1. Introduction

In recent years, 3D printing technology has been developing in depth in the field of food, and many literature have pointed out the application of 3D printing technology in food, and studied how to improve the printing materials needed to improve the success rate or quality of printing. Most of the literature mentions the problems and difficulties in the development of 3D food printing technology into a common technology, but no actual questionnaire research has been carried out. So the finishing on the basis of predecessors’ research contents, this paper delves into the 3D printing technology applied in the field of food, in order to increase understanding of 3D printing technology food, using questionnaire survey to explore the present people’s opinions about food for 3D printing technology, find problems and challenges in the development of this technology, and help this technology to popularization.

2. 3D printing technology

2.1. Basic principles of 3D printing technology

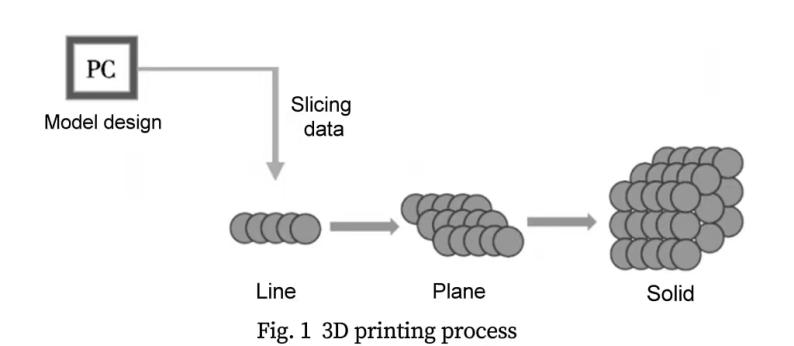

3D printing technology is based on the production of layered manufacturing method, and gradually developed an intelligent manufacturing technology. After modeling in the computer modeling software, the file is stored in STL format, and then imported into the slicing software to slice the 3D model layer by layer. Finally, according to the transmitted slice data, the 3D printer uses light-curing and paper layering and other technologies to print layer by layer on a plane. After the accumulation of layers, a three-dimensional 3D product is quickly formed. The basic process of 3D printing is shown in Figure 1 and the finished product of 3D printing is shown in Figure 2.

Figure 1. 3D printing process.

Figure 2. 3D printed products.

2.2. The development trend of 3D printing technology

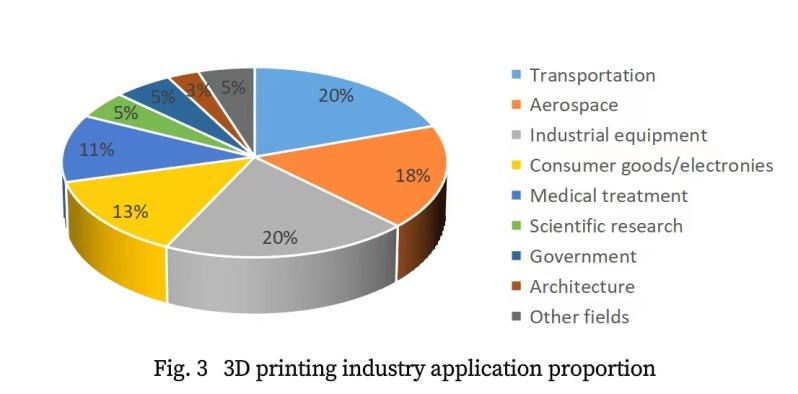

3D printing technology along with the advance of science and technology, the material utilization, energy consumption and the processing and manufacturing efficiency compared with the traditional way of manufacturing has obvious advantages, and the diversity of the material selection of 3D printing, so is gradually widely used in various manufacturing areas, such as aerospace, construction, industrial machinery, automobile, etc., as shown in Figure 3. According to the information in Figure 3, it is not difficult to find that the application of 3D printing technology is getting closer and closer to people’s life. In recent years, because of the personalized and free manufacturing characteristics of this technology, 3D printing technology has also been combined with the food neighborhood, and 3D food printer has been developed on the basis of the original 3D printer, so the application of 3D technology in food has become the main trend of future development.

Figure 3. 3D printing industry application proportion.

