1. Introduction

Micro-gripping technology, as one of the core technologies in micro-electromechanical system (MEMS) assembly, biomedical operations (e.g., cell manipulation and microsurgery), and precision industrial manufacturing, directly determines the manipulation accuracy and reliability of microscale objects. At the micron or even nanoscale, grippers must integrate high-precision displacement control with adaptive stiffness modulation to accommodate diverse object characteristics (e.g., fragility, geometric variability) and environmental uncertainties [1].

However, existing variable stiffness mechanisms face significant limitations in structural efficiency and dynamic performance. First, pneumatic actuation systems rely on complex fluidic networks and airtight sealing components, leading to bulky designs and delayed responses. For instance, pneumatic soft grippers often require multi-chamber coordination to achieve basic functionality. Second, although shape memory alloys (SMAs) are able to switch stiffness through phase transitions, control inaccuracies induced by thermal hysteresis and low response frequencies, limit real-time adaptability. For example, SMA-based microgrippers require intricate pulse modulation and are prone to performance degradation under fluctuating ambient temperatures. These challenges underscore inherent compromises between system simplicity, operational speed, and environmental reliability in traditional approaches.

To address these challenges, this study proposes two bidirectional gripping micro-gripper designs based on material stiffness-switching mechanisms, aiming to overcome the bottlenecks of traditional variable stiffness technologies through structural innovation and material synergy. These designs eliminate complex pneumatic pipelines and thermal actuation, and achieve rapid stiffness switching and precise control by combining two materials with distinct stiffness properties in a tailored structural configuration. The feasibility of the variable stiffness system is verified in this paper through 3D modeling and simulation. In addition, this paper compares the contact area and load distribution between the two designs in reverse clamping operations using comparative analysis with the goal of analyzing the influence of structural parameters on gripping performance. The comparative analysis also includes a comparison with existing solutions, such as pneumatic or thermally actuated grippers to evaluate their potential for system simplification (e.g., eliminating external pumps and valves or high-frequency heat sources), and stiffness-switching efficiency.

The significance of this research lies in bridging a technological gap in variable-stiffness micro-grippers, offering a novel solution for automated microassembly and biomedical micromanipulation. Its low-cost, easy-to-integrate features make it widely applicable to industrial scenarios such as semiconductor chip packaging and micro-sensor assembly, while also providing technical support for single-cell manipulation and microsurgical tool development, thereby driving cross-disciplinary innovation in precision manufacturing and life sciences.

2. Existing variable-stiffness systems

2.1. Pneumatic soft manipulators

The pneumatic soft gripper typically employs a fast pneumatic network (FPN) structure, which has multiple interconnected chambers to achieve bending deformation via gas pressurization [2]. By optimizing structural parameters, such as chamber length, sidewall thickness, and strain-limiting layers, the gripper achieves higher load capacity (up to 5 N) and rapid actuation through coordinated inflation of adjacent chambers. Although this design improves adaptability to irregular objects and enables compliant grasping, its reliance on multi-chamber coordination introduces inherent complexities [3]. The necessity for precise gas channel sealing, bulky external pneumatic pumps/valves, and multi-chamber synchronization result in response times delay (e.g., delay in pressure propagation across chambers) and system miniaturization challenges. Furthermore, the addition of auxiliary stiffness-enhancing components (e.g., springs) to compensate for the inherent low material stiffness complicates the structural design, further limiting its applicability in scenarios requiring compact, high-speed operation, such as industrial microassembly or biomedical micromanipulation.

2.2. Shape Memory Alloy (SMA)-based micro-grippers

SMA-driven micro-grippers utilize phase transitions for stiffness modulation, with one SMA micro-gripper design exploiting bidirectional shape memory effects through cyclic thermal training, and reversible opening/closing motions via Joule heating (current pulses) and passive cooling. The system achieves a maximum gripping displacement of 0.2 mm with sub-micron resolution [4]. However, the SMA’s intrinsic thermal hysteresis and slow cooling rates significantly limit dynamic stiffness regulation. For instance, precise control of heating pulses (e.g., 2.4 V amplitude, 100 ms period) and cooling intervals is required to maintain stable gripping forces, making the system susceptible to environmental temperature fluctuations. Additionally, SMA actuators exhibit strong saturation hysteresis, where output displacement depends on historical thermal inputs, leading to nonlinear control errors [5]. Consequently, These issues result in low response frequencies and poor repeatability, rendering SMA-based systems inadequate for high-speed industrial applications or delicate biomedical tasks demanding real-time stiffness adaptation.

