1. Introduction

Flexible tactile sensors are finding applications in an increasing number of robotic manipulations, especially when fine grasping is essential. Traditional rigid sensors simply cannot adapt to the geometrical diversity and complexity of real-world objects, especially fragile ones or those with uneven surface features. While the above-mentioned geometries are sometimes complicated to be covered, flexible sensors have a large advantage because they can adapt to these geometries and maintain high sensitivity in force detection. These sensors are usually made from conductive rubber, piezoelectric, or capacitive elements, which allow monitoring multi-axis forces-normal and shear-applied on the grasping target.

Robotic dexterity refers to the precise and controlled manipulation of objects using tactile feedback. For a robot to manipulate an object effectively, it wouldn't just apply the right amount of force but recognize when the object may be slipping out of its grasp. This is where flexible tactile sensors play a critical role. They can provide real-time data regarding the distribution of forces from a robot's hand or gripper, thereby enabling a robot to make dynamic modifications in grasping. Slip detection plays a crucial role in robotic manipulation. Slipping occurs when the force applied by the robotic hand is insufficient to maintain a stable grasp. If this is allowed to continue, the result is loss of control with the object, leading to damage or failure to accomplish the task. Indeed, state-of-the-art methods for analyzing tactile sensor signals, such as DWT, allow robots to detect the onset of slippage well before it becomes critical. These developments will improve the stability of robotic grasps and enable robots to handle a wider variety of objects, including fragile items and those with complex geometries. Flexible tactile sensors, which boast an extraordinary degree of sensitivity and adaptive capability, are the perfect solutions to upscale from the conventional sensor. It is such innovative development that allows robots to perform so much more complex tasks, such as assembling sensitive components or manipulating soft materials, especially in industries like manufacturing, logistics, and healthcare. Embedding these into robotic systems can substantially improve the precision, controllability, and overall effectiveness of their real-world use [1].

2. Advancements in Flexible Tactile Sensors for Robotic Dexterous Grasping

2.1. Technological Components of Flexible Tactile Sensors

The paper introduces a highly sensitive flexible tactile sensor array that provides precise 3D force detection. This sensor is highly responsive to both normal and tangential forces, enabling accurate grasping of objects with varying shapes, weights, and materials. Additionally, a grasp stability dataset was created by performing multiple grasping operations on various objects, ranging from plastic bottles to fragile items like eggs, and collecting pressure distribution data from the tactile sensor array. Both stable and unstable grasping scenarios were represented in the dataset. The system then utilized this tactile sensor data to train multiple machine learning models, including Support Vector Classifier (SVC), K-Nearest Neighbors (KNN), and Logistic Regression (LR), to predict whether the grasping state was stable or unstable. An ensemble model combining these individual models showed superior prediction performance, with a grasp stability prediction accuracy exceeding 98%.

