1. Introduction

As a critical piece of equipment in construction projects, the tower crane is responsible for transporting materials on-site. Due to its unique structure and the substantial energy it contains, any unintended energy release during operation poses a significant risk. If the released energy exceeds the structural safety threshold of the surrounding environment, it can lead to severe casualties and property loss. The resilience of the tower crane system—its capacity to resist and recover from such disturbances—is essential for maintaining operational safety. Li Hongbing et al., based on an improved DEMATEL method using the C-OWA operator, argue that personnel competence and skill levels significantly influence lifting operation safety [1]. Zhou Hongbo et al. analyzed tower crane accident cases using a hybrid of complex networks and the N-K model, highlighting the risk of multi-factor coupling among human, machine, environment, and management under adverse conditions and advocating for stronger management interventions [2]. Ye Yongjun et al., using improved naive Bayesian networks and Apriori-based association rule mining, found that tower crane collapses are mainly caused by mechanical defects, high-altitude falls by human errors, and object strikes by a combination of mechanical failures and poor environmental conditions [3]. Previous studies have largely focused on individual or static influencing factors without accounting for the inherent resilience of the system—its capacity to withstand, adapt to, and recover from disturbances. In 1973, Holling first introduced the concept of resilience in ecology, defining it as the ability of a system to maintain its structure and functions after disturbances [4]. Xiahou Xia’er et al. identified fire safety influencing factors in subway stations from the perspectives of absorptive and resistance capacities, proposing fire prevention optimization measures [5]. Sun Lei et al. examined engineering safety management from organizational, human, and material-technical dimensions, emphasizing the importance of information management [6]. Liu Jingyan introduced resilience theory into safety management by constructing a resilience assessment framework for subway construction that integrates physical, social, and informational spaces [7]. Chen Weigong et al. identified urban governance capacity, emergency information completeness, and economic regulatory capacity as fundamental factors influencing urban disaster resilience [8]. Resilience thinking emphasizes the dynamic changes in system attributes during an event, including the ability to maintain, respond, recover, and optimize. Therefore, this study builds upon a previously developed evaluation index system tailored to the safety operation capacity of tower crane systems. By employing a combined weighting method to determine indicator weights and applying system dynamics principles, this research investigates the effects of both single and combined intervention strategies on improving safety operation capacity. The findings serve as a reference for enhancing the operational resilience of tower crane systems.

2. Influencing factors of safety operation capacity in tower crane systems

2.1. Preliminary identification of influencing factors

Based on relevant literature reviews [9,10] and field investigations, the safety operation capacity of tower crane systems is defined as follows: during tower crane operations, the system acknowledges the existence of risk and proactively resists it. When the risk level exceeds the system’s threshold and signs of an accident emerge, the system immediately initiates response measures to eliminate those signs. Through fault-tolerant mechanisms, the system continues to operate safely and stably. Finally, by learning retrospectively, the system enhances its risk resistance capacity, thereby achieving a more robust safety status. Drawing on the Hall three-dimensional structure methodology [11,12] and preliminary expert consultations, an index system was developed comprising four primary indicators—risk resistance capability, fault tolerance, safety response capability, and adaptive capacity—and a total of 23 secondary indicators. This index system represents the influencing factors of safety operation capacity in tower crane systems (see Table 1).

2.2. Weight calculation of influencing factors

Five experts were invited to score the influence level of each indicator. The Improved Analytic Hierarchy Process (IAHP) [13] was used to calculate the subjective weights (W’), while the Entropy Weight Method (EW) [14] was employed to determine the objective weights (W’’). These were then integrated using the combined weighting method [15] to obtain the comprehensive weights for each indicator (see Table 1).

Table 1: Results of weight calculation for indicators

Primary Indicator (Code) | Comprehensive Weight | Secondary Indicator (Code) | Comprehensive Weight | Normalized Value |

Risk Resistance Capability (X1) | 0.31 | Operator’s Overall Competence (X11) | 0.17 | 0.053 |

Overall Quality and Performance of Crane (X12) | 0.14 | 0.043 | ||

Implementation of Safety Regulations (X13) | 0.14 | 0.043 | ||

Working Environment Conditions (X14) | 0.12 | 0.037 | ||

Strength of Safety Supervision (X15) | 0.14 | 0.043 | ||

Reliability of Monitoring System (X16) | 0.15 | 0.047 | ||

Rationality of User Operation Platform (X17) | 0.14 | 0.043 | ||

Fault Tolerance (X2) | 0.21 | Reliability of Spare Parts (X21) | 0.19 | 0.040 |

Reliability of Interlocking Limiters (X22) | 0.21 | 0.044 | ||

Reliability of Limit Switches (X23) | 0.19 | 0.040 | ||

Reliability of Overload Protection Devices (X24) | 0.21 | 0.044 | ||

Safety Protection Measures (X25) | 0.20 | 0.042 | ||

Safety Response Capability (X3) | 0.20 | Reliability of Information Feedback System (X31) | 0.20 | 0.040 |

Emergency Shutdown Control Reliability (X32) | 0.19 | 0.038 | ||

Reliability of Fault Alarm System (X33) | 0.22 | 0.044 | ||

Implementation of Emergency Plans (X34) | 0.19 | 0.038 | ||

Emergency Coordination Capability (X35) | 0.20 | 0.040 | ||

Adaptive Capacity (X4) | 0.28 | Application of New Technologies (X41) | 0.18 | 0.050 |

Deployment of Intelligent Crane Systems (X42) | 0.16 | 0.045 | ||

Implementation of Rectification and Supervision Policies (X43) | 0.17 | 0.048 | ||

