1. Introduction

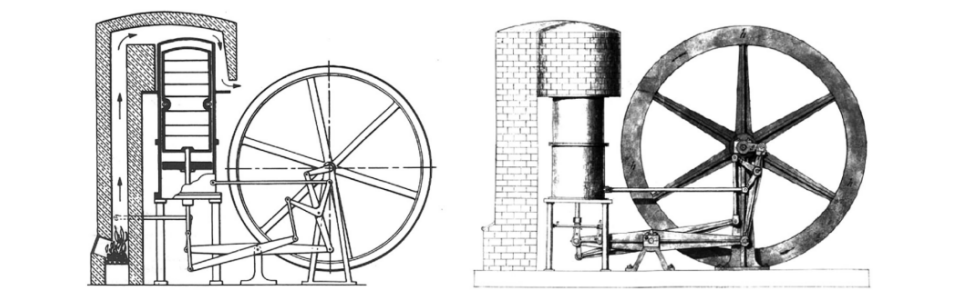

Stirling engines have a long history. A Scottish clergyman named Robert Stirling created the first regenerative cycle heat engine in 1816 and received a patent for it. It was a low-pressure, coal-burning air engine designed to rival saturated steam engines in the supply of supplemental power for mining and manufacturing [1], as shown in Fig. 1. The first Stirling is very bulky. Besides, it has a relatively low heat engine efficiency. With those drawbacks, Stirling engine needs to be improved by somebody else. The second generation of Stirling engines debuted in 1937.The Philips of Holland reached an extremely high level by utilizing new materials and technologies. The understanding of fluid mechanics and heat transmission, which is crucial for strengthening the structure and increasing stability [2]. The second generation of the Stirling engine becoming more modern. This improvement made Stirling engine more efficient and productive “Philips was able to substantially improve the performance of Stirling engines, a good example being a portable 200W air-engine generator set (seen from Fig. 2) [3].

Stirling engines have a variety of use in the miniaturization and home market, integration of renewable energy, aerospace and defense, industrial applications, environmentally friendly development. “With the increasingly serious problems such as environmental pollution and energy crisis, it is urgent to develop new vehicle power. A heat pump, typically integrated into a building’s climate control system, functions for both heating and cooling purposes. For heating, it extracts heat from ambient sources like rivers, lakes, or the ground, elevating the heat to a higher temperature for distribution within the building. In communication relay stations and automatic weather stations, power generation equipment that can achieve long-term automatic operation without frequent maintenance is needed, and Stirling engines are just suitable for this field, because such engines can work with different energy sources, and have high thermal efficiency and good reliability [4]. From the article, one can find Stirling engine has lots of advantages in those areas. Unlike other engines combustion inside, Stirling engines is an external combustion engine which means it has an external heat source. In this case, Stirling engines will have relatively high efficiency and less pollution because they can use environmentally friendly energy such as solar energy as heat sources. On the contrary, because its complex structure, the Stirling engines cause a high price and require high technology. It can be further developed with advances in materials science and thermal energy management technology. This paper focuses on the application of the Stirling engine. This paper will discuss the issue of descriptions of engines, principle of Stirling engine, state-of-art Facilities, applications, limitations and Prospects.

Figure 1. First generation of the Stirling engines [1].

Figure 2. Philips 200W air-engine [3].

2. Descriptions of engines

Engines basically mean different kind of machines that can convert different energy into mechanical energy. Engines can be broadly divided into heat engines, electric motors, gas turbine engines, nuclear engines, fuel cells and compressed engines. The most common and oldest of these is the heat engines, which convert thermal energy to mechanical energy. It can be further divided into internal combustion engine (ICE), Stirling engine and steam engine [5-7]. Table 1 shows the different structures of three engines

Table 1. Comparisons of the three engines.

Principle | Theoretical maximum efficiency | |

ICE | Mechanical components are driven by the heat generated inside the burning fuel. | 45%-50% |

Stirling engine | Mechanical system driven by temperature difference between external heat and cold sources | >50% |

steam engine | Using steam from heated water to drive a piston or turbine | 20%-45% |

