1. Introduction

In 1911, Kamerlingh Onnes discovered the first superconductor[1]. He founded that the resistivity of silver disappeared when the temperature was below 4.2K. Subsequently, scientists discovered other properties of superconductors such as high current density, Meissner effect and Josephson effect, which have high potential for practical applications[2]. In 1950s, the discovery of Nb series materials make a great advance in the field of superconducting research. In 1961, Hulm et al discovered NbTi superconducting alloy[3]. The critical transition temperature(TC) of NbTi is 9.7K and the corresponding critical field(HC2) is 12T. Matthias discovered Nb3Sn in 1954. Its onset temperature is 18K and when Tc is 4.2K, the critical field could arrive at 25T[3]. However, although Nb3Sn was discovered before NbTi, its brittle structure made it commercialized later than NbTi.

In 1980s, high temperature superconducting materials such as Bi series and Y series have also been discovered subsequently. A bismuth-based (BiSrCaCuO) oxygen superconductor with a critical temperature of 110 K has been discovered by Maida in 1988. It was later confirmed that they had obtained Bi2Sr2CaCu2O8(90K) and Bi2Sr2Ca2Cu3O10(110K). Bi2223 mainly used in superconducting cables while Bi2212 mainly used in interpolated magnet applications at low temperatures and high fields[3]. The yttrium superconductor(YBaCuO, YBCO) is the first discovered high temperature superconductor with TC over 77K[3,4]. Wu et al. discovered the new superconducting composite system with a Tc of 93K at ambient pressure and estimated the upper critical field HC(0K) between 80T and 180T[5]. Tl series is another high temperature superconducting materials with a high Tc of over 120K. However, Tl is highly toxic, its oxides are volatile and its composition is difficult to control during preparation[6,7]. These disadvantages lead to a less widespread use than for Bi-series and Y-series copper-based superconductors, despite their high Tc values[7]. In addition, there exist other superconducting materials like Iron based materials and MgB2 which are also worthy to explore in the future.

Among them, NbTi and Nb3Sn of Nb series materials are the most widely used superconducting materials at present. While compared to NbTi, Nb3Sn has relatively high Tc and HC. However, its brittle structure leads to limited working conditions. In this paper, I provided several methods to test the critical working condition, which could help readers to find the proper use condition.

2. Fabrication

Nb3Sn cannot be prepared according to the same process as NbTi wire due to its brittleness, there are vapour phase deposition, bronze-route method, diffusion method, internal tin method and powdered tubing method. Among them, the bronze method and internal tin method are the main manufacturing process[3,8].

2.1 Bronze route

Bronze route is one of the most preferred techniques to fabricate Nb3Sn multifilamentary composite wire, which was provided by Kaufmann[9] in 1970. Pure Nb rods or Nb/Ta are inserted in high tin bronze(13wt%-14wt% Sn), extruded and stretched to the required size, then twisted and shaped, and then annealed at 550-750℃[8,10]. The particular time of heat treatment depends on the requirements to grow Nb3Sn superconductor[11]. Afterwards, the Sn in the bronze interpenetrates with the Nb core, eventually producing Nb3Sn at the interface between the bronze matrix and the niobium core. The bronze/Nb rods are placed in the pure copper shell as a stabilizer, which is separated from the shell by a very thin barrier layer. The composite is then sealed and extruded, repeatedly stretched and annealed to obtain a Nb3Sn superconducting wire.

2.2 Internal tin method

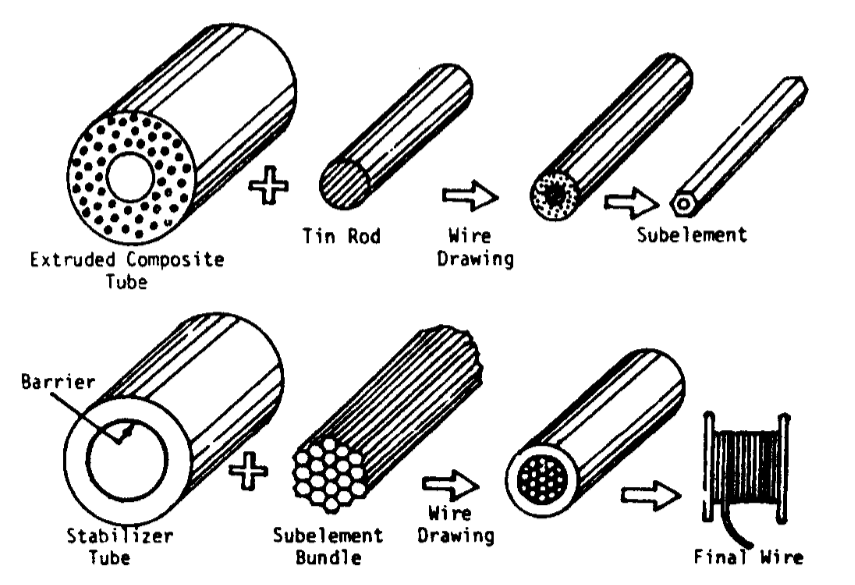

In 1974, Y. Hashimoto and K. Yoshizaki invented Internal tin method, which solved the problem of limit critical current density due to the insufficient Sn content[12].

