1. Introduction

With the rapid development of the economy and society, the construction industry has gradually become an important pillar of the national economy, but there are widespread phenomena such as long construction cycles and serious resource waste in the industry. One of the main factors causing these phenomena is rework, which exists in almost every construction project. This not only increases the project duration but also leads to higher engineering costs [1]. According to statistics, the increased cost of rework in construction projects accounts for about 12% of the total project investment [2], and some complex projects can reach 19% of the overall project cost [3]. The issue of rework not only causes huge losses to the project, but also exacerbates the waste of engineering materials, increases energy consumption, and carbon emissions, which is inconsistent with the green construction goals under the current “dual carbon” strategy. Therefore, how to use technological innovation to reduce rework rates has become an urgent problem to be solved in the construction industry.

Building Information Modeling (BIM) technology is an important tool for achieving digital transformation, providing a systematic solution for solving rework problems [4]. The rework of the project is mainly due to pipeline collisions and low coordination between specialties [5]. BIM technology can not only visualize the spatial relationships between building components, but also enable multidisciplinary collaboration among architecture, structural engineering, and Heating, Ventilation and Air Conditioning (HVAC) systems. This effectively prevents pipeline conflicts caused by elevation discrepancies or design clashes that often occur in traditional 2D drawings. This can expose potential problems of the project in advance, reduce repetitive operations, and improve construction efficiency [6].

This study adopts the Caojiadu underground garage project as an case study to explore the application of BIM technology in controlling construction rework rate from three aspects: design conflict, insufficient collaboration, and spatial cognitive bias.

2. Project overview

The Caojiadu project is located in Jing'an District, Shanghai. The building category is a multi-story residential building, and the basement is a sub-item of this project. It is a first-class garage with a total construction area of 19964.81 square meters. The project has three underground floors, with the first floor being 7.2 meters high, including a 3.3-meter nonmotorized garage mezzanine in some areas. The second and third underground floors are both 4.0 meters high. The underground garage has complex functions and a large building area, increasing the types and quantities of pipelines. At the same time, the garage space is limited, and if there is a lack of effective coordination during the design and construction process, pipeline collisions are prone to occur.

3. Problem and solution

3.1. Design conflict

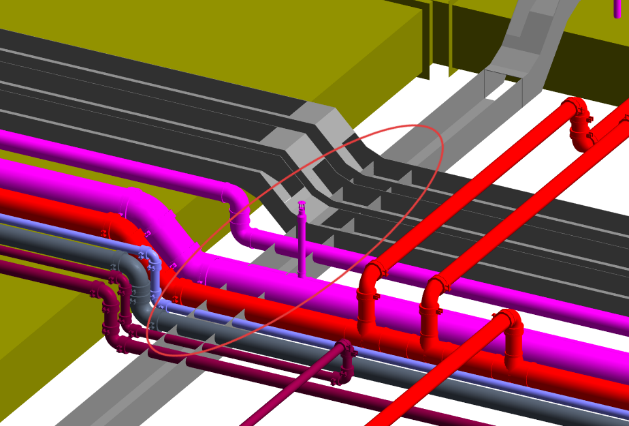

The underground space of this project is relatively complex, and the pipelines are also densely packed. Due to the complex and intricate pipeline position relationships formed by the multi-layered composite arrangement of pipelines and equipment, there are phenomena of pipeline hard collision, soft collision, and gap collision in the underground space, which brings great difficulties to construction. Hard collision is a visible collision that refers to the physical intersection or overlap of two or more solid components in three-dimensional space, such as water pipes passing through cable trays, and air ducts crossing structural beams. Soft collision is a “hidden demand contradiction” that refers to collisions caused by insufficient reserved space between components or conflicting installation sequences of components. Gap collision is the “standard red line”, which refers to the failure of components to meet the minimum safety distance requirements, which can lead to safety hazards.

