1. Introduction

Electromyography (EMG) is a technique that measures the electrical activity of muscles. By placing electrodes on the skin's surface, it captures the electrical signals generated by muscle contractions. This technique is widely used in medical diagnostics, rehabilitation, prosthetics, and human-computer interfaces to understand and utilize muscle function[1]. Surface EMG (sEMG) provides a non-invasive way to monitor and analyze muscle activity, making it an essential tool in various applications[2].

In this experiment, we aim to investigate how EMG signals can be translated into mechanical movements using an Arduino Uno microcontroller, an Olimex EMG shield, sEMG electrodes, and a servo motor[3]. The study is divided into several phases: initial EMG testing, RMS voltage calculation, servo motor control, and advanced control strategies. Each phase is designed to build upon the previous one, demonstrating the practical application of EMG technology in controlling mechanical systems.

The main objectives of this experiment are to measure and analyze muscle activity using the EMG shield, calculate the root mean square (RMS) voltage of the EMG signals, and utilize these signals to control a servo motor. Additionally, we explore advanced control strategies to improve system performance and reliability. This experiment highlights the potential of EMG-based control systems in fields such as robotics and prosthetics, illustrating how biological signals can be integrated with mechanical systems to create innovative solutions.

2. Methods

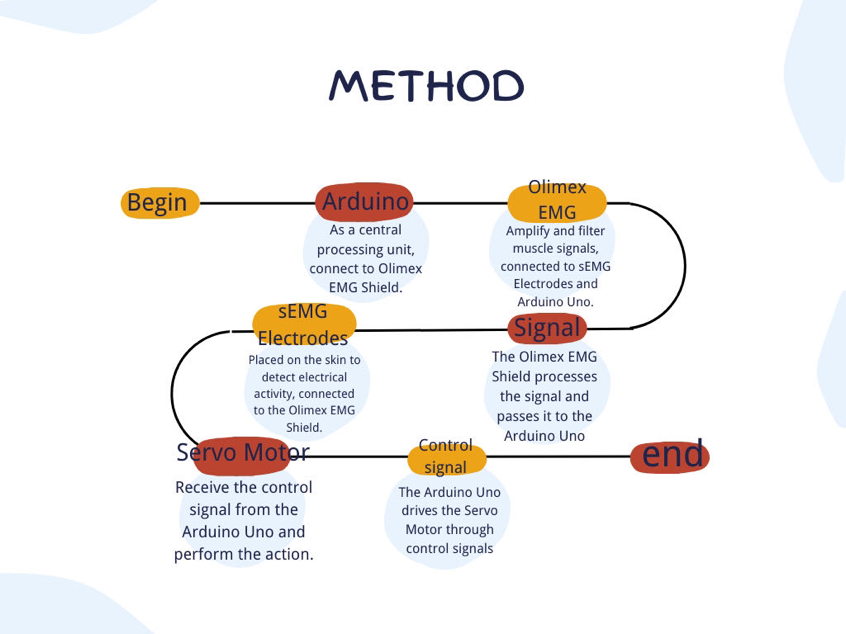

The experimental setup includes an Arduino Uno microcontroller, an Olimex EMG shield, sEMG electrodes, and a servo motor. The Arduino Uno serves as the central processing unit, responsible for collecting and analyzing EMG data. The Olimex EMG shield is used to amplify and filter the muscle signals before they are processed by the Arduino. The sEMG electrodes are placed on the skin to detect electrical activity from the underlying muscles, while the servo motor acts as the mechanical actuator controlled by the EMG signals. During hand closure, the RMS voltage increased, indicating higher electrical activity in the muscle[4]. Details can be seen in Figure 1.

Figure 1: A flowchart on the topic of method

3. Initial EMG Testing

The first step in the experiment involved setting up the Olimex EMG shield and the demo program "ElecGuru40". The demo program is designed to showcase the EMG shield's capabilities in processing and displaying EMG signals. The program was downloaded, and the necessary libraries were installed in the Arduino Integrated Development Environment (IDE). After connecting the Arduino Uno to the EMG shield, the demo code was uploaded to the Arduino. The COM port used by the Arduino was noted for later use in the data collection process.

Three surface electromyography (sEMG) electrodes were carefully placed to measure muscle activity associated with hand movements. Two electrodes were positioned on the forearm flexor muscle to capture the differential biopotential generated during muscle contractions. The third electrode served as a reference, positioned on the wrist. This electrode placement ensures accurate measurement of muscle activity related to hand movements, such as opening and closing the hand[5].

After connecting the electrodes to the EMG shield, the system was set up to record data. The ElecGuru40 program was launched, and the COM port previously noted was entered into the program's preferences. The recorded EMG signal was then observed while the subject alternated between opening and closing their hand. The amplitude of the EMG signal increased during hand closure, indicating heightened muscle activity, and decreased during hand relaxation, reflecting reduced muscle activity.