Personnel Learning Ability (X44) | 0.16 | 0.045 | ||

Safety Education and Training (X45) | 0.15 | 0.042 | ||

Optimization of Emergency Management Systems (X46) | 0.18 | 0.051 |

3. Construction of a system dynamics model for the safety operation capacity of tower crane systems

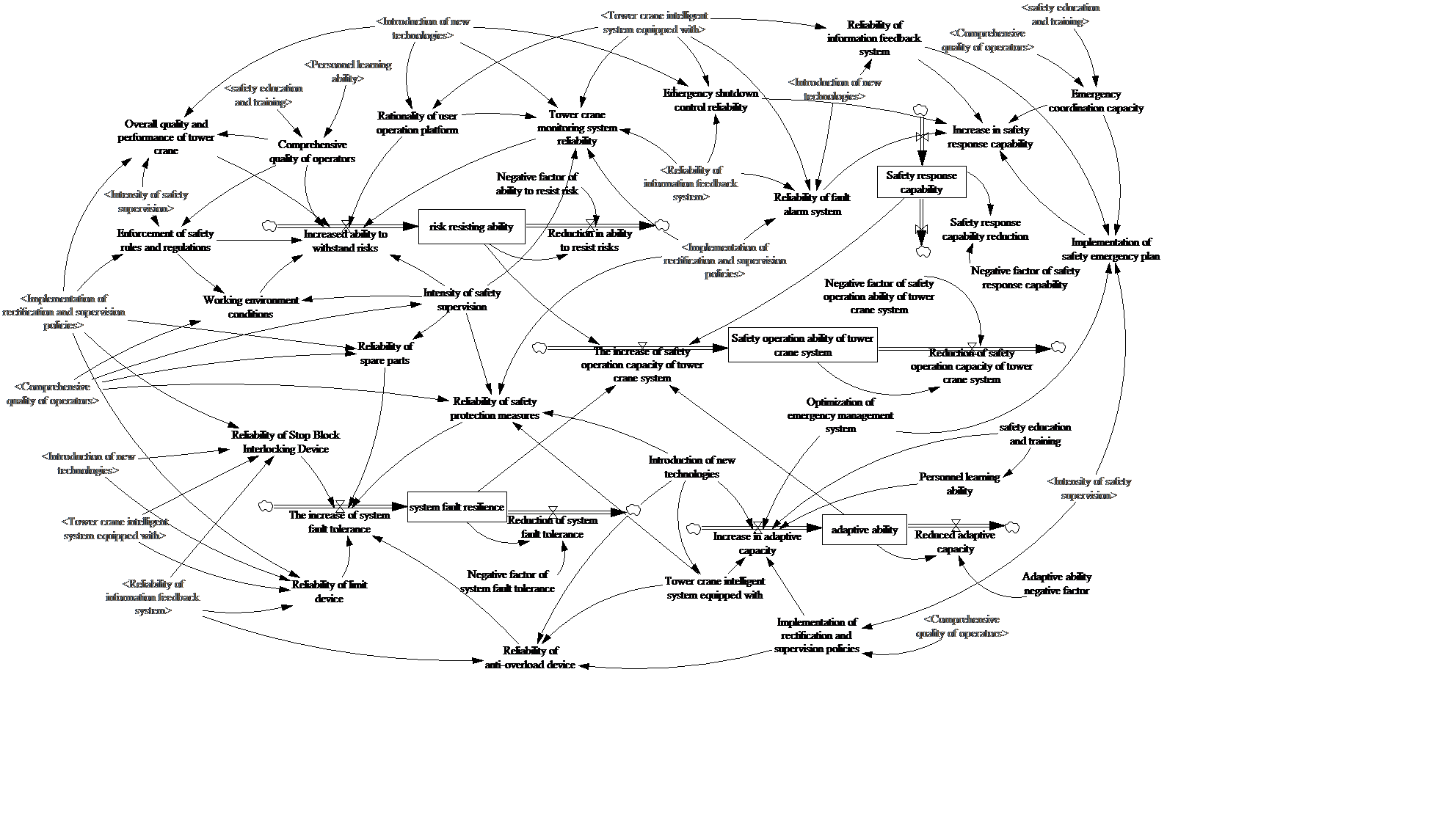

Based on the comprehensive weights of the indicators established in the previous section, parameter variables for the System Dynamics (SD) model of the safety operation capacity of tower crane systems were defined (see Table 2). Among these, state variables refer to variables that accumulate over time within the system; rate variables describe the rate of change of state variables; auxiliary variables are intermediate variables that define the relationships between state and rate variables; and constants are parameters that remain unchanged over time. In accordance with the principles of system dynamics and parameter settings, the SD model of tower crane system safety operation capacity was constructed, as illustrated in Figure 1.

Table 2: Summary of model variables

Variable Type | Variable Names |

State Variables | Risk Resistance Capability, Fault Tolerance Capability, Safety Response Capability, Adaptive Capacity, Tower Crane System Safety Operation Capacity |

Rate Variables | Increment and Decrement of Risk Resistance Capability, Increment and Decrement of Fault Tolerance Capability, Increment and Decrement of Safety Response Capability, Increment and Decrement of Adaptive Capacity, Increment and Decrement of Tower Crane System Safety Operation Capacity |

Auxiliary Variables | Reliability of Information Feedback System, Reliability of Monitoring System, Reliability of Fault Alarm System, Deployment of Intelligent Crane Systems, Working Environment Conditions, Optimization of Emergency Management Systems, Implementation of Safety Regulations, Safety Education and Training, Implementation of Emergency Plans, Strength of Safety Supervision, Implementation of Rectification and Supervision Policies, Rationality of User Operation Platform, Operator’s Overall Competence, Emergency Coordination Capability, Personnel Learning Ability, Overall Quality and Performance of Crane, Application of New Technologies, Reliability of Interlocking Limiters, Reliability of Emergency Shutdown Controls, Reliability of Spare Parts, Safety Protection Measures, Reliability of Limit Switches, Reliability of Overload Protection Devices |

Constants | Negative Factors for Risk Resistance, Fault Tolerance, Safety Response, Adaptive Capacity, and Tower Crane System Safety Operation Capacity |

Figure 1: Stock and flow diagram of the SD model for tower crane system safety operation capacity

3.1. Case simulation analysis

Five experts were invited to evaluate the initial values of the state variables for a construction project in Shanghai. The initial scores were as follows: Risk Resistance Capability: 80 Fault Tolerance Capability: 83 Safety Response Capability: 79 Adaptive Capacity: 77 Overall Tower Crane System Safety Operation Capacity: 79 The weights of the indicators were used as influence coefficients among variables, and functional relationships were established accordingly. All parameters were dimensionless. The simulation’s initial time was set to the project investigation date, August 23, 2024, with a total simulation duration of 20 months, a time step of 1 month, and time units expressed in months.