BIM technology can analyze project data, establish 3D models [7], make pipelines of various specialties clear and visible, and accurately find collision points. In the current field of construction engineering, Revit software is mainly used to establish 3D models and collision detection [6]. Link all buildings, structures, and models into MEP models in Revit, use the pipeline collision detection function provided by Revit software for detection and analysis, and output relevant reports. This report can display all potential conflict points of this project, and adjust the model based on the displayed conflict points. But when adjusting the model, the following points should be noted:

(1) Pressure gives priority to gravity, and gravity pipelines are only allowed to flip downwards in the direction of water flow, without presenting a concave or convex shape;

(2) Small pipes give way to large pipes;

(3) Fewer pipelines make more pipelines;

(4) There are large cables inside the large cable tray, and their bending should be reduced. The bending of the cable tray should be greater than 45° to facilitate cable construction and a space should be left in the middle of the cable tray for maintenance.

After model adjustment, hard collisions of pipelines can be avoided, as shown in Fig. 1. For soft collision and gap collision, it is necessary to adjust the pipeline gap and direction according to the specifications based on the conflict points displayed in the report, and ultimately achieve a collision-free model. BIM's comprehensive collision detection technology can reduce the rate of construction rework, save construction time and costs [6], and collision detection can ensure construction safety and reduce safety accidents caused by design errors.

Figure 1. Comparison before and after comprehensive management optimization

Picture credit original

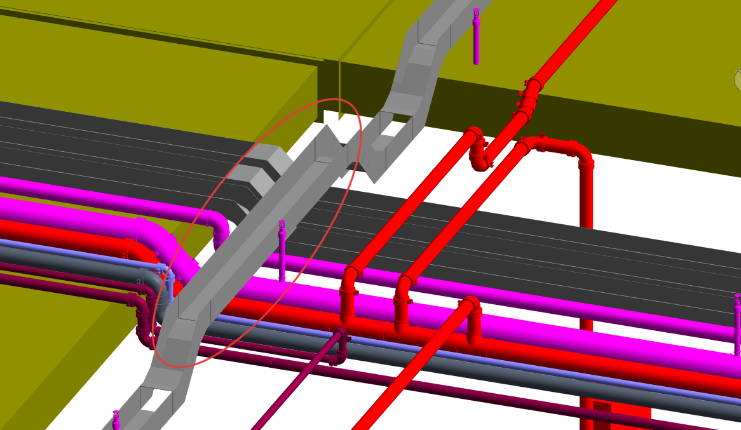

3.2. Insufficient collaboration

Due to the involvement of multiple disciplines, such as architecture, structure, and HVAC, in this project, if there is a lack of effective collaboration among these disciplines, there may be a situation where electrical pipelines and ventilation ducts are installed in the same area competing for space. This not only increases the difficulty of construction but also causes damage to some already installed components due to repeated adjustments in position, requiring rework and increasing a significant amount of rework costs.

BIM technology can perform model integration and fine inspection. Lightweight the Revit models of various disciplines, such as civil engineering and mechanical and electrical engineering, integrate the models in Navisworks software, and conduct reviews [8]. After integration, engineers can intuitively see the spatial layout of the entire basement, including the mezzanine of the motor garage, the non-motor garage, and the positional relationship of various equipment pipelines. This allows all parties involved to conduct a model review on a unified platform, and through segmentation tools, they can observe whether there are any problems with the local model, as shown in Fig. 2. If any problems are found, circle the incorrect viewpoint, as shown in Fig. 3, and analyze and discuss the problems that exist in the project to reduce rework caused by misunderstandings.