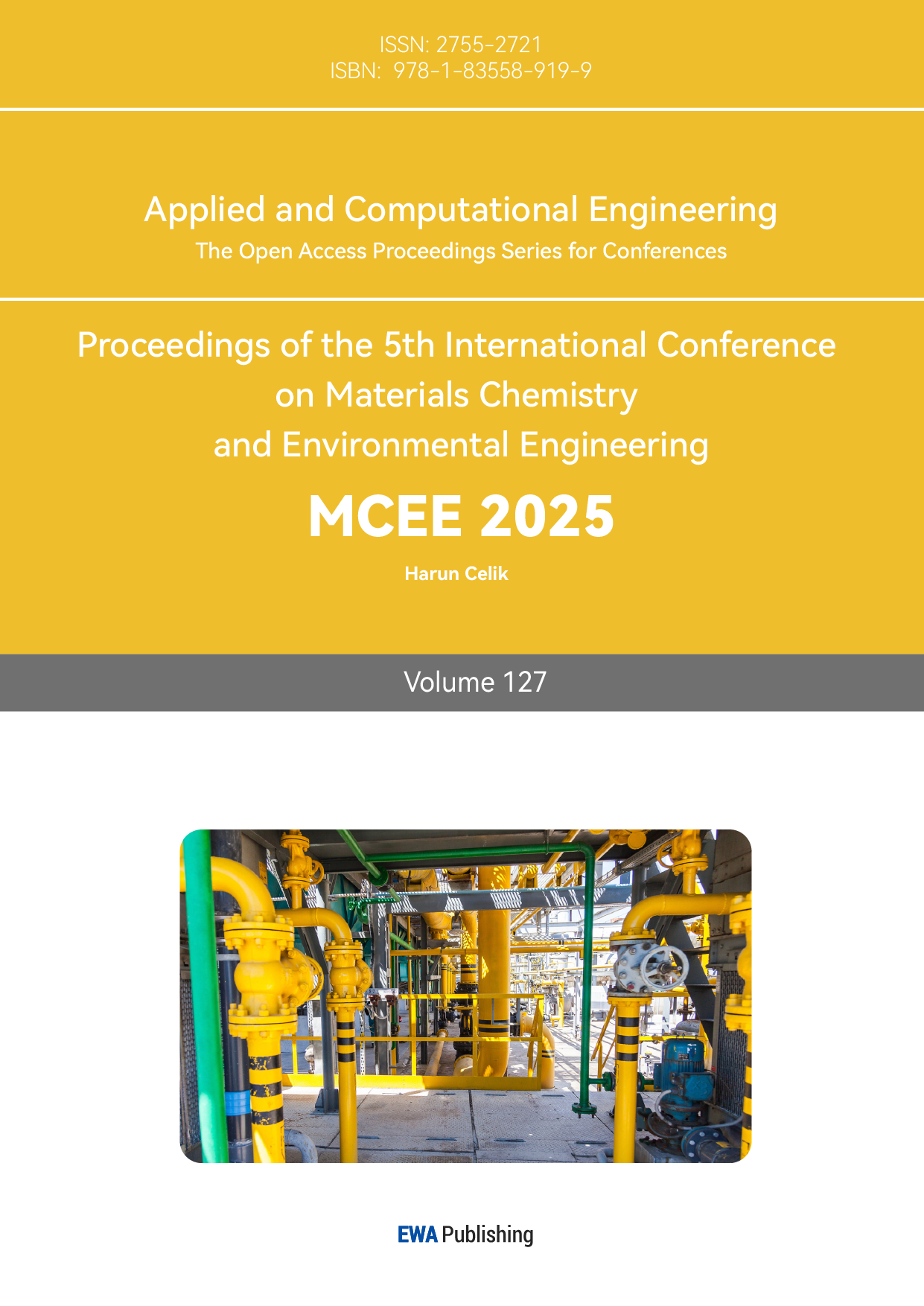

Figure 1: Robot with flexible tactile sensor array. (a) Schematic diagram of grasping operation with tactile sensor. (b) Instalation of tactile sensor array at the clamp of robot. (c) The assembly of tactile data collecting system [2]

The system also features real-time feedback and adaptation. During each control cycle, the stability state is predicted based on feedback from the sensor array, allowing the system to adjust control parameters to ensure a reliable and stable grasp. Quantitative results showed that for most objects, the judgment accuracy for stable grasping exceeded 95% across all models, with the ensemble learning model achieving the highest overall accuracy at 98.7%. Among the individual models, the best-performing SVC achieved 98% accuracy when trained on 60% of the available data, striking an optimal balance between accuracy and computational cost. The tactile sensor array demonstrated high sensitivity, with a spatial resolution of 8/cm² and the ability to detect forces as low as 0.05 N, achieving up to 20.8 kPa⁻¹ sensitivity in the <200 Pa range (Figure 1) [2].