Firstly, multiple Cu/Nb composite rods are stretched to the target size and assembled, which are processed subsequently to obtain multi-core Cu/Nb composite rods. Afterwards, the Sn rod is inserted into the multi-core Cu/Nb composite tube and then is stretched to obtain a proper ‘sub-element’ for restaking[8,13]. A number of these 'sub-elements' are stacked together in a stabilizing copper tube with a thin tantalum barrier and cold drawn to the final size of wire, figure 1[13].

Nb3Sn wire fabricated by bronze method can provide the smallest filament size about 2-3μm[12]. However, the limited content of Sn results in a relatively low critical current density. In addition, the unavoidable repeated anneals during bronze route can easily produce brittle phase, which limit the length of wire and affect the properties of products[8,12]. In contrast, Nb3Sn wire prepared by internal tin has sufficient amount of Sn, which makes it have a higher critical current density compared to the ones fabricated by bronze route. Moreover, there are no intermediate anneals during the fabrication. Thus there is no prereaction and the components of wire are ductile and uniform[13].

3. Mechanical properties

The mechanical loads in magnets are mainly arose from three principal sources: fabrication, thermal contraction and Lorentz force experienced by the superconductor when the magnet is energized, which is the most considerable source especially in high-field and large-volume magnets[14].

3.1 Axial experiment

The critical current IC of Nb3Sn superconducting materials is closely related to three factors: temperature, magnetic field and axial strain, and the relationship between them can be described by the following exponent scaling expression[15]:

\( {I_{C}}≅(H,T,ε)\frac{C1}{{μ_{0}}H}∙s(1-{t^{1.52}})×(1-{t^{2}})∙{h^{p}}∙{(1-h)^{q}} \) (1)

In this equation, μ0, C1, t, h is magnetic permeability of vacuum, constant, reduced temperature, reduced magnetic field respectively, and s(ε) is a strain-related function.

The axial mechanical properties are the most important property in application. Scientists developed several devices to test the mechanical properties.

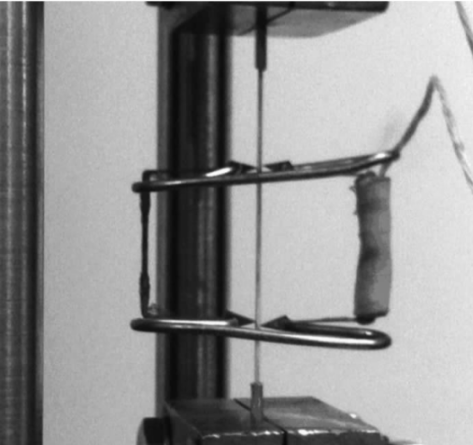

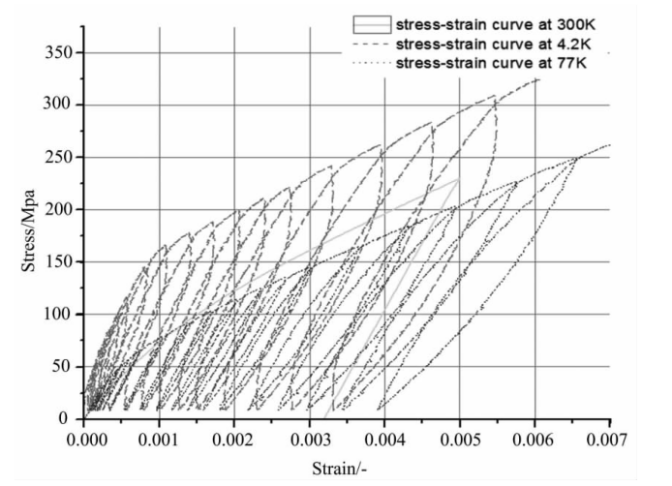

Dai Chao et al. carried out stress-strain tests on Nb3Sn at 300K, 77K and 4.2 K respectively, using a special double-sided knife edge extensometer, figure 2. He found the highest strength of the heat-treated Nb3Sn superconducting wire is at 4.2 K while the highest plasticity of the sample is at 77K[16].