3. Principle of Stirling engine

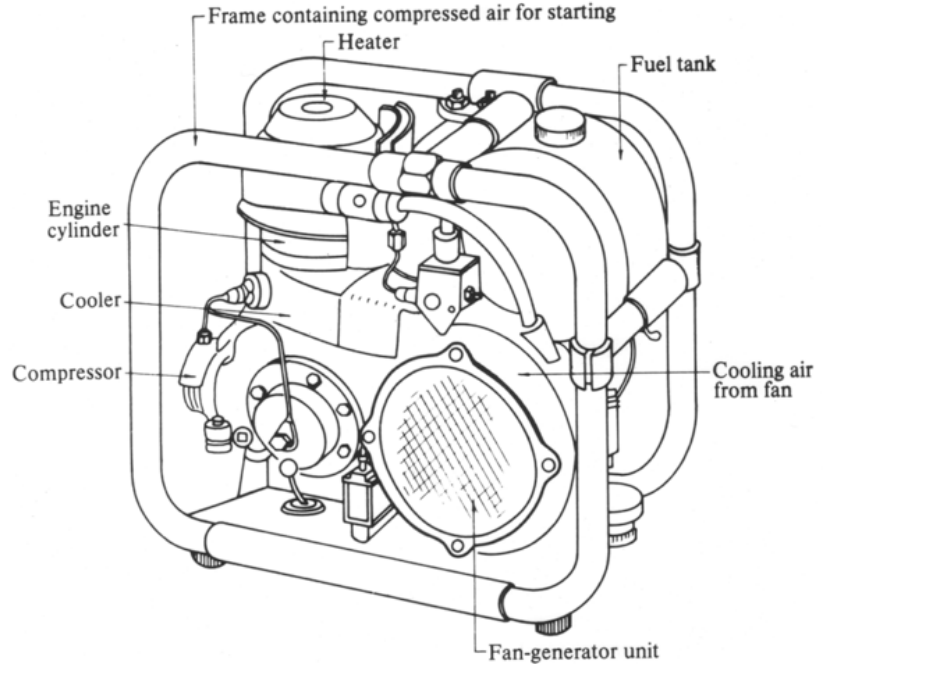

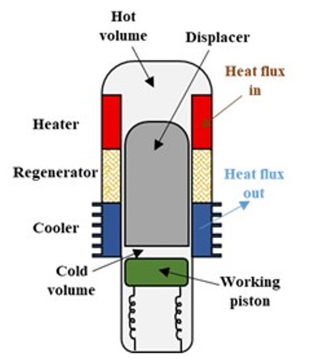

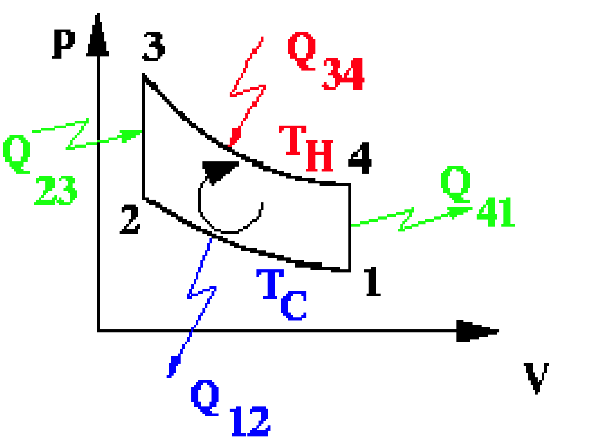

Like with other heat engines, the primary operations involve cooling, compression, heating, and expansion p8[. An exterior heat source and an external heat sink with a significant enough temperature differential between them are needed for a Stirling engine to function (seen from Fig. 3) [9]. Fig. 3 shows the structure of Stirling engine as well as the pressure-volume diagram of Stirling engine.

A thermodynamic cycle known as Stirling engines, which consists four processes:

• Isothermal Expansion: The working gas is heated by an external heat source, causing it to expand and do work on a piston.

• Constant-Volume Cooling: The gas passes through a regenerator, where it transfers heat to the regenerator material and cools down.

• Isothermal Compression: The cooled gas is compressed by the piston, requiring less work due to its lower temperature.

• Constant-Volume Heating: The gas passes back through the regenerator, where it absorbs heat from the regenerator material and warms up before returning to the expansion space.

Figure 3. Schematic diagram of the Stirling engine [9] and the Stirling engine theoretical cycle [2].

The regenerator is a critical component of Stirling engine, it can make the Stirling engine more efficient. It acts as a heat exchanger which can temporarily stores heat during the Constant-Volume Cooling process and return heat during the Constant-Volume Heating. Therefore, the external heat source required for production can be reduced.

