1. Introduction

The maintenance of industrial equipment is a very important task for factory. However, the various methods currently in widespread use all have drawbacks For example, visual inspection relies on the experience of the inspector and may miss hidden problems, while inspection of mechanical components may require disassembly of the equipment, which is time-consuming and may cause new damage. In addition, electrical testing requires specialized equipment and knowledge, otherwise it may not be possible to detect all potential electrical problems. However, there is currently no integrated device that can assist maintenance personnel in completing most of the maintenance work on industrial equipment.

Research on the elephant trunk robot has already yielded initial results and has entered practical application. For example, soft robotic arm developed by Jiang et al. inspired by the elephant trunk can accomplish various manipulation tasks in daily life, such as opening doors and drawers, wiping glass, and twisting bottle caps [01]. This soft robotic arm has inherent compliance and continuous deformation characteristics, and it has a broad application prospect in fields such as intelligent manufacturing, medical rehabilitation, and home services. In addition, Guan et al.developed a "trunk-like" soft robot with good compliance, high mobility, and excellent environmental adaptability [02]. A bionic handling assistant developed by Festo can easily move and grasp objects without endangering humans,which can be widely used in industrial automation [03]. Inspired by the large range of motion and grasping ability of an elephant's trunk, this mechanical arm consists of three interconnected parts for movement, with a "gripper" at the end for grasping and picking up objects. However, these research results cannot be directly applied to industrial equipment maintenance at present.

Based on the development and application of the elephant trunk robot, this paper designs a new flexible robot scheme that integrates tactile sensors and infrared sensors, taking into account the problems in equipment maintenance, such as lighting environment and working hours, so that the flexible robot can be applied to the maintenance of industrial equipment and can adapt to dim and low-light environments [4]. The design of this scheme lays the foundation for the development of future new materials, sensor technology, artificial intelligence, and robotics, promoting interdisciplinary research that requires the collaborative effort of multiple disciplines such as mechanical engineering, electronic engineering, material science, and computer science.

In this robot design scheme, the soft robot can be inserted into the interior of large machinery for equipment maintenance work. With the aid of tactile sensors, it can transmit signals upon encountering obstacles, helping to control the soft robot to change its local stiffness and achieve obstacle avoidance behavior. Meanwhile, infrared sensors can accurately detect areas of abnormal temperature inside and precisely locate them, greatly enhancing the efficiency and accuracy of the maintenance work. Moreover, in the future, it can be applied to locations that are difficult or impossible for humans to access, for exploration and research.

2. Related work

2.1. Limitations of robots in precision manipulation

During the operation of precision equipment, the rigid parts of these robots may damage sensitive parts due to their inflexible characteristics. Furthermore, the control mechanisms of rigid robots are typically predicated on pre-defined trajectories and velocities, which can impede the achievement of precise control for tasks necessitating minute adjustments. The adaptability of rigid robots to complex operating environments is also limited by their inability to adjust local stiffness, which requires the replacement of parts to address different operating needs..

Additionally, rigid robots face challenges in obstacle avoidance, often due to their inherent fixed motion paths that hinder the ability to effectively bypass obstacles.These robots cannot exert forces with sufficient precision to achieve precise force control Of paramount importance is the interference with sensor performance caused by the metallic materials that constitute the robots' mechanical structure. This interference significantly impedes the integration of a diverse array of sensors, thereby limiting the robots' capacity for comprehensive environmental perception.

2.2. The types of sensors selected

In order to operate effectively in low-light environments, soft robots need to integrate sensors that can operate in different lighting conditions, so as to maintain sensing accuracy and stability to ensure maintenance tasks can be carried out successfully. At the same time, the scale of the sensors should not be too large and need to be highly integrated to avoid affecting the flexibility and softness of the soft robot. Overall, an integrated feedback control system is needed to achieve precise closed-loop control, which includes various sensors that sense the environment and send signals to provide corresponding feedback.

