1. Introduction

The aerospace engine has rapidly developed since the Second Industrial Revolution, and is greatly improved so far. In 1906, the first pulsejet engine was invented by Karavodin, a Russian engineer [1]. In 1913, René Lorin patented the first ramjet engine but failed to make it work due to the low airspeed of existing airplanes that could not reach the demand of the engine [2]. As people began to pursue higher efficiency and airspeed, they tend to look into the jet engine which was not well-developed rather than the piston aerospace engine. Then Frank Whittle submitted his patent of a centrifugal compressor in 1930, and made the first centrifugal turbojet engine in 1937 [3]. Hans von Ohain started working on centrifugal engines which was similar to the idea of Whittle, and in 1939, his HeS3B engine managed to provide thrust for He-178 airplane to fly, which was the first turbojet-powered aircraft [4]. Their work provided new ideas for the design of aircraft engines. As time moves on, higher transportation efficiency is required due to the developing productive forces, so more domains, such as freight transportation, the transportation of people and even military affairs, are in need of aircrafts. Later on, more advancements were made on the basis of the turbojet engine, and the turboprop engine, turboshaft engine and the turbofan engine were invented to meet the requirements of different purposes. The turbine engine slowly replaced the piston engine due to their high efficiency and ability to suit various kinds of aircrafts, and the turbofan engine is most commonly utilized [4].

In modern times, the engineers have improved the jet engines in many aspects. Ji et al. proposed a new hybrid propulsion and power systems called HPP, and analyzed its performance, showing it can provide thrust and thrust specific fuel consumption of 4 kN and 15.32 g/s/kN at the optimized conditions when the pressure ratio of 7 and the fuel utilization is 0.6 [5]. Balli and Caliskan did an assessment of the performance of the hydrogen fuel powered turbojet engine, and found that compared to using JP-8 fuel, the specific fuel consumption decreases 63.987% when using hydrogen fuel, and the engine performs better at the same time, despite the decrease in specific thrust and energy efficiency [6]. Modern large ships typically use slow or medium speed diesel engines, which primarily burn heavy oil (HFO), a byproduct of crude oil extraction. In response to global environmental standards such as the International Maritime Organization's (IMO) sulfur emission restrictions, many ships have installed emission control devices such as scrubbers. At the same time, some ships are gradually shifting towards using liquefied natural gas (LNG) as an alternative fuel, but this transformation is still developing due to infrastructure limitations.

Some modern ship designs adopt hybrid power systems, combining diesel engines and electric motors to use steam generated from exhaust gas to power auxiliary equipment, thereby reducing overall fuel consumption. This type of design reduces pollution by utilizing electric propulsion systems during low-speed navigation [6]. Like the American battleship USS Missouri, it is using the Babcock & Wilcox Heavy oil water tube boiler and four General Electric electrical geared steam turbines, giving out a power of 156,000 kilowatts (212,000 horsepower) as given in Fig. 1 [7]. Due to the large and complex size of engines on large vessels, a team of highly skilled engineers is usually required for maintenance for these large ships. During the docking period, ships usually undergo routine engine maintenance and upkeep. From the history that is showed above, it is significant to learn the ideas of former researchers as people may gain new thoughts by looking at the past. Therefore, this article aims to arrange the basic structures and principles of common jet engine types, and conclude some modifications that has been made.

Figure 1. A sketch of the engines [7].

