1. Introduction

With the rapid growth of the vehicle sector/industry, the global vehicle industry is increasingly adopting Electric Vehicles as a primary goal/direction. The growth of the new energy vehicle industry is attributable to its advantages in high efficiency and sustainability, coupled with policy support and growing consumer awareness regarding sustainability. According to the IEA, more than 20% of new cars sold worldwide were electric [1].

But as electric vehicles develop quickly, they also face many technical thermodynamic challenges, particularly in the areas of battery system, vehicle thermal management, and energy efficiency. Since batteries are at the heart of the electric vehicle, poor battery thermal management directly affects vehicle performance, safety, and user experience; it can result in aging and decreased range as well as serious safety incidents like fire and explosion due to thermal runaway.

This paper will concentrate on two main issues: firstly, the development trend of the electric vehicle. Secondly, the primary thermodynamic challenges that the current generation of the electric vehicle faces This study employs Qualitative Research Methods and incorporates typical cases from the industry, such as CATL and Tesla’s battery technologies.

The purpose of this study is to systematically sort out the thermodynamics-related issues and technical paths of the electric vehicle in order to provide theoretical underpinnings and technical support for the development of the electric vehicle’s performance, safety, and industrialization.

2. Analysis of the development trend of electric vehicle

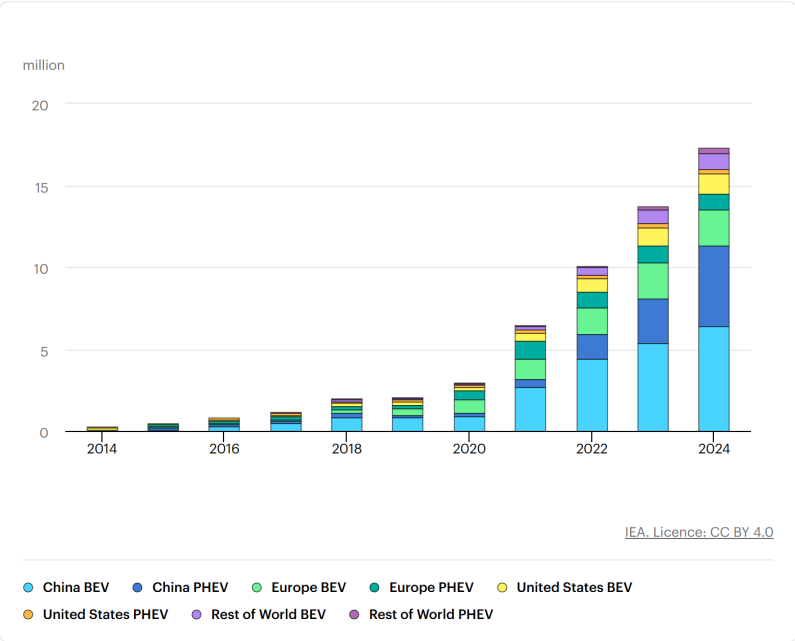

Electric car sales topped 17 million worldwide in 2024, rising by more than 25%[1].

It can be observed from Figure 1 that China, America and EU are the major market and China takes the prime location. China’s electric vehicle sales account for almost two-thirds of electric cars sold globally which is about 11.3 million even higher than 2020’s global car sales. So China will be a major future market for trams. From 2014 to 2024, the number of electric car sales has increased by a factor of 57 The rapid increase in electric car sales is due to government policies and consumer support.

