1. Introduction

Polylactic acid (PLA), as a bio-based plastic derived from biomass resources, has high mechanical strength and good processability, can be degraded under natural environment, and the degradation products are safe for organisms, renewable and biocompatible advantages, and has a wide range of application prospects in packaging, textile, biomedical and other industries. However, the drawbacks of PLA such as poor heat resistance, slow crystallization rate, hard and brittle texture, poor impact resistance, notch sensitivity. and low notch impact strength, and difficult to control degradation cycle have put the application and development of PLA into a bottleneck.

In order to improve and enhance the performance of PLA, nano-composite modification is usually used. Nano-composite modification is to improve the toughness of PLA by promoting heterogeneous nucleation of nanoparticles in the system and the effect of selective positioning of rigid particles on the morphology of dispersed phases. Polymers combined with the common advantages of PLA and additional filler components typically have excellent heat resistance, degradation or mechanical properties.

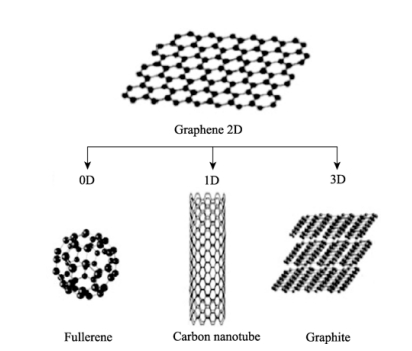

Graphene is a two-dimensional carbon material with a honeycomb structure composed of Sp2 hybrid atoms. Monolayer graphene is only 0.335 nm, which is the thinnest inorganic material found so far and one of the materials with the highest mechanical properties known at present. Its ultimate tensile strength is up to 130 GPa, Young's modulus is up to 1 TPa, and graphene has very high electrical conductivity (1×106 S/cm) and thermal conductivity (5000 W/(m·K)), as well as outstanding specific surface area (up to 2630 m2/g theoretically). The excellent properties of graphene lay a good foundation for the preparation of high-performance graphene/polylactic acid composites. At the same time, compared with other nanocarbon materials (such as carbon nanotubes, carbon nanofibers, fullerenes), graphene is rich in graphite sources and can be produced in large quantities, so graphene has the advantage of low cost. At the same time, the two-dimensional nanostructure of graphene itself makes it have antibacterial properties. This makes PLA/graphene nanocomposites made from PLA and graphene exhibit better thermal, electrical and mechanical properties than pure PLA, while also having antibacterial properties and retaining good biocompatibility. Since graphene has these excellent mechanical properties, electrical and thermal conductivity properties, and is also a nanoscale filler material, it can also form a multi-component composite with a variety of matrix materials. Then, the composite material prepared by using graphene can both improve the performance of the material and expand the scope of use of the material.

Figure 1: Structure diagram of graphene and its derivatives

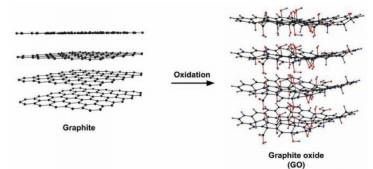

Graphene oxide, as an intermediate for the preparation of graphene, is the product of graphite powder after chemical oxidation and stripping. After oxidation treatment, GO still maintains the layered structure of graphite, but the difference is that hydroxyl and epoxy groups are introduced into the graphene sheet, and the edge of the sheet contains carboxyl and carbonyl groups. After the introduction of oxygen-containing functional groups, the sp2 hybrid carbon atoms in the original graphene become sp3 hybrid, and the large π bond is destroyed, and the mechanical and electrical properties are reduced. However, it is precisely these oxygen-containing groups that bring opportunities for the surface modification of GO. With oxygen-containing groups as reaction sites, small molecules can be grafted to the surface of GO through chemical reactions to change the chemical composition and polarity of GO and enrich its functions. At the same time, these oxygen-containing functional groups make the layer spacing of GO larger, the van der Waals force smaller, and the aggregation is not easy, so that the solubility of GO in water and common organic solvents is increased, and the dispersion in the matrix is enhanced. While maintaining a variety of excellent properties, GO has better reactivity, wettability and surface activity, and as a nano component, it is easier to prepare composite materials with polymers, inorganic substances and small molecules, which provides a guarantee for the preparation and application of GO composite materials.