2. Description of engines

The turbojet is consisted of the inlet guide vanes, the compressor, the combustion chamber, the propelling turbine and the nozzle. There is turbojet engines designed for subsonic flights and supersonic flights with small differences on their structure. The inlet of a subsonic engine is in pitot style, obtaining a round and smooth leading edge. The supersonic engine usually has a Inclined plate or a center cone inside the inlet, to form oblique shock waves and higher the efficiency of slowing down the fluid [4]. The process of the turbojet engine follows the Brayton cycle. As the air flows in, it goes through the inlet guide vanes which avoids air vortex to be formed inside compressor, then is compressed in the compressor. After the air is mixed and combusted in the combustion chamber, the airflow drives the turbine to rotate. Finally, the fluid is reburned by an afterburner before exhausted or released through the nozzle directly. The turbojet engine is the simplest type of turbine engines, and it provides the most thrust among them for that almost all the air that flows in the inlet takes part in the cycle. However, it costs a lot of fuel to drive a turbojet engine, and the engine produces loud noise during its flight. Therefore, the turbojet engine is now mostly used on military aircrafts [8, 9].

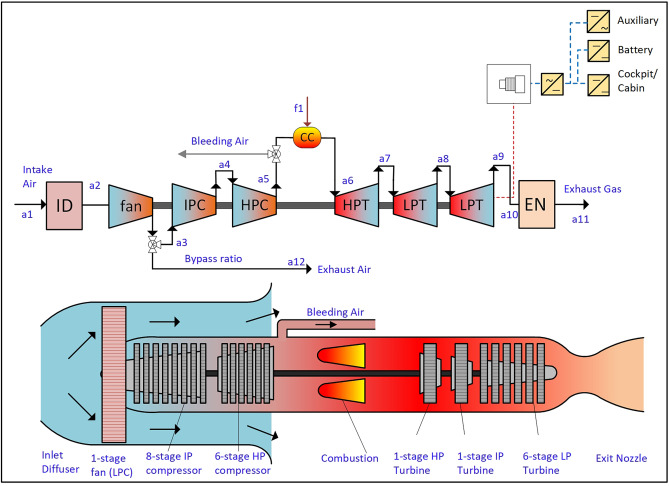

The biggest difference between the turbojet engine and the turbofan engine is that the turbofan engine has a large fan at the very front of the inlet section. There are two kinds of turbofan engines, the high bypass turbofan engine and the low bypass turbofan engine. The bypass ratio is the mass flow rate of the bypass flow over the mass flow rate of air that actually enters the engine center and takes part in the cycle. The bypass stream wraps around the exhausted jet and reduces noise. Moreover, the bypass stream provides extra thrust for the aircraft and deplete specific fuel consumption. The progress that the turbofan engine and the turbojet engine follow is almost the same, as they have similar structures except for the fan at the front. Besides, afterburners are also used on low bypass turbofan engines to provide more thrust. With higher efficiency and lower noise, the high bypass turbofan engine is widely applied to airliners, while the low bypass turbofan engine is mostly applied to military aircrafts [4].

The turboshaft engine and turboprop engine are similar in structure, as they both use the power turbine to drive a mechanism. As the helicopter rotors or propellers have a greater mass and could not reach the speed of the turbine, they are connected to a reduction gearbox that reduces the speed of the shaft. The other parts of the turboshaft engine and the turboprop engine are almost the same as the turbojet engine. These two kinds of engines rely on the helicopter rotor or propeller to provide elevating force rather than thrust provided by the exhausted jet. They are relatively efficient at low flight speed, so the turboprop engine is commonly used on subsonic aircrafts and the turboshaft engine is used on helicopters and ships [4, 9].

The ramjet engine is consisted of a diffusor, combustor and nozzle. It has no moving parts except for the fuel injector in the combustor, and compress the air by the change of volume at the inlet section. For subsonic and low supersonic speed aircrafts, the inlet of the engine is pitot style as the shock formed is normal at low supersonic speed, and works similarly as the one for subsonic turbojet engines. For supersonic aircrafts, the inlet of the ramjet engine is usually in the shape of a spike or cone, in order to form oblique shocks to reduce the loss of fluid. Because the ramjet engine has no compressor, it is unable to work properly at low flight speed. Therefore, the ramjet engine is used with other engines to start off and provide dense thrust at high flight speed. As a consequence of burning the gas mixture at a high velocity, the efficiency of the ramjet engine is always relatively low and it costs a lot of fuel [4].

