1. Introduction

Bridges and tunnels are crucial transport networks that provide fuel for business and human movement. But their complexities and vulnerability to environmental and operational pressures make it difficult to track, repair and ensure long-term functionality. The traditional management methods of periodic maintenance inspections and reactive maintenance are unable to deal with these issues effectively, resulting in repairs and risks to the workers. The digital twin enables a radical solution in creating dynamic, data-driven virtual replicas of physical assets that adapt to the physical environment. Digital twins bring together IoT sensors, cloud computing and predictive analytics to deliver real-time tracking, dynamic reporting, and predictive analytics [1]. This provides the ability to make proactive decisions and enable reactive to predictive maintenance, which in turn reduces the cost of operations and lengthens the lives of infrastructure. Second, digital twins enable everyone from engineers and policymakers to maintenance personnel to collaborate across an all-data-driven platform. While technically feasible, there are a number of obstacles that digital twins can encounter in bridge and tunnel infrastructure including steep up-front investment, lack of standardisation, and interoperability of data. These challenges need to be overcome in order to unlock the full potential of this technology. The paper explores the lifecycle management framework of digital twins, their use cases, pitfalls and prospects. It also talks about future technologies like AI, edge computing and blockchain that can be used to develop digital twins. Incorporating these technologies promises digital twin technology for making bridge and tunnel infrastructure safer, more robust, and more sustainable.

2. Digital Twin Framework for Bridge and Tunnel Infrastructure

2.1. Conceptual Overview

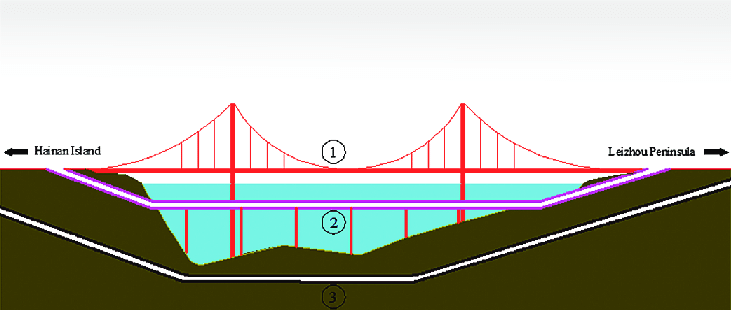

Digital twin technology is an actual-time data-driven simulation of bridges and tunnels that imitate the actual structure and operation of the bridges and tunnels to produce a living digital replica that can change in response to its real-time physical counterpart [2]. It is a robust offering that integrates IoT sensors, cloud computing and advanced analytics to enable real-time monitoring, dynamic analysis, and detailed infrastructure simulation. The theory of digital twins relies on a two-way information flow, with real-time data from the physical building being fed back to the digital counterpart, and insights from the digital model being used to make decisions regarding the physical asset. This nexus gives unrivalled access to structural health data and predictive insight in real time, helping engineers and stakeholders take active, informed action. By providing interoperability between the physical and digital environments, it allows for structural problems to be detected early, risk assessments to be conducted in high resolution, and proactive actions to avoid disaster. Beyond surveillance, the digital twin approach promises to facilitate lifecycle management of infrastructure assets from design and construction through operation, maintenance and decommissioning. Through combined dynamic modeling, digital twins can save infrastructure designers money, eliminate waste and increase the lifespan of bridges and tunnels. This technique works especially well when implementing large, intricate structures like bridges and tunnels where timely data is essential to maintaining safety, productivity, and strength. Figure 1 shows an example bridge and tunnel schematic diagram of what can be included in a digital twin architecture. It illustrates how critical infrastructure components are coordinated into a unified system. The map also reveals the possibilities for cooperation among engineers, maintenance, policymakers, and researchers, operating in an integrated, data-based environment. This integration allows for strategic and operational decision-making and thereby ensures the effective and long-term management of infrastructure [3].

