1. Introduction

3D printing (3DP) technology is a method for fabricating solid objects by depositing materials layer by layer [1]. The "Made in China 2025" plan issued by the Chinese State Council in 2015 emphasizes the promotion of 3D printing for smart construction to address challenges such as industrial upgrades and labor shortages caused by an aging population [2]. Concrete, being one of the most widely used construction materials, benefits significantly from 3D printing technology. Using 3D printing for concrete can reduce construction waste by 30-60%, save 50-80% in labor costs, and cut production time by 50-70%, while also providing features such as no need for formwork, high geometric freedom, and environmental sustainability [3]. Therefore, research into 3D printed concrete (3DPC) is of considerable importance.

Many scholars worldwide have explored various aspects of 3DPC, including mix design, mechanical properties, and structural design. However, research on 3DPC is still in its early stages compared to traditional concrete (TC). The unique construction methods associated with 3D printing lead to differences in mechanical properties, construction techniques, and structural design compared to traditional concrete structures. Thus, this paper focuses on a literature review of 3DPC mix design and structural design. It first compares the mix designs of 3DPC with traditional cast-in-place concrete, with a focus on studies of binders, aggregates, and fibers. The review then covers the fresh properties and mechanical performance of 3D printed concrete, comparing experimental methods for evaluating the fresh properties and focusing on the interlayer bond strength of 3D printed concrete.

2. Overview of material properties

Various materials can be used for 3D printing, including fibers, metals, composites, ceramics, and concrete. Unlike other types of materials, ceramics and concrete-based materials do not solidify quickly after extrusion. Therefore, concrete and similar materials need to meet specific mechanical properties. Additionally, due to limitations of printing equipment such as nozzle size, pipe diameter, and printing parameters, 3D printed concrete exhibits significant differences in mix design, fresh properties, and hardened properties compared to traditional concrete, as illustrated in Table 1.

Table 1: The difference between TC and 3DPC in mix ratio.

Supplement cementitious materials | Aggregate | Fiber/Reinforcement | Admixture | |

3DPC | Rapid hardening sulphoaluminate cement | Fine aggregate | Polyvinyl alcoholfiber, polypropylene fiber | Viscosity modifying agent, coagulant |

TC | Ordinary Portland cement | Coarse aggregate | Steel bar prestressing steel strand | |

Reason | High early strength | Nozzle size limitation | Making up for tensile strength | satisfying special fresh performance |

3. Mix property of 3DPC

3.1. Cementitious materials

Unlike traditional concrete, this formwork-free construction method requires the concrete to possess sufficient early strength to support the weight of subsequent layers. Numerous researchers have explored the effects of supplementary materials on the printability and mechanical properties of 3DPC. Joanna was the first to investigate the printability of geopolymer concrete based on fly ash (FA) and metakaolin (MK) [4]. They tested two mix ratios: "95% geopolymer + 5% cement" and "5% geopolymer + 95% cement," finding that the "5% geopolymer + 95% cement" mixture exhibited better buildability and printing performance. Li studied the effect of fly ash on the printability of magnesium phosphate cement, finding that while fly ash had minimal impact on setting time, it negatively affected mechanical properties [5]. They found that a fly ash content of 20%–25% of the magnesium phosphate cement weight met the rheological and mechanical performance requirements for 3D printing. These findings underscore the importance of optimizing material compositions to enhance both the printability and structural integrity of 3D-printed concrete, thereby facilitating the successful application of this innovative construction method.

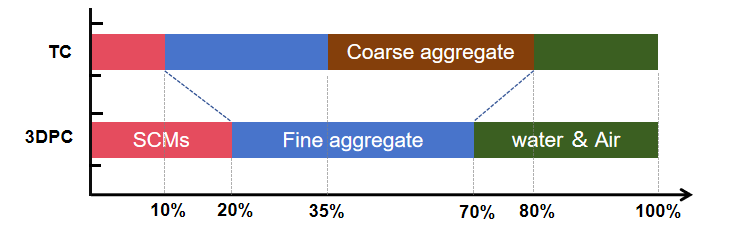

3.2. Aggregate

Due to limitations in printing equipment such as pipe diameter, nozzle size, and concrete extrusion methods, printing with coarse aggregate concrete presents certain challenges. Many researchers have explored the use of fine aggregates, such as quartz sand, to replace traditional coarse aggregates in concrete, as illustrated in Figure 1 [6-7].