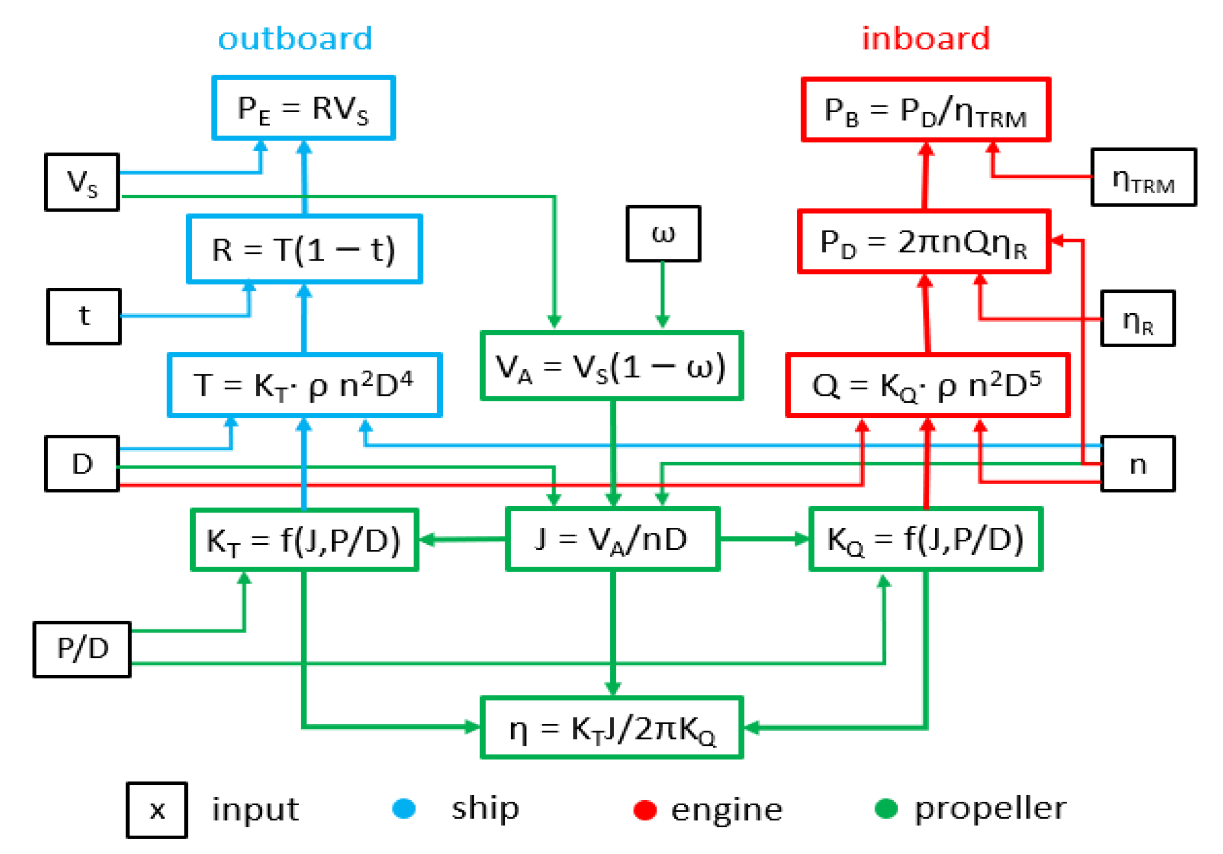

The structure and working principle of large civil ship engines mainly revolve around efficient fuel use, reliability, and adaptability to various operating conditions. Here are their basic structures and working principles as illustrated in Fig. 2 [10]:

• Main engine: Most modern large ships use slow two-stroke or medium four stroke diesel engines. The design of these engines is usually very large and suitable for long-term high load operation.