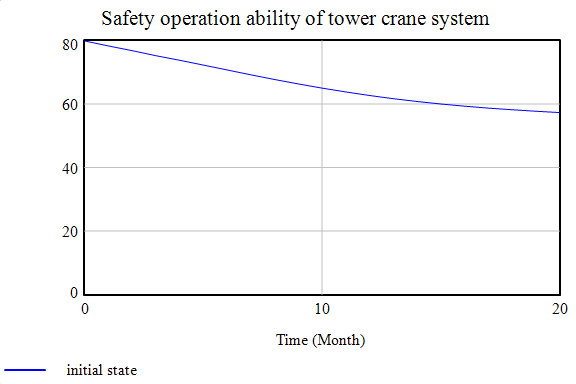

3.2. Simulation results under initial conditions

The simulation results under the initial conditions are shown in Figure 2. The tower crane system’s safety operation capacity exhibits nonlinear variation, with an initial simulation value of 79. If no corrective measures are taken, the system's safety capacity shows a gradual downward trend. Over time, natural wear and aging of equipment components, along with performance degradation of some parts and weakening of enterprise supervision and management, result in reduced safety awareness and responsibility among operators. Consequently, the precision of equipment operations and the enthusiasm for maintenance also decline. This leads to a progressive deterioration in the overall safety operation capacity of the tower crane system. By the 15th month, the system's safety capacity falls to a poor level, indicating a critical point at which construction activities should be halted immediately for corrective measures.

Figure 2: Simulation results of tower crane system safety operation capacity under initial conditions

3.3. Simulation results analysis of intervention strategies

This study uses the control variable method to simulate the intervention strategies by enhancing the values of individual and combined influencing factors. By reviewing relevant literature [16] and the indicator weights, the key influencing factors and their corresponding action paths were identified. The key influencing factors are: operator competence, overall crane quality and performance, safety supervision strength, crane monitoring system reliability, overload protection device reliability, safety protection measures, information feedback system reliability, fault alarm system reliability, implementation of emergency plans, application of new technologies, crane intelligent system deployment, and implementation of rectification and supervision policies. Among these, overall crane quality and performance, crane monitoring system reliability, safety protection measures, fault alarm system reliability, and implementation of emergency plans are the result factors that are more likely to be affected by other factors. On the other hand, application of new technologies, implementation of rectification and supervision policies, crane intelligent system deployment, operator competence, safety supervision strength, information feedback system reliability, and safety education training are cause factors that more easily influence other factors. The key action paths are: Path 1: Safety education training → Personnel learning ability → Operator competence → Safety supervision strength → Implementation of rectification and supervision policies → Overload protection device reliability → Overall crane quality and performance; Path 2: Safety education training → Personnel learning ability → Operator competence → Safety supervision strength → Implementation of rectification and supervision policies → Limit switch reliability → Overall crane quality and performance; Path 3: Safety education training → Personnel learning ability → Operator competence → Safety supervision strength → Implementation of rectification and supervision policies → Compliance with safety regulations → Working environment conditions