2.2. Slip Detection Mechanisms

The paper provides a comprehensive review of state-of-the-art tactile sensing technologies designed to enable advanced in-hand manipulation tasks, such as regrasping, rotation, and translation, pushing beyond the basic grasping functions of robotic systems. It outlines the functional and technical requirements necessary for replicating human-like dexterous manipulation in robots, focusing on the detection of normal and tangential forces, force distribution analysis, and object slip prevention. These capabilities require high spatial and temporal resolution, as well as the ability to detect fine-grained force variations.

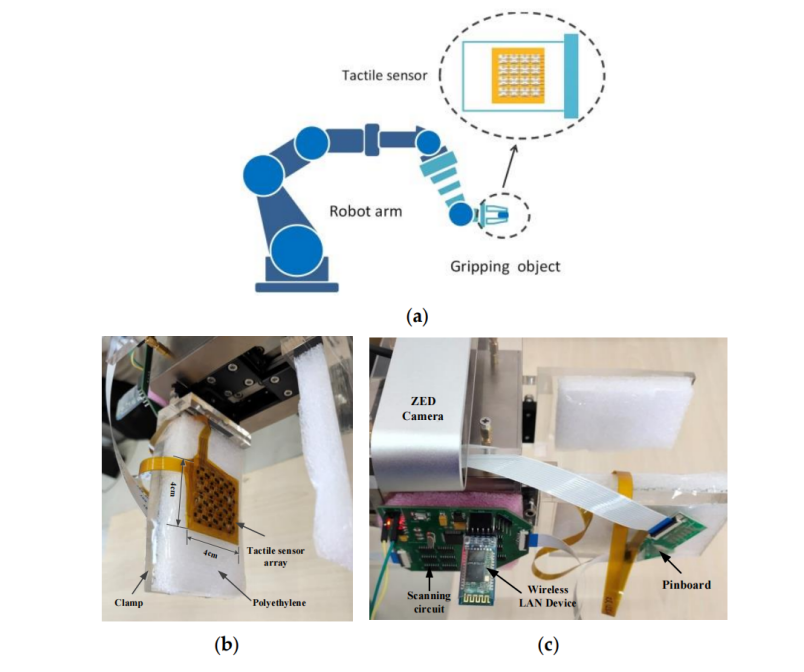

Figure 2: (a) Silicon flexible skin wrapped around a half-inch diameter aluminium block. (b) Schematic illustration of an approach to integrating silicon flexible skin with textiles. (c) Photograph of silicon skin stitched onto a canvas fabric [3]

The paper also compares various tactile sensing technologies, including resistive, capacitive, piezoelectric, optical, and organic field-effect transistors. For instance, micromachined strain gauges offer high sensitivity and spatial resolution but are fragile, while capacitive sensors are both highly sensitive and mechanically flexible, making them suitable for large-area applications. To meet the wide range of demands for dexterous in-hand manipulation, the paper proposes hybrid systems that integrate different sensor types. This hybrid approach combines highly sensitive, miniaturized 3D force sensors with large-area pressure-sensitive substrates, expanding the versatility and effectiveness of robotic manipulation systems.

Quantitative results highlight significant advancements in spatial resolution and force sensitivity. The sensors reviewed in the paper feature spatial resolutions optimized for specific hand regions: high-resolution sensors with 1 mm spacing for the fingertips, providing precision in manipulation tasks, and lower-resolution sensors with 5 mm spacing for the palm, ideal for broader force detection during grasping. Force sensitivities vary by sensor type, with strain gauges achieving sensitivities around 2.1%/N for normal forces, while conductive polymer-based sensors maintain stable sensitivity of 0.023%/kPa up to 600 kPa. The dynamic range of these sensors covers forces from 0.01 N to 10 N, with some systems, such as those using conductive fluids, supporting even higher ranges up to 40 N, enabling robust performance across various objects (Figure 2) [3].