• Cylinder and piston: Each engine is composed of multiple large cylinders, and the internal pistons drive the crankshaft to rotate through fuel combustion.

• Crankshaft: The crankshaft converts the linear motion of the piston into rotational motion, driving the thruster of the ship.

• Turbocharger: In order to improve efficiency, engines are usually equipped with a turbocharger, which uses exhaust gas to compress the air entering the combustion chamber, thereby improving combustion efficiency.

• Propulsion system: The engine is connected to the propeller (thruster) through a shaft system to propel the ship forward in the water. The size and design of the propeller are optimized based on the intended use of the vessel, such as cargo ships or cruise ships.

• Fuel system: Due to the use of heavy fuel oil (HFO) in large vessels, the fuel system includes multiple components to process fuel. Fuel needs to be heated, filtered, and injected into the cylinder through fuel injectors.

Figure 2. Outboard and inboard formulae for engines [10].

3. The current modifications made in recent years

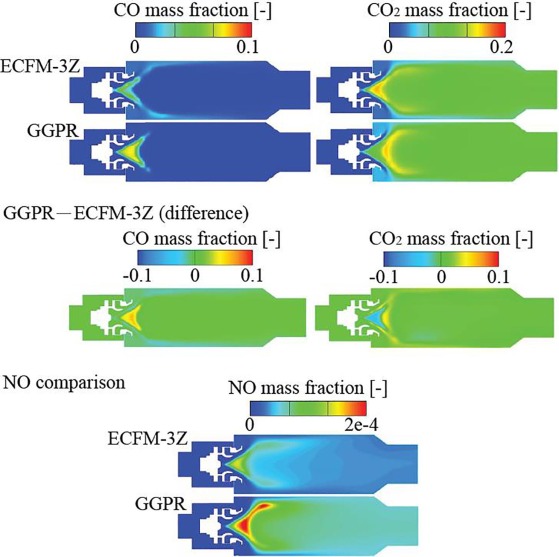

The biggest problem that engineers face at the moment is environmental issues. Pollution that was brought affected the lives of people and animals, and made people concerned about future development. The emission and energy consumption caused by vehicles contributed to this, so it is necessary to improve the efficiency of the jet engines and lower their gas emission. Researchers are making progress on finding out the how some components of the engines are related to NO emission. A study focused on the emission of the engine combustor of a model airliner and found the NO mass fraction reach a higher value at the area with higher temperature and longer resident time [11]. Damijan stimulated how different nozzle configurations performs and how fuel introduction affect the way temperature and vapor scatter. Using a series of mathematical models and simulations on commercial 3D CFD software AVL FIRE, they proved the result of the previous research that high temperature regions increase NO production, and found that with more nozzle holes, rather than one, the formation of vapor is more even, and thus the area of high temperature regions drops, producing less NO gas. In their research, they compared the ECFM-3Z combustion model and the GGPR framework, and found ECFM-3Z combustion model more accurate in predicting the working process of the combustor (seen from Fig. 3) [12]. The researches provided the relationship of structure and gas emission in certain conditions. From the results of analyses, researchers concluded that under specific circumstances, with more combustion chambers and less nozzle holes, it is more likely to have higher NO emission.

Figure 3. ECFM-3Z combustion model simulations [12].