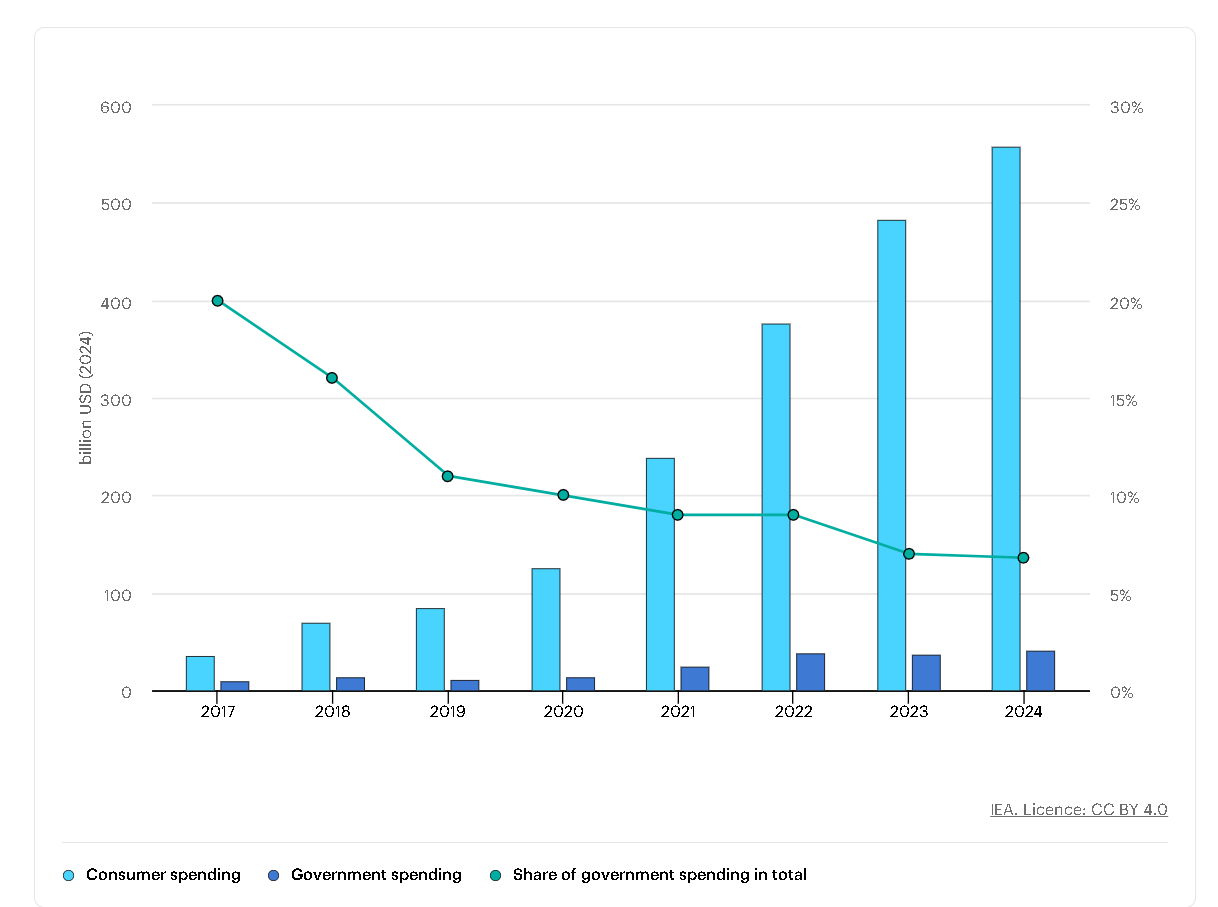

From Figure 2, consumer and government spending is gradually increasing. The government takes 20 percent of total spending at the initial phase, which is about 9 billion USD. This means that in the initial phase, the government plays a key role in the electric vehicle industry. As the industry matures, market forces are gradually replacing government initiatives as the dominant driver, with consumers becoming the primary force behind the growth of the electric vehicle market.

The global electric vehicle fleet grows fourfold to 2030 under stated policies and is projected to reach 2.5 hundred million vehicles [1].

Although the electric vehicle market is rapidly increasing, the safety and performance are major challenges. Especially the battery system, which is the core of the electric vehicle, has problems such as thermal runaway and battery aging.

3. Battery thermal management challenges

3.1. Thermal runaway

Thermal runaway (TR) is a critical safety hazard in lithium-ion batteries (LIBs), especially under high energy density applications such as electric vehicles (EVs). When internal or external misuse causes an uncontrollably high battery temperature, it might result in exothermic chain reactions that could cause an explosion or fire.

