1. Introduction

With the continuous advancement of urbanization, the issues of building energy consumption and resource consumption are becoming increasingly prominent, urgently requiring green and low-carbon development through technological innovation [1]. Smart buildings, relying on advanced information technology, can effectively improve the level of building operation and management, reduce energy consumption, extend service life, and enhance comfort, making them a key measure to promote sustainable urban development. This paper proposes an innovative solution that integrates BIM, IoT, cloud computing, big data analytics, and artificial intelligence technologies to meet the demand for intelligent building management [2]. The system aims to establish an efficient building lifecycle management system, providing solid technical support for the operation of green intelligent buildings.

2. System overall design

2.1. System Architecture Design

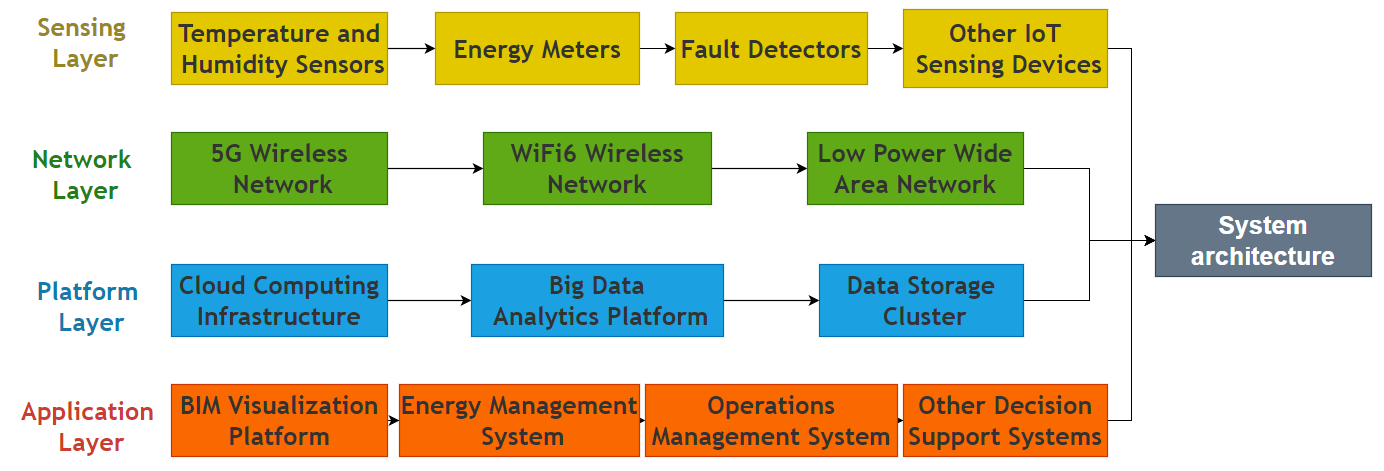

As shown in Figure 1, the intelligent building management system adopts a layered architecture design, consisting of the perception layer, network layer, platform layer, and application layer from bottom to top [3]. The perception layer consists of various IoT sensors for real-time collection of building equipment status, environmental parameters, etc., including temperature and humidity sensors, energy meters, fault detectors, etc. The network layer is responsible for data transmission, which can utilize wireless communication technologies such as 5G, WiFi 6, Low-Power Wide-Area Network (LPWAN), etc. The platform layer includes infrastructure such as cloud computing and big data for massive data storage, processing, and analysis. The application layer provides various management decision-making services systems, such as the BIM visualization platform, energy management system, operation and maintenance management system, etc. The four-layer architecture is organically integrated to achieve integration of perception, transmission, computation, and application [4].