In addition, the robot is composed of soft pneumatic actuators and interference plates. By implementing the interference plates in various patterns, the local stiffness of the robot can be pre-programmed, and its stiffness can be altered by adding or removing the interference plates. Additionally, to overcome the limitation of constant stiffness in traditional soft robots, rigid interference plates are introduced and installed independently on various parts of the robot, thereby achieving localized stiffness regulation. Different stiffness requirements are met through different combinations of interference plates, and motion is achieved by changing the internal air pressure of the robot. By controlling the valves with a PLC, the air pressure in each section can be precisely adjusted, thus controlling the robot's bending and movement.

In terms of materials, the piezoelectric tactile sensor made of lead zirconate titanate (PZT) material is adopted as the solution for touch sensation [5]. The principle is that when the material is subjected to external mechanical forces, the electric dipole moments inside it change, causing charges proportional to the external force to be generated at both ends of the material, thereby achieving the conversion of mechanical energy into electrical energy. However, due to the small current of the signals generated by the tactile sensor and their susceptibility to interference, it is necessary to process them through a signal conditioning circuit. The processed analog signals are converted into digital signals by an analog-to-digital converter (A/D converter) and transmitted to the upper machine for processing and outputting obstacle avoidance signals, thereby controlling the movement of the soft robot.

Moreover, the thermal infrared sensors can detect infrared radiation, which is emitted by all objects based on their temperature and is independent of visible light. Therefore, they are not affected by changes in ambient lighting and can work in low-light or dimly lit environments. Since infrared radiation can penetrate some minor obstructions, it can be used to scan and identify abnormal heat sources inside equipment, and in conjunction with tactile sensors, quickly locate potential safety hazards in the equipment and resolve them in a timely and efficient manner.

When embedding the sensor in the elephant trunk structure, it is necessary to ensure that the sensor matches the shape and function of the soft robot, and that it can ensure the stability and accuracy of sensor data collection without affecting the normal movement of the robot, so as to avoid misjudgment.

3. Results

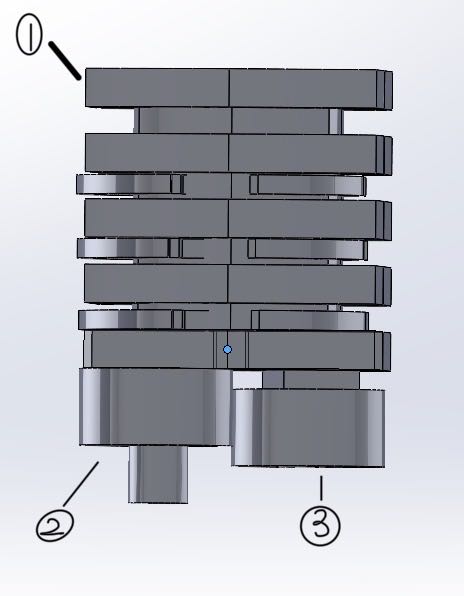

The overall design consists of three major components, inspired by the flexible robot with the trunk of an elephant, piezoelectric tactile sensors and infrared sensors (Figure 1).

Figure 1. Schematic diagram of the assembly of the elephant trunk robot with sensors.

3.1. Elephant Trunk Flexible Robot

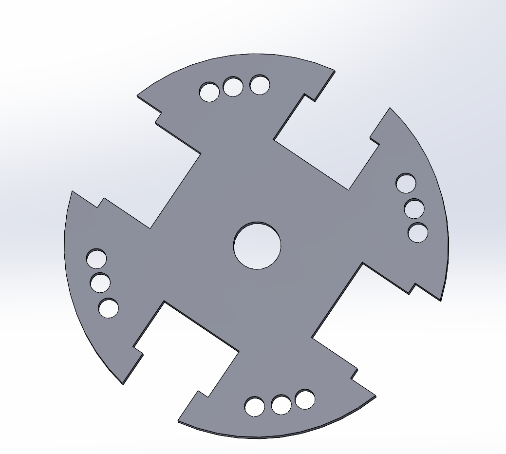

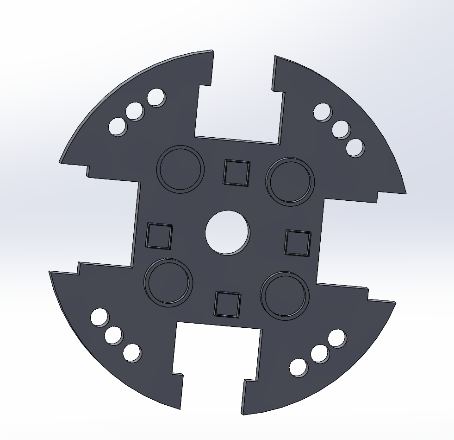

As shown in Figure 2, the elephant trunk robot structure is composed of an interference plate and a pneumatic P.