2.3. Applications in Robotic Dexterity

The paper provides an overview of the tactile sensing technologies used in robotic hands, including but not limited to piezoresistive, capacitive, piezoelectric, optical, and barometric-based sensors. Each technology is assessed for its peculiar advantages, limits, and specific applications in robotic hand systems. Therefore, the paper also discusses some of the challenges found in the integration of tactile sensors into robotic hands, such as complex wiring, attaching sensors to curved surfaces, and technological constraints in the design of current sensors that offer limited effectiveness when performing a manipulation task.

A key focus is given to how tactile feedback is processed to support robust control in robotic manipulation tasks, including applications such as grasp stability estimation, force control, object recognition, and tactile servoing. The review also provides a classification of 28 different tactile sensors based on their transduction methods and functionalities. Each sensor is evaluated for its sensitivity, spatial resolution, and dynamic range, and an in-depth comparison is provided of their performances.

Quantitative results show large differences between these sensors' performances. Fingertip tactile sensors, responsible for fine manipulation tasks, would ideally need to have a spatial resolution of about 1 mm; in fact, most of the current robotic fingertips reach only resolutions of about 5 mm, which restricts the precision of such tasks. Sensitivity also depends on the technology: the highest sensitivities achieved by capacitive sensors reach 6.25 mN, while piezoresistive sensors support forces as high as 250 kPa with an order of magnitude lower sensitivity. Regarding dynamic tasks such as slip detection and high-speed manipulation, sensors based on piezoelectric materials and accelerometers exhibit frequency responses up to 7 kHz, hence becoming well-suited for such applications [4].

The paper introduces a novel flexible tactile sensor design that features 18 sensing units, strategically arranged to conform to the curved surface of a robotic hand finger. This arrangement enables distributed force measurement across the entire finger surface, offering comprehensive tactile feedback for robotic manipulation. The sensor's structural design was achieved using a point cloud fitting and triangle calculation method, ensuring a precise fit on the complex curved surface of the robotic finger. Furthermore, the sensor is capable of three-axis force sensing, measuring both normal and shear forces, making it ideal for detailed tactile perception in robotic tasks.

The sensor is highly flexible, allowing it to wrap around the finger without significant loss of functionality. With a spatial resolution of 4.0 mm, it provides sufficient precision for detecting contact forces. The sensor was integrated into a robotic hand and tested on various objects, both soft and hard, under different grasping modes, enabling distributed force sensing across multiple contact points during manipulation.

Quantitative results highlight the sensor's sensitivity and performance. For z-axis (normal force) detection, the sensor demonstrated two sensitivities: 1.87 V/N for small forces (0.1–0.7 N) and 0.47 V/N for larger forces (0.7–3 N). For x- and y-axis (shear forces), the sensitivities were 1.59 V/N and 1.49 V/N, respectively. The sensor exhibited excellent reproducibility, with stable voltage responses observed over 180 cycles of loading and unloading under a 1.0 N normal force. It also showed minimal cross-talk interference between adjacent sensing units, with each unit working independently and without significant signal leakage [5].

In grasping force sensing tests, the sensor successfully provided real-time force measurements when grasping soft objects (e.g., a tennis ball) and hard objects (e.g., a plastic ball). The sensor distinguished between the two types of objects: the deformable tennis ball exhibited greater fluctuations in measured forces due to its variable contact state, while the hard plastic ball produced more stable force readings.

The paper introduces the development of an innovative flexible tactile sensor made from conductive silicone rubber, embedded within a robotic finger to allow precise measurement and monitoring of grip forces during various manipulation tasks. The sensor design features an 8×8 array of microsensors, providing high flexibility and the ability to conform to the complex shapes of robotic fingers. This integration empowers the robot to manage and monitor grasping with enhanced precision. The system combines pneumatic and electric control mechanisms, enabling real-time adjustment of finger movement and grip strength based on feedback from the tactile sensors. The paper also investigates the creep and hysteresis behavior of the sensors, analyzing how their resistance changes under sustained pressure over time. This analysis is crucial for understanding the long-term stability of the sensors, ensuring consistent performance during extended use.