(b)

In order to better simulate the actual working environment of superconducting materials and to provide more accurate measurement parameters, scientists have designed several experimental devices.

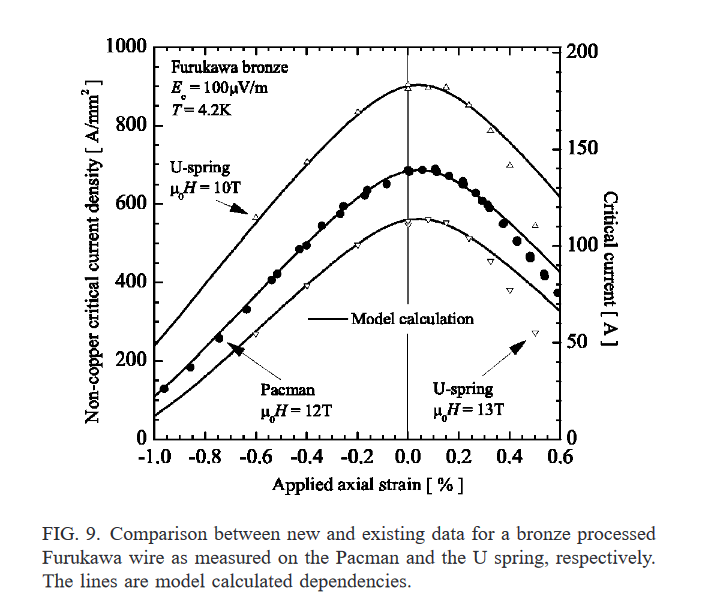

Hidetoshi et al. measured the strain of the Nb-rod-processed Cu/Nb reinforced Nb3Sn wires by a strain gauge method. They found the irreversible strain of this material reached 0.77% at a temperature of 4.2 K and a field strength of 14T. The maximum critical current was obtained at a stress of 230MPa[17]. Liang Ming et al. used a Pacman spring apparatus to measure the critical current-strain characteristic curves of Nb3Sn multi-core strands with an internal preload strain of -0.055% at 4.2K, 12T. The experimental results show that IC reaches 277A when the applied strain is zero, the irreversible strain limit of the material is +0.6%, and the strain has a small effect on material retensioning at tensile strains less than +0.3%, figure 2[18]. Walters et al. designed an apparatus(figure 3) which allowed the sample to be over a length of 70mm and increased the strain that can be applied to almost 1.3%. They discover that the three bronze Nb conductors are reversible up to 0.4% strain and the maximum current occurs when the compression in the superconducting filaments is reduced to 0[19]. In order to increase the available sample length while remaining the advantages of U-spring design, Godeke et al. designed Pacman device to characterize the axial strain dependence of critical current density in superconductors. They performed measurements on Pacman device and U-spring respectively, and they founded that the data resulting from Pacman device indicate reversibility up to +0.6% applied strain, which was never observed on data from the U-spring device[20].