Figure 1: Structural Schematic of Bridges and Tunnels (Source: ResearchGate)

2.2. Data Integration and Analytics

The greatest strength of a digital twin is that it can read and compute with massive data from IoT sensors placed on critical infrastructure like bridges and tunnels. These sensors continuously measure parameters like strain, vibration and environment and produce real-time data. This data is then fed into cloud servers, and subsequently parsed by machine learning and artificial intelligence (AI) algorithms to detect patterns, patterns and anomalies. Digital twins enable the early identification of problems, resulting in safety gains and faster inspections. Beyond this, digital twins bring together various data sources – from weather, traffic movement, to material stress – on one platform, giving you an overall overview of the infrastructure’s health. This comprehensive model allows for improved lifecycle control through accurate predictive modeling and makes maintenance decisions based on long-term, cost-effective approaches. Through this combination of insights, digital twins enable stakeholders to optimize resources, increase asset life and operational risk and are key to today’s infrastructure management [4].

2.3. Predictive Maintenance and Decision Support

The most disruptive use of digital twin is predictive maintenance which shifts the focus away from reactive strategies and toward proactive and predictive measures. Digital twins using powerful machine learning algorithms compare real-time sensor measurements to past performance records to predict structural failures with unrivalled accuracy. Such an ability significantly reduces the possibility of emergency closures, increases safety, and extends the life of bridges and tunnels. For instance, digital twins can simulate growing traffic, harsh weather, or even material deterioration to detect stress points and potential vulnerabilities so engineers can patch them before they become critical [5]. Predictive maintenance also provides cost savings by coordinating the frequency, time and location of maintenance as well as the amount of work to be done so that resources are efficiently used. Beyond upkeep, decision support tools in digital twin platforms allow stakeholders to compare different scenarios and determine the best course of action. Digital twins, for example, could predict what the outcome of different maintenance schedules, repair methods or material selections would be, so that managers could select interventions that maximise structural integrity at the lowest possible cost.

In addition, this data-driven decision making also seamlessly integrates with wider sustainability objectives, such as material reduction, energy conservation and the environmentally sustainable operation of maintenance activities. Table 1 describes key elements of predictive maintenance and decision support, detailing how all the inputs, processes and results work together to form a unified and sustainable approach to infrastructure management. With real-time monitoring, modeling and planning integrated into a single system, digital twins transform the future of infrastructure management, keeping bridges and tunnels safe, usable and resilient across their lifetime [6].

Table 1: Key Components of Predictive Maintenance and Decision Support in Digital Twin Systems

Component | Description | Examples |

Real-Time Data Inputs | Continuous data collection from IoT sensors monitoring structural and environmental parameters | Strain, temperature, vibration, corrosion, traffic loads |

Historical Data Analysis | Trend analysis and performance tracking based on historical datasets | Stress curves, service history, environmental impact |

Predictive Modeling | Machine learning and AI-driven simulations to forecast potential structural failures | Fatigue detection, load prediction |

Scenario Simulation | Analysis of maintenance strategies, repair methods, and material choices under varying conditions | Maintenance scheduling, material durability tests |

Decision-Making Framework | Tools for evaluating and selecting optimal interventions based on cost, sustainability, and safety | Cost-benefit analysis, resource allocation |

3. Implementation Challenges and Opportunities

3.1. Data Integration and Analytics

Digital twin technology can be revolutionary in its ability to control bridges and tunnel systems, but the technology and financial challenges are daunting. The use of IoT devices in large infrastructure is going to involve massive upfront investments into hardware (sensors, gateways, communication, etc.) and in building high-end analytics applications [7]. In public infrastructure projects, these costs are often at odds with tight budgets and delay widespread adoption. In addition, the integration of many different technologies (from real-time monitoring devices and cloud-based computing environments to advanced simulation programs) requires technical staff with specialized skills. Organizations tend to have a steep learning curve which makes implementation even more daunting. Cybersecurity and privacy issues are another challenge as digital twins depend on constant data flows between physical assets and digital platforms [8]. This sharing involves the store and use of sensitive data which has to adhere to strict regulatory standards to ensure it cannot be stolen or abused. Despite these barriers, new sensor technologies and cloud computing technology are slowly lowering the barriers to entry. For example, low power sensors and edge computers have become cheaper and more cost-effective so that they can be scaled even for small-scale work. In addition, increased understanding of the longer-term economic advantages, including lower maintenance costs and asset lifetimes, are leading governments and private investors to focus on investments in digital twin technologies as a path to achieving greater infrastructure resilience and efficiency.