(a) |

(b) |

Figure 2. Structural diagram of the interferometer. (a)The front side of the interferometer; (b)The back side of the interferometer

Interference plates are rigid structures that adjust local stiffness by altering the bending characteristics of Soft Pneumatic Actuators (SPAs) [6]. As shown in the figure 2, by inserting different numbers and configurations of interference plates between the SPAs, the stiffness of specific parts of the robot can be pre-set, and each segment of the robot can be controlled through independent pneumatic valves, thereby precisely regulating the air pressure and adjusting the robot's shape and movement. Through the finite element analysis conducted by the research team, a pressure library has been constructed, which includes the robot's bending curvature under different air pressures and assembly configurations [4]. Therefore, the required data can be found from this pressure library, and the assembly method of the interference plates can be correspondingly changed to achieve the desired local stiffness [7]. After the first operation, analyze the obtained internal structure to determine the required force load for the elephant trunk robot, search the corresponding data in the finite element analysis database, then install the interference plate using the corresponding assembly method found from the query, and proceed with the operation.

Connect the sensor's output to a signal conditioning circuit, and then to a microcontroller or control unit. Use signal conditioning circuits (such as amplifiers, filters) to enhance and purify the sensor signal, making it suitable for digital processing. Convert the analog signal to a digital signal through an analog-to-digital converter (ADC) so that the microcontroller can read and process it. Write control algorithms on the microcontroller to adjust the air pressure of the SPAs based on sensor input. For example, when the sensor detects a specific pressure, the algorithm triggers an increase or decrease in the air pressure of the SPAs. Ensure that the control system can respond to sensor inputs in real-time to quickly adjust the robot's movements. This paper provides a design scheme but does not give a detailed control scheme between the sensor and the robot [8-9].

3.2. Piezoelectric Tactile Sensor

Piezoelectric tactile sensors have many advantages in this design scheme. First, lead zirconate titanate (PZT) has a high piezoelectric coefficient, which means they can produce a significant voltage response to minor mechanical stress changes. This allows the sensors to be highly sensitive and detect even the slightest changes. The ability of robots to perceive its environment and respond quickly to external stimuli is crucial to the operation of soft robots. At the same time, due to their good flexibility and plasticity, piezoelectric tactile sensors can be combined with the robot's flexible structure, reliably completing tasks and achieving goals in a variety of different working environments and conditions. The sensors themselves are small in size and easy to integrate into the top of the robot, without adding extra volume or weight, which maximizes the robot's flexibility and lightness [10-11].

In addition, PZT materials and their composites have the advantages of good stability, easy doping modification, high sensitivity, fast response speed, and a large piezoelectric constant. PZT is prepared from raw materials such as PbO, ZrO2, and TiO2 [12]. It has the advantages of low cost, fast response, high precision, and good chemical inertness, and has been widely used in the field of MEMS and other areas.

3.3. Infrared sensors

Infrared sensors are devices that use infrared radiation for detection and measurement. They can sense and measure infrared radiation and are widely used in remote control, security systems, temperature measurement, and other fields. The working principle is mainly based on the interaction between infrared radiation and matter, including the thermoelectric effect, photoelectric effect, and pyroelectric effect. In this design scheme, an infrared thermal imaging visual sensor is selected [7].

Thermal imaging CCD cameras create images by detecting differences in thermal radiation emitted or reflected from objects in a scene. Therefore, they can operate under various lighting conditions, providing strong support for solving problems such as shadows, abrupt changes in lighting, and nighttime visibility that affect traditional computer vision [13].