Figure 1. Architecture Design of Intelligent Building Management System

2.2. System Module Division

The intelligent building management system can be divided into data acquisition module, BIM modeling module, energy management module, equipment operation and maintenance module, decision support module, etc., according to functionality [5]. The data acquisition module obtains various environmental and equipment data in real-time through IoT technology. The BIM modeling module constructs detailed three-dimensional building models based on standards such as Industry Foundation Classes (IFC). The energy management module provides decision-making support for energy conservation and emission reduction through data analysis. The equipment operation and maintenance module implement functions such as fault diagnosis and maintenance management. The decision support module integrates intelligent algorithms to provide scientific basis for various decisions. These modules work closely together to form an efficient closed-loop management system [6].

2.3. System Database Design

The system database adopts a hybrid architecture of relational and NoSQL databases. In the relational database, the modeling database stores geometric, attribute, and other data related to BIM models [7]. The sensing database stores various monitoring data, while the operation and maintenance database stores equipment failure, maintenance, and other information. In the NoSQL database, the document database stores source files of BIM models such as IFC, while the time-series database efficiently stores massive time-series data, applied in real-time monitoring scenarios. Coupled with distributed file systems and in-memory databases, a high-performance data storage system is formed to meet the storage and management requirements of massive structured and unstructured data.

3. System key technologies implementation

3.1. BIM Model Data Collection and Processing

The system adopts IFC (Industry Foundation Classes) as the standard data format for BIM models, capable of describing rich information about buildings without loss [8]. To efficiently obtain BIM source data, it is necessary to convert various proprietary formats (such as RVT for Revit, DWG for AutoCAD, etc.) into the IFC format, which can be achieved using open-source tools like IfcConvert. For the converted IFC files, the system further processes them: extracting entity objects and attribute information, importing them into a structured modeling database; simplifying complex parametric geometries to enhance three-dimensional visualization efficiency; setting different levels of detail (LOD) based on the model’s purpose to balance accuracy and performance; precomputing common query conditions and optimizing query efficiency using spatial indexing techniques.

3.2. Building Information Visualization Technology

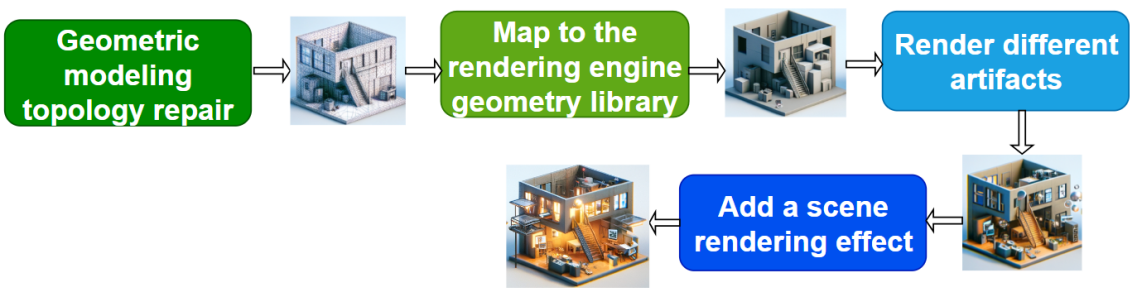

Three-dimensional visualization is the most intuitive way to present BIM models. This system adopts modern web graphics technologies like WebGL to achieve efficient and cross-platform three-dimensional rendering and interaction. The core of visualization is to construct a three-dimensional scene that meets realism based on the geometric data of the BIM model. As shown in Figure 2, topological repair is performed on the IFC geometric modeling to eliminate defects such as coplanar surfaces and fractures; then, the IFC geometry is mapped to the geometry libraries of rendering engines like Three.js; subsequently, different material and rendering effects are assigned to different component types, for example, walls use PBR materials, and wires use wireframe rendering. Additionally, combining computer graphics techniques such as camera projection, lighting, and post-processing enhances the realism and immersion of the three-dimensional scene[9]. Finally, the system supports interactive operations such as free viewpoint roaming, measurement, and annotation.