Figure 2. Partial sectional view of the model

Picture credit original

Figure 3. Project error viewpoint diagram

Picture credit original

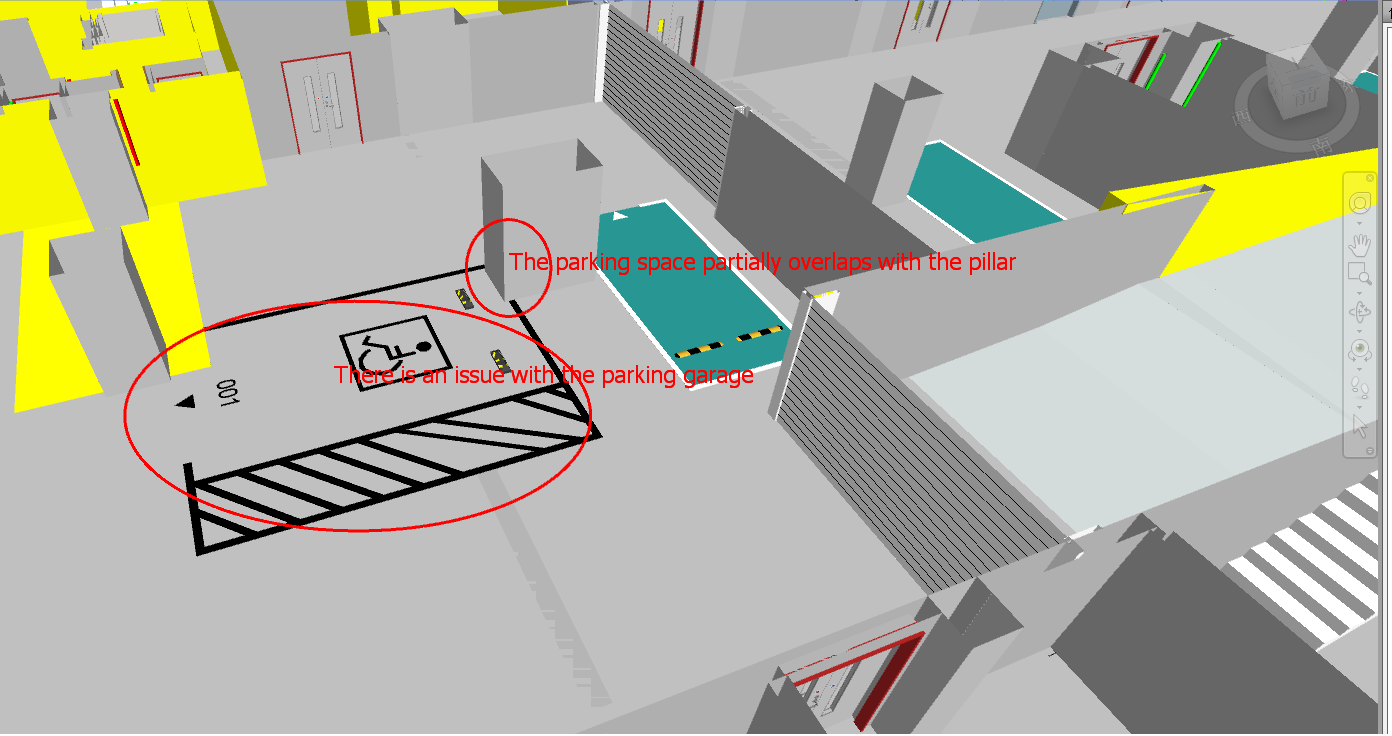

3.3. Spatial cognitive bias

The underground space relationship of this project is complex, and traditional two-dimensional drawings make it difficult for project personnel to accurately grasp the spatial relationship. BIM technology can perform roaming simulation and construction feasibility verification. Fuzor software can further create virtual roaming and export models as independent .exe files to verify the spatial rationality of the project [9]. Through a first-person perspective, the project personnel can freely shuttle between the underground parking garages, allowing them to intuitively experience the layout of the building space, lane width, parking space size, etc., as shown in Fig. 4. Through roaming, it is possible to verify whether the spatial connection between the motor vehicle area on the basement level and the non-motor vehicle area on the local mezzanine is reasonable and to check whether there are any narrow or obstructed garage passages. At the same time, during the roaming process, it can also be found that the distance between underground parking spaces and column grids is too small, and there are insufficient reserved equipment maintenance channels. Design adjustments can be made in advance to avoid rework caused by unreasonable space in the later stage.

Figure 4. Roaming interface

Picture credit original

4. Conclusion

This study takes the Caojiadu underground garage project as a case study and has achieved certain results in project construction rework control through BIM software such as Revit, Navisworks, Fuzor, etc. Through collision detection, model review, virtual roaming, and other functions of BIM technology, a large number of pipeline collisions, insufficient collaboration, unreasonable spatial layout, and other problems were discovered before construction, and these problems were solved and optimized before construction. Therefore, the application of BIM technology can reduce the occurrence of project rework, save engineering costs, improve construction efficiency, and provide great assistance to the promotion of construction projects.