3. Methodology

3.1. Related work

Hua et al. proposed a bi-directional gripping mechanism using a symmetric four-bar linkage to achieve bi-directional object manipulation. The experimental results demonstrated that bi-directional motion capability could enhance grasping flexibility without increasing the control complexity, particularly by symmetrical forces application on both inner and outer surfaces of the object [6]. Building upon this bidirectional motion principle, this paper proposes that stiffness variability can be effectively achieved by strategically combining materials with distinct elastic properties in antagonistic configurations. This design philosophy aligns with the inherent bidirectional kinematics of the referenced mechanism while introducing a material-level solution for stiffness modulation. It potentially enables adaptive compliance transition between rigid and soft grasping modes without compromising the mechanism's inherent motion symmetry.

3.1.1. Bidirectional stiffness-switching

The proposed bidirectional gripping mechanism introduces a variable-stiffness strategy through asymmetric material properties and directional actuation. The bidirectional stiffness-switching system realises low-stiffness reverse gripping (soft-contact mode) and high-stiffness forward gripping (rigid-clamping mode) by integrating dissimilar stiffness materials on the upper and lower surfaces of the gripping jaws to satisfy the bimodal operation. This design eliminates the need for external actuators or complex mechanical linkages, instead relying on the inherent stiffness gradient between materials and directional force application. When flipped 360° along its axis, the gripper switches between modes, and adapts to compliance or rigid fixation based on target object properties. This bidirectional approach decouples stiffness modulation from actuation complexity, ensuring rapid adaptation while maintaining structural simplicity.

3.1.2. Design requirements

The proposed bidirectional variable-stiffness micro-gripper must implement adaptive manipulation of objects with contrasting rigidity requirements through reversible clamping modes that combines material property gradients with directional motion control. For biomedical applications, the reverse clamping mode must ensure low-stiffness contact with uniform force distribution, satisfying the sensitivity of biological tissues (e.g., cell clusters, vascular grafts) to micronewton-level contact forces. Simultaneously, the forward clamping mode must exhibit sufficient structural rigidity to maintain sub-millimeter positioning accuracy and avoid slippage or angular deviation when handling rigid instruments, such as biopsy needles or surgical blades [7]. Therefore, material configurations should incorporate stiffness gradients through heterogeneous layering (e.g., upper-layer rigid polymer and lower-layer elastomer composite) to enable abrupt stiffness transitions during mode switching [8].

In electronics assembly, the reverse clamping mode must enable nondestructive handling of deformable components (e.g., flexible circuits, silicone-encapsulated sensors) by limiting contact pressure below kPa-level thresholds to prevent surface indentation or delamination [9]. Meanwhile, the forward clamping mode must guarantee stable gripping of rigid substrates like ceramic boards or metal connectors, suppressing vibration-induced micron-scale positional drift during high-speed assembly. And structural integration requires a 360° rotational switching mechanism driven by directional motion of the tail guide rail, ensuring rapid mode transitions while adhering to spatial constraints typical in microelectronics manufacturing [10].

As a micro-robotic end-effector, the gripper must reconcile miniaturization with multifunctionality. The reverse clamping mode absorbs impact energy through low-stiffness characteristics to protect fragile components (e.g., optical lenses, MEMS devices), while the forward mode maintains structural stability for precision tasks like micro-bearing press-fitting or fiber-optic alignment. This requires the design of a system that achieves autonomous stiffness switching without external actuation, ensuring seamless integration into robotic workcells in automated production lines. Additionally, it requires the designed system to meet a durability requirement of 10,000-cycle, adhering to the principle of "structural minimalism", to achieve functional breakthroughs by eliminating complex transmission mechanisms through innovative material-motion coupling.