Practical application tests showcase the robotic finger’s ability to grasp objects of varying shapes and sizes, demonstrating the sensor’s capability to detect and adjust grasp forces in real-time. Quantitative results highlight the sensor’s force sensitivity and performance characteristics. The tactile sensor has a force measurement range of 0 N to 10 N, showing a sharp resistance change for forces between 0 N and 5 N, with a more gradual change from 5 N to 10 N. This non-linear response indicates high sensitivity in the lower force range, making it ideal for delicate manipulation tasks.

The analysis also identified an optimal bending angle of 138° for the robotic finger, where it achieves the maximum stress and grip force of up to 8.6 N. Beyond this angle, further bending results in reduced stress and grip force. In the creep analysis, the sensor stabilized within 75 seconds under a constant pressure of 3 N to 5 N, with resistance remaining stable thereafter, ensuring accurate force measurements over prolonged periods. The robotic finger successfully grasped various objects, including soft items like oranges and rigid objects like plastic bottles. Feedback from the tactile sensors enabled real-time adjustments to the grasping force, preventing slippage and ensuring a secure hold on the objects [6].

2.4. Comparative Analysis of Tactile Sensing Technologies

The paper presents the development of an innovative force/tactile sensor designed to emulate the human sense of touch, capable of detecting both contact forces and torsional moments, which are essential for dexterous robotic manipulation. The sensor incorporates a soft, deformable layer and an optoelectronic sensing array, allowing for distributed force sensing. This configuration enables the sensor to estimate contact forces, detect slip, and perceive object geometry, contributing to more advanced manipulation capabilities.

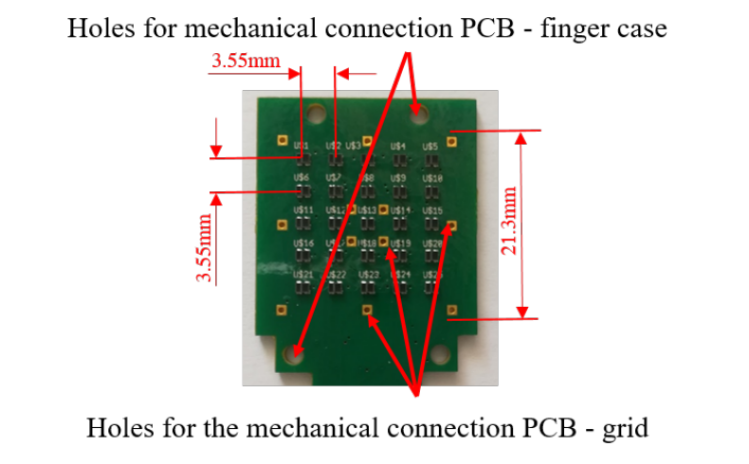

Figure 3: Details of the sensitive area on the Printed Circuit Board (PCB) [7]

A key contribution of the paper is the introduction of a neural network-based calibration procedure. Using a feed-forward neural network (FF-NN), the proposed calibration method significantly enhances the accuracy of contact force, moment, and contact surface orientation estimation, addressing the limitations of traditional models. Additionally, the sensor was integrated into a commercial parallel gripper for industrial robots, demonstrating its practical application in real-world tasks. The sensor supports wireless communication and high sampling rates, allowing for real-time data transmission and manipulation feedback. Quantitative results demonstrate the sensor's high performance. It operates within a wide force measurement range of 0.5 N to 16 N, maintaining a low error of approximately 0.7 N at the upper limit. This wide range, combined with high accuracy, makes the sensor versatile for manipulating both delicate and heavier objects. The sensor also excels in estimating tangential forces, achieving an error of less than 0.2 N, which is critical for preventing slippage during object handling.

The sensor's torsional moment sensitivity is another highlight, with the ability to detect moments as small as 0.0068 Nm, and a maximum of 0.061 Nm. Experiments demonstrated that the sensor could manage torsional deformations without causing slippage at normal forces as low as 2.5 N. Furthermore, the sensor accurately reconstructs the contact plane's orientation with an error of less than 0.5°, ensuring precise measurement of both normal and tangential forces during manipulation (Figure 3) [7].