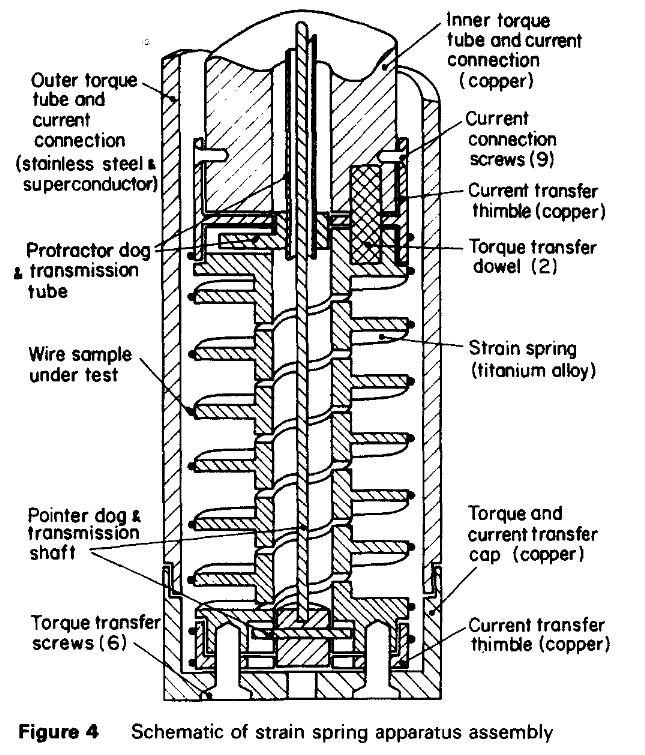

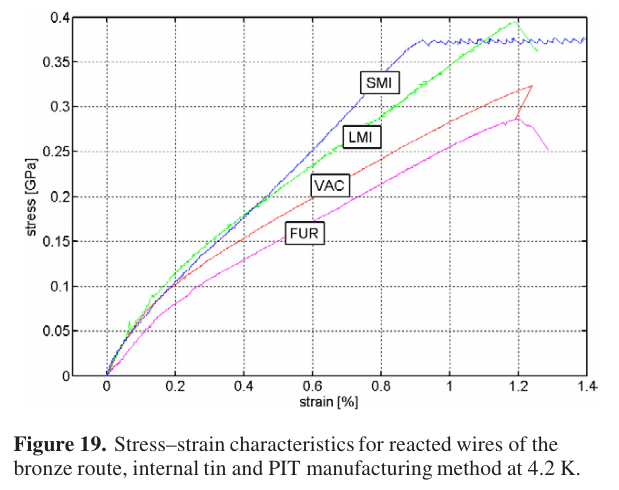

In addition, different preparation processes change the size and arrangement of the internal core filaments, which affects the current-carrying capacity of the material. By comparing the sensitivity of different companies' Nb3Sn superconducting materials IC to strain, Liang et al. learned that NIN&WST strands prepared by the internal tin method have better resistance to external strain[16]. Ei jnden et al. discovered a significantly higher strain for bronze route wires compared to the internal tin and powder-in-tube fabrication methods with a higher yielding stress level by using TARSIS(Test Arrangement for Strain Influence on Strands), figure 4[21].