3.2. Structural designed

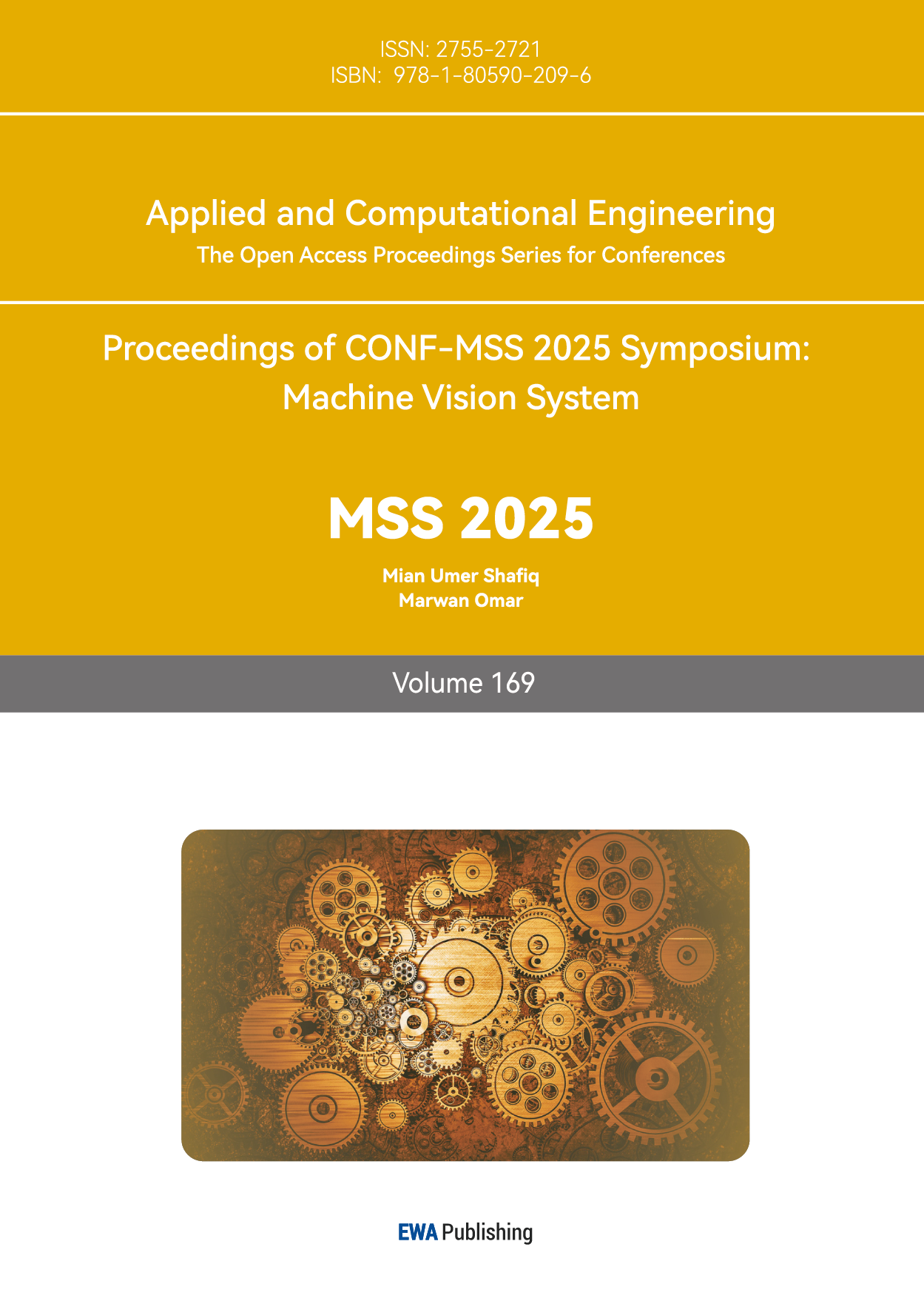

The first-generation gripper architecture illustrated in Figures 1, utilises a hybrid fixed-rotary configuration to reconcile functional versatility with structural integrity. A stationary jaw (thick jaw in Figures 1(a)) is permanently affixed to the central drive shaft, establishing a rigid mechanical reference frame, while its counterpart is integrated into a circular guide rail through a low-friction sliding module. This asymmetric arrangement decouples rotational motion from gripping force transmission, and prioritizes positional stability during bidirectional mode transitions. Also, the rotary jaw (thin jaw in Figures 1(a)) features material-heterogeneous upper and lower surfaces, enabling stiffness modulation through 360° rail-guided reorientation. By executing a 360° rotation, the gripper can alternate between high-stiffness engagement (rigid surface contact) and low-stiffness interaction (compliant surface contact). In addition, the circular guideway’s continuous curvature and closed-loop topology ensure smooth angular displacement while mitigating stress concentration, with the fixed jaw providing a stable geometric datum for precision manipulation tasks.

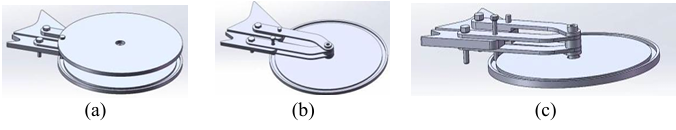

The refined design presented in Figure 2(a) resolves spatial and operational constraints through geometric unification. The optimised two jaws exhibit identical form factors and symmetrical rail mounting, replacing the original asymmetric architecture. This standardization simplifies the manufacturing process by eliminating specialized components and penetrating recessed geometries more deeply than the previously bulkier first-generation jaw could penetrate. The dual-jaw symmetry permits either surface to serve as the primary engagement interface, enhancing operational flexibility in constrained environments. And geometric harmonization further ensures balanced force distribution across contact surfaces, critical for handling delicate objects requiring uniform pressure application. Moreover, the optimized profile reduces overall lateral dimensions, enhancing compatibility with multi-axis robotic manipulators and narrow workspace configurations.