4. The state-of-art facilities

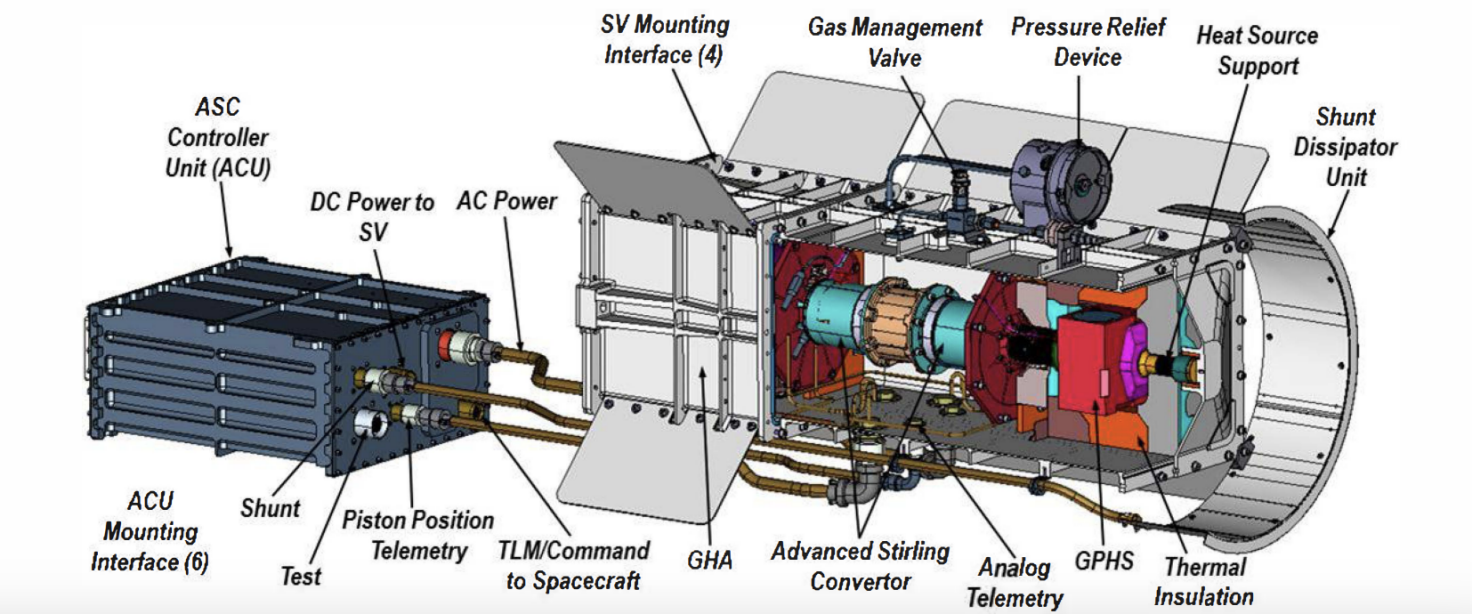

In recent years, NASA has invented a high-technology Stirling engine called Advanced Stirling Radioisotope Generator (ASRG). Consists of the Advanced Stirling Convertor Controller Unit (ACU) and the Generator Housing Assembly (GHA), two physical parts [10]. This engine utilizes heat from radioactive decay as the energy source and it can generate electricity power. To replicate the ASRG mission, two electric heat sources and 500 watts of total electric power are needed; however, if the hot end temperature is dropped from 760°C to 600°C, whole system performance can be shown with as little as 270 watts of electric power. Since the electric heat source is utilized for system-level acceptance testing before fueling, it was created to satisfy program flight requirements. The ASRG will generate about 137 watts of electricity when the heat sources are powered by 500 watts of electricity [10]. From the above data, ASRG has approximately 140 watts of power, and its efficiency is about 28%, which is significantly higher than other traditional heat engines. So, NASA put ASRG in the use of space exploration. The Fig. 4 shows the structure of the ASRG engine.