3.2 Transverse force experiment

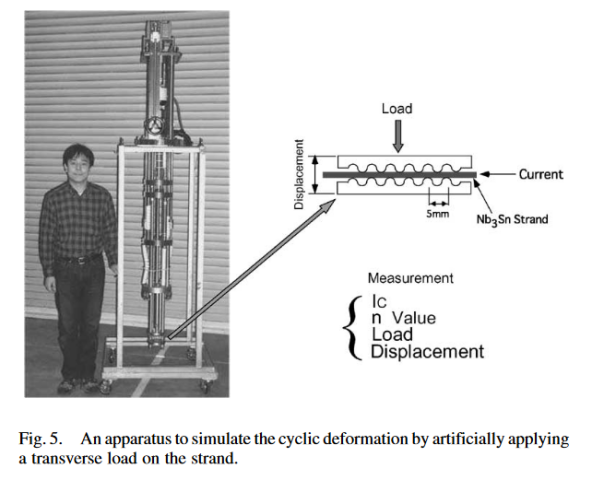

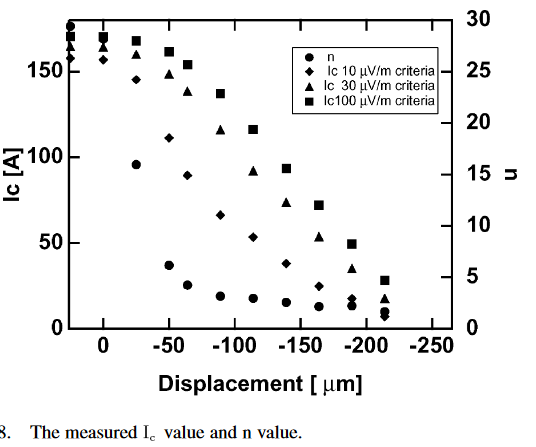

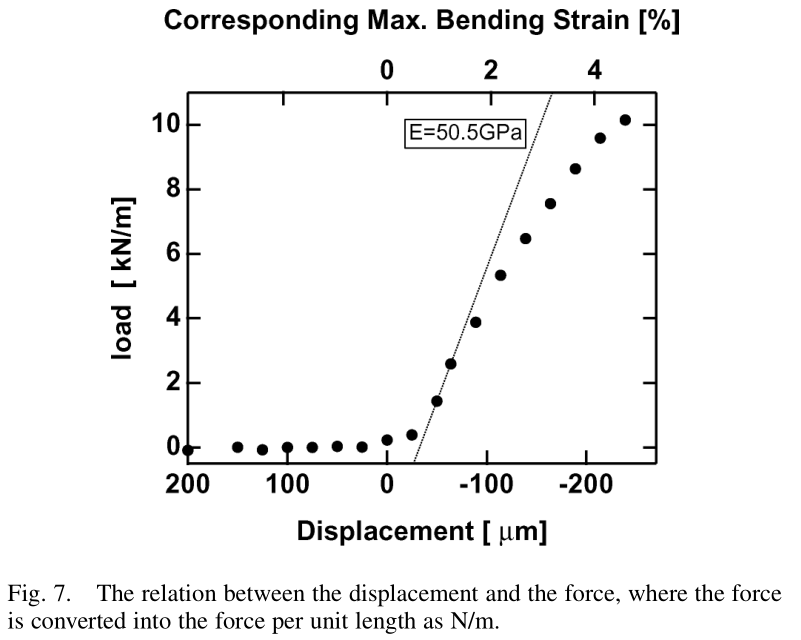

In a CIC conductor, each strand is mechanically supported by nearby strands, which produces a cyclic deformation along the strand length. Nunoya and his team[22] designed an apparatus, as shown in figure 6, which could apply a transverse load on strands artificially to simulate the cyclic deformation. They discovered that when the strand received the transverse force of 103-104 N/m, n-value reduced from the original value of 30 to less than 15, as figure 7.

3.3 Spatial periodic contact loading cycles

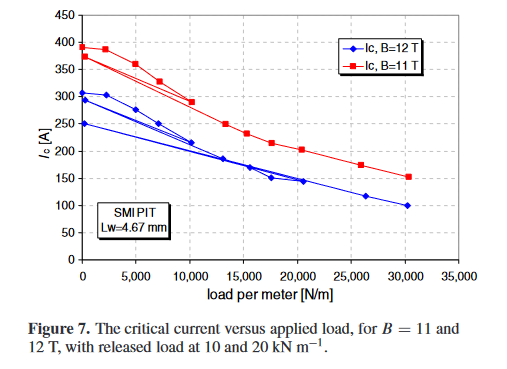

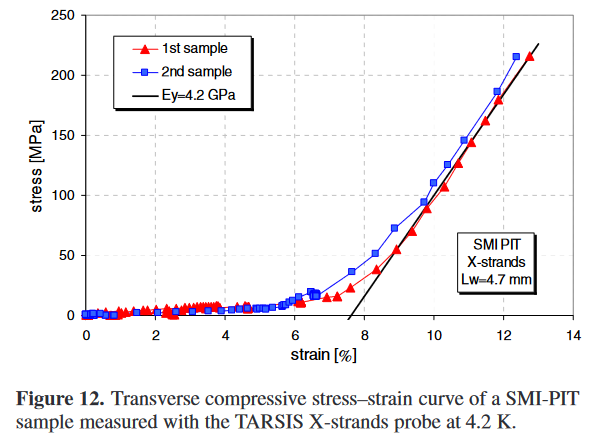

Nijhius et al. developed a new TARSIS probe that could measure the effect of spatial periodic contact loading cycles with direct measurement of the strand compression amplitude and load. They discovered that when the contact stress reached 70MPa, the critical current of strand has become irreversible, and the transverse stiffness of the strand increases as deformation grows, with a dynamic elastic modulus of 4.2GPa, figure 8-9[23].

3.4 Periodic bending

Wessel et al. designed a test setup: Test Arrangement Strain Influence on Strands(TARSIS) to evaluate the effects of deformation and strain caused by periodic bending and transverse loads. They discovered that the IC decreases by 26 % after cycling, from virgin to full load of 4400 N/m(associated bending amplitude is 20μm), with released load the permanent IC reduction is 8 %[24].

4. Application

The properties of relatively high critical transition temperature and the ability of providing high magnetic field make Nb3Sn widely used in many application areas. Nb3Sn are mainly used in nuclear magnetic resonance (NMR), magnetic confinement nuclear fusion and circular accelerators in the field of high energy physics[25].

Among them, high energy physics(HEP) requires high JC for Nb3Sn superconductors while International Thermonuclear Experimental Reactor(ITER) requires very low hysteresis losses for it. Thus, these two objectives have led to two main directions for the development of Nb3Sn superconductors: high JC research and low hysteresis loss research in ITER.

4.1 ITER

In order to control nuclear fusion reactions and achieve direct applications of fusion energy, scientists have undertaken the International Thermonuclear Experimental Reactor(ITER) collaboration to build an all-superconducting Tokamak type fusion experimental reactor as a means of providing a high magnetic field to control the plasma's potential shape and confine the plasma. The ITER program mainly uses large amounts of Nb3Sn, NbTi and other low-temperature superconducting materials as superconducting magnets[26].