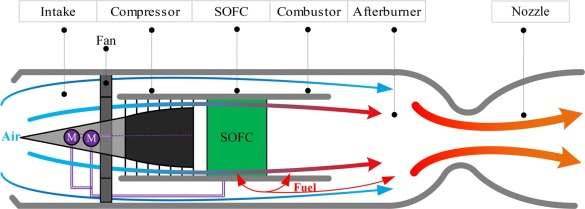

Other researchers focus on changing the way the engine provide motivation for the aircraft. Ji et al. proposed a kind of hybrid jet engine, which uses solid oxide fuel cells and has fans and afterburners. The hybrid engine uses the oxide fuel cells to drive the fan instead of using a turbine, and is able to reduce carbon emission during the flight. They tested its performance, and found that it has higher specific work than traditional turbofan engines, while reaching a thermal efficiency of 60.5% at the temperature of 2217K. However, the total weight and volume of the hybrid engine is relatively large due to the low power density that fuel cells have, so it is necessary to make further improvements in decreasing the weight of the engine [3]. Others presented and compared two kinds of hybrid turbofan engines with three shafts and high bypass ratio. The two engines use kerosene or an alternative fuel blend of 75% methane and 25% hydrogen, and their performance using these two types of fuel is contrasted (as given in Fig. 4) [13]. One engine is combined with a molten carbonate fuel cell, the other is combined with a solid oxide fuel cell. From the results they concluded that the two hybrid engines both have higher thermal and energy efficiency than that of the traditional turbofan engine, and the MCFC turbofan engine has an obviously bigger increment. Using the alternative fuel blend, the carbon emissions greatly decrease, reducing from 18 kg/s to about 3.7 kg/s. Still, the two hybrid engines have the same problem as the one that was talked about. The utilization of SOFC and MCFC raises the total weight of the engine by 18% and 40%, while producing lower maximum thrust force (seen from Fig. 5) [14]. From the three engines above, it is obvious that the hybrid engines have higher efficiency and less pollution produced compared to the traditional engines, but their weight and thrust force are still problems to overcome before they are turned into wider range of applications.

Figure 4. A sketch for SOFC and overall structure of engines [13].

Figure 5. A sketch of hybrid turbofan engines [14].

Researchers are also looking for more sorts of alternative fuel that could reduce the gas emissions. Some scholars analyzed how different types of fuel affect the performance of PW4056, a two-shaft high bypass turbofan engine produced by Pratt & Whitney. They did energy, exergy and sustainability analyses are performed at the same dead state conditions in the research. Using hydrogen fuel, compared to using kerosene fuel, the environmental effect factor and ecological effect factor of the engine is higher, and the sustainable efficiency factor becomes higher. From the results of the data, they concluded that the thermodynamic performance of the engine using hydrogen fuel is close to that of using kerosene fuel, so the hydrogen fuel could be a considerable alternative fuel despite its high cost [15]. So far, the ways to produce hydrogen are not well developed. Some existing methods produce unacceptable pollution or are too expensive. There are some promising ways of hydrogen production, such as the Water electrolysis and plasmolysis, may be competitive in the future and should be further studied [16].

For a normal ship engine, the basic of the design is that the engine makes a power stroke at a certain speed to convert the chemical energy of the fuel into torque, and then transmits the power to the propeller through the shafting, generating the thrust that overcomes the ship's resistance, enabling the ship to sail at a certain speed. Lubricating oil flows through the moving parts of the engine through pipelines and pump systems, reducing friction and preventing overheating. In diesel engines, fuel is injected into the cylinder through fuel injectors, mixed with air, and ignited by the high temperature generated by compression. This combustion process generates strong pressure, pushing the piston downwards. The reciprocating motion of the piston is transmitted to the crankshaft through the connecting rod, and the rotational motion of the crankshaft is ultimately driven by the ship's shaft system to propel the propeller forward. The combustion exhaust gas is discharged through the exhaust system, and the engine is usually equipped with an exhaust turbocharger to recover some energy and improve overall efficiency. The engine is not only responsible for propulsion, but can also provide power to other equipment on board through a generator. Some ship engines use exhaust gas to drive steam boilers, generating steam to power auxiliary generators.