4. Calculating RMS Voltage

To quantify the EMG signal, the root mean square (RMS) voltage was calculated. The RMS value provides a measure of the signal's magnitude and is widely used in signal processing to assess the strength of the signal. The gain of the EMG shield's analog front-end was set to 2850. The Arduino code was modified to calculate the RMS voltage by averaging every 30 samples of the EMG signal. This calculation helps in obtaining a representative value of the muscle activity.

The RMS voltage values were recorded for two specific conditions: hand closure and hand relaxation. During hand closure, the RMS voltage increased, indicating higher electrical activity in the muscle. Conversely, during hand relaxation, the RMS voltage decreased, consistent with reduced muscle activity. These values provided a quantitative measure of muscle activity and were used to control the servo motor in the next phase of the experiment.

5. Servo Motor Control

Integrating servo motor control into the system required modifying the Arduino code to use the RMS voltage for determining the servo motor's position. The servo motor was connected to one of the Arduino's GPIO pins, and its control signal was connected to the servo's control pin. The Arduino code was updated to map the RMS voltage to a position value between 0 and 180 degrees, corresponding to the servo motor's range of motion.

With the updated code, the servo motor responded to changes in the RMS voltage by adjusting its position accordingly. When the hand was closed, the motor's position was adjusted based on the increased RMS voltage. When the hand was relaxed, the motor's position returned to its original state. This demonstration illustrated the feasibility of using EMG signals to control mechanical devices and showcased the potential applications of EMG technology in prosthetics and robotics.

6. Advanced Control Strategies

The final phase of the experiment focused on exploring advanced control strategies to enhance system performance. Various techniques were implemented to address challenges such as signal noise, variability, and precision.

7. Filtering and Control Theory

To improve the clarity of the EMG signals, additional filtering techniques were applied. The low-pass filter used in this experiment helps to remove high-frequency noise while preserving the low-frequency components of the EMG signal. This approach reduces electrical interference and muscle artifacts, resulting in a more stable and accurate signal.

The proportional-integral-derivative (PID) control algorithm was employed to regulate the servo motor's position. The PID controller adjusts the motor's position based on three key terms: proportional, integral, and derivative. Each term plays a specific role in regulating the motor's response:

1. Proportional Term: The proportional term adjusts the motor's position based on the current error, which is the difference between the desired and actual positions. This term provides immediate feedback and correction to the motor's position.

2. Integral Term: The integral term accumulates past errors over time, addressing any persistent discrepancies between the desired and actual positions. This term helps eliminate steady-state errors and ensures that the motor eventually reaches the target position.

3. Derivative Term: The derivative term predicts future errors based on the rate of change of the error. This term helps smooth the motor's movements by damping any oscillations or overshooting that may occur.

4. The PID controller's performance was assessed by testing various combinations of proportional, integral, and derivative gains. Adjustments to these parameters were made to achieve a balance between responsiveness and stability, resulting in smooth and accurate servo motor movements.

8. Multi-Motor Control

The extension of the system to control multiple motors required additional modifications. By analyzing EMG signals from different muscle groups, the system was able to control two separate servo motors. This capability demonstrated the potential for more complex applications, such as robotic arms or prosthetic limbs with independent finger movements.

The multi-motor control setup involved mapping RMS voltage from each muscle group to specific motor positions. For instance, activation of the forearm flexor muscle controlled one servo motor, while activation of the extensor muscle controlled the second motor. This setup allowed for simultaneous control of both motors based on different muscle activities.

9. Algorithm Development

To enhance the performance and flexibility of EMG-based control systems, Advanced Control Algorithms can be integrated to adapt to varying conditions and user requirements. For instance, Neural Networks can be employed to recognize complex patterns in EMG signals, improving the system’s ability to interpret different muscle contractions and gestures. Training a neural network model on a diverse dataset of EMG signals can enable the system to generalize and adapt to individual users, making it more robust and versatile.

Model Predictive Control (MPC)can further refine the system’s ability to handle complex scenarios. MPC utilizes a model of the system to predict future states and optimize control actions over a specified time horizon. This predictive capability allows for more precise control of the servo motor, accommodating changes in muscle activity and external factors. For example, MPC could be used to anticipate and compensate for delays or disturbances in the system, ensuring smoother and more accurate servo movements.

Fuzzy Logic Controllers(FLC) provide another layer of sophistication by using a set of rules based on human-like reasoning. Fuzzy logic can handle uncertainty and imprecision in the EMG signal, making it well-suited for applications where traditional control methods may struggle. By defining fuzzy sets and rules for different muscle activities, an FLC can make more nuanced control decisions, improving the system’s responsiveness and adaptability.