4. Discussion

In the design proposed in this paper, the elephant trunk-like structure can be flexibly moved and operated in narrow or hard-to-reach spaces, and can perform complex actions such as bending to adapt to different maintenance environments and task requirements. By altering local stiffness, the elephant trunk-like soft robots can adjust their hardness or flexibility according to the specific demands of the task, and work in conjunction with the piezoelectric tactile sensors and infrared sensors mentioned earlier for precise detection and analysis, ensuring the accuracy and reliability of the maintenance work. Furthermore, upon detecting contact, the robot can perform obstacle avoidance maneuvers through pneumatic actuators. soft robots are usually designed to be easy to maintain and repair, which reduces downtime due to faults. They also have excellent environmental adaptability, strong safety features, and good human-robot interaction, which is crucial for improving work efficiency and reducing human errors.

By integrating sensing sensor technology and innovative flexible robot structures, this design solution broadens the scope of flexible robot applications and also provides new possibilities for the design and functions of future robots. It helps to improve industrial automation, increase productivity and quality, while reducing the risk of injury to employees, thus contributing to more sustainable industrial production and operations. Additionally, the high adaptability and sensitivity of flexible robots provide a more natural and comfortable experience when interacting with humans.

As technology advances and production costs decrease, the scope of soft robots will continue to expand, and their role in future society will become increasingly important. After being widely used in industrial equipment maintenance, this technology can then perform precision assembly, inspection and maintenance tasks on automated production lines, while relying on its flexible characteristics to access narrow or dangerous areas. In precision agriculture, they can be used for harvesting, sowing and crop monitoring. In deep-sea exploration and sampling, their flexible structure can adapt to high pressure and complex underwater environments to complete exploration and sampling tasks. In radioactive or toxic environments, they can assist manual operations and reduce the risk of worker exposure.

5. Conclusion

In this paper, a design scheme for a soft robot is proposed, which can perform basic maintenance work on large mechanical equipment. The robot has basic obstacle avoidance capabilities and is equipped with a primary visual system to assist it in operating in low-light and dark environments. Unlike the research directions of various teams mentioned earlier, this scheme has a high degree of sensor integration, enabling linkage and continuous motion of the robot.

Due to limitations in resources and time, the author was unable to implement the design scheme, and thus could not confirm whether the actual operating efficiency would be as high as theoretically predicted. Moreover, the scope of the proposed scheme is currently limited to a relatively small range. Additionally, the limited sample size of the research subjects will to some extent affect the universality of the scheme.

In the future, the focus will be on efficient collaboration between robots and sensors. Regarding the design of the electrical components, efforts will be made to ensure the smooth implementation of this scheme.

References

[1]. Jiang, H., Wang, Z., Jin, Y., Chen, X., Li, P., Gan, Y., ... & Chen, X. (2021). Hierarchical control of soft manipulators towards unstructured interactions. The International Journal of Robotics Research, 40(1), 411-434.

[2]. Guan, Q., Sun, J., Liu, Y., Wereley, N. M., & Leng, J. (2020). Novel bending and helical extensile/contractile pneumatic artificial muscles inspired by elephant trunk. Soft robotics, 7(5), 597-614.

[3]. Mishra, M. K., Samantaray, A. K., & Chakraborty, G. (2022). Joint-space kinematic control of a bionic continuum manipulator in real-time by using hybrid approach. IEEE Access, 10, 47031-47050.

[4]. Ma, K., Chen, X., Zhang, J., Xie, Z., Wu, J., & Zhang, J. (2023). Inspired by physical intelligence of an elephant trunk: Biomimetic soft robot with pre-programmable localized stiffness. IEEE Robotics and Automation Letters, 8(5), 2898-2905.

[5]. Wan, Y., Wang, Y., & Guo, C. (2017). Recent progresses on flexible tactile sensors. Materials Today Physics, 1: 61-73.

[6]. Hannan, M.W., & Walker, I.D. (2001). The 'elephant trunk' manipulator, design and implementation. 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No.01TH8556), 1, 14-19 vol.1..

[7]. Wang, S., Bao, J. & Fu, Y. (2017). Real-time motion planning for robot manipulators in unknown environments using infrared sensors. Robotica, 25(2): 201-211.

[8]. Hu, J., Zhang, J., Zheng, Y., Wang, B., Wu, J., Wang, X., & Yang, Y. (2024). Hybrid-Driven Continuum Robot with Decoupled Motion Patterns for Dexterous Manipulation. IEEE Robotics and Automation Letters.