Figure 2: Schematic diagram of graphene oxide structure

Polymer-based inorganic nanocomposites not only have the properties of surface effect and quantum size effect of nanomaterials, but also combine the rigidity, dimensional stability and thermal stability of inorganic substances with the toughness and processability of polymers, resulting in many specific properties. At present, three main methods are mainly used to prepare PLA/ graphene nanocomposites, which are in-situ polymerization, solution polymerization and melt polymerization [1].

In situ polymerization is to disperse the nano-filler in a liquid monomer or a solution containing monomers, and then the monomers are polymerized. The process polymerizes into polymers between graphene intercalations, helping to improve the graphene layer spacing and strip the layered structure of the graphite. However, in situ intercalation requires good dispersion of the nanofillers themselves. Functionalized graphene and graphene oxide have this property and can disperse well in monomer solution. The disadvantage of this method is that a large number of monomer reagents are required in the polymerization process, and the synthetic reaction conditions of high molecular weight polylactic acid are demanding and costly, making it difficult to produce industrially.

The solution polymerization method dissolves the polymer in a solvent, and the nano-filler is dispersed in the same solvent. By simple stirring or ultrasonic treatment, the nano-filler is evenly dispersed in the matrix. After the solvent evaporates, the nano-filler is included in the polymer matrix to form a nano-composite material. This way requires a solvent to meet the dissolution of the polymer and the dispersion of the nano filler, generally choose acetone, chloroform, tetrahydrofuran, dimethyl formamide or toluene as solvents.

The solution embedding method has the advantages of simple operation and low cost, but the removal and reuse of solvent is an important problem to be solved. Simple and inexpensive, but need to find and use the right organic solvent.

Melt polymerization heats the polymer to a molten state and mixes it into graphene. This method does not require the use of organic solvents. Melt intercalation polymerization can be used for both polar and non-polar polymers, and is easy to mass produce. However, due to the strong van der Waals force of graphene and the connection between the layers, graphene is easy to agglomerate in the polymer matrix, and it is difficult to disperse evenly. The uneven dispersion of nano fillers in the polymer matrix will lead to stress concentration, which is not conducive to the improvement of mechanical properties. The dispersion of graphene can be greatly improved by modifying the graphene surface to functionalize.

Using the green advantages of polylactic acid and the good functional properties of graphene, the prepared polylactic acid/graphene composites have good potential in the application of biomedicine, electricity conduction, gas barrier and other fields. A variety of polylactic acid/graphene composites can be obtained through different materials, different modified fillers and different preparation processes. Compared with pure polylactic acid, polylactic acid/graphene composites show better mechanical, thermal stability, electromagnetic shielding, antibacterial, gas blocking, biological compatibility and other properties. These properties make the multifunctional film made of polylactic acid/graphene composite material have a better play in the packaging and other fields where polylactic acid has been widely used, and polylactic acid/graphene composite material has opened up a new application direction in the medical field such as bone repair and dentistry as a tissue engineering scaffold material.

2. Polylactic acid composite material using graphene filler

Graphene has good electrical, thermodynamic and mechanical properties as well as cost advantages, making it a high quality filler for polylactic acid nanocomposite modification. Compared with pure PLA material, graphene /PLA composite material has significantly improved its performance in many aspects, broadened the scope of use of PLA material, and attracted a large number of scholars for research, development and application.

Wu Haihua et al[2,3]. prepared the graphene/polylactic acid composite material by ball milling method. The bending strength of the composite material was increased to 57. 87MPa, which was 114. 61% higher than that of pure PLA material. When the amount of graphene was 9%,the conductivity of the composite material could reach the highest 0. 202S·cm Then the prepared composite material is used as a wire in fused deposition molding 3D printing technology. When the graphene content is above 7%, the conductivity of the material reaches 10S/cm order of magnitude, reaching the standards of conductors and electromagnetic shielding materials; Elongation at break and tensile strength reached 28. 8 MPa and 5. 1%, which met the requirements of the wire.

Yanhua Chen et al[4]. prepared PLA/ graphene nanocomposites using chloroform as a dispersing solvent by solution blending method, and found that the thermal stability of PLA could be significantly improved with a lower graphene addition amount, and the thermal decomposition temperature of PLA was delayed. Meanwhile, graphene hindered the cold crystallization process of PLA.

Shi et al[5]. adopted a local enrichment strategy (LES) to prepare PLA/ graphene nanosheet composites by precisely controlling the selective distribution of fillers. After adding graphene nanosheets, the electromagnetic interference shielding efficiency of the materials was greatly improved. At the same time, melt deposition modeling 3D printing technology was used to successfully manufacture functional 3D printed honeycomb parts with porous structure, light weight and high efficiency electromagnetic interference shielding performance.