3.3. Material for bidirectional gripping

3.3.1. Selection

The bidirectional gripping mechanism integrates a high-performance aluminum alloy with an engineered silicone elastomer. This material pairing directly supports the dual-mode stiffness requirement, where the aluminum provides structural rigidity for forward clamping, while the silicone enables compliant reverse gripping.

The aluminum component, optimized from 7XXX-series alloys containing zinc, magnesium, and copper, achieves tensile strengths exceeding 500 MPa while maintaining density below 3 g/cm³. This strength-to-weight ratio is critical for minimizing inertial effects during rapid stiffness-switching operations.Its thermal stability derives from nanoscale η-phase precipitates (MgZn₂) resistant to coarsening below 150°C, combined with zirconium-containing dispersoids that maintain structural integrity during thermal cycling between -50°C and 150°C. These properties ensure consistent performance in environments with temperature fluctuations, aligning with the design goal of environmental adaptability. Chromate conversion coatings applied to the aluminum surface provide corrosion resistance surpassing 1,000 hours in salt spray tests, critical for non-magnetic applications where traditional ferrous materials are prohibited.Precision manufacturing through warm forging and CNC machining achieves micron-level tolerances with surface finishes below Ra 0.8 μm for critical interfaces. This manufacturing strategy addresses the need for seamless integration of dissimilar materials, ensuring reliable contact transitions between rigid and compliant modes without parasitic energy losses [11].

The silicone counterpart utilizes a platinum-catalyzed liquid silicone rubber (LSR) formulation with elastic modulus tuned between 0.5-1.5 MPa, enabling adjustable compliance to accommodate diverse object geometries during reverse clamping operations. Capable of 400% elongation while recovering 95% of its original shape after 10⁶ compression cycles, such durability aligns with the requirement for long-term cyclic stability in repetitive grasping tasks.