[9]. Wang, X., & Rojas, N. (2024, April). Cosserat Rod Modeling and Validation for a Soft Continuum Robot with Self-Controllable Variable Curvature. In 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft) (pp. 705-710). IEEE.

[10]. Wu, W. Q., Wang, C. F., Han, S. T., & Pan, C. F. (2024). Recent advances in imaging devices: image sensors and neuromorphic vision sensors. Rare Metals, 1-29.

[11]. Dargahi, J. (2000). A piezoelectric tactile sensor with three sensing elements for robotic, endoscopic and prosthetic applications. Sensors and Actuators A-physical, 80, 23-30..

[12]. Ning, L. & Gao G. (2022). Research Progress of PZT-Based Piezoelectric Tactile Sensor. Piezoelectrics & Acoustooptics, 44 (4), (2022): 625.

[13]. Zhang X., Ding Y., and Yan P. (2011). Visual Inspection of Metal Surface Defects Based on Infrared Imaging. Acta Optica Sinica, 31(3): 312004-1

Cite this article

Hu,Y. (2024). Design Scheme of a Flexible Robot Inspired by an Elephant Trunk with Integrated Infrared and Tactile Sensors. Applied and Computational Engineering,106,81-86.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 2nd International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Jiang, H., Wang, Z., Jin, Y., Chen, X., Li, P., Gan, Y., ... & Chen, X. (2021). Hierarchical control of soft manipulators towards unstructured interactions. The International Journal of Robotics Research, 40(1), 411-434.

[2]. Guan, Q., Sun, J., Liu, Y., Wereley, N. M., & Leng, J. (2020). Novel bending and helical extensile/contractile pneumatic artificial muscles inspired by elephant trunk. Soft robotics, 7(5), 597-614.

[3]. Mishra, M. K., Samantaray, A. K., & Chakraborty, G. (2022). Joint-space kinematic control of a bionic continuum manipulator in real-time by using hybrid approach. IEEE Access, 10, 47031-47050.

[4]. Ma, K., Chen, X., Zhang, J., Xie, Z., Wu, J., & Zhang, J. (2023). Inspired by physical intelligence of an elephant trunk: Biomimetic soft robot with pre-programmable localized stiffness. IEEE Robotics and Automation Letters, 8(5), 2898-2905.

[5]. Wan, Y., Wang, Y., & Guo, C. (2017). Recent progresses on flexible tactile sensors. Materials Today Physics, 1: 61-73.

[6]. Hannan, M.W., & Walker, I.D. (2001). The 'elephant trunk' manipulator, design and implementation. 2001 IEEE/ASME International Conference on Advanced Intelligent Mechatronics. Proceedings (Cat. No.01TH8556), 1, 14-19 vol.1..

[7]. Wang, S., Bao, J. & Fu, Y. (2017). Real-time motion planning for robot manipulators in unknown environments using infrared sensors. Robotica, 25(2): 201-211.

[8]. Hu, J., Zhang, J., Zheng, Y., Wang, B., Wu, J., Wang, X., & Yang, Y. (2024). Hybrid-Driven Continuum Robot with Decoupled Motion Patterns for Dexterous Manipulation. IEEE Robotics and Automation Letters.

[9]. Wang, X., & Rojas, N. (2024, April). Cosserat Rod Modeling and Validation for a Soft Continuum Robot with Self-Controllable Variable Curvature. In 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft) (pp. 705-710). IEEE.

[10]. Wu, W. Q., Wang, C. F., Han, S. T., & Pan, C. F. (2024). Recent advances in imaging devices: image sensors and neuromorphic vision sensors. Rare Metals, 1-29.

[11]. Dargahi, J. (2000). A piezoelectric tactile sensor with three sensing elements for robotic, endoscopic and prosthetic applications. Sensors and Actuators A-physical, 80, 23-30..

[12]. Ning, L. & Gao G. (2022). Research Progress of PZT-Based Piezoelectric Tactile Sensor. Piezoelectrics & Acoustooptics, 44 (4), (2022): 625.

[13]. Zhang X., Ding Y., and Yan P. (2011). Visual Inspection of Metal Surface Defects Based on Infrared Imaging. Acta Optica Sinica, 31(3): 312004-1