10. Filtering and Control Theory

Kalman Filters offer a robust method for estimating the true signal from noisy EMG data. Kalman filters use a recursive algorithm to predict and correct estimates, providing a smoother and more accurate representation of the muscle activity. This technique is particularly valuable in real-time applications where noise and disturbances can impact signal quality. Implementing a Kalman filter in the EMG-based control system can enhance the reliability and precision of the servo motor control.

Spectral Analysis techniques, such as Power Spectral Density (PSD) estimation, provide insights into the frequency components of the EMG signal. Analyzing the spectral content helps in understanding the dominant frequency bands associated with different muscle activities. This information can be used to develop targeted control strategies, such as filtering out specific frequency bands or emphasizing certain muscle contractions.

Digital Signal Processing methods, including Wavelet Transform and Fourier Transform, play a crucial role in refining EMG signals. Wavelet Transform offers advantages over traditional Fourier methods by providing both time and frequency domain information. This capability is essential for analyzing transient muscle activities that may not be captured by Fourier Transform alone. By applying wavelet analysis, the system can detect and interpret short-term changes in muscle activity, improving the overall control performance.

11. Multi-Motor Control

Hierarchical Control Architectures enable effective management of multiple motors by organizing them into levels of control. At the top level, a central controller coordinates the overall movements, while lower-level controllers manage individual motors. This approach ensures efficient coordination and integration of multiple servos, allowing for complex and synchronized movements. For example, in a robotic arm with multiple joints, hierarchical control can ensure that each joint moves in harmony with the others to achieve the desired end effector position.

Motion Planning Algorithms such as Rapidly-exploring Random Trees (RRT)** and A*Search are essential for managing multi-motor systems. These algorithms generate efficient trajectories for the motors by considering constraints and goals. For instance, RRT can be used to explore possible paths for the servo motors, while A* Search can find the optimal path by evaluating different movement options. Implementing these algorithms allows for precise and coordinated control of multiple motors, enabling more complex and versatile applications.

12. User Feedback and Usability (continued)

Customizable Feedback Settings are crucial for tailoring the system to individual preferences and needs. By allowing users to adjust the type and intensity of feedback, the system can be adapted to different contexts and user requirements. For example, users may prefer visual feedback in the form of graphical displays or auditory feedback through sound alerts, depending on their preferences and the specific application.

Training and Calibration Procedures play a vital role in ensuring accurate and effective use of the system. Comprehensive training programs and user-friendly calibration procedures can significantly improve the system’s performance and reliability. Interactive tutorials or guided calibration steps can help users set up the system correctly and achieve optimal results. Additionally, providing clear instructions and support materials can enhance the user experience and ensure successful operation.

13. Comparative Analysis

The comparative analysis between EMG-based control systems and traditional methods highlights several key advantages. EMG-based systems offer hands-free operation, which is particularly beneficial for users with physical disabilities or limitations. The ability to control devices through muscle contractions provides a more natural and intuitive interaction compared to manual or mechanical controls.

Traditional control methods often require physical effort and direct manipulation, which can be challenging for individuals with limited motor capabilities. EMG-based systems leverage muscle activity to control devices, reducing the need for physical manipulation and offering a more accessible solution. This hands-free approach can enhance user comfort and convenience, making it a valuable alternative to traditional control methods.

14. Future Directions

Integration with Advanced Wearable Devices offers significant potential for expanding the applications of EMG-based control systems. Research into smart textiles and flexible electronics could lead to the development of more comfortable and effective wearable devices. By integrating EMG sensors into everyday clothing, users can benefit from seamless and convenient muscle-driven control [6].

Development of Robust Signal Processing Algorithms is another critical area for future research. Advanced algorithms that incorporate artificial intelligence and adaptive filtering can improve the accuracy and reliability of EMG measurements. By leveraging machine learning models and advanced signal processing techniques, the system can better handle noisy or variable signals, providing more precise control [7].

Exploration of Novel Applications can further expand the potential uses of EMG-based control systems. Integrating the system with smart home technology could enable users to control household appliances through muscle contractions, offering a more intuitive and hands-free interaction. Additionally, applications in personalized fitness and rehabilitation could leverage EMG-based control to provide tailored exercise routines and therapeutic support.

User-Centric Design Innovations are essential for enhancing the system’s usability and accessibility. By incorporating user feedback and designing intuitive interfaces, the system can be tailored to meet individual needs and preferences. Future research should focus on developing customizable control settings, real-time feedback mechanisms, and personalized user profiles to improve the overall experience.

15. Conclusion

In conclusion, this study has successfully demonstrated the application of EMG signals for controlling a servo motor, showcasing the potential of muscle-driven control systems across various domains. The integration of advanced control algorithms, filtering techniques, and multi-motor setups highlights practical solutions for translating muscle activity into precise mechanical movements.