3.2. Standardization and Interoperability

The interoperability of the systems and the lack of standardization remain among the most pressing barriers to the success of using digital twins for bridge and tunnel systems. Infrastructure projects typically involve many stakeholders: from construction companies, to maintenance staff, to the governments themselves, all with their own proprietary software, data formats, and protocols. That fragmentation equates to inefficiencies, communication delays, and complex projects. For instance, sensors from different manufacturers may accumulate information in different formats that make it difficult to connect them to a single platform [9]. Towards the solution to this problem, common data formats and protocols should be created to make communication between IoT devices, clouds, and analytics systems as seamless as possible. Standardization must also include rules on sensor calibration, data synchronization, and interoperability testing to assure consistent and robust performance in different systems. Table 2: shows some of the gaps that need to be standardised and the stakeholder groups that are responsible for filling these.

Table 2: Key Areas for Standardization and Stakeholder Roles

Area of Standardization | Description | Key Stakeholders |

Sensor Data Formats | Development of unified data formats for compatibility across devices and platforms | Sensor manufacturers, standards bodies |

Communication Protocols | Establishing common protocols for real-time data exchange between IoT devices and clouds | Network providers, IoT developers |

Simulation and Modeling Standards | Guidelines for integrating simulation tools with digital twin platforms | Software developers, research institutions |

Data Security and Privacy Frameworks | Policies for protecting sensitive data and ensuring compliance with regulations | Governments, cybersecurity firms |

Interoperability Testing Procedures | Standardized methods for testing and validating system interoperability | Certification agencies, industry consortia |

By addressing the challenges presented in Table 2, the industry can reduce inefficiencies and increase collaboration throughout the infrastructure lifecycle management. Partnerships between governments, industry and research centres are especially important in guiding the creation and implementation of these standards. International consortia based on digital twin interoperability, for instance, could lead to development of common protocols and best practices to speed up the adoption of the technology in bridge and tunnel operations. Further, early adopter case studies that show what a concrete benefit standardization has can provide benchmarks for other stakeholders and drive widespread adoption and innovation.

3.3. Opportunities for Future Research

Digital twin technologies will revolutionise bridge and tunnel construction, providing significant development potential in conjunction with the use of cutting edge computing. Artificial intelligence is involved by providing better prediction models for structural structures, thus resulting in better maintenance and design options. The Edge computing improves efficiency by minimizing latency via localized data processing, and the Blockchain protects data integrity, transparency, and security in multi- stakeholder environments. Beyond direct use cases, digital twins have broader uses in smart city construction, renewable energy projects and climate change mitigation. They can, for instance, analyse real-time traffic flow to improve flow and congestion, or synchronize infrastructure with the availability of renewable energy for sustainability. In the next 10 years, continuing progress in digital twin technology will generate smarter, more resilient and sustainable infrastructure solutions, creating new standards in the design, construction, and operations of bridges and tunnels [10].

4. Conclusion

Digital twins are a radical revolution in bridge and tunnel operations that provides unrivalled real-time monitoring, predictive maintenance and lifecycle optimization. Digital twins, through IoT, cloud computing and advanced analytics, overcome the constraints of conventional management systems and facilitate autonomous decisions. Although a cost-intensive first implementation and standardisation are challenges, improvements in sensors and sharing structures are making the use of digital twins more viable. And finally, with the new technologies such as AI, edge computing and blockchain, it’s a great opportunity to further expand the capabilities and scalability of digital twins. This paper shows how digital twins will contribute to the structural safety, efficiency and sustainability of bridges and tunnels. With multistakeholder coordination, and support for wider targets such as energy conservation and resource efficiency, digital twin technology offers a holistic solution to contemporary infrastructure issues. As the science and practice progresses, digital twins are destined to play a key role in resilient and sustainable infrastructure systems across the globe.