4. Prospects

The researches that are talked about in the text above show that there are still many problems that haven’t been solved. In the future, it is likely for researcher to improve the power density of the fuel cells so that the total weight and volume of the hybrid engines could be reduced, and the engines may provide higher specific thrust and lower energy consumption during the flights. Moreover, as people find out more clues about how the structure of the engine affect the performance of the engine, future deigns may be more reasonable and more efficient. The combination of different number of chambers, nozzle holes and the shape of the inlet may bring various results that can suit different types of aircrafts. At last, people might try more kinds of alternative fuel and make improvements on the production of eco-friendly resources. Also, for large ship engines, they often use heavy fuel oil (HFO), which is a cheaper but dirtier byproduct of oil refining. These engines need extra equipment to process this fuel. Some ships are switching to cleaner fuels like LNG (liquefied natural gas). Regular Engines mostly use diesel fuel, which is cleaner and doesn’t require much extra processing. Regular engines also face stricter emissions regulations, so they use more environmentally friendly fuels.

Most ships use two-stroke engines, which complete their power cycle with just two strokes of the piston. This makes the engine simpler and more efficient for long-term use. Regular Engines usually have four-stroke engines, where the piston goes through four strokes (intake, compression, power, exhaust). These engines are smoother and quieter, ideal for daily use. For Large Ship Diesel Engines, since they use heavy oil as the income of energy, they emit more sulfur oxides and particulates. Ships use special systems to reduce harmful emissions to meet international environmental standards. They also require complex cooling and lubrication systems because of their high power, and they need to work stably for a very long time. These systems help keep the engine from overheating and reduce wear.

5. Conclusion

To sum up, the jet engines are widely applied and have greatly improved so far. This research showed the diversity between some common jet engines, including the turbojet engine, the turboprop engine, the turboshaft engine, the turbofan engine and the ramjet engine. Besides, the article talked about several recent advancements on the jet engines which are from the perspective of structure, power system and fuel. However, the article has presented the diversities and the modifications in a brief manner and could cover very few researches. Hence, it is necessary for future researches to look deeper into the topic.

Author contribution

All the authors contributed equally and their names were listed in alphabetical order.

References

[1]. Amezcua Sánchez A 2022 Design construction and testing of a Pulsejet engine Doctoral dissertation, Universitat Politècnica de València.

[2]. București P O and Marcel I 2018 Computational studies of the aero-thermodynamics of supersonic propulsion systems UPB vol 8

[3]. Calmon J 1988 From Sir Frank Whittle to the year 2000 — what is new in propulsion? The Aeronautical Journal vol 92(920) pp 397-408

[4]. Dong Y and Feng Y 2021 Principles and Construction of General Aviation Engines (2ed): Beihang University Press

[5]. Ji Z, Rokni M M, Qin J, Zhang S and Dong P 2020 Energy and configuration management strategy for battery/fuel cell/jet engine hybrid propulsion and power systems on aircraft Energy Conversion and Management p 225

[6]. New York Naval Shipyard 1948 USS MISSOURI BATTLESHIP – NO63 Booklet of general plans Maritimes

[7]. The Babcock & Wilcox Company 2020 Reliable and efficient stem generation systems for modern utility service. BABCOCK & WILCOX energy | environmental

[8]. Balli O and Caliskan H 2022 Energy exergy environmental and sustainability assessments of jet and hydrogen fueled military turbojet engine International Journal of Hydrogen Energy vol 47(62) pp 26728-26745

[9]. Leishman J G 2023 Introduction to Aerospace Flight Vehicles: Embry-Riddle Aeronautical University

[10]. Mauro F, Braidotti L and Trincas G 2019 A model for intact and damage stability evaluation of CNG ships during the concept design stage Journal of Marine Science and Engineering vol 7(12) p 450

[11]. Man Z, Zhen F, Yu L and Ji L 2012 CFD Study of NOx Emissions in a Model Commercial Aircraft Engine Combustor Chinese Journal of Aeronautics vol 25(6) pp 854-863

[12]. Cerinski D, Vujanović M, Petranović Z, Jakov B N S and Hriberšek M 2020 Numerical analysis of fuel injection configuration on nitrogen oxides formation in a jet engine combustion chamber Energy Conversion and Management p 220