3. 3D food printing technology

3.1. Basic principles of 3D food printing technology

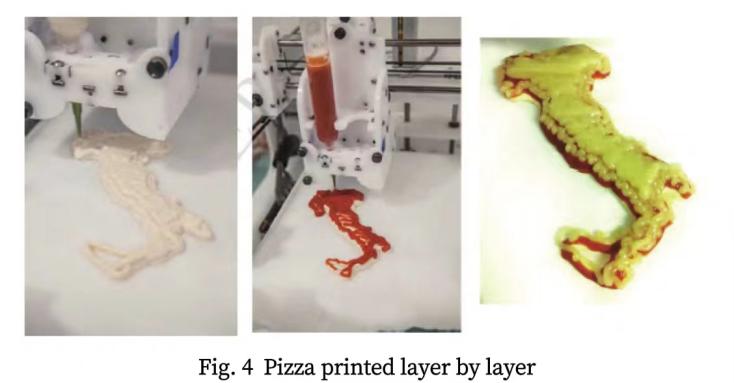

A 3D food printer, as the name suggests, is a machine that can “print” food, and it works in a similar way to a 3D printer. It uses a new electronic blueprint system that allows people to design their own food and “print” it. The printing materials used in 3D food printers are edible ingredients, in the form of paste or liquid, such as chocolate sauce, batter and syrup. People on a dedicated computer modeling software modeling drawing the kind of food to print, then the plane down into layers, namely layered slices, after the transmission of data to the 3 d food printer, installed the required food raw material, the printer will be in accordance with the received data to squeeze out the raw material, layer upon layer print (as shown in figure 4), the generated three-dimensional object of edible.

Figure 4. Pizza printed layer by layer.

3.2. History of development

Western countries were the first to apply 3D printing technology to food. American Charles Hull invented 3D printing, also known as stereoscopic printing, in 1984 and developed the world's first commercial 3D printing machine in 1986. In 2011, Godoi from Cornell University proposed and developed a 3D injectable printing device for food manufacturing. The raw material is mainly liquid. In the same year, the research institute of the University of Exeter made the first 3D food printer based on chocolate, which entered the market in 2012 after undergoing technical improvements [1]. In 2013, Spain's Natural Machines created the first commercial 3D food printer, called the Foodini (Figure 5). The machine has six nozzles and five “cartridges” set up inside to store ingredients made from carbohydrates, proteins and other nutrients, just as a normal printer contains different colored cartridges. In 2014, Biozoon, a German company, developed a 3D food printer to make delicious and easy to swallow food for the elderly. It adds food-grade coagulant to the raw materials to melt the food formed layer by layer into a whole, ensuring the food shape is complete and exquisite. In the same year, Serizawa, an American company, developed a 3D food glue printer to print soft food for the elderly. In May, Hao Liang developed the second generation of chocolate 3D printer ChocCreator 2.0, a new generation of 3D chocolate printer, which has greatly improved its speed and accuracy. In April 2016, Food Ink, the world's first 3D-printed restaurant, opened in the Netherlands. All the items in the restaurant are 3D printed. So far, there have been more than 10 industrial-grade 3D food printers on the market.

Figure 5. Foodini and the food it printed.

3.3. Current application of 3D printing technology in food area

3.3.1. Fruits, vegetables and snacks. The ingredients of 3D-printed food are mostly powders and liquids because they are easy to mix, easy to keep and have a longer shelf life. Foods such as chocolate and cake are also among the first to be 3D printed because the ingredients are so close to the ideal ingredients for food printing that they have a high chance of being printed successfully and do not need to be heated before being eaten. In addition, when combined with 3D food printing, the shape of fruits and vegetables or snacks can be customized by people, reflecting personalized characteristics. Like some too complex and detailed cookie patterns, may not be able to be made manually, but after changing the raw material formula, perfect print. In addition, 3D food printing technology has made some snacks healthier. Some traditional snacks are high in oil and sugar, which will affect people's health if consumed for a long time. Therefore, food printing technology can reduce the content of oil and sugar in raw materials to meet the nutritional needs of diversified people.