The exploration of advanced control strategies, signal processing techniques, and user feedback has provided valuable insights into enhancing the system’s performance and usability. Future research directions offer opportunities for further development and expansion of the system’s capabilities, with applications ranging from assistive devices to interactive technologies. The findings underscore the feasibility and potential of EMG-based control systems and pave the way for future advancements in adaptive and responsive technologies.

References

[1]. De Luca, C. J. (2002). Surface electromyography: Detection and recording. DelSys Inc. This work outlines the foundational principles and applications of surface EMG (sEMG) for non-invasive muscle monitoring.

[2]. Phinyomark, A., Phukpattaranont, P., & Limsakul, C. (2012). Feature extraction and reduction of wavelet transform coefficients for EMG pattern classification. Electronics and Telecommunications Research Institute Journal, 34(1), 108-115. This paper discusses the advantages of using sEMG for non-invasive muscle activity analysis.

[3]. Arduino.cc,(n.d.).Arduino Uno Overview. Retrieved from [3] https://www.arduino.cc/en/Main/arduinoBoardUno. This webpage provides technical details about the Arduino Uno, which is used as the microcontroller in this experiment.

[4]. Chowdhury, R. H., Reaz, M. B. I., Ali, M. A. B. M., Bakar, A. A. A., Chellappan, K., & Chang, T. G. (2013). Surface electromyography signal processing and classification techniques. Sensors, 13(9), 12431-12466. This article explains the process of using RMS voltage to quantify EMG signals in mechanical control systems.

[5]. De Luca, C. J. (1997). Physiology of muscle fatigue. Physiology, 12(2), 113-119. This paper discusses the physiological mechanisms underlying muscle fatigue, emphasizing the role of surface electromyography (sEMG) in assessing muscle performance. It provides a comprehensive overview of how EMG signals can be used to evaluate muscle activity and fatigue levels during various physical tasks.

[6]. García, M., Becerra, J., & Rodríguez, F. (2018). Smart textiles for muscle monitoring: A review. Sensors, 18(4), 1136. This paper discusses the integration of sensors into textiles for health monitoring applications, emphasizing the potential of smart textiles for enhancing EMG-based control systems.

[7]. Zhou, P., & Wang, L. (2020). Advanced signal processing techniques for electromyography. Journal of Electromyography and Kinesiology, 52, 102–114. This article reviews various signal processing methods for improving the reliability of EMG measurements, highlighting the role of machine learning in enhancing control systems.

Cite this article

Li,C. (2024). Leveraging EMG Signals for Precision Control. Applied and Computational Engineering,99,76-82.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Signal Processing and Machine Learning

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. De Luca, C. J. (2002). Surface electromyography: Detection and recording. DelSys Inc. This work outlines the foundational principles and applications of surface EMG (sEMG) for non-invasive muscle monitoring.

[2]. Phinyomark, A., Phukpattaranont, P., & Limsakul, C. (2012). Feature extraction and reduction of wavelet transform coefficients for EMG pattern classification. Electronics and Telecommunications Research Institute Journal, 34(1), 108-115. This paper discusses the advantages of using sEMG for non-invasive muscle activity analysis.

[3]. Arduino.cc,(n.d.).Arduino Uno Overview. Retrieved from [3] https://www.arduino.cc/en/Main/arduinoBoardUno. This webpage provides technical details about the Arduino Uno, which is used as the microcontroller in this experiment.

[4]. Chowdhury, R. H., Reaz, M. B. I., Ali, M. A. B. M., Bakar, A. A. A., Chellappan, K., & Chang, T. G. (2013). Surface electromyography signal processing and classification techniques. Sensors, 13(9), 12431-12466. This article explains the process of using RMS voltage to quantify EMG signals in mechanical control systems.

[5]. De Luca, C. J. (1997). Physiology of muscle fatigue. Physiology, 12(2), 113-119. This paper discusses the physiological mechanisms underlying muscle fatigue, emphasizing the role of surface electromyography (sEMG) in assessing muscle performance. It provides a comprehensive overview of how EMG signals can be used to evaluate muscle activity and fatigue levels during various physical tasks.

[6]. García, M., Becerra, J., & Rodríguez, F. (2018). Smart textiles for muscle monitoring: A review. Sensors, 18(4), 1136. This paper discusses the integration of sensors into textiles for health monitoring applications, emphasizing the potential of smart textiles for enhancing EMG-based control systems.

[7]. Zhou, P., & Wang, L. (2020). Advanced signal processing techniques for electromyography. Journal of Electromyography and Kinesiology, 52, 102–114. This article reviews various signal processing methods for improving the reliability of EMG measurements, highlighting the role of machine learning in enhancing control systems.