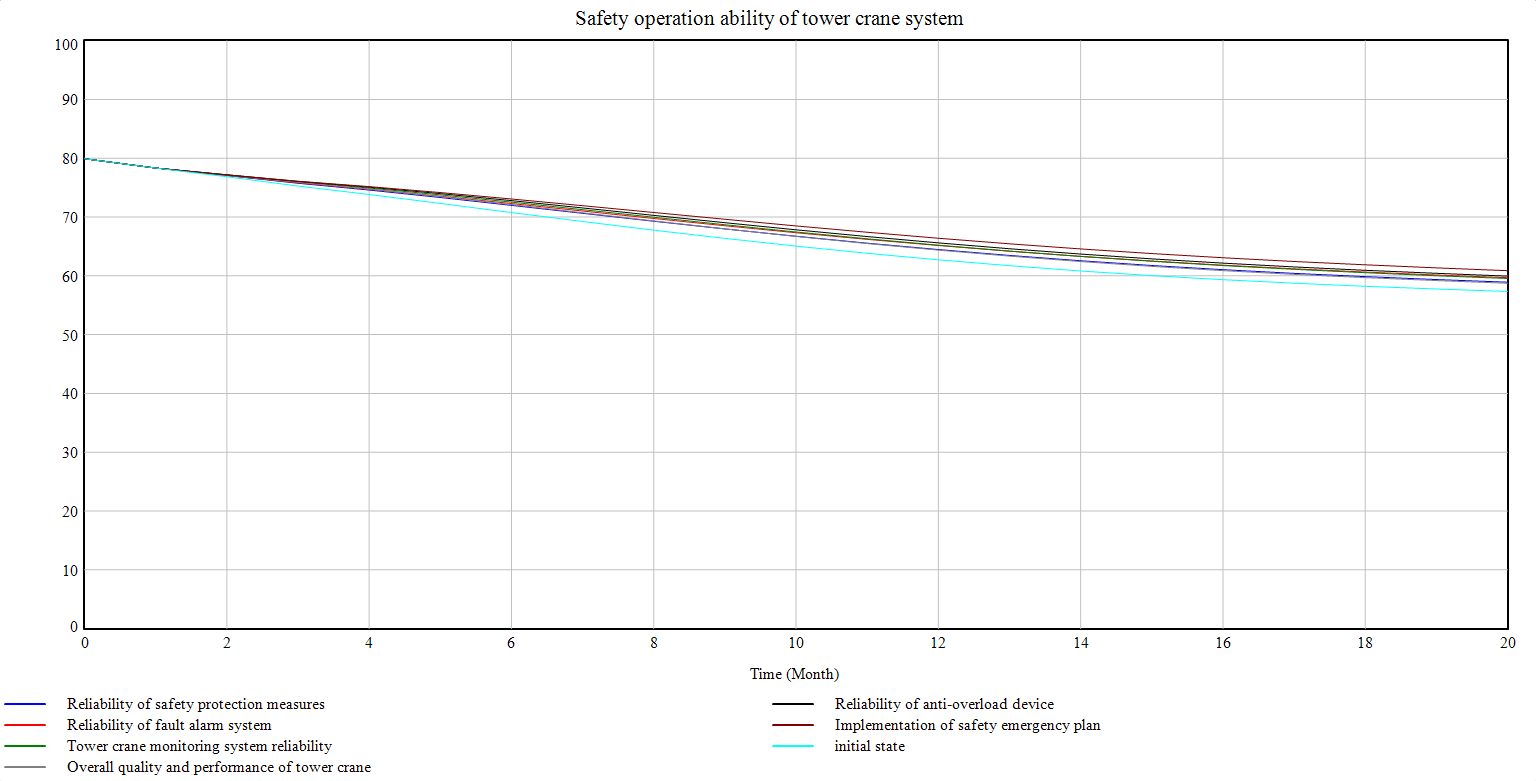

(1) Simulation of Single Intervention Strategy

(i) Intervention Strategy on Result Factors

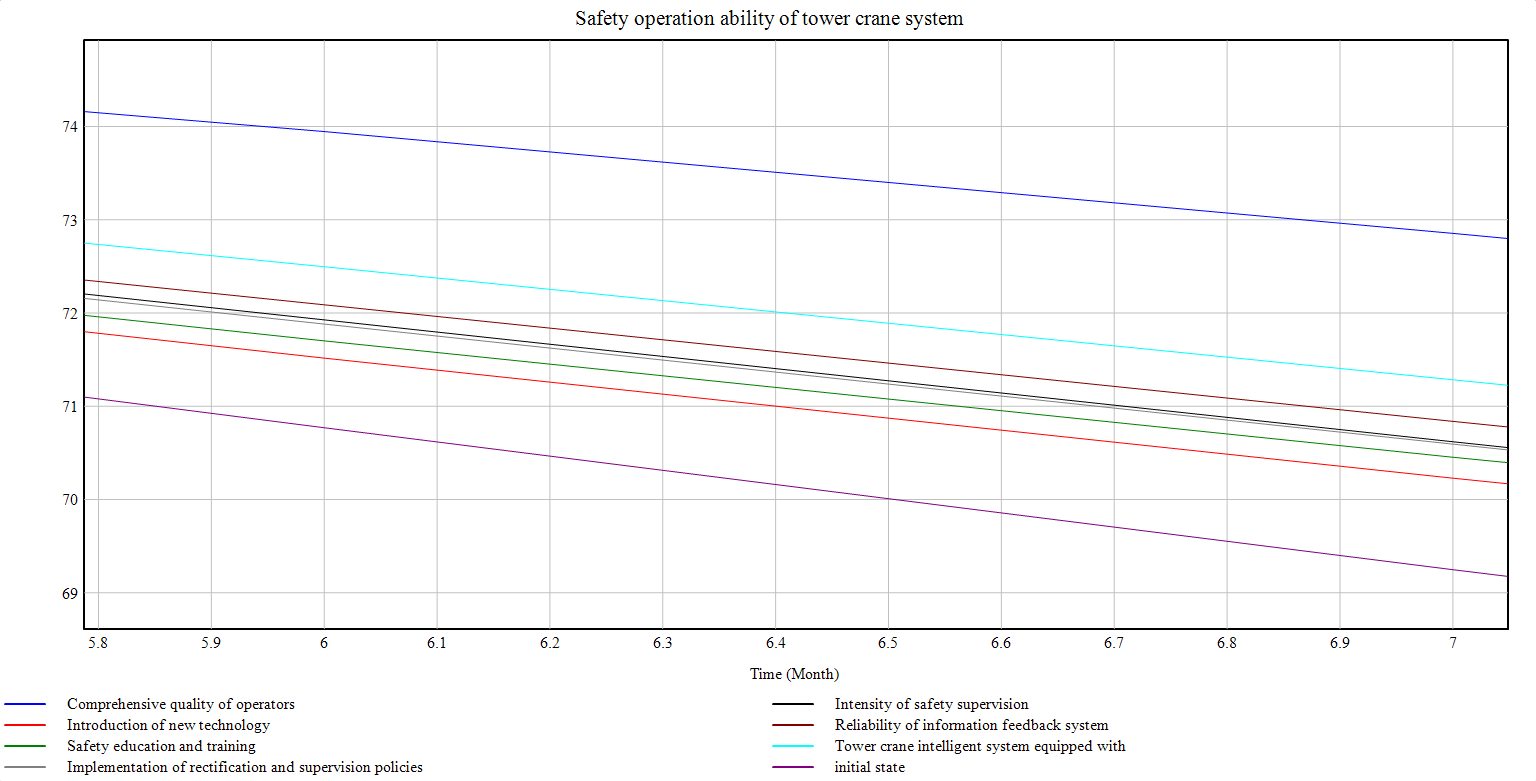

A single management strategy was applied to the key influencing factors among the result factors, which involved increasing the values of these factors to simulate the evolution of the tower crane system's safety operation capacity. The simulation results are shown in Figure 3.

|

|

Figure 3: Simulation results of single intervention strategy on key influencing factors of result factors (note: left image shows the original graph, and the right image shows a magnified portion)

As shown in Figure 3, after implementing the intervention measures, the safety operation capacity significantly improved. The effectiveness of the intervention strategies on the system is as follows: Implementation of emergency plans (5.2%); Overload protection device reliability (4.76%); Overall crane quality and performance (4.67%); Crane monitoring system reliability (4.48%); Fault alarm system reliability (4.32%); Safety protection measures (4.31%)