China designed and developed the EAST (also known as the "Eastern Super Ring") device, which is the world's first fully superconducting Tokamak device, and its completion marks China's magnetic confinement fusion research to the world's forefront. The device could provide a magnetic field of 3.5T and a temperature environment crossing from 108 ℃ in the core of the device to -269℃ in the superconducting coil. In December 2020, China Loop II M device (HL-2M) was completed in Chengdu, and completed its first discharge, which achieved a plasma temperature of 1.5×108 ℃[22].

4.2 Circular accelerators

The energy of relativistic particles in a circular accelerator with magnetic field and machine radius can be estimated in this equation[12]:

\( E≈0.3qBr \) (2)

Applying high magnetic fields is therefore an effective way to achieve high-energy machines for hadron and ion collisions. In order to obtain high magnetic fields, the critical current density is a key parameter, which affects dramatically the performance of superconducting magnets. Compared with NbTi, Nb3Sn(usually fabricated by IT and PIT method) could produce a higher JC over 3kA/mm2 at 12T(4.2K), which makes it become the next generation superconducting materials of circular accelerators.

5. Conclusion

In summary, this paper briefly introduced the development history of superconducting materials since the early 19th century and showed the basic parameter of properties of those materials. Subsequently, this article describes two mainstream methods for the preparation of Nb3Sn and compares the differences between them. Afterwards, the paper focused on the experiments to measure the mechanical properties of Nb3Sn. Several devices such as Pacman and TRASIS are designed to test the axial strain/stress, transverse force, spatial periodic contact loading cycles and periodic bending. Finally, the applications of Nb3Sn in the fields of HEP and ITER are introduced. There is no denying that Nb3Sn with a high critical transition temperature and a high critical magnetic field is one of the state-of-art superconducting materials in the application of many areas. However, the poor mechanical performances due to its brittle ceramic structure and the relatively high fabrication costs are still needed to overcome in the future studies.

References

[1]. Fan Jiangdi. Endless Quests: Theory, Experiments and Application of Frontiers of Superconductivity[M]. Beijing: Peking University Press, 2014.

[2]. Xiao Liye, Liu Xianghong, Wang Qiuliang et al. Superconducting materials and their application status and development prospects[J]. China Industry & Information Technology, 2018, 8: 30-37.

[3]. Ma Yan-Wei. Recent development of practical superconducting materials[J]. Physics, 2015, 44(10): 674-683.

[4]. Zhao Zhongxian, Chen Liquan, Yang Qiansheng et al. Superconductivity of Ba-Y-Cu oxides in the liquid nitrogen temperature region[J]. Chinese Science Bulletin, 1987, 58(6): 412-414.

[5]. M. K. Wu, J. R. Ashburn, and C. J. Torng. Superconductivity at 93 K in a New Mixed-Phase Y-Ba-Cu-O Compound System at Ambient Pressure[J]. Physical Review Letters, 1987, 58(9): 908-910.

[6]. Zhang, L., Liu, J. Z., Littlewood, I. M., & Shelton, R. N. Crystal growth and superconductivity of TlBa2Ca3Cu4O11-δ[J]. Journal of Crystal Growth, 1997, 174(1-4): 342-345.

[7]. Xingdong Wang. Thallium-based and Mercury-based High Temperature Superconductors and their Application in the Field of Microwave[J]. Guangzhou Chemical Industry, 2013, 41(16): 24-26.

[8]. Zhang Pingxia, Li Jianfeng et al. Recent Development of Low Temperature Superconducting Wire for ITER[J]. Materials China, 2009, 28(4): 10-15.

[9]. Kaufmann, A. R., & Pickett, J. J. Multifilament Nb3Sn Superconducting Wire[J]. Journal of Applied Physics, 1971, 42(1): 58-58.

[10]. Tang Xiande. Practical multi-core Nb3Sn superconductor fabrication method and superconductivity[J]. Rare Metal Materials and Engineering, 1985, 6: 51-62.

[11]. T. Laurila, V. Vuorinen, A. K. Kumar, A. Paul. Diffusion and growth mechanism of Nb3Sn superconductor grown by bronze technique[J]. Applied Physics Letters, 2010, 96(23): 231910.

[12]. Daniel Schoerling, Alexander V. Zlobin. Nb3Sn Accelerator Magnets[M]. Springer Open, 2019: 18.

[13]. Sharma, R. G. Review on the fabrication techniques of A-15 superconductors[J]. Cryogenics, 1987, 27(7): 361-378.

[14]. Ekin, J. W. Mechanical Properties and Strain Effects in Superconductors[J]. Superconductor Materials Science: Metallurgy, Fabrication, and Applications, 1981: 455-510.