It proposes a flexible tactile sensor array in a 3×3 grid of sensing units, with each capable of measuring normal and shear forces in three axes. It guarantees very good flexibility, allowing the sensor to effectively distribute the force measurements over the entire grasping surface on the curved surface of the robotic hand. It integrates a five-electrode pattern under each unit and uses conductive rubber as a sensing material to provide high flexibility and sensitivity.

The contribution toward the slip detection methodology with DWT has been used to analyze tactile signals. The system will distinguish between stable grasping and slip conditions by monitoring the high-frequency components of the measured forces. Slip detection threshold values were obtained using wavelet coefficients that ensure valid and reliable slip detection during manipulation tasks. The tactile sensor array has been successfully integrated into a robotic hand to provide real-time feedback of contact forces and slip detection during grasping operations. This, in turn, will enable the robotic system to make the necessary adjustment in grip strength in real time and prevent object slippage.

Quantitative results emphasize the performance of the sensor. It has sensitivities of 0.471 V/N and 0.466 V/N for shear forces along the x-axis and y-axis, respectively. Besides, it provides sensitivities of 0.201 V/N for normal forces along the z-axis for forces below 6 N and 0.067 V/N between 6 and 15 N. The spatial resolution of this sensor array is 3.5 mm to provide distributed force measurement with high precision on the surface of the robotic hand. For slip detection, there are predefined thresholds of wavelet coefficients, 0.06 on the z-axis and 0.01 on the x- and y-axis. In addition, such thresholds were then validated with experiments conducted with different objects-a cylindrical beaker and a plastic ball-endowed the system with good performance in detecting slips during grasping [8].

3. Conclusion

The paper reviews the development of flexible tactile sensors and their applications for robotic dexterous grasping. With the integration of material components such as conductive rubber and piezoelectric components, these sensors have gained the ability to detect multi-axis forces that could lead to slipping. Utilizing techniques such as the Discrete Wavelet Transform, they offer high resolution in slip detection and thus can handle a wide range of objects. This review demonstrates how such sensors enhance the dexterity and reliability of robotic performance in various grasping tasks.

In the near future, development related to flexible tactile sensors for robotic applications will be focused on a number of main issues, namely: First, further development is needed to increase the spatial resolution and sensitivity of these sensors. This will enable them to detect very slight variations in the magnitude of forces and contacts on various object surfaces.

Higher resolution opens up possibilities for ever finer and more delicate tasks that eventually involve assembling micro-components or manipulating soft and deformable materials in fields concerning healthcare and precision manufacturing. Second, there is huge potential in the integration of machine learning with tactile sensors. By training robotic systems to recognize patterns of tactile data, these systems can predict and respond to indications of slippage or force anomalies in real time.

Lastly, more robust and durable sensors can potentially be made through advancements in flexible electronics and materials science. Sensors will have to be developed for hostile industrial environments, involving extreme temperatures, chemicals, or mechanical stress, without losing their sensitivity or accuracy. Further emphasis on the durability and versatility of flexible tactile sensors will continue to expand their applications. This expansion will reach areas of higher demand, such as aerospace, underwater robotics, hazardous material manipulation, and a wider scope of industries.