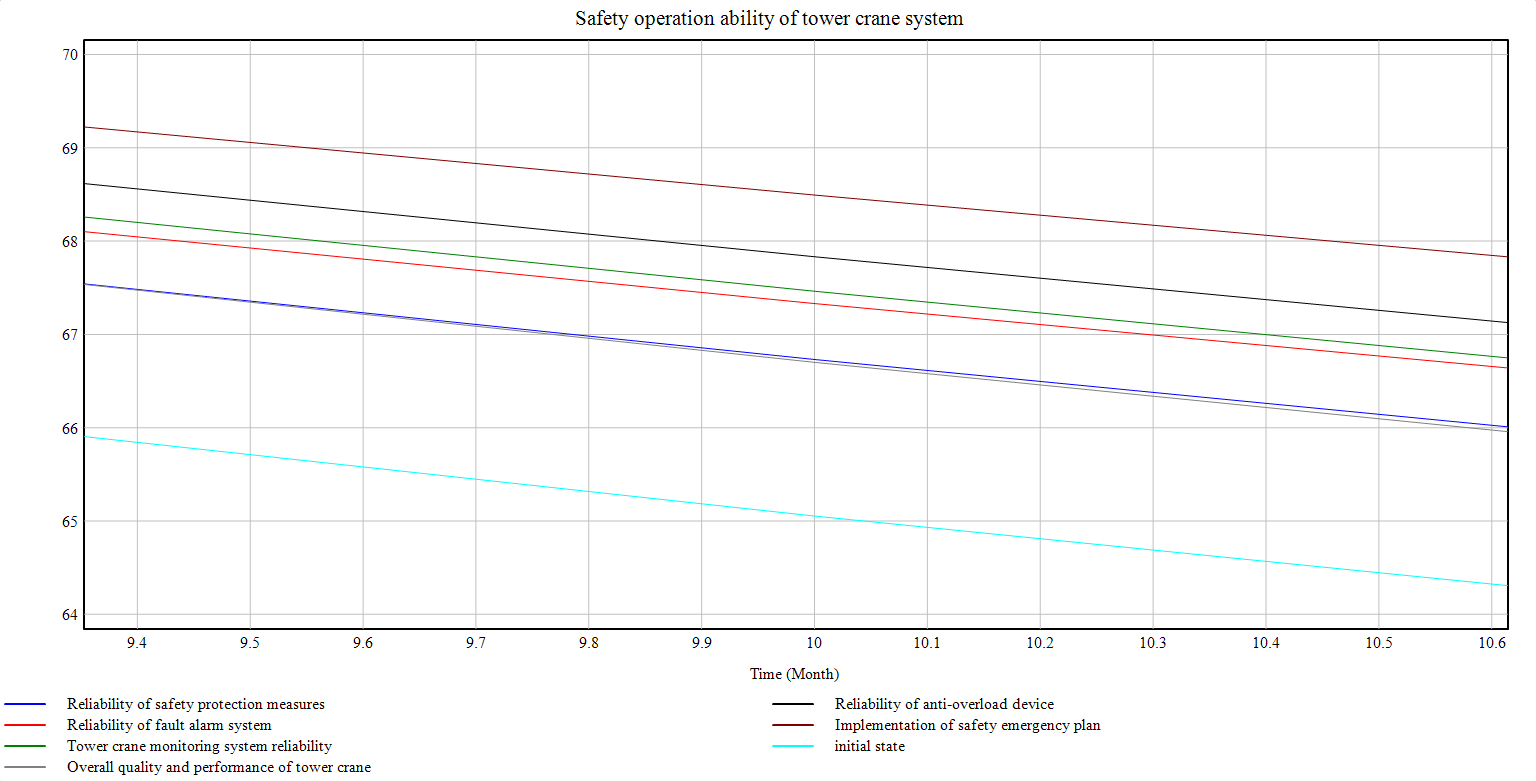

(ii) Intervention Strategy on Cause Factors

A single management strategy was also applied to the key influencing factors among the cause factors, involving an increase in the values of these factors to simulate the evolution of the safety operation capacity of the tower crane system. The simulation results are shown in Figure 4.

|

|

Figure 4: Simulation results of single intervention strategy on key influencing factors of cause factors (note: left image shows the original graph, and the right image shows a magnified portion)

As shown in Figure 4, after the intervention measures were taken, the safety operation capacity notably improved. The effectiveness of the intervention strategies on the system is as follows: Personnel safety skills (9.7%); Safety education training (8.95%); Technological innovation application (7.6%); Crane intelligent system deployment (5.25%); Information feedback system reliability (4.42%); Safety supervision strength (2.46%); Implementation of rectification and supervision policies (2.29%)