[15]. Nijhuis, A., Pompe van Meerdervoort, R. P., Krooshoop, H. J. G., Wessel, W. A. J., Zhou, C., Rolando, G., … Yu, W. The effect of axial and transverse loading on the transport properties of ITER Nb3Sn strands[J]. Superconductor Science and Technology, 2013, 26(8): 084004.

[16]. Chao Dai, Bo Liu, Jianggang Qin et al.. Study on the mechanical properties NbTi and Nb3Sn superconducting strand[J]. Chinese Journal of Low Temperature Physics, 2014, 36(6): 475-781.

[17]. Oguro, H., Awaji, S., Watanabe, K., Sugimoto, M., & Tsubouchi, H. Mechanical and superconducting properties of Nb3Sn wires with Nb-rod-processed CuNb reinforcement[J]. Superconductor Science and Technology, 2013, 26(9): 094002.

[18]. Liang Ming, Zhang Pingxiang, Tang Xiande et al. Strain effect on transport properties of Nb3Sn Multifilament strands prepared by internal tin route[J]. ACTA Metallurgica Sinica, 2009. 45(2): 223-226.

[19]. Walters, C. R., Davidson, I. M., & Tuck, G. E. Long sample high sensitivity critical current measurements under strain[J]. Cryogenics,1986, 26(7): 406-412.

[20]. Godeke, A., Dhalle, M., Morelli, A., Stobbelaar, L., van Weeren, H., van Eck, H. J. N., … ten Haken, B. A device to investigate the axial strain dependence of the critical current density in superconductors[J]. Review of Scientific Instruments, 2004, 75(12): 5112-5118.

[21]. Eijnden, N. C. van den, Nijhuis, A., Ilyin, Y., Wessel, W. A. J., & Kate, H. H. J. ten. Axial tensile stress–strain characterization of ITER model coil type Nb3Sn strands in TARSIS[J]. Superconductor Science and Technology, 2005, 18(11): 1523–1532.

[22]. Nunoya, Y., Isono, T., & Okuno, K. Experimental Investigation on the Effect of Transverse Electromagnetic Force on the V-T Curve of the CIC Conductor[J]. IEEE Transactions on Appiled Superconductivity, 2004, 14(2): 1468-1472.

[23]. Nijhuis, A., Ilyin, Y., & Wessel, W. A. J. Spatial periodic contact stress and critical current of a Nb3Sn strand measured in TARSIS. Superconductor Science and Technology, 2006, 19(11): 1089-1096.

[24]. Wessel, W. A. J. A Novel “Test Arrangement for Strain Influence on Strands” (TARSIS): Mechanical and Electrical Testing of ITER Nb3Sn Strands[J]. AIP Conference Proceedings, 2004.

[25]. Liang Ming, Zhang Pingxiang, Lu Yafeng, Li Jinshan, Li Chengshan, Tang Xiande. Advances in Nb3Sn Superconductor for Magnet Application[J]. Materials Reports, 2006, 20(12): 1-4.

[26]. Qiao Li. Critical properties of Nb3Sn superconductors for magnets[M]. Publishing House of Electronics Industry, 2021.

Cite this article

Jin,Y. (2023). Mechanical properties and application of superconducting materials of Nb3Sn. Applied and Computational Engineering,7,281-290.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Materials Chemistry and Environmental Engineering (CONF-MCEE 2023), Part II

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Fan Jiangdi. Endless Quests: Theory, Experiments and Application of Frontiers of Superconductivity[M]. Beijing: Peking University Press, 2014.

[2]. Xiao Liye, Liu Xianghong, Wang Qiuliang et al. Superconducting materials and their application status and development prospects[J]. China Industry & Information Technology, 2018, 8: 30-37.

[3]. Ma Yan-Wei. Recent development of practical superconducting materials[J]. Physics, 2015, 44(10): 674-683.

[4]. Zhao Zhongxian, Chen Liquan, Yang Qiansheng et al. Superconductivity of Ba-Y-Cu oxides in the liquid nitrogen temperature region[J]. Chinese Science Bulletin, 1987, 58(6): 412-414.

[5]. M. K. Wu, J. R. Ashburn, and C. J. Torng. Superconductivity at 93 K in a New Mixed-Phase Y-Ba-Cu-O Compound System at Ambient Pressure[J]. Physical Review Letters, 1987, 58(9): 908-910.

[6]. Zhang, L., Liu, J. Z., Littlewood, I. M., & Shelton, R. N. Crystal growth and superconductivity of TlBa2Ca3Cu4O11-δ[J]. Journal of Crystal Growth, 1997, 174(1-4): 342-345.