Figure 2. Three-dimensional Visualization Effect

3.3. Intelligent Decision-making and Optimization Algorithms

The system integrates various artificial intelligence algorithms for fault diagnosis, energy consumption optimization, and operation and maintenance decision-making scenarios. Taking fault diagnosis as an example, the system adopts a combination of knowledge-based expert systems and data-driven machine learning to improve the accuracy and interpretability of diagnosis. The expert system incorporates domain knowledge in fields such as building equipment and materials to form a diagnostic rule library, where the diagnostic rule library is represented as follows:

\( R=\lbrace {r_{1}},{r_{2}},⋯{r_{n}}\rbrace \)

where ri is a diagnostic rule based on domain knowledge.

Knowledge-based expert system:

\( {F_{KE}}=KE(R) \)

Meanwhile, the machine learning model is trained based on historical fault data to achieve automatic pattern recognition [10]. Both operate synergistically, where the historical fault data set is represented as follows:

\( D=\lbrace ({x_{1}},{y_{1}}),({x_{2}},{y_{2}}),⋯,({x_{m}},{y_{m}})\rbrace \)

where xi is the fault feature, and yi is the fault type.

Machine learning model:

\( {F_{ML}}=ML(D) \)

Combining the expert system and machine learning model:

\( {F_{diagnosis}}=Combine({F_{KE}},{F_{ML}}) \)

In terms of energy consumption optimization, a building energy consumption prediction model is constructed using time series analysis:

\( {E_{prediction}}=TimeSeriesAnalysis(Data) \)

Combined with optimization algorithms such as genetic algorithms and ant colony algorithms, the operating strategies of systems such as air conditioning and lighting are optimized to achieve energy conservation and emission reduction goals:

\( {F_{Optimization}}=Optimization({E_{prediction}}) \)

Regarding operation and maintenance decision-making, optimization algorithms are utilized to organically combine multiple constraints (such as manpower, materials, etc.) and multiple optimization objectives (such as time, cost, etc.), automatically planning the optimal maintenance scheme:

\( {F_{Optimization}}=Optimization({E_{prediction}}) \)

3.4. Integration of Cloud Computing and Big Data Technologies

The system integrates cloud computing and big data technologies, using the open-source cloud platform OpenStack to build the infrastructure layer, deploying Hadoop/Spark and other big data frameworks in the platform service layer, and providing a multi-tenant intelligent building management platform at the software service layer. The cloud platform hosts various big data components such as real-time computing engines (such as Storm/Flink) and batch processing engines (such as Hadoop/Spark), forming a high-performance data processing pipeline. Real-time stream computing is suitable for low-latency scenarios, while batch computing is suitable for scenarios with high throughput requirements. Finally, through data visualization and business intelligence technologies, the system presents the analysis results to decision-makers

4. Equations and mathematics

4.1. Testing Environment and Parameter Settings

Testing in a comprehensive office building spanning 210,000 square meters involves the utilization of 5 servers (128-core CPU, 512GB memory), 4 storage nodes (96TB), and various sensors (temperature, humidity, energy consumption, power monitoring, etc.). The sensors operate at a sampling rate of 1Hz, with energy meter telemetry intervals set at 10 minutes. Software environment encompasses IFC Viewer, Spark big data analytics, relational and NoSQL databases. Test cases cover fault injection, building simulation, and query analysis functionalities, among others.

4.2. Data Collection Efficiency and Real-time Performance Testing

The core metrics for evaluating data collection efficiency and real-time performance include throughput, average latency, and peak response time. Taking the full device data for a specific one-hour period as an example, with a total of 3.85 million records, the message queue backend runs continuously for 8 minutes, indicating a processing rate of 80,000 records per second, fully meeting the requirement for minute-level energy consumption analysis, as shown in Table 1.

