochemistry Communications. 51, 41-45

[4]. Wang H Y, Wang W Q, Kim J J, et al. 2023 Sci. Adv. 9 eadi2445

[5]. Wang L, Zhang X H, Xiong H Y, et al. 2011 Biosensors & Bioelectronics. 26, 3, 991-995.

[6]. Bai Y, Yue H, Wang J, et al. 2020 Science. 369, 6507, 1104-1106

[7]. Liu N, Chortos A, Lei T, et al. 2017 Sci. Adv. 3, 9, e1700159

[8]. Hao D P, Yang R X, Yi N, et al. 2021 Science China Technological Sciences. 64 2408-2414.

[9]. Cai L, Song L, Luan P, et al. 2013 Scientific Reports. 3, 3048

[10]. Wang Y, Jin X, Jin Z, et al. 2023 Computers and Electronics in Agriculture. 210 107909.

[11]. Ge X, Gao Z, Zhang L, et al. 2023 Nano Energy. 113 108541

[12]. Park S, Kim J, Chu M, et al. 2017 Advanced Materials Technologies. 3, 1, 1-8

[13]. Zeng Z, Shahabadi S I S, Che B, et al. 2017 Nanoscale. 9, 17396–17404

[14]. Guo Y, Zhong M, Fang Z, et al. 2019 Nano Lett. 19 1143-1150.

[15]. Aleksanyan M S, Sayunts A G, Shahkhatuni G H, et al. 2022 Adv. Nat. Sci: Nanosci. Nanotechnol. 13 035003

[16]. Ma J, et al. 2019 AIP Advances. 9 075207

[17]. Huang B, Tong X, Zhang X, et al. 2023 Chemosensors. 11, 258

[18]. Khan F, Julien C M, Islam S S, et al. 2023 Flat Chem. 40 100521

[19]. Chen Z, Yang Z, Yu T, et al. 2023 Composites Science and Technology. 232 109881.

[20]. Wan S, Zhang W, Xing C, et al. 2021 Proc. IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS) (Xiamen, China). (Piscataway: IEEE) p 1023-1026

Cite this article

Chen,S. (2024). Carbon nanomaterials in flexible wearable sensors. Applied and Computational Engineering,85,120-126.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 4th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Han S, Kim J, Won S M, et al. 2018 Science translational medicine. 10 eaan4950

[2]. Bae C W, Toi P T, Kim B Y, et al. 2019 ACS Appl. Mater. Interfaces. 11 14567-14575

[3]. Kim J, de Araujo W R, Samek I A, et al. 2015 Electrochemistry Communications. 51, 41-45

[4]. Wang H Y, Wang W Q, Kim J J, et al. 2023 Sci. Adv. 9 eadi2445

[5]. Wang L, Zhang X H, Xiong H Y, et al. 2011 Biosensors & Bioelectronics. 26, 3, 991-995.

[6]. Bai Y, Yue H, Wang J, et al. 2020 Science. 369, 6507, 1104-1106

[7]. Liu N, Chortos A, Lei T, et al. 2017 Sci. Adv. 3, 9, e1700159

[8]. Hao D P, Yang R X, Yi N, et al. 2021 Science China Technological Sciences. 64 2408-2414.

[9]. Cai L, Song L, Luan P, et al. 2013 Scientific Reports. 3, 3048

[10]. Wang Y, Jin X, Jin Z, et al. 2023 Computers and Electronics in Agriculture. 210 107909.

[11]. Ge X, Gao Z, Zhang L, et al. 2023 Nano Energy. 113 108541

[12]. Park S, Kim J, Chu M, et al. 2017 Advanced Materials Technologies. 3, 1, 1-8

[13]. Zeng Z, Shahabadi S I S, Che B, et al. 2017 Nanoscale. 9, 17396–17404

[14]. Guo Y, Zhong M, Fang Z, et al. 2019 Nano Lett. 19 1143-1150.

[15]. Aleksanyan M S, Sayunts A G, Shahkhatuni G H, et al. 2022 Adv. Nat. Sci: Nanosci. Nanotechnol. 13 035003

[16]. Ma J, et al. 2019 AIP Advances. 9 075207

[17]. Huang B, Tong X, Zhang X, et al. 2023 Chemosensors. 11, 258

[18]. Khan F, Julien C M, Islam S S, et al. 2023 Flat Chem. 40 100521

[19]. Chen Z, Yang Z, Yu T, et al. 2023 Composites Science and Technology. 232 109881.

[20]. Wan S, Zhang W, Xing C, et al. 2021 Proc. IEEE 16th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS) (Xiamen, China). (Piscataway: IEEE) p 1023-1026