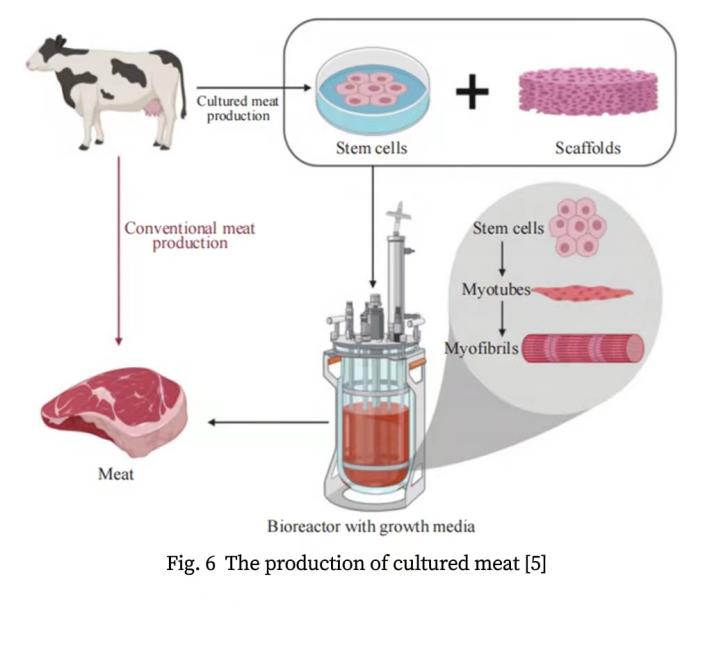

3.3.2. Meat. Meat provides the body with protein, and the ingredients are heated during the printing process of 3D food printers, which improves food safety and taste. However, such food needs to be heated before it can be eaten after 3D printing, and further experiments are needed to determine whether the heating will affect the printed food. In addition, the printing of meat food is very little at present, and direct meat raw materials cannot be applied to 3D food printing, so the application of this technology in meat needs to be further improved. At present, there is a technology for cell culture of meat, mainly using the principles of tissue engineering (Figure 6), animal stem cells are used to grow "biological meat" by in vitro cell culture. This kind of cell culture meat oversteps the traditional livestock rearing process, and the quality of the meat is not significantly different from the conventional one.

Figure 6. The production of cultured meat [2].

3.3.3. Special customized food. The biggest advantage of 3D food printing technology is that it can be customized for different people. The 3D-printed food will take into account diverse groups of people, such as athletes, children, pregnant women and patients, etc. According to their conditions, the proportion of food ingredients can be gradually optimized in the design stage, such as reducing the proportion of unnecessary food ingredients (oil and sugar) or the characteristics of the ingredients themselves, while increasing the proportion of healthy ingredients. It can also provide convenient chewing and digesting food for the elderly in nursing homes and hospitals [3]. Another feature of customization is the creative nature of the food's appearance. Food printing offers great creative space and flexibility, making it a great platform for creative chefs and other users. Some sellers or parents can also use the "visual impact" of food to increase consumers' desire to buy or children's appetite. In addition, some special industries, such as aerospace and military, have also started to invest a lot of money to develop food 3D printers [4], such as NASA, so that astronauts can also eat delicious food in space.

4. Influencing factors of 3D food printing technology

4.1. Interior factors

The raw material used for printing is an internal factor affecting 3D food printing. In the process of food 3D printing, food materials may collapse and deform due to their own weight. Therefore, the selection of raw materials has a great influence on the success of 3D food printing, which is mainly reflected in the consistency, raw material status, characteristics and so on.

The gelatinization of starch has a great influence on the success of printing. Under the gas pressure, the starch internal molecules will shrink, through the nozzle extrusion, the molecules will expand, so the printing effect is reduced, the shape is also affected; Oligosaccharide (a general term for saccharide formed by 2-10 monosaccharide molecules connected by glycosidic bonds) has little solubility and functions as edible fiber and thickening agent. When combined with protein and fat, it can achieve ideal viscosity and print ideal food. Protein polymers carry electrical charges, which can affect the results of 3D printing; Fat-soluble vitamins are easily oxidized, so pay attention to air contact during printing, etc. The main ingredients of these foods have a significant impact on the 3D printing process.

4.2. External factors

Temperature is a big external factor that affects print results. Different raw materials need to be printed and molded at different temperatures, so as to ensure smooth extrusion of raw materials and smooth molding of materials. Raw materials need to be heated to a certain temperature, from the nozzle to the platform, the temperature is too high will affect the cooling molding time, will also destroy the taste of food. Therefore, chocolate and candy are generally printed at high temperature, while meat and pasta are generally printed at room temperature [5].

Different extrusion methods will affect the appearance of the printed product. Common extrusion methods include pressure type, spiral type and syringe type. Pressure extrusion is by pressure extrusion raw materials, can avoid contact with raw materials, but the speed is slow, easy to produce bubbles; Screw extrusion is an electric screw pull down the raw material, reduce bubbles, but will contact with the raw material; Syringe extrusion depends on the machine to produce pressure extrusion raw materials, there will be contact, suitable for printing solid and semi-solid food raw materials.

The distance between the nozzle and the printed food on the platform will affect the molding effect. If the distance is too close, the extruded food will receive pressure, so that the raw materials can not be well formed, and will stick the raw materials in the nozzle, causing pollution and blockage; If the distance is too far, the extruded food will be carried away by the nozzle before it touches the platform, which will lead to the destruction of the previously designed layer structure and the failure to print the ideal appearance.