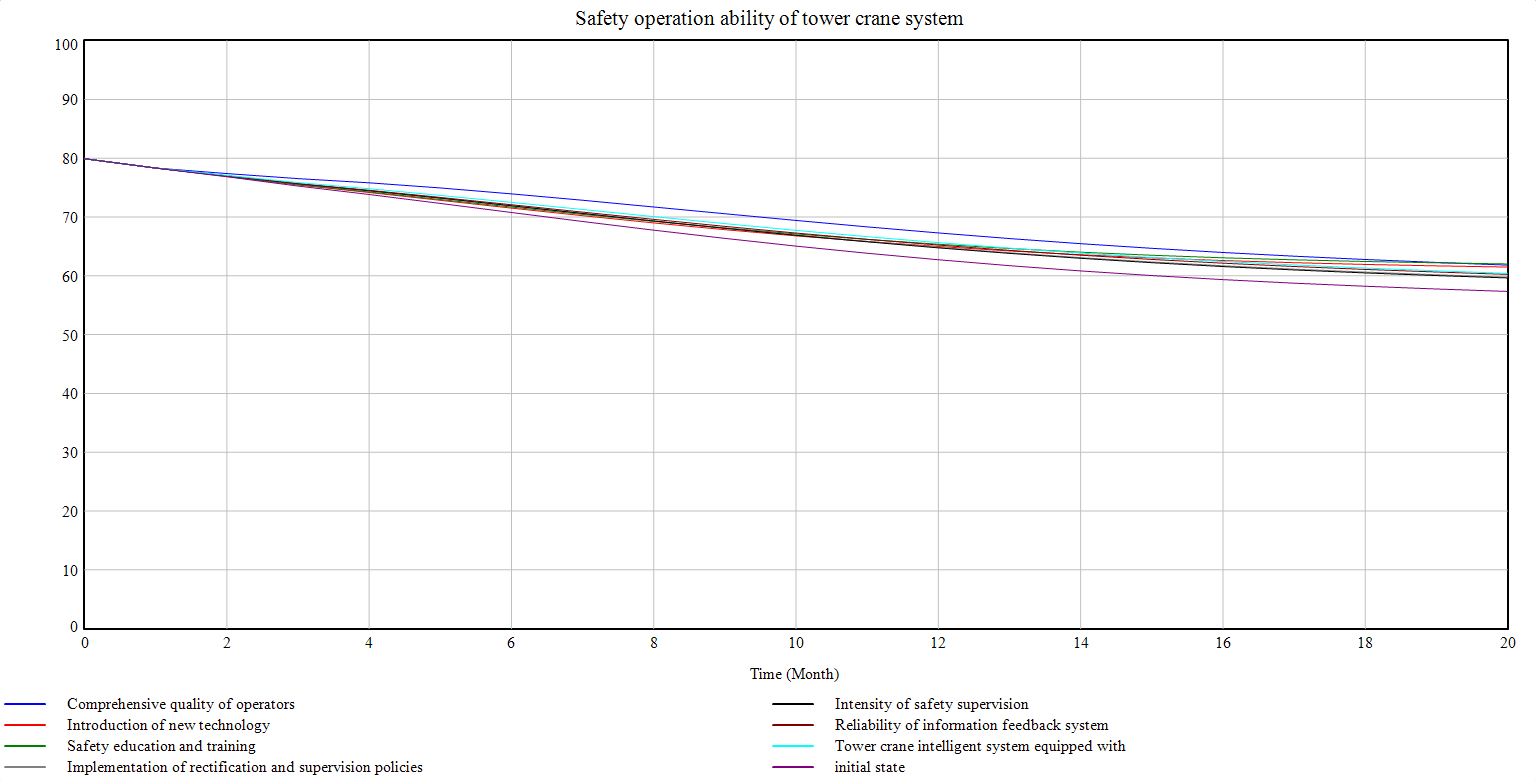

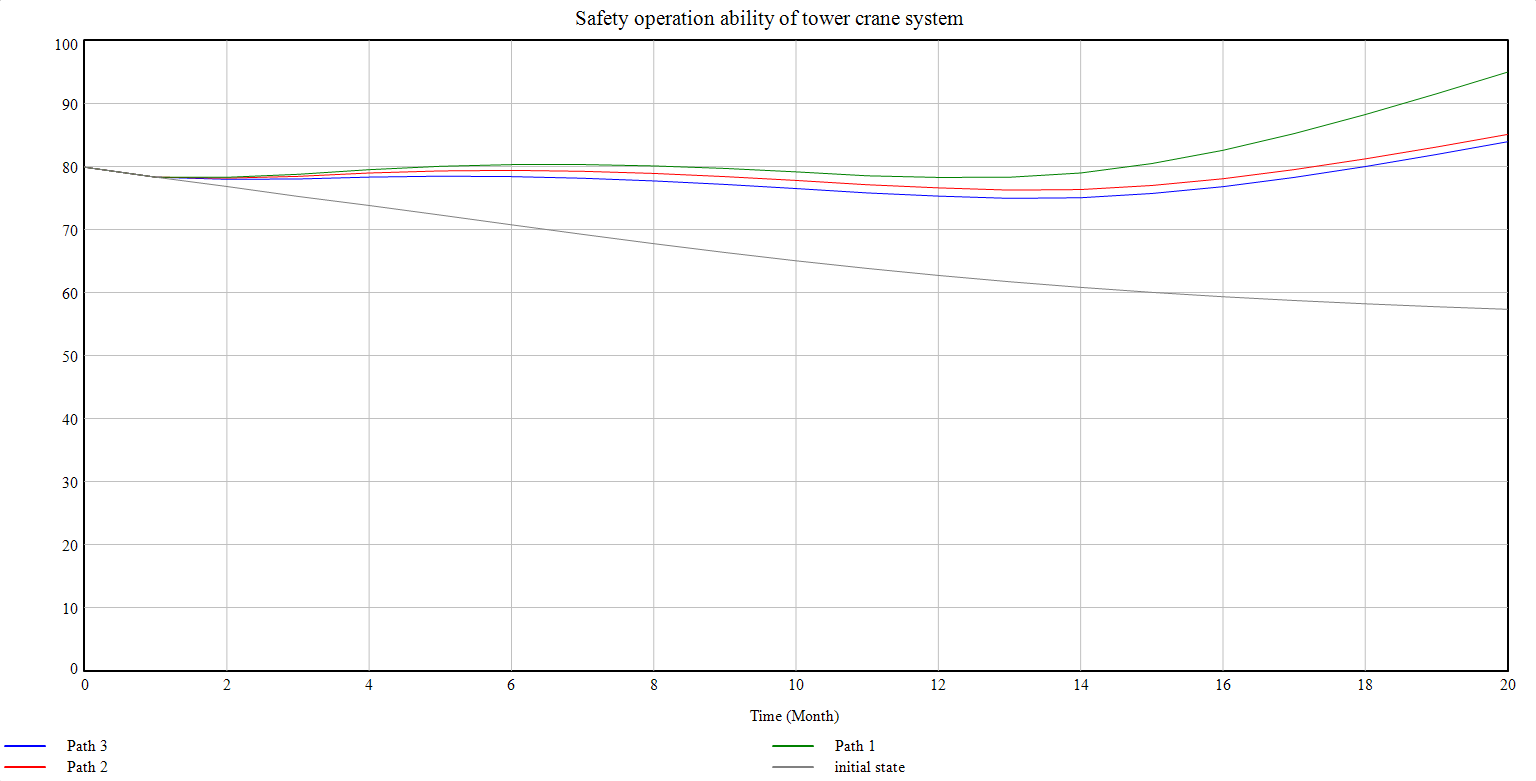

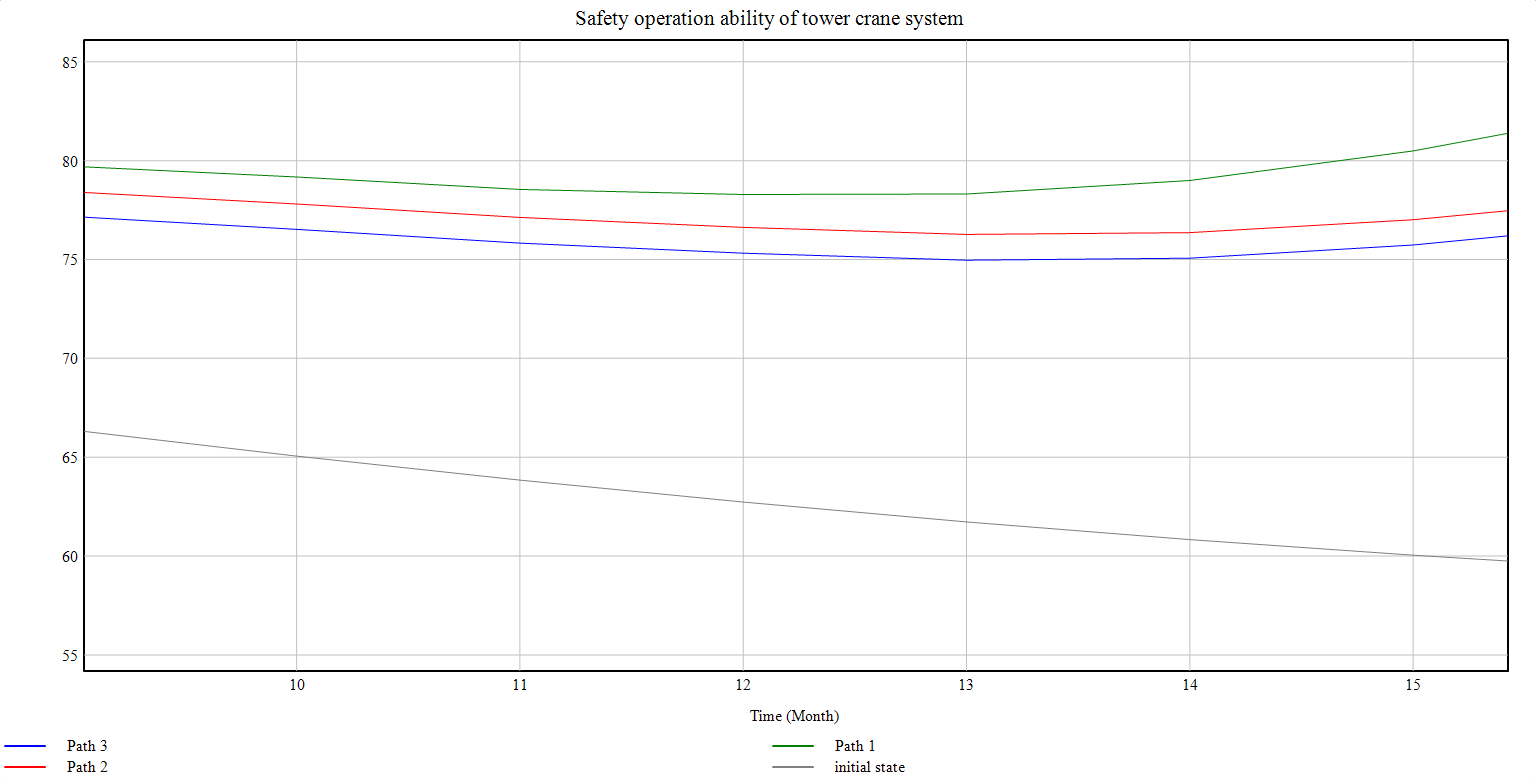

(2) Simulation Analysis of Combined Intervention Strategy

|

|

Figure 5: Simulation results of combined intervention strategy (note: left image shows the original graph, and the right image shows a magnified portion)

As shown in Figure 5, combined intervention does not necessarily imply that more influencing factors should be increased; rather, the optimal combination of interventions is identified through system dynamics simulation. Furthermore, the effectiveness of combined intervention is significantly better than that of a single intervention. The effectiveness of each combined intervention strategy on the system is as follows: Action Path 1 (18.15%); Action Path 2 (17.83%); Action Path 3 (16.6%). Therefore, by strengthening safety education training, improving personnel learning abilities, enhancing safety skills, promoting increased safety supervision, and ensuring the effective implementation of rectification and supervision policies, the reliability of overload protection devices can be improved. This will ensure the excellent performance of the overall crane quality and performance, ultimately enhancing the safety operation capacity of the tower crane system.

4. Enhancement strategies

(1) Strengthen Safety Education and Training: Regularly organize professional safety training sessions for operators. The training content should cover tower crane operation protocols, emergency accident handling, and other related topics to enhance the overall competence of operators and ensure the effective implementation of safety regulations. Improve personnel learning ability by establishing an incentive mechanism that encourages operators to engage in self-directed learning, and provide a variety of learning resources.

(2) Enhance Monitoring of Regulatory Compliance: Ensure that safety regulations are effectively implemented by strengthening the supervision of compliance. Increase the frequency of safety inspections by establishing dedicated safety monitoring positions to conduct both regular and random safety checks of tower crane operations. For issues identified during inspections, develop specific corrective measures and timelines, and enhance supervision and follow-up of these measures to ensure that problems are effectively resolved.