References

[1]. Korus, Kamil. "Digital twins of bridges: establishing principles of virtualization with practical use cases." (2023).

[2]. Datta, Shoumen. "Digital Twin, Didymos, Meets Digital Cousin, Didymium. From Paradox to Paradigm or a Paradoxical Paradigm?." (2024).

[3]. Piras, Giuseppe, Sofia Agostinelli, and Francesco Muzi. "Digital twin framework for built environment: a review of key enablers." Energies 17.2 (2024): 436.

[4]. Moshood, Taofeeq D., et al. "Infrastructure digital twin technology: A new paradigm for future construction industry." Technology in Society 77 (2024): 102519.

[5]. Weise, Matthias, et al. "Importance of Digitalization and Standardization for Bridge and Tunnel Monitoring and Predictive Maintenance." ce/papers 6.5 (2023): 592-599.

[6]. Lahna, Tarik. The use of BIM for the management of predictive maintenance in airport infrastructure. Diss. Institut National Polytechnique de Toulouse-INPT, 2023.

[7]. Jeon, Chi-Ho, et al. "Prescriptive maintenance of prestressed concrete bridges considering digital twin and key performance indicator." Engineering Structures 302 (2024): 117383.

[8]. Sebastian, R., et al. "Towards European standardization of digitalization approaches for monitoring and safety of bridges and tunnels." ECPPM 2022-eWork and eBusiness in Architecture, Engineering and Construction 2022. CRC Press, 2023. 204-210.

[9]. Kušić, Krešimir, René Schumann, and Edouard Ivanjko. "A digital twin in transportation: Real-time synergy of traffic data streams and simulation for virtualizing motorway dynamics." Advanced Engineering Informatics 55 (2023): 101858.

[10]. Maheshwari, Pratik, et al. "Digital twin-driven real-time planning, monitoring, and controlling in food supply chains." Technological Forecasting and Social Change 195 (2023): 122799.

Cite this article

Wang,K. (2025). Lifecycle Management of Bridge and Tunnel Infrastructure Using Digital Twin Technology. Applied and Computational Engineering,140,133-138.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Mechatronics and Smart Systems

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Korus, Kamil. "Digital twins of bridges: establishing principles of virtualization with practical use cases." (2023).

[2]. Datta, Shoumen. "Digital Twin, Didymos, Meets Digital Cousin, Didymium. From Paradox to Paradigm or a Paradoxical Paradigm?." (2024).

[3]. Piras, Giuseppe, Sofia Agostinelli, and Francesco Muzi. "Digital twin framework for built environment: a review of key enablers." Energies 17.2 (2024): 436.

[4]. Moshood, Taofeeq D., et al. "Infrastructure digital twin technology: A new paradigm for future construction industry." Technology in Society 77 (2024): 102519.

[5]. Weise, Matthias, et al. "Importance of Digitalization and Standardization for Bridge and Tunnel Monitoring and Predictive Maintenance." ce/papers 6.5 (2023): 592-599.

[6]. Lahna, Tarik. The use of BIM for the management of predictive maintenance in airport infrastructure. Diss. Institut National Polytechnique de Toulouse-INPT, 2023.

[7]. Jeon, Chi-Ho, et al. "Prescriptive maintenance of prestressed concrete bridges considering digital twin and key performance indicator." Engineering Structures 302 (2024): 117383.

[8]. Sebastian, R., et al. "Towards European standardization of digitalization approaches for monitoring and safety of bridges and tunnels." ECPPM 2022-eWork and eBusiness in Architecture, Engineering and Construction 2022. CRC Press, 2023. 204-210.

[9]. Kušić, Krešimir, René Schumann, and Edouard Ivanjko. "A digital twin in transportation: Real-time synergy of traffic data streams and simulation for virtualizing motorway dynamics." Advanced Engineering Informatics 55 (2023): 101858.

[10]. Maheshwari, Pratik, et al. "Digital twin-driven real-time planning, monitoring, and controlling in food supply chains." Technological Forecasting and Social Change 195 (2023): 122799.