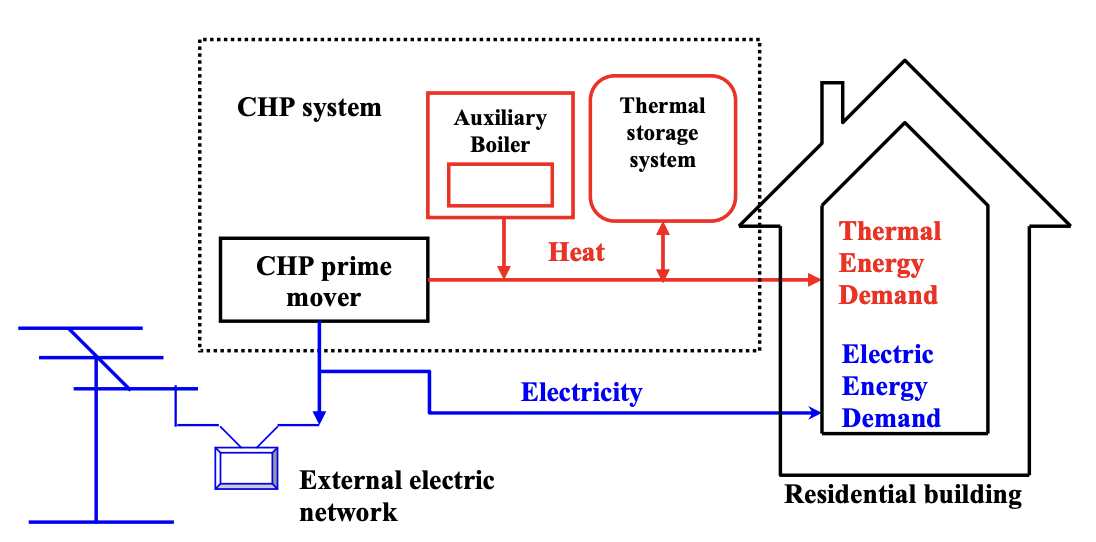

Another advanced-technology Stirling engine known as Micro combines heat and energy (MCHP). It is a Stirling engine which can both produce heat and electricity. The Micro CHP Stirling systems that are currently on the market and have an electric power capacity of up to 10 kW are primarily prototypes. They have an equivalent thermal power capacity of 5 kW to 25 kW and an electric power capacity of 1 kW to 9 kW, which makes them a viable alternative to residential boilers. With the CHP efficiency above 80% and possibly even surpassing 95%, the electric efficiency falls between 13% and 28% [11]. As one can see in the data, this system is extremely efficient. Fig. 5 shows the schematic diagram of the CHP system.

Figure 4. ASRG engine cut-away [10].

Figure 5. Lay out of the CHP system [11].

5. Applications

The Stirling engine uses solar energy to generate mechanical energy which is used to pump water. It is especially useful in areas far away from civilization and where there’s not enough electricity supply. The Stirling engine usually does two main things. Firstly, agricultural irrigation. The water pump uses solar power to run the Stirling engine and pump water from the ground for irrigation. Such as the agricultural irrigation project in Niger and South Africa. The Use of Stirling pumps those areas in order to increase crop yields and support local agricultural development. Secondly, drinking water. There's the use of Stirling pumps to solve problems regarding drinking water in rural areas. For example, In Rural areas of India, Solar Stirling pumps in some villages can provide villagers with clean drinking water and improve public environment. Additionally, at National parks in Kenya application of Stirling pumps can provide water for wildlife watering points and help protect endangered species.

With the high thermal efficiency of the Stirling cycle, it is possible to have solar power converted to electricity and stored to provide a continuous and stable power source. The system generates and stores electricity in day to be used for lighting or whatever at night. With solar energy and electricity storage, rural areas can have an independent electricity source. Roelf J. Meijer received a patent for one design in 1987. His idea generates electricity by combining a solar dish collector with a heat engine, such as a Stirling cycle engine. This device is made up of a big dish that gathers solar energy and focuses it on a focal point in the middle [11]. A solar Stirling cooler is the opposite of the Stirling engine, where one utilizes solar energy to create work to be used to cool things done. For the AC, solar energy is used in the day, when the temperature is higher, to drive the Stirling cooler and cool the house. As for the refrigeration, solar energy is used to power the Stirling cooler. It's usually used in places with abundant solar energy to save the energy consumption.

6. Limitations and prospects

However, Stirling engines also have some drawbacks, which hinder their development. Firstly, the balance in efficiency and cost. Theoretically, Stirling engine can have a high efficiency, but in practical use it cannot reach the expected efficiency, especially when there is not enough temperature difference. Furthermore, Stirling engine requires high-precision and high-quality materials, which leads to high manufacturing costs. Compared to traditional heat engines and electric motors, Stirling engine has a relatively low quality-price ratio. Secondly, Stirling engines cannot change output level quickly. To put it in another way, when you want it to start, it needs a while to fully get to work. The same thing happens when you need it to stop working. This makes it difficult to participate in road applications. Thirdly, gas Seal Problems. The Stirling engine needs to work in a closed system where there remains gas pressure. The materials will be worn out during long time working, this will cause gas leakage, which reduces engine efficiency and lifetime. Lastly, Stirling engine has a complex structure, often takes up lots of space, this will limit its application in certain areas, such as vehicle area.