(3) Regularly Calibrate Overload Protection Devices: Use high-precision sensors to ensure stable operation of the equipment under various environmental conditions. Optimize equipment structural design by using high-strength, high-quality materials to enhance durability and anti-interference capabilities. Improve the performance of the tower crane’s information platform by upgrading both software and hardware to enable more accurate data analysis and fault warning, allowing for the timely detection of operational anomalies.

5. Conclusion

The safety operation capacity of the tower crane system is influenced by multiple factors. Based on the previously established indicator system for tower crane system safety operation capacity, this study used the improved Analytical Hierarchy Process (IAHP) and Entropy Weight Method (EW) combined weighting to determine the comprehensive weights of the influencing factors. A system dynamics flow chart for tower crane safety operation capacity was constructed using the expert consultation method, and intervention strategies were formulated from both single and combined perspectives. Simulation and comparative analysis using Vensim software were conducted to examine the impact of different intervention strategies on the tower crane system's safety operation capacity, ultimately identifying the optimal intervention strategy. The research results can provide valuable references for managers in developing safety management strategies during subsequent construction processes.

References

[1]. LI Hongbing, XIA Yaohui, XIE Dingkun, et al. An enhanced DEMATEL method for analyzing key safety risks in hoisting construction of prefabricated buildings[J]. Journal of Safety and Environment, 2024, 24(04): 1314-1327.

[2]. ZHOU Hongbo, YANG Qi, YANG Zhenguo, et al. Analysis of the risk involved factors and safety control of the tower crane based on the complex network and N-K model [J]. Journal of Safety and Environment, 2020, 20(03): 816-823.

[3]. YE Yongjun, ZHANG Xiaoyu, ZHANG Yingpeng. Tower crane operation accident association rule mining and Bayesian modeling analysis [J]. Journal of Safety and Environment, 2024, 24(02): 610-616.

[4]. HOLLING, C. S. Resilience and stability of ecological systems. Annual Review of Ecology and Systematics, 1973,4:1-23.