[13]. Ji Z, Qin J, Cheng K, Zhang S and Dong P 2021 Performance assessment of a solid oxide fuel cell turbine-less jet hybrid engine integrated with a fan and afterburners Aerospace Science and Technology p 116

[14]. Seyam S, Dincer I and Agelin-Chaab M 2021 Investigation of two hybrid aircraft propulsion and powering systems using alternative fuels Energy p 232

[15]. Balli O and Akdeniz H Y 2022 Energy exergy environmental and sustainability assessments of jet and hydrogen fueled military turbojet engine International Journal of Hydrogen Energy vol 47(62)

[16]. Younas M, Shafique S, Hafeez A, Javed F and Rehman F 2022 An Overview of Hydrogen Production: Current Status Potential and Challenges Fuel p 316

Cite this article

Li,D.;Xu,H. (2024). Analysis of the Efficiency Improvements for Engines: Evidence from Jet and Marine Engines. Applied and Computational Engineering,89,1-8.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Amezcua Sánchez A 2022 Design construction and testing of a Pulsejet engine Doctoral dissertation, Universitat Politècnica de València.

[2]. București P O and Marcel I 2018 Computational studies of the aero-thermodynamics of supersonic propulsion systems UPB vol 8

[3]. Calmon J 1988 From Sir Frank Whittle to the year 2000 — what is new in propulsion? The Aeronautical Journal vol 92(920) pp 397-408

[4]. Dong Y and Feng Y 2021 Principles and Construction of General Aviation Engines (2ed): Beihang University Press

[5]. Ji Z, Rokni M M, Qin J, Zhang S and Dong P 2020 Energy and configuration management strategy for battery/fuel cell/jet engine hybrid propulsion and power systems on aircraft Energy Conversion and Management p 225

[6]. New York Naval Shipyard 1948 USS MISSOURI BATTLESHIP – NO63 Booklet of general plans Maritimes

[7]. The Babcock & Wilcox Company 2020 Reliable and efficient stem generation systems for modern utility service. BABCOCK & WILCOX energy | environmental

[8]. Balli O and Caliskan H 2022 Energy exergy environmental and sustainability assessments of jet and hydrogen fueled military turbojet engine International Journal of Hydrogen Energy vol 47(62) pp 26728-26745

[9]. Leishman J G 2023 Introduction to Aerospace Flight Vehicles: Embry-Riddle Aeronautical University

[10]. Mauro F, Braidotti L and Trincas G 2019 A model for intact and damage stability evaluation of CNG ships during the concept design stage Journal of Marine Science and Engineering vol 7(12) p 450

[11]. Man Z, Zhen F, Yu L and Ji L 2012 CFD Study of NOx Emissions in a Model Commercial Aircraft Engine Combustor Chinese Journal of Aeronautics vol 25(6) pp 854-863

[12]. Cerinski D, Vujanović M, Petranović Z, Jakov B N S and Hriberšek M 2020 Numerical analysis of fuel injection configuration on nitrogen oxides formation in a jet engine combustion chamber Energy Conversion and Management p 220

[13]. Ji Z, Qin J, Cheng K, Zhang S and Dong P 2021 Performance assessment of a solid oxide fuel cell turbine-less jet hybrid engine integrated with a fan and afterburners Aerospace Science and Technology p 116

[14]. Seyam S, Dincer I and Agelin-Chaab M 2021 Investigation of two hybrid aircraft propulsion and powering systems using alternative fuels Energy p 232

[15]. Balli O and Akdeniz H Y 2022 Energy exergy environmental and sustainability assessments of jet and hydrogen fueled military turbojet engine International Journal of Hydrogen Energy vol 47(62)

[16]. Younas M, Shafique S, Hafeez A, Javed F and Rehman F 2022 An Overview of Hydrogen Production: Current Status Potential and Challenges Fuel p 316