Figure 1: Percentage of materials used in traditional concrete (TC) and 3DPC.

Shi investigated the performance of cement mortar made from recycled quartz sand and found that the flowability of the mortar produced with recycled quartz sand was superior to that of the same-grade natural river sand, with lower yield stress and plastic viscosity compared to quartz sand, indicating its potential value in 3D printed concrete [7]. However, the high engineering cost of quartz sand and its limited availability in some regions make it challenging for on-site construction. Consequently, Zhou explored the potential of using aeolian sand as a replacement for quartz sand in 3DPC [6]. Their experimental results showed that when aeolian sand replaced 60% of quartz sand, the compressive strength of 3DPC reached its peak at 28 days.These findings provide viable alternatives to address the challenges posed by coarse aggregate limitations in 3D printing, demonstrating that the strategic use of fine aggregates can enhance both the printability and structural performance of 3DPC, thereby facilitating its application in construction.

3.3. Fiber

The characteristic of concrete having higher compressive strength than tensile strength makes traditional cast concrete structures prone to tensile failure, which is often mitigated by incorporating steel reinforcement. Researchers have also explored the addition of fibers to enhance the tensile strength of concrete [8-9]. 3D-printed concrete (3DPC) faces similar issues with insufficient tensile strength. Therefore, research on fiber-reinforced 3DPC remains a current and popular area of study.

Arunothayan investigated the impact of steel fibers on the mechanical properties of 3DPC [10]. His study revealed that the incorporation of steel fibers significantly improved the mechanical performance of 3DPC, with the highest compressive strength observed parallel to the printing direction. Due to the presence of more interlayer defects in 3D printed structures, the axial compressive strength of 3DPC remains lower than that of cast specimens. Nevertheless, bending strength tests showed that 3D printed specimens had higher bending strength compared to cast specimens. Arunothayan attributed this to the orientation of fibers along the printing plane during the printing process, which enhanced the tensile strength within the printing plane. Additionally, they conducted direct tensile tests to assess the interlayer bond strength of 3DPC, finding that steel fibers also improved interlayer bond strength to some extent. However, the underlying mechanism requires further investigation. While Liu used the cross-cutting method to test the interlayer bond strength of fiber-reinforced 3DPC, aiming to reduce the impact of specimen eccentricity on bond strength results [11]. Their findings indicated that the incorporation of fibers did not enhance the interlayer bond strength of 3DPC.

4. Fresh and harden performance of 3DPC

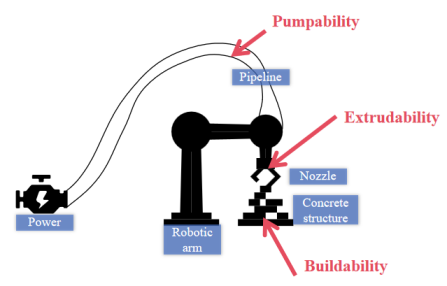

The fresh properties of 3D-printed concrete (3DPC) are crucial for the success of the printing process. Due to the unique construction method of 3D printing, the concrete must be extruded smoothly through narrow conduits, and the previously printed layers must support the weight of subsequent layers, as shown in Figure 2. Therefore, the printability of 3DPC encompasses both extrudability and buildability. However, since the technology for 3D printing concrete is still in its developmental stages, there are no standardized testing methods or procedural guidelines established by governments or relevant institutions. As a result, there is considerable variation among researchers regarding the methods and criteria for assessing the early fresh properties of 3DPC.

Figure 2: 3D printed concrete construction process diagram.