Zhao Zhongguo et al[6]. used solution- melting method to prepare the electrical conductivity and crystallization properties of graphene-carbon nanotube - polylactic acid composite material, and the crystallization temperature increased from 100°C to about 130°C. At the same time, the material exhibits low temperature positive temperature coefficient (PTC) and high temperature negative temperature coefficient (NTC) effects in the cycle temperature range of 37°C to 140°C, which can be used in the field of highly sensitive temperature sensors.

Wang Yudong et al[7]. prepared PLA/rGO composite nanofiber film by electrospinning method using reduced graphene oxide as polylactic acid filler, which significantly improved the mechanical strength of PLA. When rGO reached 0. 6% mass fraction, the fracture strength of the composite reached 2. 02MPa, and it also had good cellular compatibility. It has good application prospect in biomedicine, packaging and other fields.

Girdthep et al [8]. found that graphene nanosheets (GNPs) can not only improve the crystallinity of PLLA/PDLA neutral composite crystals, but also improve the Young' s modulus and barrier properties of the composite materials, and also improve the heat resistance and hydrolysis resistance to some extent.

3. Polylactic acid composites using graphene oxide fillers

As an important derivative of graphene, graphene oxide has a wide range of raw materials, simple preparation process, low cost, excellent mechanical properties, wear resistance and adsorption properties, etc. It can also be modified according to the required properties of graphene oxide, and is an ideal filler for polymer -based nanocomposites.

Zhao Yang et al[9]. prepared PLA/ graphene oxide (GO) composite by solution blending method. When the GO mass fraction was 1. 0%, the tensile strength of the composite reached 60. 2MPa, and the elongation at break reached 11. 5%, which was 45. 8% and 71. 6% higher than that of PLA, respectively. When the GO mass fraction was 1. 5%,The thermal decomposition temperature (5% mass decomposition rate) of the composite reached 351.2C,25. 1C higher than that of PLA, and the contact Angle was 60.88°,which was 24. 84% lower than that of PLA.

Ma et al [10]. prepared polylactic acid (PLLA)/graphene oxide (GO) composite nanofibers by electrospinning method, and the mechanical properties of PLLA/GO composite nanofibers were significantly improved by GO content. In the presence of 6wt% GO, the tensile stress increased by 400%, reaching 0. 61MPa. After the addition of GO, the glass transition temperature and melting temperature of the material are increased to a certain extent. The simultaneous enhancement of thermal and mechanical properties may be due to the homogeneous dispersion of GO in the PLLA matrix, which improves the interface interaction. With the incorporation of GO, the degradation of PLLA/GO composite nanofiber net was higher than that of pure PLLA. With the increase of GO content from 2wt% to 6wt%, the degradation trend increased. After 9 days of degradation, The weight loss of PLLA/GO nanofiber net with three GO addition contents reached 10. 71wt%,13. 45wt% and 16. 83wt%, respectively.

Wang Huanhuan et al [11]. prepared polylactic acid/ functional graphene (PLA/GO-ODA) nanocomposite film material by solution blending method. GO-ODA is a functional graphene that links octadecyl to the carboxyl functional group of GO to improve its oleophilicity and enable it to be stably dispersed in organic solvents. The results show that the addition of GO-ODA can improve the tensile strength, modulus and elongation at break of the material, and the thermal stability and gas barrier properties are also improved to varying degrees. When the content of GO-ODA was 0. 2wt %, the tensile strength and modulus of the nano-composite film reached the maximum, which were 46. 5% and 85. 7% higher than that of pure PLA, respectively. When the content of GO-ODA was 0. 6wt %, the elongation at break of the nano-composite was 2 times higher than that of pure PLA. Considering the mechanical properties comprehensively, the two formulations with 0. 6wt % or 0. 4wt % of GO-ODA are the best.

Sha Lili et al [12]. prepared GO/PLA composite film by solution blending method. The addition of GO significantly improved the thermal stability of the material, and increased with the addition of GO. The improvement effect was best when the GO content reached 1. 25wt %, while the thermal stability decreased at 1. 50wt % compared with 1. 25wt %. This may be due to the uneven dispersion of GO in the matrix caused by excessive GO addition. At the same time, the addition of GO greatly improves the mechanical properties of the material. When the amount of GO is 0. 50wt %, the tensile strength of GO/PLA composite film reaches the maximum value of 65. 3MPa, an increase of 58. 5% compared with PLA, and the tensile strength of the material decreases slightly with the addition of graphene. This is because too much GO is easy to agglomerate in the matrix, resulting in uneven dispersion and many defects. The elongation at break of the composite reaches a maximum of 17. 3% when GO content is 0. 75wt%, which is 5. 6 times higher than that of pure PLA.