Usually, mechanical deformation, overcharging, overheating, or internal short circuits are the initial abuse events that trigger TR. These catalysts cause the solid electrolyte interphase (SEI) layer to break down, which is followed by exothermic reactions involving the anode, electrolyte, and ultimately the cathode material[4]. Heat and gas are released as each layer disintegrates, reducing thermal stability and speeding up future reactions to create a self-reinforcing cycle.

Feng et al. [5] used a unique 'energy release diagram’ to methodically describe the process, charting the order and dynamics of thermal events during TR Internal short circuits represent a significant consistency across many misuse scenarios, according to their study. After being activated, TR goes through several stages of reaction, each of which has a key starting temperature and distinct thermal signature.

Thermal runaway can be divided into three main stages:

1. The initial low-temperature exothermic stage (approximately 90-130℃), involving SEI layer decomposition and anode reactions;

2. The intermediate sustained exothermic stage (approximately 130-200℃), during which electrolyte decomposition and lithium-ion de-intercalation occur, further accelerating heat generation;

3. The high-temperature violent combustion stage (above 200℃), where cathode material decomposition and oxygen release lead to intense combustion and full thermal runaway.

Extended-volume accelerating rate calorimetry (EV-ARC) experimental data have verified that TR, especially in high-capacity cells, entails rapid mass loss, gas emission, and energy spikes. In large battery packs, where propagation from a single cell can cause cascading failures if improperly handled, these characteristics present additional risks [5].

Furthermore, TR risks are increased by the move toward Ni-rich cathode materials like NCM811, which is motivated by the requirement for a higher energy density. Thermal management and material safety design are more important than ever, as these materials exhibit poorer thermal stability than conventional chemistries like LiFePO4 [5, 6].

3.2. Battery aging

Long-term use of lithium-ion batteries (LIBs) causes considerable thermal aging, especially in high temperatures and complex working environments. The main symptoms of thermal aging are a decrease in overall thermal stability, an increase in internal resistance, and a progressive loss of capacity. The structural damage to the graphite anode, ongoing electrolyte breakdown, and the dynamic equilibrium between deterioration and regeneration of the solid electrolyte interphase (SEI) layer are key degradation mechanisms responsible for these alterations in the battery materials. Degradation of the SEI layer shortens the battery's lifespan and reduces cycle performance by aggravating parasitic side reactions and increasing internal resistance[7]. The battery's electrochemical activity and thermal resilience are further reduced by irreversible lithium loss in the anode and chemical changes in the electrolyte.

A serious safety risk during thermal aging is the gradual buildup of hydrogen gas inside the graphite anode. According to Galushkin et al. [8] this hydrogen buildup causes early-stage low-temperature exothermic reactions that are not influenced by the battery's state of charge (SOC) but become more intense with repeated cycles of charge and discharge. This lowers the onset temperature for thermal reactions [8]. By integrating these results with the multistage thermal runaway (TR) mechanism, the TR process in LIBs can be conceptually divided into three stages: a low-temperature initial stage with gas accumulation and exothermic reactions, an intermediate stage with SEI degradation and lithium de-intercalation and continuous heat generation, and a high-temperature final stage with cathode breakdown and oxygen release, which leads to violent combustion [8]. By building up reactive species like hydrogen and drastically reducing the triggering temperature and thermal stability, thermal aging increases the possibility of thermal runaway and raises safety concerns.

In order to optimize battery design, thermal management techniques, and safety prevention systems, a thorough grasp of the interaction between thermal aging and thermal runaway is necessary. Successfully postponing the onset of thermal runaway, thereby increasing the safety and lifespan of lithium-ion batteries, is achievable by monitoring hydrogen generation at the anode, enhancing material thermal stability, and carefully managing operating conditions.