Tests for buildability can be broadly categorized into macro and micro tests [3]. Macro testing involves assessing buildability by monitoring the macro deformation of the component. Le quantified the buildability of 3DPC by the number of printed layers [12]. Ma used a geometric parameter to describe structural stability [13]. Yuan designed a deformation monitoring device to assess the buildability of 3DPC during the printing process [14]. Wolfs developed a numerical model based on the Mohr-Coulomb criterion and linear stress-strain assumptions to predict the early mechanical behavior of 3DPC, which can accurately forecast failure modes of 3D printed structures [15]. Another approach involves evaluating based on rheological properties, including dynamic and static yield stress, viscosity, and thixotropy. Materials with high yield stress, low plastic viscosity, and high thixotropy are more suitable for 3D printing [3]. Jeong theoretically derived the relationship between printing height and the required initial yield strength and hardening coefficient of concrete, which was validated by a fluid dynamics analysis model [16]. Wu investigated the rheological properties of 3D printed recycled aggregate concrete (3DPC-RAC), comparing the effects of 0%, 50%, and 100% replacement rates on buildability [17]. Results showed that, within the first 15 minutes of printing, buildability increased with the replacement rate, and an exponential relationship was found between the flowability and yield stress of 3DPC-RAC.

Another critical indicator for 3D printing technology is the mechanical performance of the concrete. Similar to traditional concrete, this includes compressive strength, flexural strength, and shear strength. However, unlike traditional concrete, 3D printing builds structures layer by layer, which can result in significant interlayer defects and considerable anisotropy in the printed structures [18-19]. Therefore, interlayer bond strength is also a key metric for 3D printed components. Venkatesh investigated the effects of incorporating fly ash and silica fume on the mechanical properties of 3DPC from both macro and micro perspectives [18]. They found that the addition of supplementary cementitious materials effectively mitigates the reduction in flexural strength and interlayer bond strength caused by time intervals between layers. Additionally, from a microscopic perspective, it was observed that 3DPC with only cement had higher interface porosity, with more porosity defects being a contributing factor to its inferior mechanical performance. Sun reported that the mechanical properties of 3DPC decrease with increasing porosity [19]. They analyzed the impact of different nozzle shapes—triangular, circular (15 mm diameter), and rectangular—on porosity. The results indicated that the triangular nozzle produced the lowest porosity (6.78%), while the circular nozzle had the highest porosity (7.9%).

5. Conclusion

This review underscores the substantial advancements in 3D-printed concrete (3DPC), particularly regarding mix design and the enhancement of its fresh and hardened performance. The distinct characteristics of 3DPC, including its high geometric flexibility and reduced material consumption, present considerable advantages over conventional concrete. Ongoing research on optimized mix designs has explored the use of various cementitious materials, fibers, and fine aggregates, which are pivotal in improving the workability and mechanical properties of 3DPC.

Despite these notable developments, 3DPC technology remains in its nascent stages, with several critical challenges that need to be addressed. One of the primary concerns is the anisotropy inherent in the layer-by-layer printing process, which significantly impacts the mechanical performance of 3DPC, particularly in terms of interlayer bonding strength. Additionally, the absence of standardized testing methods and guidelines for assessing the fresh and hardened properties of 3DPC limits its broader acceptance and application within the construction industry.

Moving forward, future research efforts should prioritize overcoming these limitations. This includes the development of novel material formulations aimed at improving interlayer adhesion and reducing defects during the printing process. Furthermore, the establishment of standardized testing methods is essential to ensure the consistent evaluation of 3DPC performance. Another promising direction lies in the integration of sustainable materials, which could enhance the environmental viability of 3DPC. Additionally, the incorporation of advanced design methodologies, such as the use of artificial intelligence for topology optimization, holds significant potential in accelerating the practical application of 3DPC in the construction sector. Addressing these challenges will be crucial in realizing the full potential of 3DPC and its eventual widespread adoption in modern construction.

References

[1]. Hou, S., Duan, Z., Xiao, J., & Ye, J. (2020). A review of 3D printed concrete: Performance requirements, testing measurements and mix design. Construction and Building Materials.

[2]. Baktheer, A., & Classen, M. (2024). A review of recent trends and challenges in numerical modeling of the anisotropic behavior of hardened 3D printed concrete. Additive Manufacturing, 104309.

[3]. Sun Xiaoyan, Wang Hailong. Additive intelligent concrete structure [M]. Lin Xiqiang. Beijing: China Construction Industry Press, 202:5.