4. Summary and Prospect

Numerous studies at home and abroad have shown that graphene materials and graphene oxide materials lave greatly improved the mechanical properties of PLA, which mainly focuses on tensile strength and elongation at break, and other aspects such as bending strength have also significantly improved. At the same time, the improvement of material properties is also related to the method used in the preparation process. The research and comparison literature found that the thermal stability of graphene nanocomposites prepared by solution blending method has a certain degree of improvement, while the literature using melt bl ending method rarely mentions the thermal stability performance. Based on the improvement of the thermal stability of the composite material may be attributed to the good thermal stability of the graphene sheet and its good dispersion, we can guess that this is due to the fact that the fillers in the nanocomposite prepared by the solution blending method are more dispersed, and the thermal stability of the nanocomposite prepared by the melt blending method is not ideal due to the agglomeration phenomenon caused by the dispersion of the fillers is not uniform Sheet structure of graphene and graphene oxide in the matrix of good.

Table 1: Preparation methods of composite materials

Ingredients | Preparation method | Material property change | Ref. |

GNPs | Melt blending method | Improved bending resistance and conductivity | 2-3 |

Melt blending method | Improve electrical conductivity and electromagnetic interference shielding | 5 | |

Solution-melt blending method | Improve electrical conductivity and crystallization properties, resistance thermal sensitivity | 6 | |

Solution blending method | Improve thermal stability | 4 | |

Solution blending method | Improve mechanical properties and biocompatibility | 7 | |

Solution blending method | Improve mechanical, thermal and hydrolytic properties | 8 | |

GO | Solution blending method | Improve mechanical properties, thermal stability, hydrophilicity | 9 |

Solution blending method | Improve mechanical properties, water degradation rate, thermal stability | 10 | |

Solution blending method | Improve thermal stability, gas barrier, mechanical properties | 11 | |

Solution blending method | Improve mechanical properties, wear resistance, hydrophilicity, thermal stability | 12 |

Dispersion will also significantly improve the gas barrier properties of the composite material, this is because the filler dispersed in the matrix can play a role in bending the gas channel, delaying the passage of the gas, while the sheet structure itself can also block the passage of a part of the gas. The difference in the physical properties of graphene and graphene oxide itself also leads to the difference in the properties of the two nanocomposites, the conductivity and electromagnetic shielding performance of graphene /PLA composite is more prominent, and the highlight of graphene /PLA composite is hydrophilic and wear resistance. In addition, as graphene oxide is added as a filler in PLA, most of them will be covalently modified or non-covalently modified first to obtain the required better performance, and the surface of graphene oxide contains a large number of oxygen-containing functional groups, and under certain conditions the ionization of functional groups produces electrostatic repulsion, making it easy to disperse stably in water or organic solvents. Therefore, the preparation of graphene oxide /PLA composite material is mostly carried out by solution bl ending method.

The improvement of the mechanical properties of graphene /PLA composite makes PLA perform better in the original packaging, textile, biomedical and other industries, while the improvement of the gas isolation performance and hydrophilic properties of the composite makes it more widely used in these industries. Moreover, the new excellent properties of graphene /PLA composites, such as electrical conductivity, also provide a new direction for 3D printing materials.

References

[1]. Li Yang, Zhou Qin, Sun Xin, et al. Research progress of graphene/polylactic acid composites [J]. Plastics Industry, 2017, 45 (09) :9-11+23.

[2]. WU Haihua, Wu Chao, Lv Jiawei, et al. Preparation and properties of graphene/polylactic acid composites [J]. Materials for Mechanical Engineering, 2017, 41 (04) :49-53.

[3]. Wu Haihua, Wang Jian, CAI Yu, et al. Preparation and properties of graphene/polylactic acid 3D printing composite wire [J]. Carbon Technology, 2018, 37 (06) :61-65. (in Chinese)

[4]. Chen Y H. Study on preparation and properties of polymer/graphene nanocomposites [D]. Soochow University, 2013.

[5]. Shi Shaohong et al. Preparation of Highly Efficient Electromagnetic Interference Shielding Polylactic Acid/Graphene Nanocomposites for Fused Deposition Modeling Three -Dimensional Printing [j]. INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH. 2020,59 :15565-15575.