In the future, with the development of materials technology, especially the materials of high strength, high temperature and corrosion resistance which can significantly improve durability of the Stirling engine. Additionally, 3D printing will reduce the cost of high-precision structures. Moreover, Stirling engine combining renewable energy such as Solar Stirling Power has a good performance in the pilot now, further expansion is expected in the future. Furthermore, the MCHP system, with future technologies, may become more compact and efficient. Last but not least, Stirling engine can take advantage of industry waste heat to produce energy, in this case, it can achieve the goal of environmental protection.

7. Conclusion

To sum up, it is a long process for Stirling engine generate from the initial design to various designs in nowadays. It has been widely used from agriculture irrigation to space exploration, Stirling engine show its potential and advantages in those areas. However, Stirling engine still has issues wirh high costs, slow dynamic response, and complex structure. Which limits its application. In the future, with further development of technology, Stirling engine may play a major role in protecting environment. The analysis of the history, principle, advanced technology, application scenarios and future prospects of Stirling engine in this paper, indicates the research significance and development potential of Stirling engine in modern science and technology.

References

[1]. Bakar R B 2019 Stirling Engines: Operational Theory, Development History, Design Configurations and Applications Online Data p 11.

[2]. Christoph M, Arnaud G, Rafael A, et al. 2007 Stirling engine University of Gavle

[3]. Berchowtiz D 2018 A personal history in the development of the modern Stirling engine. Athens: Global Cooling Inc., p 18

[4]. Yao X 2023 Stirling engines: Advancements, applications, and environmental benefits Theoretical and Natural Science vol 25 pp 186-191.

[5]. Dartnell L, Mayo J M and Twombly M 2018 Ancient Roots of the Internal Combustion Engine Scientific American p 3193

[6]. Torres G M, Carvajal T E, Vélez G J A and Sánchez M D 2018 Thermodynamic model for performance analysis of a Stirling engine prototype Energies vol 1110 p 2655

[7]. Our Steam Engine Retrieved from: https://amesburycarriagemuseumorg/news/2022/1/28/our-steam-engine

[8]. Perozziello C, Grosu L and Vaglieco B M 2021 Free-piston stirling engine technologies and models: A review Energies vol 1421 p 7009

[9]. Chan J, LeRoy R, Schulze E, Connolly D and Quinn R 2014 March Concept for an ASRG hosted payload mission IEEE Aerospace Conference pp 1-6.

[10]. Maghanki M M, Ghobadian B, Najafi G and Galogah R J 2013 Micro combined heat and power MCHP technologies and applications Renewable and Sustainable Energy Reviews vol 28 pp 510-524

[11]. Ferreira A C, Nunes M L, Teixeira J C, Martins L A and Teixeira S F 2016 Thermodynamic and economic optimization of a solar-powered Stirling engine for micro-cogeneration purposes Energy vol 111 pp 1-17

Cite this article

Li,B. (2024). Analysis of the Principle of Stirling Engine and State-of-art Applications. Applied and Computational Engineering,98,23-28.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Bakar R B 2019 Stirling Engines: Operational Theory, Development History, Design Configurations and Applications Online Data p 11.

[2]. Christoph M, Arnaud G, Rafael A, et al. 2007 Stirling engine University of Gavle

[3]. Berchowtiz D 2018 A personal history in the development of the modern Stirling engine. Athens: Global Cooling Inc., p 18

[4]. Yao X 2023 Stirling engines: Advancements, applications, and environmental benefits Theoretical and Natural Science vol 25 pp 186-191.

[5]. Dartnell L, Mayo J M and Twombly M 2018 Ancient Roots of the Internal Combustion Engine Scientific American p 3193

[6]. Torres G M, Carvajal T E, Vélez G J A and Sánchez M D 2018 Thermodynamic model for performance analysis of a Stirling engine prototype Energies vol 1110 p 2655

[7]. Our Steam Engine Retrieved from: https://amesburycarriagemuseumorg/news/2022/1/28/our-steam-engine

[8]. Perozziello C, Grosu L and Vaglieco B M 2021 Free-piston stirling engine technologies and models: A review Energies vol 1421 p 7009

[9]. Chan J, LeRoy R, Schulze E, Connolly D and Quinn R 2014 March Concept for an ASRG hosted payload mission IEEE Aerospace Conference pp 1-6.

[10]. Maghanki M M, Ghobadian B, Najafi G and Galogah R J 2013 Micro combined heat and power MCHP technologies and applications Renewable and Sustainable Energy Reviews vol 28 pp 510-524

[11]. Ferreira A C, Nunes M L, Teixeira J C, Martins L A and Teixeira S F 2016 Thermodynamic and economic optimization of a solar-powered Stirling engine for micro-cogeneration purposes Energy vol 111 pp 1-17