5. Challenges and trends of 3D food printing technology development

5.1. The challenges of 3D food printing technology development

The first challenge is raw materials. The ingredients of 3D printed food need to meet the requirements of heating and printing, so the choice of ingredients is very limited. And only liquid, powder and paste ingredients can be used, but the food printed from these ingredients is still a certain gap compared with traditional food. At present, some researchers have also developed some new printing materials. For example, Zhang.M et al. have developed surimi gel as a potential material for 3D food printing [6]. Prakash et al. changed the fluidity of materials by changing the temperature during post-processing or adding plasticizer [7]. Gauss et al. studied how cellulose and other substances are applied to 3D printing [8].

Cost and production speed issues will also affect the technology's popularity. A 3D food printer currently costs thousands of euros, and researchers say it could fall to around 500 euros in the next five years, but that's still a lot of money for the average family. In addition to the price of the machine itself, the particularity of the printing material also makes its price become not low. The high cost of 3D food printing makes it impractical to use 3D food printers for large-scale food production in factories, as in the snacking industry, where their main competitive advantage is low price. The speed of 3D printing also depends on the size and complexity of the food blueprint, with a food printer taking more than 40 minutes to produce something that could be made in 10 minutes by hand. So cost and speed of production are the main obstacles to overcome.

Security is also an important issue. Food safety is related to people’s health and life safety, so the food printed by this technology must be guaranteed to be 100 percent safe. 3D food printers need to be cleaned regularly to ensure that the food is clean and hygienic. In the process of printing food, the nozzle of the machine will be stuck with some food ingredients, if not clean for a long time, it is likely to grow bacteria. In addition, even small temperature fluctuations can completely change the nature of the food ingredients, so we should always be aware of the unsafe factors caused by the degeneration of the food ingredients during the printing process.

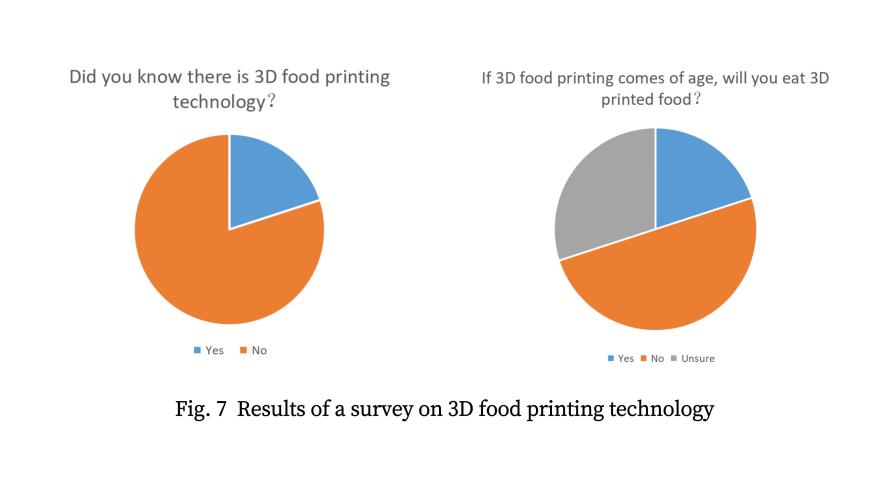

The limitation of traditional concepts is an important factor that makes 3D food technology not popular. In a questionnaire samples of 200 people, the result is shown in Figure 7. Nearly twenty percent of people don’t know how 3D food to print the technique, and even if the technology development of mature, dare to 3D printing foods are few and far between, fifty percent of people will choose not to eat, nearly thirty percent of people are not sure, but only twenty percent of people would choose to eat. Most people have the stereotype that printed food itself is not edible, so how to break the public's perception of 3D food technology is a big problem to solve.

Figure 7. Results of questionnaire on 3D food printing technology.

5.2. The development trends of 3D food technology

3D food printing technology formed by the combination of 3D printing technology and food neighborhood is an important embodiment of the development and progress of contemporary industry. People's eating habits will be greatly changed by this technology in the future, and the world's food supply problem will be solved, and the development will be in the direction of sustainable development. People will not only seek to be able to eat enough, but can eat enough, can eat more healthily. Therefore, 3D food printing will definitely become a very important technology in life and production in the future.

Like 3D printing technology, 3D food printing technology will be applied to more fields. For example, in the field of aerospace, when astronauts are in space, 3D food printing technology can be used to print the food they need because it has no shelf life limit and occupies less space than traditional food. In the field of commercial food, this technology can be used to draw sugar people, and the rendering of plane into three-dimensional three-dimensional rendering, no longer affected by the complexity of the process and human skills. This technology has been gradually integrated into people's life and developed towards various aspects of people’s life and production [9].