[5]. XIAHOU Xiaer, YAN Zixuan, LUO Yang, et al. Design-oriented evaluation of fire safety resilience of subway stations[J]. Journal of Safety Science and Technology, 2022, 18(12): 169-176.

[6]. SUN Lei, XIE Hongping, YU Yuezhong, et al. Influencing Factors of Engineering Construction Safety Management Based on Resilience [J]. Journal of Civil Engineering and Management, 2020, 37(04): 60-65.

[7]. LIU Jingyan, ZHENG Wenwen, ZHAO Liqin, et al. Ternary Space Safety Resilience Evaluation of Subway Engineering Construction [J]. Journal of Railway Engineering Society, 2024, 41(05): 111-117.

[8]. CHEN Weigong, ZHANG Na, ZHANG Yousen, et al. Study on Influencing Factors of Urban Disaster Resilience Based on DEMMATEL-SM[J]. Journal of Catastrophology, 2021, 36(01): 1-6+17.

[9]. HUANG Lang, WU Chao, YANG Mian, et al. Application of resilience theory in field of safety science[J]. Chinese Safety Science Journal, 2017, 27(03): 1-6.

[10]. HUANG Lang, WU Chao, Wang Bing. Modeling on shaping and assessment of system safety resilience [J]. Journal of Safety Science and Technology, 2016, 12(12): 15-21.

[11]. HALL A D.Three-dimensional morphology of systems engineering[J].IEEE Transactions on System Science and Cybernetics, 1969, 5(2): 156-160.

[12]. Xie J,Xiong Z.Analysis and Research of Electric Bicycle Design Based on Hall Three-Dimensional Structure[J].Journal of Physics:Conference Series, 2020, 1631[1]: 1-8.

[13]. CAO Min, FANG Qiancheng. Research on green degree evaluation model of prefabricated buildings based on combination weighting and attribute recognition model [J]. Journal of Safety and Environment, 2022, 22(04): 2166-2175.

[14]. XIE Bin, LIU Yan, CUI Libing. High Altitude Railway Construction Risk Warning Based on Improved Game Theory-2d Cloud Model[J]. Railway Standard Design, 2025, 69(02): 144-152.

[15]. XIONG Fan, LI Peihong, Yuan Yimin, et al. Urban flood disaster risk assessment based on GIS and combined weights [J]. Yangtze River, 2023, 54(08): 60-66.

[16]. WANG Hongchun, CHEN Yawen. Study on the Influence Factors of Resilience of the Prefabricated Construction Supply Chain Based on DEMATEL-ISM Model[J]. Journal of Engineering Management, 2023, 37(02): 13-18.

Cite this article

Yao,L. (2025). A Simulation Study on the Safety Operation Capacity of Tower Crane Systems from a Resilience Perspective. Applied and Computational Engineering,144,223-230.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Functional Materials and Civil Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. LI Hongbing, XIA Yaohui, XIE Dingkun, et al. An enhanced DEMATEL method for analyzing key safety risks in hoisting construction of prefabricated buildings[J]. Journal of Safety and Environment, 2024, 24(04): 1314-1327.

[2]. ZHOU Hongbo, YANG Qi, YANG Zhenguo, et al. Analysis of the risk involved factors and safety control of the tower crane based on the complex network and N-K model [J]. Journal of Safety and Environment, 2020, 20(03): 816-823.

[3]. YE Yongjun, ZHANG Xiaoyu, ZHANG Yingpeng. Tower crane operation accident association rule mining and Bayesian modeling analysis [J]. Journal of Safety and Environment, 2024, 24(02): 610-616.

[4]. HOLLING, C. S. Resilience and stability of ecological systems. Annual Review of Ecology and Systematics, 1973,4:1-23.

[5]. XIAHOU Xiaer, YAN Zixuan, LUO Yang, et al. Design-oriented evaluation of fire safety resilience of subway stations[J]. Journal of Safety Science and Technology, 2022, 18(12): 169-176.

[6]. SUN Lei, XIE Hongping, YU Yuezhong, et al. Influencing Factors of Engineering Construction Safety Management Based on Resilience [J]. Journal of Civil Engineering and Management, 2020, 37(04): 60-65.

[7]. LIU Jingyan, ZHENG Wenwen, ZHAO Liqin, et al. Ternary Space Safety Resilience Evaluation of Subway Engineering Construction [J]. Journal of Railway Engineering Society, 2024, 41(05): 111-117.

[8]. CHEN Weigong, ZHANG Na, ZHANG Yousen, et al. Study on Influencing Factors of Urban Disaster Resilience Based on DEMMATEL-SM[J]. Journal of Catastrophology, 2021, 36(01): 1-6+17.

[9]. HUANG Lang, WU Chao, YANG Mian, et al. Application of resilience theory in field of safety science[J]. Chinese Safety Science Journal, 2017, 27(03): 1-6.

[10]. HUANG Lang, WU Chao, Wang Bing. Modeling on shaping and assessment of system safety resilience [J]. Journal of Safety Science and Technology, 2016, 12(12): 15-21.

[11]. HALL A D.Three-dimensional morphology of systems engineering[J].IEEE Transactions on System Science and Cybernetics, 1969, 5(2): 156-160.

[12]. Xie J,Xiong Z.Analysis and Research of Electric Bicycle Design Based on Hall Three-Dimensional Structure[J].Journal of Physics:Conference Series, 2020, 1631[1]: 1-8.

[13]. CAO Min, FANG Qiancheng. Research on green degree evaluation model of prefabricated buildings based on combination weighting and attribute recognition model [J]. Journal of Safety and Environment, 2022, 22(04): 2166-2175.

[14]. XIE Bin, LIU Yan, CUI Libing. High Altitude Railway Construction Risk Warning Based on Improved Game Theory-2d Cloud Model[J]. Railway Standard Design, 2025, 69(02): 144-152.

[15]. XIONG Fan, LI Peihong, Yuan Yimin, et al. Urban flood disaster risk assessment based on GIS and combined weights [J]. Yangtze River, 2023, 54(08): 60-66.

[16]. WANG Hongchun, CHEN Yawen. Study on the Influence Factors of Resilience of the Prefabricated Construction Supply Chain Based on DEMATEL-ISM Model[J]. Journal of Engineering Management, 2023, 37(02): 13-18.