[6]. Zhao H C, Xue R, Wang Z X, et al. Preparation and temperature-sensitive response behavior of graphene-carbon nanotube -polylactic acid/ polyethylene glycol phase-change energy storage composites [J]. Chinese Journal of Composite Materials, 2019, 41 (01) :250-260.

[7]. Wang Shudong, Dong Qing, Wang Ke, et al. Preparation and properties of polylactic acid nanofiber membrane reinforced by reduced graphene oxide [J]. Journal of Textiles and Textiles, 2021, 42(12) :28-33. (in Chinese)

[8]. Sutinee Girdthep et al. Enhanced crystallization, thermal properties, and hydrolysis resistance of poly (l-lactic acid) and its stereocomplex by incorporation of graphene nanoplatelets[J]. Polymer Testing,2017, 61 : 229-239.

[9]. Zhao Yang, Miao Zongcheng, Zhang Yongming, et al. Preparation and properties of polylactic acid/graphene oxide composites [J]. New Chemical Materials, 2022, 50(11) :83-86. (in Chinese)

[10]. Ma H et al. Structure and performance analysis of flatter ribbon-like electrospun poly (L-lactic acid) / graphene oxide nanofiber webs. Journal of Engineered Fibers and Fabrics. 2020; 15.

[11]. Wang Huanhuan. Preparation, structure and properties of polylactic acid/ functionalized graphene nanocomposite films [D]. Zhengzhou Universi ty, 2014.

[12]. Sha Lili. Study on preparation and performance optimization of graphene oxide/polylactic acid composites [D]. Nanjing University of Aeronautics and Astronautics, 2017. (in Chinese)

Cite this article

Zhang,H. (2025). Research Progress of Polylactic Acid/Graphene Composites and Polylactic Acid/ Graphene Oxide Composites. Applied and Computational Engineering,130,23-29.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 5th International Conference on Materials Chemistry and Environmental Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li Yang, Zhou Qin, Sun Xin, et al. Research progress of graphene/polylactic acid composites [J]. Plastics Industry, 2017, 45 (09) :9-11+23.

[2]. WU Haihua, Wu Chao, Lv Jiawei, et al. Preparation and properties of graphene/polylactic acid composites [J]. Materials for Mechanical Engineering, 2017, 41 (04) :49-53.

[3]. Wu Haihua, Wang Jian, CAI Yu, et al. Preparation and properties of graphene/polylactic acid 3D printing composite wire [J]. Carbon Technology, 2018, 37 (06) :61-65. (in Chinese)

[4]. Chen Y H. Study on preparation and properties of polymer/graphene nanocomposites [D]. Soochow University, 2013.

[5]. Shi Shaohong et al. Preparation of Highly Efficient Electromagnetic Interference Shielding Polylactic Acid/Graphene Nanocomposites for Fused Deposition Modeling Three -Dimensional Printing [j]. INDUSTRIAL & ENGINEERING CHEMISTRY RESEARCH. 2020,59 :15565-15575.

[6]. Zhao H C, Xue R, Wang Z X, et al. Preparation and temperature-sensitive response behavior of graphene-carbon nanotube -polylactic acid/ polyethylene glycol phase-change energy storage composites [J]. Chinese Journal of Composite Materials, 2019, 41 (01) :250-260.

[7]. Wang Shudong, Dong Qing, Wang Ke, et al. Preparation and properties of polylactic acid nanofiber membrane reinforced by reduced graphene oxide [J]. Journal of Textiles and Textiles, 2021, 42(12) :28-33. (in Chinese)

[8]. Sutinee Girdthep et al. Enhanced crystallization, thermal properties, and hydrolysis resistance of poly (l-lactic acid) and its stereocomplex by incorporation of graphene nanoplatelets[J]. Polymer Testing,2017, 61 : 229-239.

[9]. Zhao Yang, Miao Zongcheng, Zhang Yongming, et al. Preparation and properties of polylactic acid/graphene oxide composites [J]. New Chemical Materials, 2022, 50(11) :83-86. (in Chinese)

[10]. Ma H et al. Structure and performance analysis of flatter ribbon-like electrospun poly (L-lactic acid) / graphene oxide nanofiber webs. Journal of Engineered Fibers and Fabrics. 2020; 15.

[11]. Wang Huanhuan. Preparation, structure and properties of polylactic acid/ functionalized graphene nanocomposite films [D]. Zhengzhou Universi ty, 2014.

[12]. Sha Lili. Study on preparation and performance optimization of graphene oxide/polylactic acid composites [D]. Nanjing University of Aeronautics and Astronautics, 2017. (in Chinese)