[4]. Marczyk, J., Ziejewska, C., Gądek, S., Korniejenko, K., Łach, M., Góra, M., ... & Szechyńska-Hebda, M. (2021). Hybrid materials based on fly ash, metakaolin, and cement for 3D printing. Materials, 14(22), 6874.

[5]. Li Nan, Liang Yun, Zhong Jianjun, Li Weihong,& Wan Detian.(2024). Effect of fly ash content on properties of lightly fired magnesia base to prepare magnesium phosphate cement for 3d printing. Journal of Functional Materials,55(3),3170-3177.

[6]. Zhou Gangming, Yang Fumin, Sun Chengxiao, Yan Chunfu & Wang Rui.(2024). Experimental study on mechanics and shrinkage properties of eolian sand 3D printing mortar. Concrete and Cement Products (06),12-17.doi:10.19761/j.1000-4637.2024.06.012.06.

[7]. Shi Yingying.(2023). Performance and mechanism analysis of cement mortar prepared from waste quartz sand (Master's thesis, North China University of Water Resources and Electric Power). Master of https://link.cnki.net/doi/10.27144/d.cnki.ghbsc.2023.000501doi:10.27144/d.cnki.ghbsc.2023.000501.

[8]. Ahmad, J., González-Lezcano, R. A., Majdi, A., Ben Kahla, N., Deifalla, A. F., & El-Shorbagy, M. A. (2022). Glass fibers reinforced concrete: Overview on mechanical, durability and microstructure analysis. Materials, 15(15), 5111.

[9]. Shafei, B., Kazemian, M., Dopko, M., & Najimi, M. (2021). State-of-the-art review of capabilities and limitations of polymer and glass fibers used for fiber-reinforced concrete. Materials, 14(2), 409.

[10]. Arunothayan, A. R., Nematollahi, B., Ranade, R., Bong, S. H., & Sanjayan, J. (2020). Development of 3D-printable ultra-high performance fiber-reinforced concrete for digital construction. Construction and Building Materials, 257, 119546.

[11]. Liu Zhi-Yuan, Wang Zhendi, Wang Ling,& Zhao Xia.(2019). Interlayer tensile strength and interlayer shear strength of 3D printed cement paste. Chinese Journal of Ceramics,47(5),648-652.

[12]. Le, T. T., Austin, S. A., Lim, S., Buswell, R. A., Gibb, A. G., & Thorpe, T. (2012). Mix design and fresh properties for high-performance printing concrete. Materials and structures, 45, 1221-1232.

[13]. Ma, G., Li, Z., & Wang, L. (2018). Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Construction and building materials, 162, 613-627.

[14]. Yuan, Q., Li, Z., Zhou, D., Huang, T., Huang, H., Jiao, D., & Shi, C. (2019). A feasible method for measuring the buildability of fresh 3D printing mortar. Construction and building materials, 227, 116600.

[15]. Wolfs, R. J. M., Bos, F. P., & Salet, T. A. M. (2018). Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cement and Concrete Research, 106, 103-116.

[16]. Jeong, H., Han, S. J., Choi, S. H., Lee, Y. J., Yi, S. T., & Kim, K. S. (2019). Rheological property criteria for buildable 3D printing concrete. Materials, 12(4), 657.

[17]. Wu, Y., Liu, C., Liu, H., Zhang, Z., He, C., Liu, S., ... & Bai, G. (2021). Study on the rheology and buildability of 3D printed concrete with recycled coarse aggregates. Journal of Building Engineering, 42, 103030.

[18]. Nerella, V. N., Hempel, S., & Mechtcherine, V. (2019). Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Construction and Building Materials, 205, 586-601.

[19]. Sun Xiaoyan, Le Kaidi, Wang Hailong, Zhang Zhicheng,& Chen Long.(2020). Influence of extrusion shape/size on mechanical properties of 3D printed concrete. Journal of Building Materials,23(6),1313-1320.

Cite this article

Chen,J. (2025). Review of 3D Printed Concrete: Mix Design. Applied and Computational Engineering,127,24-29.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Hou, S., Duan, Z., Xiao, J., & Ye, J. (2020). A review of 3D printed concrete: Performance requirements, testing measurements and mix design. Construction and Building Materials.