Table 1. Test Results of Total Data Throughput

Test Scenario | Total Records | Processing Time | Throughput (records/second) |

Full Data (1 hour) | 3,850,000 | 8 minutes | 80,000 |

Peak Pressure Test | 10,000,000 | 78 seconds | 128,205 |

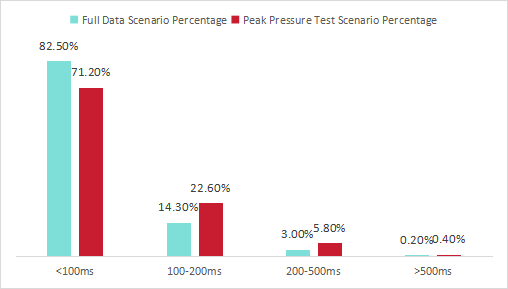

For peak pressure testing, simulating the injection of 10 million sensor data points, the message queue processing time was 78 seconds, with an average latency of less than 100ms, capable of handling second-level building environment monitoring applications, as shown in Figure 3.

Figure 3. Latency Distribution

From the perspective of real-time performance, elevator operation status monitoring was selected as a test case. There are a total of 15 elevators, each equipped with 2 operation status sensors, with a sending frequency of 1 time per second. A dedicated message channel was set up, and the average latency from the sensor to the large screen display was 205ms, with a peak latency of 542ms, fully meeting the requirements for real-time monitoring.

4.3. Fault Diagnosis Accuracy Testing

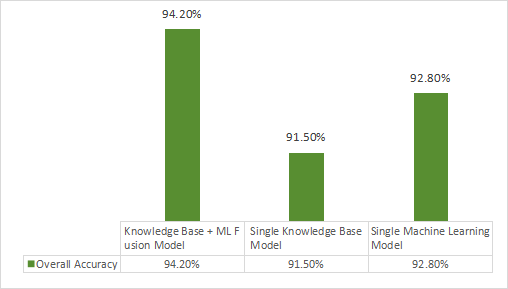

This study constructed a validation set covering 103 fault modes of 15 typical systems including air conditioning, elevators, and power supply, and tested the fault diagnosis module. The results in Figure 4 show that the overall accuracy of the combined diagnostic model based on knowledge base and machine learning reached 94.2%, significantly better than a single model.

Figure 4. Overall Model Accuracy Comparison

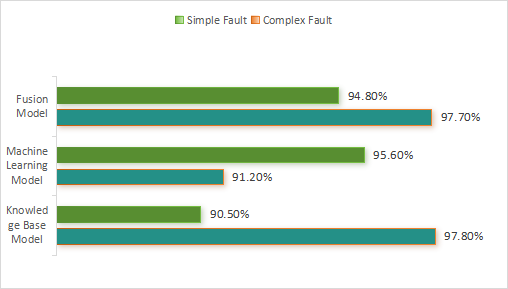

For complex fault types that require domain knowledge, such as refrigerant leakage and accumulated scale, the knowledge base performed well with an average accuracy of 97.8%. For relatively simple patterns with a large amount of historical data, such as abnormal noise and temperature offset, the machine learning model performed better with an average accuracy of 95.6%, as shown in Figure 5.

Figure 5. Accuracy of Different Models for Different Fault Types

This study also compared the performance of different machine learning algorithms in fault diagnosis. The random forest algorithm had the highest overall accuracy of 97.1%, surpassing SVM’s 95.3% and BP neural network’s 93.8%. However, in terms of diagnostic time, BP neural network had an absolute advantage with an average of 15ms, which is one-fifth of the random forest’s, as shown in Table 2.

Table 2. Comparison of Accuracy of Different Machine Learning Algorithms

Algorithm | Accuracy | Average Diagnostic Time |

Random Forest | 97.10% | 75ms |

SVM | 95.30% | 62ms |

BP Neural Network | 93.80% | 15ms |

5. Conclusion

This paper elaborates on the overall design, key technology implementation, and performance testing of an intelligent building management system based on BIM and IoT. The system adopts a layered architecture and integrates cutting-edge technologies such as BIM modeling, three-dimensional visualization, artificial intelligence decision-making, cloud computing, and big data, forming an efficient closed-loop management system. Practical tests demonstrate that the system exhibits excellent data collection efficiency, real-time performance, and fault diagnosis accuracy, providing solid technical support for the green operation of buildings throughout their lifecycle.