References

[1]. Han, Y., Nagahama, K., Fukuda, H., Kukihara, K., & Wan, W. (2023). Recent advances in flexible tactile sensors for robotic manipulation: A comprehensive review. Robotics and Autonomous Systems, 159, 104283. https://doi.org/10.1016/j.robot.2022.104283

[2]. Yousef, H., Boukallel, M., & Althoefer, K. (2011). Tactile sensing for dexterous in-hand manipulation in robotics—A review. Sensors and Actuators A: Physical, 167(1), 171-187. https://doi.org/10.1016/j.sna.2011.02.038

[3]. Kappassov, Z., Corrales, J.-A., & Perdereau, V. (2015). Tactile sensing in dexterous robot hands—Review. Robotics and Autonomous Systems, 74, 195-220. https://doi.org/10.1016/j.robot.2015.07.015

[4]. Wang, Y., Wu, X., Mei, D., Zhu, L., & Chen, J. (2019). Flexible tactile sensor array for distributed tactile sensing and slip detection in robotic hand grasping. Sensors and Actuators A: Physical, 297, 111512. https://doi.org/10.1016/j.sna.2019.07.036

[5]. Li, T., Sun, X., Shu, X., Wang, C., Wang, Y., Chen, G., & Xue, N. (2021). Robot grasping system and grasp stability prediction based on flexible tactile sensor array. Machines, 9(6), 119. https://doi.org/10.3390/machines9060119

[6]. Tang, Z., Wang, Z., Lu, J., & Ma, G. (2019). Design of robot finger based on flexible tactile sensor. International Journal of Advanced Robotic Systems, 16(5), 1-10. https://doi.org/10.1177/1729881419879853

[7]. Costanzo, M., De Maria, G., Natale, C., & Pirozzi, S. (2019). Design and calibration of a force/tactile sensor for dexterous manipulation. Sensors, 19(4), 966. https://doi.org/10.3390/s19040966

[8]. Wang, Y., Ding, W., & Mei, D. (2021). Development of flexible tactile sensor for the envelop of curved robotic hand finger in grasping force sensing. Measurement, 180, 109524. https://doi.org/10.1016/j.measurement.2021.109524

Cite this article

Zhang,K. (2025). Advancements in Flexible Tactile Sensors for Robotic Dexterous Grasping. Applied and Computational Engineering,127,193-199.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Han, Y., Nagahama, K., Fukuda, H., Kukihara, K., & Wan, W. (2023). Recent advances in flexible tactile sensors for robotic manipulation: A comprehensive review. Robotics and Autonomous Systems, 159, 104283. https://doi.org/10.1016/j.robot.2022.104283

[2]. Yousef, H., Boukallel, M., & Althoefer, K. (2011). Tactile sensing for dexterous in-hand manipulation in robotics—A review. Sensors and Actuators A: Physical, 167(1), 171-187. https://doi.org/10.1016/j.sna.2011.02.038

[3]. Kappassov, Z., Corrales, J.-A., & Perdereau, V. (2015). Tactile sensing in dexterous robot hands—Review. Robotics and Autonomous Systems, 74, 195-220. https://doi.org/10.1016/j.robot.2015.07.015

[4]. Wang, Y., Wu, X., Mei, D., Zhu, L., & Chen, J. (2019). Flexible tactile sensor array for distributed tactile sensing and slip detection in robotic hand grasping. Sensors and Actuators A: Physical, 297, 111512. https://doi.org/10.1016/j.sna.2019.07.036

[5]. Li, T., Sun, X., Shu, X., Wang, C., Wang, Y., Chen, G., & Xue, N. (2021). Robot grasping system and grasp stability prediction based on flexible tactile sensor array. Machines, 9(6), 119. https://doi.org/10.3390/machines9060119

[6]. Tang, Z., Wang, Z., Lu, J., & Ma, G. (2019). Design of robot finger based on flexible tactile sensor. International Journal of Advanced Robotic Systems, 16(5), 1-10. https://doi.org/10.1177/1729881419879853

[7]. Costanzo, M., De Maria, G., Natale, C., & Pirozzi, S. (2019). Design and calibration of a force/tactile sensor for dexterous manipulation. Sensors, 19(4), 966. https://doi.org/10.3390/s19040966

[8]. Wang, Y., Ding, W., & Mei, D. (2021). Development of flexible tactile sensor for the envelop of curved robotic hand finger in grasping force sensing. Measurement, 180, 109524. https://doi.org/10.1016/j.measurement.2021.109524