[2]. Baktheer, A., & Classen, M. (2024). A review of recent trends and challenges in numerical modeling of the anisotropic behavior of hardened 3D printed concrete. Additive Manufacturing, 104309.

[3]. Sun Xiaoyan, Wang Hailong. Additive intelligent concrete structure [M]. Lin Xiqiang. Beijing: China Construction Industry Press, 202:5.

[4]. Marczyk, J., Ziejewska, C., Gądek, S., Korniejenko, K., Łach, M., Góra, M., ... & Szechyńska-Hebda, M. (2021). Hybrid materials based on fly ash, metakaolin, and cement for 3D printing. Materials, 14(22), 6874.

[5]. Li Nan, Liang Yun, Zhong Jianjun, Li Weihong,& Wan Detian.(2024). Effect of fly ash content on properties of lightly fired magnesia base to prepare magnesium phosphate cement for 3d printing. Journal of Functional Materials,55(3),3170-3177.

[6]. Zhou Gangming, Yang Fumin, Sun Chengxiao, Yan Chunfu & Wang Rui.(2024). Experimental study on mechanics and shrinkage properties of eolian sand 3D printing mortar. Concrete and Cement Products (06),12-17.doi:10.19761/j.1000-4637.2024.06.012.06.

[7]. Shi Yingying.(2023). Performance and mechanism analysis of cement mortar prepared from waste quartz sand (Master's thesis, North China University of Water Resources and Electric Power). Master of https://link.cnki.net/doi/10.27144/d.cnki.ghbsc.2023.000501doi:10.27144/d.cnki.ghbsc.2023.000501.

[8]. Ahmad, J., González-Lezcano, R. A., Majdi, A., Ben Kahla, N., Deifalla, A. F., & El-Shorbagy, M. A. (2022). Glass fibers reinforced concrete: Overview on mechanical, durability and microstructure analysis. Materials, 15(15), 5111.

[9]. Shafei, B., Kazemian, M., Dopko, M., & Najimi, M. (2021). State-of-the-art review of capabilities and limitations of polymer and glass fibers used for fiber-reinforced concrete. Materials, 14(2), 409.

[10]. Arunothayan, A. R., Nematollahi, B., Ranade, R., Bong, S. H., & Sanjayan, J. (2020). Development of 3D-printable ultra-high performance fiber-reinforced concrete for digital construction. Construction and Building Materials, 257, 119546.

[11]. Liu Zhi-Yuan, Wang Zhendi, Wang Ling,& Zhao Xia.(2019). Interlayer tensile strength and interlayer shear strength of 3D printed cement paste. Chinese Journal of Ceramics,47(5),648-652.

[12]. Le, T. T., Austin, S. A., Lim, S., Buswell, R. A., Gibb, A. G., & Thorpe, T. (2012). Mix design and fresh properties for high-performance printing concrete. Materials and structures, 45, 1221-1232.

[13]. Ma, G., Li, Z., & Wang, L. (2018). Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Construction and building materials, 162, 613-627.

[14]. Yuan, Q., Li, Z., Zhou, D., Huang, T., Huang, H., Jiao, D., & Shi, C. (2019). A feasible method for measuring the buildability of fresh 3D printing mortar. Construction and building materials, 227, 116600.

[15]. Wolfs, R. J. M., Bos, F. P., & Salet, T. A. M. (2018). Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cement and Concrete Research, 106, 103-116.

[16]. Jeong, H., Han, S. J., Choi, S. H., Lee, Y. J., Yi, S. T., & Kim, K. S. (2019). Rheological property criteria for buildable 3D printing concrete. Materials, 12(4), 657.

[17]. Wu, Y., Liu, C., Liu, H., Zhang, Z., He, C., Liu, S., ... & Bai, G. (2021). Study on the rheology and buildability of 3D printed concrete with recycled coarse aggregates. Journal of Building Engineering, 42, 103030.

[18]. Nerella, V. N., Hempel, S., & Mechtcherine, V. (2019). Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing. Construction and Building Materials, 205, 586-601.

[19]. Sun Xiaoyan, Le Kaidi, Wang Hailong, Zhang Zhicheng,& Chen Long.(2020). Influence of extrusion shape/size on mechanical properties of 3D printed concrete. Journal of Building Materials,23(6),1313-1320.