References

[1]. Cai H. Building Construction Operation Simulation Based on BIM Technology and Intelligent Robots[J]. Journal of Interconnection Networks, 2022.

[2]. Cui W, Chen Y, Xu B. Application research of intelligent system based on BIM and sensors monitoring technology in construction management[J]. Physics and Chemistry of the Earth, 2024, 134.

[3]. Huang L, Pradhan R, Dutta S, et al. BIM4D-based scheduling for assembling and lifting in precast-enabled construction[J]. Automation in Construction, 2022.

[4]. Mamaghani O A, Noorzai E. A framework to implement augmented reality based on BIM to mprove operation and maintenance of mechanical facilities of commercial omplexes[J].Facilities, 2023.

[5]. Quan Q, Palaoag T, Sun H H. Design and implementation of intelligent pig house environment monitor system based on Internet plus[J]. Proceedings of the 2022 4th Asia Pacific Information Technology Conference, 2022.

[6]. Wang Z, Ouyang B, Sacks R. Graph-based inter-domain consistency maintenance for BIM models[J]. Automation in construction, 2023(Oct.):154.

[7]. Lai S C, Yang M L, Wang R J, et al. Remote-control System for Elevator with Sensor Technology[J]. Sensors and materials: An International Journal on Sensor Technology, 2022(5 Pt.1):34.

[8]. Elkholy M, Metwally H, Farahat M, et al. Dynamic centralized control and intelligent load management system of a remote residential building with V2H technology[J]. Journal of Energy Storage, 2022.

[9]. Hmidah N A, Haron N A, Alias A H, et al. The Role of the Interface and Interface Management in the Optimization of BIM Multi-Model Applications: A Review[J].Sustainability, 2022, 14.

[10]. Sacks R, Wang Z, Ouyang B, et al. Toward artificially intelligent cloud-based building information modelling for collaborative multidisciplinary design[J].Advanced engineering informatics, 2022.

Cite this article

Liu,C. (2024). Development of an intelligent building management system based on BIM technology. Applied and Computational Engineering,72,211-217.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Cai H. Building Construction Operation Simulation Based on BIM Technology and Intelligent Robots[J]. Journal of Interconnection Networks, 2022.

[2]. Cui W, Chen Y, Xu B. Application research of intelligent system based on BIM and sensors monitoring technology in construction management[J]. Physics and Chemistry of the Earth, 2024, 134.

[3]. Huang L, Pradhan R, Dutta S, et al. BIM4D-based scheduling for assembling and lifting in precast-enabled construction[J]. Automation in Construction, 2022.

[4]. Mamaghani O A, Noorzai E. A framework to implement augmented reality based on BIM to mprove operation and maintenance of mechanical facilities of commercial omplexes[J].Facilities, 2023.

[5]. Quan Q, Palaoag T, Sun H H. Design and implementation of intelligent pig house environment monitor system based on Internet plus[J]. Proceedings of the 2022 4th Asia Pacific Information Technology Conference, 2022.

[6]. Wang Z, Ouyang B, Sacks R. Graph-based inter-domain consistency maintenance for BIM models[J]. Automation in construction, 2023(Oct.):154.

[7]. Lai S C, Yang M L, Wang R J, et al. Remote-control System for Elevator with Sensor Technology[J]. Sensors and materials: An International Journal on Sensor Technology, 2022(5 Pt.1):34.

[8]. Elkholy M, Metwally H, Farahat M, et al. Dynamic centralized control and intelligent load management system of a remote residential building with V2H technology[J]. Journal of Energy Storage, 2022.

[9]. Hmidah N A, Haron N A, Alias A H, et al. The Role of the Interface and Interface Management in the Optimization of BIM Multi-Model Applications: A Review[J].Sustainability, 2022, 14.

[10]. Sacks R, Wang Z, Ouyang B, et al. Toward artificially intelligent cloud-based building information modelling for collaborative multidisciplinary design[J].Advanced engineering informatics, 2022.