In recent years, 4D printing technology has been slowly developed on the basis of 3D printing technology. 4D technology adds the “time” variable to the traditional 3D printing technology, which not only includes the three dimensions of 3D length, width and height, but also adds a time dimension, so that the printed object can adjust itself intelligently in the form and structure with the passage of time, and finally automatically meet the pre-design requirements. If 4D food printing technology is realized, it will be a significant and leap forward revolution in the food industry.

6. Conclusion

In this paper, 3D food printing technology is introduced in detail, focusing on its application and challenges. With the improvement of its own, 3D food printing technology can be applied to more and more area in the future. At present, 3D food printing technology is gradually applied to aviation food and special population food, because different people have slightly different nutritional needs, so 3D food printing can be well used to customize personalized food. And some new alternative materials or hybrid materials are being developed to change the structural properties of materials to meet the requirements of 3D food printing.

The main contribution of this paper is to conduct a practical questionnaire to know people's views on 3D food printing technology. It is also found that the main challenge in the development of this technology is that people's traditional ideas and prejudices about this technology, because their insufficient understanding of this technology.

In order to make 3D food printing technology truly popular, we need to do the following things: develop printing heads that are easy to clean, produce a wider range of food, and more importantly, let people better understand this technology, take the initiative to try and contact, to promote the popularization of this technology.

References

[1]. Kou.D.Z, Yang.W.J, Zhang.X.L, Tan.C.P. Application of 3D printing technology in food industry[J]. Journal of Qilu University of Technology, 2020, 34(03): 11-16.

[2]. Handral H K, Tay H S, Chan W W, et al. 3D Printing of cultured meat products[J]. Crit Rev Food Sci Nutr, 2020, 21: 1−10.

[3]. Zhang.L, Lou.Y, Schutyser M, et al. 3D printing of cereal-based food structures containing probiotics[J]. Food Structure, 2018, 18: 14-22.

[4]. Fang.P. Deep Space food science research helps improve 3D printing capability [J]. Dual-use Technology and Products, 2019, 11: 42-44.

[5]. Tian.Z.P, Huang.L.Q. Application status and development trend of 3D food printing technology[J]. China Academic Journal Publishing House, 2021, 5: 22-26.

[6]. Min.Z, Lin.W, Bhesh.B, et al. Investigation on fish surimi gel as promising food material for 3D printing[J]. Journal of Food Engineering, 2018, 220.

[7]. Prakash S B, Godoi F C, B.R. 3D printing technologies applied for food design: Status and prospects[J]. Journal of Food Engineering, 2016, 179: 44-54.

[8]. Gauss C, Pickering K L, Muthe L P.The use of cellulose in bio-derived formulations for 3D/4D printing: A review[J]. Composites Part C: Open Access, 2021, 4: 100-113.

[9]. Shi.P, Bai.Y.Q. Application of 3D printing technology in food processing[J]. Food industry, 2021, 42(10): 231-234.

Cite this article

Zeng,Y. (2023). The application and challenges of 3D printing technology in food. Applied and Computational Engineering,3,84-90.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Materials Chemistry and Environmental Engineering (CONF-MCEE 2023)

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Kou.D.Z, Yang.W.J, Zhang.X.L, Tan.C.P. Application of 3D printing technology in food industry[J]. Journal of Qilu University of Technology, 2020, 34(03): 11-16.

[2]. Handral H K, Tay H S, Chan W W, et al. 3D Printing of cultured meat products[J]. Crit Rev Food Sci Nutr, 2020, 21: 1−10.

[3]. Zhang.L, Lou.Y, Schutyser M, et al. 3D printing of cereal-based food structures containing probiotics[J]. Food Structure, 2018, 18: 14-22.

[4]. Fang.P. Deep Space food science research helps improve 3D printing capability [J]. Dual-use Technology and Products, 2019, 11: 42-44.

[5]. Tian.Z.P, Huang.L.Q. Application status and development trend of 3D food printing technology[J]. China Academic Journal Publishing House, 2021, 5: 22-26.

[6]. Min.Z, Lin.W, Bhesh.B, et al. Investigation on fish surimi gel as promising food material for 3D printing[J]. Journal of Food Engineering, 2018, 220.

[7]. Prakash S B, Godoi F C, B.R. 3D printing technologies applied for food design: Status and prospects[J]. Journal of Food Engineering, 2016, 179: 44-54.

[8]. Gauss C, Pickering K L, Muthe L P.The use of cellulose in bio-derived formulations for 3D/4D printing: A review[J]. Composites Part C: Open Access, 2021, 4: 100-113.

[9]. Shi.P, Bai.Y.Q. Application of 3D printing technology in food processing[J]. Food industry, 2021, 42(10): 231-234.