Laser-textured surface features below 50 μm height enhance frictional coefficients to 1.8-2.2 to prevent slippage of delicate or irregularly shaped targets, without compromising biocompatibility per ISO 10993 standards for potential biomedical or food-handling applications. The phenyl-methyl siloxane backbone maintains flexibility from -100°C to 300°C, ensuring consistent performance under thermal extremes encountered in industrial sterilization or aerospace environments, exhibiting less than 5% volume change during ethylene oxide sterilization or immersion in pH 2-12 solutions to resist chemical degradation in harsh workflows.

Its viscoelastic network dissipates 40% of vibrational energy in the 100-500 Hz range through controlled crosslink density and fumed silica reinforcement, a critical feature for maintaining grip stability in high-vibration settings like robotic assembly lines or unmanned aerial vehicle (UAV) manipulators [12].

The materials synergy enables balanced functionality unattainable with single-material systems. The aluminum component concentrates clamping forces at critical contact points, while the silicone redistributes lateral stresses to prevent damage to fragile substrates. This combination simultaneously addresses conflicting requirements for precision handling and deformation accommodation, particularly in biomedical contexts where rigid tools must interact safely with delicate tissues. Both materials exhibit robust thermal stability, with the aluminum alloy maintaining structural integrity across a broad operational temperature range and the silicone elastomer retaining flexibility under extreme thermal conditions. This complementary thermal behaviors ensures coordinated performance during environmental fluctuations, aligning with the system's adaptability requirements in diverse application scenarios, from industrial automation to biomedical procedures [13-14].

Thermal compatibility between the materials ensures coordinated performance during temperature fluctuations, maintaining grip integrity without force drift across operational cycles. The system's architecture leverages the aluminum's structural efficiency and the silicone's energy-absorbing characteristics to suppress resonant vibrations, thereby enabling stable operation in high-speed automation scenarios. This integration of material properties achieves a unified solution for applications demanding surgical-grade safety, industrial durability, and sub-millimeter precision[13,15].

3.3.2. Process treatment

To ensure robust integration of the aluminum-silicone material pair and optimize gripping reliability, two critical manufacturing processes were implemented: surface modification of the aluminum substrate and silicone-metal adhesion through controlled molding. These techniques address adhesion, durability, and operational stability challenges inherent in bidirectional micro-grippers.

The first process enhances gripping force transmission and mechanical anchoring by controlling abrasion to reinforce surface roughness By creating microscale textures on the aluminum surface, this treatment significantly increases friction between the gripper and target objects, preventing slippage when handling smooth materials. These textures also provide interlocking points for silicone bonding without chemical adhesives. The uniformity of the modified surface contributes to consistent force distribution and long-term resistance to abrasion during repeated operations. Crucially, this surface treatment preserves the substrate's inherent resistance to high temperatures and corrosive environments, maintaining suitability for applications ranging from medical sterilization to industrial thermal processes [16].

The second process achieves seamless bonding through precision molding of liquid silicone onto the textured substrate. By optimizing injection parameters such as temperature and speed, the silicone fully replicates surface microstructures while maintaining material fluidity before curing. High injection speeds ensure complete penetration of surface features before crosslinking occurs, eliminating voids or weak interfacial points. This adhesive-free approach avoids chemical degradation risks and delamination under dynamic loads, critical for biomedical or food-contact applications. The molded silicone layer conforms precisely to surface irregularities, retaining flexibility while resisting peeling forces. The resulting interface remains contamination-resistant, meeting cleanliness standards for semiconductor or sterile environments [17].

These processes synergize to enhance production scalability and performance stability across extreme conditions, including thermal cycling and mechanical stress. Enhanced structural replication fidelity, in particular smaller feature spacing and optimized aspect ratios, ensures consistent interfacial integrity even during repeated stiffness transitions.

3.4. Simulation

3.4.1. Experimental procedure

The feasibility of the bidirectional clamping mechanism was evaluated through kinematic simulations in SolidWorks, focusing on the rotational motion of the movable jaw in both the initial and iterative designs. As depicted in Figure 1(a), the initial design features a fixed jaw welded to the central shaft and a movable jaw mounted on a circular guide rail. The simulation replicated the 360° rotation of the movable jaw along the rail, analyzing alignment accuracy and contact geometry during mode transitions. For the iterative design, the same rotational constraints were applied to both symmetric jaws to assess their synchronized flipping motion. The simulations excluded material deformation or environmental factors, concentrating solely on verifying the mechanical feasibility of stiffness-switching through directional reconfiguration.