[7]. Xingdong Wang. Thallium-based and Mercury-based High Temperature Superconductors and their Application in the Field of Microwave[J]. Guangzhou Chemical Industry, 2013, 41(16): 24-26.

[8]. Zhang Pingxia, Li Jianfeng et al. Recent Development of Low Temperature Superconducting Wire for ITER[J]. Materials China, 2009, 28(4): 10-15.

[9]. Kaufmann, A. R., & Pickett, J. J. Multifilament Nb3Sn Superconducting Wire[J]. Journal of Applied Physics, 1971, 42(1): 58-58.

[10]. Tang Xiande. Practical multi-core Nb3Sn superconductor fabrication method and superconductivity[J]. Rare Metal Materials and Engineering, 1985, 6: 51-62.

[11]. T. Laurila, V. Vuorinen, A. K. Kumar, A. Paul. Diffusion and growth mechanism of Nb3Sn superconductor grown by bronze technique[J]. Applied Physics Letters, 2010, 96(23): 231910.

[12]. Daniel Schoerling, Alexander V. Zlobin. Nb3Sn Accelerator Magnets[M]. Springer Open, 2019: 18.

[13]. Sharma, R. G. Review on the fabrication techniques of A-15 superconductors[J]. Cryogenics, 1987, 27(7): 361-378.

[14]. Ekin, J. W. Mechanical Properties and Strain Effects in Superconductors[J]. Superconductor Materials Science: Metallurgy, Fabrication, and Applications, 1981: 455-510.

[15]. Nijhuis, A., Pompe van Meerdervoort, R. P., Krooshoop, H. J. G., Wessel, W. A. J., Zhou, C., Rolando, G., … Yu, W. The effect of axial and transverse loading on the transport properties of ITER Nb3Sn strands[J]. Superconductor Science and Technology, 2013, 26(8): 084004.

[16]. Chao Dai, Bo Liu, Jianggang Qin et al.. Study on the mechanical properties NbTi and Nb3Sn superconducting strand[J]. Chinese Journal of Low Temperature Physics, 2014, 36(6): 475-781.

[17]. Oguro, H., Awaji, S., Watanabe, K., Sugimoto, M., & Tsubouchi, H. Mechanical and superconducting properties of Nb3Sn wires with Nb-rod-processed CuNb reinforcement[J]. Superconductor Science and Technology, 2013, 26(9): 094002.

[18]. Liang Ming, Zhang Pingxiang, Tang Xiande et al. Strain effect on transport properties of Nb3Sn Multifilament strands prepared by internal tin route[J]. ACTA Metallurgica Sinica, 2009. 45(2): 223-226.

[19]. Walters, C. R., Davidson, I. M., & Tuck, G. E. Long sample high sensitivity critical current measurements under strain[J]. Cryogenics,1986, 26(7): 406-412.

[20]. Godeke, A., Dhalle, M., Morelli, A., Stobbelaar, L., van Weeren, H., van Eck, H. J. N., … ten Haken, B. A device to investigate the axial strain dependence of the critical current density in superconductors[J]. Review of Scientific Instruments, 2004, 75(12): 5112-5118.

[21]. Eijnden, N. C. van den, Nijhuis, A., Ilyin, Y., Wessel, W. A. J., & Kate, H. H. J. ten. Axial tensile stress–strain characterization of ITER model coil type Nb3Sn strands in TARSIS[J]. Superconductor Science and Technology, 2005, 18(11): 1523–1532.

[22]. Nunoya, Y., Isono, T., & Okuno, K. Experimental Investigation on the Effect of Transverse Electromagnetic Force on the V-T Curve of the CIC Conductor[J]. IEEE Transactions on Appiled Superconductivity, 2004, 14(2): 1468-1472.

[23]. Nijhuis, A., Ilyin, Y., & Wessel, W. A. J. Spatial periodic contact stress and critical current of a Nb3Sn strand measured in TARSIS. Superconductor Science and Technology, 2006, 19(11): 1089-1096.

[24]. Wessel, W. A. J. A Novel “Test Arrangement for Strain Influence on Strands” (TARSIS): Mechanical and Electrical Testing of ITER Nb3Sn Strands[J]. AIP Conference Proceedings, 2004.

[25]. Liang Ming, Zhang Pingxiang, Lu Yafeng, Li Jinshan, Li Chengshan, Tang Xiande. Advances in Nb3Sn Superconductor for Magnet Application[J]. Materials Reports, 2006, 20(12): 1-4.

[26]. Qiao Li. Critical properties of Nb3Sn superconductors for magnets[M]. Publishing House of Electronics Industry, 2021.