4. Case study

4.1. Design advantages and thermal safety challenges of the Tesla 4680 cylindrical lithium-ion battery

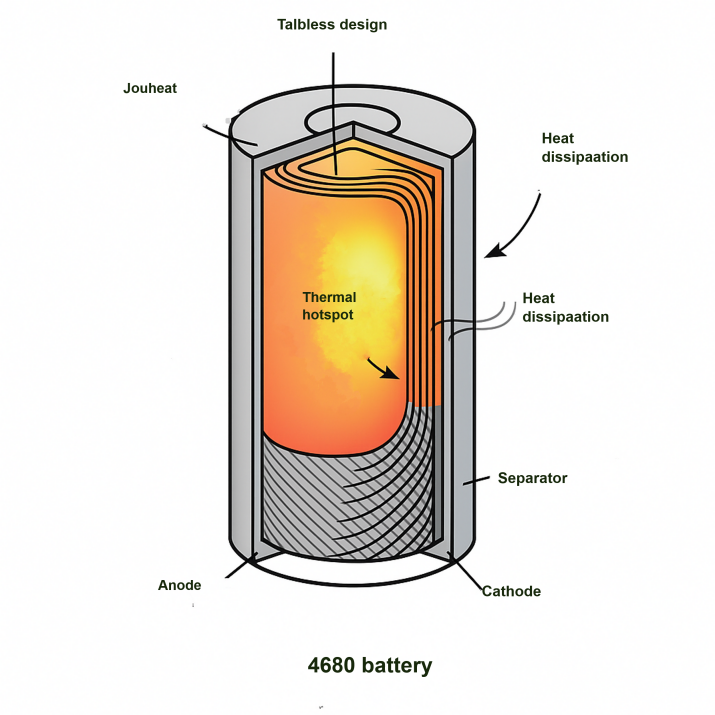

Tesla's 4680 cylindrical lithium-ion battery combines a large-format cylinder construction with an electrode layout akin to a tab-less design, introducing important design improvements. Eliminating conventional tabs improves power output and current homogeneity while reducing Joule heating by lowering localized electrical resistance and current concentration [9]. Furthermore, the expanded shape (46 mm in diameter and 80 mm in height) supports overall system weight reduction and cost optimization by increasing single-cell energy density and simplifying pack-level structural complexity.

Figure 3 presents a cross-sectional schematic of the 4680 cells, highlighting its internal jelly-roll layout, symmetrical electrode layers, and dual current collection pathways. The tabless design enables current to flow uniformly along the entire width of the electrode sheets, minimizing resistive losses. Compared to legacy 18650 or 21700 cells, the 4680’s larger surface area enhances radial thermal dissipation, theoretically facilitating improved heat flow toward the casing under moderate loading or with efficient external cooling.

However, the increased scale and unique geometry of the 4680 cell pose thermal management challenges under high discharge rates (e.g., 2C) or inadequate cooling conditions. According to electrochemical-thermal simulations and experimental measurements by Eze et al. [9], thermal gradients exceeding 10 K can develop within the cell’s internal structure, with surface temperatures surpassing 70 ℃. These thermal imbalances lead to the formation of localized hotspots, especially near the core of the jelly-roll or areas with higher current density, which in turn accelerate uneven aging, SEI degradation, and side reactions involving the electrolyte.

Figure 3 includes thermal annotations that illustrate these risks: red zones indicate potential hotspot regions, while blue arrows denote heat dissipation paths toward the cell periphery. The core region exhibits limited thermal connectivity and is thus prone to heat accumulation, whereas the outer edges offer more effective conductive and convective heat rejection. These observations emphasize the necessity for carefully engineered cooling strategies tailored to the thermal behavior of large-format cylindrical cells.

In summary, although the Tesla 4680 cell architecture offers notable advantages in energy density, mechanical simplification, and performance, it also demands precise thermal control and aging diagnostics. To ensure safety in high-demand applications such as electric vehicles and grid storage, it is imperative to develop advanced thermal management systems capable of addressing the non-uniform heating patterns inherent to this cell design [9].