3.4.2. Experimental results

Simulations confirmed that both designs achieve bidirectional clamping by rotating the movable jaw(s) 180°, successfully aligning either the rigid (positive) or compliant (negative) surfaces with the target object. The initial design demonstrated full overlap between the jaws in reverse clamping mode, ensuring complete contact along the entire gripping surface, a critical advantage for stabilizing elongated objects (e.g., 15-20 mm microfluidic chips). In contrast, the iterative design exhibited reduced overlap (≈70% contact area) due to its symmetric geometry, as visualized in Figure 1(b). While this partial contact limits stability for long loads, it allows the gripper to access narrower spaces (e.g., 1.2 mm gaps) without collision risks. Both designs validated the core principle of stiffness modulation via directional rotation, with no mechanical interference or alignment errors observed during actuation cycles.

These outcomes highlight a design trade-off: the initial asymmetric configuration prioritizes stability for large or fragile loads, whereas the symmetric iteration favors compactness and deep-reach capability. The virtual framework provides a foundation for context-specific optimization, enabling users to select between designs based on task requirements without compromising the core bidirectional functionality.

4. Conclusion

The proposed bidirectional micro-gripper leverages a stiffness-switching mechanism through asymmetric material integration and rotational reconfiguration, demonstrating practical advantages in microscale manipulation. Its simplified architecture avoids complex pneumatic or thermal actuation components, reduces production costs and assembly complexity, and enables rapid mode transitions. The design’s material-agnostic approach supports flexibility in selecting stiffness-contrast pairs (e.g., aluminum-silicone, polymer composites), broadening applicability across biomedical, electronics, and microrobotics domains. By integrating compliant and rigid gripping modes in a single device, it provides a versatile solution for handling fragile microscale objects (e.g., biological tissues, flexible circuits) and precision components with operational adaptability.

However, the current prototype exhibits limitations that warrant further refinement. Material selection, while functional, does not fully exploit advanced composites for enhanced stiffness contrast or weight reduction. Additionally, the circular guide rail, though effective for rotational stability, imposes size constraints that restrict deployment in ultra-compact workspaces, such as intravascular surgical robots or microscale 3D printing nozzles. Furthermore, the absence of comprehensive functional testing under realistic operational conditions, such as long-term reliability assessments (>10⁶ cycles) or performance validation in extreme environments (e.g., high humidity, subzero temperatures), introduces uncertainties regarding sustained efficacy in mission-critical applications.

Furthermore, future work will focus on structural miniaturization through topology-optimized guide rails and streamlined jaw geometries to improve spatial adaptability without compromising load capacity. Material innovation will prioritize lightweight, high-stiffness composites and smart polymers with self-sensing capabilities to enable real-time stiffness feedback. Experimental validation in extreme environments (e.g., cryogenic cell manipulation, high-temperature soldering) will further validate robustness, while collaborations with biomedical and semiconductor industries aim to tailor gripper variants for niche applications such as single-cell surgery or MEMS device integration. This iterative development pathway aims to transform the prototype into a universal micro-handling platform, bridging gaps between laboratory innovation and industrial scalability.

References

[1]. Zhang, P. Y., Wu, G. Y., Hao, Y. L., & Li, Z. J. (2000). Advances and prospects in microgripper research.Optics and Precision Engineering, (3), 292–296.

[2]. Chen, X., **e, Z., Tai, K., Tan, H., & Chen, X. (2023). Design and test a pneumatically actuated microgripper based on structural stiffness. Review of Scientific Instruments, 94(7).

[3]. He, H. Z. (2022). Design and performance research of pneumatic soft robotic hand (Master’s thesis,Jiangsu University). https: //link.cnki.net/doi/10.27170/d.cnki.gjsuu.2022.002429doi: 10.27170/d.cnki.gjsuu.2022.002429.