4.2. Design advantages of CATL power batteries

CATL advances battery performance and safety through a combination of material innovations and structural optimizations.

High Energy Density Integration Technologies

The implementation of Cell-to-Pack (CTP) and Cell-to-Chassis (CTC) architectures significantly enhances the volumetric utilization of battery packs, increasing it from 55% to 72%. This integration strategy enables the direct incorporation of battery cells with vehicle chassis, powertrain components, and thermal management systems, effectively reducing overall system weight and manufacturing costs [10].

Advanced Material Systems

Utilization of high-nickel 811 cathode materials, reinforced with nanostructured frameworks, enhances both mechanical stability and energy density, concurrently improving intrinsic safety characteristics. Additionally, the employment of single-crystal cathode particles alongside oxidation-resistant electrolytes facilitates voltage extension, thereby augmenting the cell's energy output capacity [10].

Intelligent Thermal Management and Autonomous Temperature Regulation

The integration of active cell heating mechanisms, precise temperature control algorithms, and big data-driven risk prediction models enables continuous real-time thermal monitoring. This approach ensures uniform temperature distribution and stable operation across a wide range of environmental conditions [10].

Thermally Stable Materials and Interface Engineering

The strategic doping of cathode materials and the application of robust protective surface coatings contribute to the formation of stable and dense solid electrolyte interphase (SEI) layers. Concurrently, the inclusion of functional electrolyte additives mitigates exothermic side reactions, thereby reducing the likelihood of thermal runaway events [10].

5. Conclusion

In conclusion, as electric vehicles continue to revolutionize the automotive industry, thermodynamic challenges—especially those related to battery safety and performance—remain critical barriers to overcome. This study has identified key concerns such as thermal runaway, accelerated battery aging, and uneven heat distribution, particularly in high-capacity or structurally integrated battery packs. Through case analyses of Tesla and CATL, the paper illustrates how innovative engineering solutions—ranging from tabless battery design to intelligent thermal regulation—are shaping the future of EV battery management.

Going forward, the integration of materials science, data-driven monitoring, and advanced cooling technologies will be essential in ensuring both the safety and efficiency of EVs. As policy support shifts toward consumer-driven demand, sustained innovation in battery thermal management will be a decisive factor in the long-term success of electric vehicles.

References

[1]. IEA (2025), Global EV Outlook 2025, IEA, Paris https: //www.iea.org/reports/global-ev-outlook-2025, Licence: CC BY 4.0

[2]. IEA (2025), Global electric car sales, 2014-2024, IEA, Paris https: //www.iea.org/data-and-statistics/charts/global-electric-car-sales-2014-2024, Licence: CC BY 4.0

[3]. IEA (2025), Global consumer and government spending on electric cars, 2017-2024, IEA, Paris https: //www.iea.org/data-and-statistics/charts/global-consumer-and-government-spending-on-electric-cars-2017-2024, Licence: CC BY 4.0

[4]. IEA (2025), Electric two-/three-wheelers stock in the Stated Policies Scenario, 2024-2030, IEA, Paris https: //www.iea.org/data-and-statistics/charts/electric-two-three-wheelers-stock-in-the-stated-policies-scenario-2024-2030 , Licence: CC BY 4.0

[5]. Feng, X., Ouyang, M., Liu, X., Lu, L., Xia, Y., & He, X. (2018). Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Materials, 10, 246-267. https: //doi.org/10.1016/j.ensm.2017.05.013

[6]. Lalinde, I., Berrueta, A., José Valera, J., Arza, J., Sanchis, P., & Ursúa, A. (2024). Perspective Chapter: Thermal Runaway in Lithium-Ion Batteries. IntechOpen. doi: 10.5772/intechopen.106539

[7]. Vetter, J., Novák, P., Wagner, M. R., Veit, C., Möller, K.-C., Besenhard, J. O., Winter, M., Wohlfahrt-Mehrens, M., Vogler, C., & Hammouche, A. (2005). Ageing mechanisms in lithium-ion batteries. Journal of Power Sources, 147(1), 269-281. https: //doi.org/10.1016/j.jpowsour.2005.01.006

[8]. Galushkin, N. E., Yazvinskaya, N. N., & Galushkin, D. N. (2018). Mechanism of Thermal Runaway in Lithium-Ion Cells. Journal of the Electrochemical Society, 165(7), A1303-A1308. https: //doi.org/10.1149/2.0611807jes

[9]. Eze, C., Zhao, J., Liu, H., Shi, Y., Chung, D., Zhao, J., Chen, G., & Chuang, A. (2025). Coupled electrochemical-thermal analysis of the novel TESLA-type large format 4680 cylindrical lithium-ion battery under normal and extreme conditions. Journal of Power Sources, 605, 237164. https: //doi.org/10.1016/j.jpowsour.2025.237164

[10]. Contemporary Amperex Technology Co., Limited (CATL). (n.d.). Technology. Retrieved June 5, 2025, from https: //www.catl.com/research/technology/

Cite this article

Yi,Q. (2025). Thermodynamic Challenges and Future Trends of Electric Vehicles: An Analysis Based on Battery Thermal Management. Applied and Computational Engineering,172,193-199.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. IEA (2025), Global EV Outlook 2025, IEA, Paris https: //www.iea.org/reports/global-ev-outlook-2025, Licence: CC BY 4.0

[2]. IEA (2025), Global electric car sales, 2014-2024, IEA, Paris https: //www.iea.org/data-and-statistics/charts/global-electric-car-sales-2014-2024, Licence: CC BY 4.0

[3]. IEA (2025), Global consumer and government spending on electric cars, 2017-2024, IEA, Paris https: //www.iea.org/data-and-statistics/charts/global-consumer-and-government-spending-on-electric-cars-2017-2024, Licence: CC BY 4.0

[4]. IEA (2025), Electric two-/three-wheelers stock in the Stated Policies Scenario, 2024-2030, IEA, Paris https: //www.iea.org/data-and-statistics/charts/electric-two-three-wheelers-stock-in-the-stated-policies-scenario-2024-2030 , Licence: CC BY 4.0

[5]. Feng, X., Ouyang, M., Liu, X., Lu, L., Xia, Y., & He, X. (2018). Thermal runaway mechanism of lithium ion battery for electric vehicles: A review. Energy Storage Materials, 10, 246-267. https: //doi.org/10.1016/j.ensm.2017.05.013

[6]. Lalinde, I., Berrueta, A., José Valera, J., Arza, J., Sanchis, P., & Ursúa, A. (2024). Perspective Chapter: Thermal Runaway in Lithium-Ion Batteries. IntechOpen. doi: 10.5772/intechopen.106539

[7]. Vetter, J., Novák, P., Wagner, M. R., Veit, C., Möller, K.-C., Besenhard, J. O., Winter, M., Wohlfahrt-Mehrens, M., Vogler, C., & Hammouche, A. (2005). Ageing mechanisms in lithium-ion batteries. Journal of Power Sources, 147(1), 269-281. https: //doi.org/10.1016/j.jpowsour.2005.01.006

[8]. Galushkin, N. E., Yazvinskaya, N. N., & Galushkin, D. N. (2018). Mechanism of Thermal Runaway in Lithium-Ion Cells. Journal of the Electrochemical Society, 165(7), A1303-A1308. https: //doi.org/10.1149/2.0611807jes

[9]. Eze, C., Zhao, J., Liu, H., Shi, Y., Chung, D., Zhao, J., Chen, G., & Chuang, A. (2025). Coupled electrochemical-thermal analysis of the novel TESLA-type large format 4680 cylindrical lithium-ion battery under normal and extreme conditions. Journal of Power Sources, 605, 237164. https: //doi.org/10.1016/j.jpowsour.2025.237164

[10]. Contemporary Amperex Technology Co., Limited (CATL). (n.d.). Technology. Retrieved June 5, 2025, from https: //www.catl.com/research/technology/