[4]. Gong, J., Li, Y. H., Shi, Z. S., & Li, Q. X. (2005). Experimental study on a micro-clamping system based on shape memory alloys. New Technology and New Processes, (6), 18–20.

[5]. Li, R. (2019). Characteristic analysis and control research of shape memory alloy flexible actuator (Master’s thesis, South China University of Technology). https: //link.cnki.net/doi/10.27151/d.cnki.ghnlu.2019.001036doi: 10.27151/d.cnki.ghnlu.2019.001036.

[6]. Hua H.L., Liao Z.Q. & Chen Y.J. (2020).A 1-Dof bidirectional graspable finger mechanism for robotic gripper.Journal of Mechanical Science and Technology, 34(11), 4735-4741.

[7]. Zhang, Z. (2018). Design, fabrication, and cell manipulation experiments of electrothermally actuated microgrippers (Doctoral dissertation, Beijing University of Technology). https: //kns.cnki.net/kcms2/article/abstract?v=_GofKS1StuQhGeL9RwpSSaFTf-NpJLGuzGBGxJn0g1u9z7VtRBnitg5gjAPL4qzD9qd5w8P8ZpLvVPL7wdr--ZRn4aGaeWiI92GtWEFimt0Iu7LAFjp2FkMI0fb8AYA7YBUziFJi_YurLoXZ5Cf-KWEREAilqpED1pFtaFfBCoZmAzzjQS-TYCJC9gwC6lENdWD1uLT7_Mk=& uniplatform=NZKPT& language=CHS

[8]. van Assenbergh, P., Culmone, C., Breedveld, P., & Dodou, D. (2021). Implementation of anisotropic soft pads in a surgical gripper for secure and gentle grip on vulnerable tissues. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 235(3), 255-263.

[9]. Gwon, M., Park, G., Hong, D., Park, Y. J., Han, S., Kang, D., & Koh, J. S. (2022). Soft directional adhesion gripper fabricated by 3D printing process for grip** flexible printed circuit boards. International Journal of Precision Engineering and Manufacturing-Green Technology, 1-13.

[10]. Sun, L.N., Chen, L.G., Rong, W.B., Xie, H., & Liu, Y.J. (2008). Key technologies of micro-manipulation equipment for MEMS assembly and packaging. Chinese Journal of Mechanical Engineering, 44(11), 13–19.

[11]. Starke Jr, E.A., & Staley, J.T. (1996). Application of modern aluminum alloys to aircraft. Progress in aerospace sciences, 32(2-3), 131-172.

[12]. Shit, S.C., & Shah, P. (2013). A review on silicone rubber. National academy science letters, 36(4), 355-365.

[13]. Han, R., Li, Y., Zhu, Q., & Niu, K. (2022). Research on the preparation and thermal stability of silicone rubber composites: A review. Composites Part C: Open Access, 8, 100249.

[14]. Xu, W., Zhang, B., Du, K., Li, X. Y., & Lu, K. (2022). Thermally stable nanostructured Al-Mg alloy with relaxed grain boundaries. Acta Materialia, 226, 117640.

[15]. Czerwinski, F. (2020). Thermal stability of aluminum alloys. Materials, 13(15), 3441.

[16]. Slătineanu, L., Potârniche, Ş., Coteaţă, M., Grigoraş, I., Gherman, L., & Negoescu, F. (2011). Surface roughness at aluminium parts sand blasting. Proceedings in Manufacturing Systems, 6(2), 69-74.

[17]. Hopmann, C., Behmenburg, C., Recht, U., & Zeuner, K. (2014). Injection molding of superhydrophobic liquid silicone rubber surfaces. Silicon, 6(1), 35-43.

Cite this article

Peng,X. (2025). Design of a Bidirectional Micro-Gripper Based on Material Stiffness-Switching. Applied and Computational Engineering,169,45-53.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MSS 2025 Symposium: Machine Vision System

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zhang, P. Y., Wu, G. Y., Hao, Y. L., & Li, Z. J. (2000). Advances and prospects in microgripper research.Optics and Precision Engineering, (3), 292–296.

[2]. Chen, X., **e, Z., Tai, K., Tan, H., & Chen, X. (2023). Design and test a pneumatically actuated microgripper based on structural stiffness. Review of Scientific Instruments, 94(7).

[3]. He, H. Z. (2022). Design and performance research of pneumatic soft robotic hand (Master’s thesis,Jiangsu University). https: //link.cnki.net/doi/10.27170/d.cnki.gjsuu.2022.002429doi: 10.27170/d.cnki.gjsuu.2022.002429.

[4]. Gong, J., Li, Y. H., Shi, Z. S., & Li, Q. X. (2005). Experimental study on a micro-clamping system based on shape memory alloys. New Technology and New Processes, (6), 18–20.

[5]. Li, R. (2019). Characteristic analysis and control research of shape memory alloy flexible actuator (Master’s thesis, South China University of Technology). https: //link.cnki.net/doi/10.27151/d.cnki.ghnlu.2019.001036doi: 10.27151/d.cnki.ghnlu.2019.001036.

[6]. Hua H.L., Liao Z.Q. & Chen Y.J. (2020).A 1-Dof bidirectional graspable finger mechanism for robotic gripper.Journal of Mechanical Science and Technology, 34(11), 4735-4741.

[7]. Zhang, Z. (2018). Design, fabrication, and cell manipulation experiments of electrothermally actuated microgrippers (Doctoral dissertation, Beijing University of Technology). https: //kns.cnki.net/kcms2/article/abstract?v=_GofKS1StuQhGeL9RwpSSaFTf-NpJLGuzGBGxJn0g1u9z7VtRBnitg5gjAPL4qzD9qd5w8P8ZpLvVPL7wdr--ZRn4aGaeWiI92GtWEFimt0Iu7LAFjp2FkMI0fb8AYA7YBUziFJi_YurLoXZ5Cf-KWEREAilqpED1pFtaFfBCoZmAzzjQS-TYCJC9gwC6lENdWD1uLT7_Mk=& uniplatform=NZKPT& language=CHS

[8]. van Assenbergh, P., Culmone, C., Breedveld, P., & Dodou, D. (2021). Implementation of anisotropic soft pads in a surgical gripper for secure and gentle grip on vulnerable tissues. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 235(3), 255-263.

[9]. Gwon, M., Park, G., Hong, D., Park, Y. J., Han, S., Kang, D., & Koh, J. S. (2022). Soft directional adhesion gripper fabricated by 3D printing process for grip** flexible printed circuit boards. International Journal of Precision Engineering and Manufacturing-Green Technology, 1-13.

[10]. Sun, L.N., Chen, L.G., Rong, W.B., Xie, H., & Liu, Y.J. (2008). Key technologies of micro-manipulation equipment for MEMS assembly and packaging. Chinese Journal of Mechanical Engineering, 44(11), 13–19.

[11]. Starke Jr, E.A., & Staley, J.T. (1996). Application of modern aluminum alloys to aircraft. Progress in aerospace sciences, 32(2-3), 131-172.

[12]. Shit, S.C., & Shah, P. (2013). A review on silicone rubber. National academy science letters, 36(4), 355-365.

[13]. Han, R., Li, Y., Zhu, Q., & Niu, K. (2022). Research on the preparation and thermal stability of silicone rubber composites: A review. Composites Part C: Open Access, 8, 100249.

[14]. Xu, W., Zhang, B., Du, K., Li, X. Y., & Lu, K. (2022). Thermally stable nanostructured Al-Mg alloy with relaxed grain boundaries. Acta Materialia, 226, 117640.

[15]. Czerwinski, F. (2020). Thermal stability of aluminum alloys. Materials, 13(15), 3441.

[16]. Slătineanu, L., Potârniche, Ş., Coteaţă, M., Grigoraş, I., Gherman, L., & Negoescu, F. (2011). Surface roughness at aluminium parts sand blasting. Proceedings in Manufacturing Systems, 6(2), 69-74.

[17]. Hopmann, C., Behmenburg, C., Recht, U., & Zeuner, K. (2014). Injection molding of superhydrophobic liquid silicone rubber surfaces. Silicon, 6(1), 35-43.