However, BIM technology still has certain shortcomings in practical applications. One issue is that BIM lacks native capabilities for real-time construction progress tracking. In the future, it can be solved by combining it with emerging technologies such as the Internet of Things and artificial intelligence. For example, using the Internet of Things to collect real-time information from the construction site, linking it to BIM for dynamic monitoring of the construction process, correcting problems that arise during the construction process on time, and avoiding major problems or rework in the later stages of the project. The second issue is that BIM technology cannot synchronize information from different stages. In the future, it is necessary to improve the process connections of projects in the planning, design, construction, and operation stages, and achieve full-process project information sharing.

References

[1]. Wu Zonghu. Analysis of the Impact of Rework on Construction Project Cost. Logistics Engineering and Management, 2015, 37 (07): 235-236.

[2]. Statistics Department of fixed assets investment, National Bureau of Statistics. China Construction Industry Statistical Yearbook (2010). China Statistical Publishing House, 2010, 322.

[3]. Atkinson, John William, Rogge, David Frederick, Haggard, Robert Lee. The field rework index: early warning for field rework and cost growth. Construction Industry Institute, Austin, 2001.

[4]. Li Peipei. Research on using BIM technology to reduce the rework rate of electromechanical installation engineering. Modern Property (Mid-term), 2019, (02): 58-59.

[5]. Liu Zhan, Feng Ke. Analysis of the causes, effects and countermeasures of project rework. Value Engineering, 2020, 39 (35): 241-243.

[6]. Lin Zhongdong.Application of BIM technology in pipe collision detection. Fujian Construction Technology, 2024, (04): 93-95 + 127.

[7]. Shao Miao, Wang Fang.Analyzing the Application of BIM Technology in Construction Project Management. Journal of Civil and Transportation Engineering, 2024, 1 (2).

[8]. Application of Li Cheng. Navisworks in 3D model review of surface engineering. Oil and gas field surface engineering, 2022, 41 (01): 86-89.

[9]. Sun Yuchen, Chen Qingyuan, Zhou Jiangxiang. Application of Fuzor simulation technology in construction projects. Intelligent Building and Smart City, 2016, (11): 73-75.

Cite this article

Yang,R. (2025). Research on Construction Rework Rate Control Based on BIM Technology—Taking the Caojiadu Underground Garage Project as an Example. Applied and Computational Engineering,156,46-51.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: AI and Machine Learning Applications in Infrastructure Engineering

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Wu Zonghu. Analysis of the Impact of Rework on Construction Project Cost. Logistics Engineering and Management, 2015, 37 (07): 235-236.

[2]. Statistics Department of fixed assets investment, National Bureau of Statistics. China Construction Industry Statistical Yearbook (2010). China Statistical Publishing House, 2010, 322.

[3]. Atkinson, John William, Rogge, David Frederick, Haggard, Robert Lee. The field rework index: early warning for field rework and cost growth. Construction Industry Institute, Austin, 2001.

[4]. Li Peipei. Research on using BIM technology to reduce the rework rate of electromechanical installation engineering. Modern Property (Mid-term), 2019, (02): 58-59.

[5]. Liu Zhan, Feng Ke. Analysis of the causes, effects and countermeasures of project rework. Value Engineering, 2020, 39 (35): 241-243.

[6]. Lin Zhongdong.Application of BIM technology in pipe collision detection. Fujian Construction Technology, 2024, (04): 93-95 + 127.

[7]. Shao Miao, Wang Fang.Analyzing the Application of BIM Technology in Construction Project Management. Journal of Civil and Transportation Engineering, 2024, 1 (2).

[8]. Application of Li Cheng. Navisworks in 3D model review of surface engineering. Oil and gas field surface engineering, 2022, 41 (01): 86-89.

[9]. Sun Yuchen, Chen Qingyuan, Zhou Jiangxiang. Application of Fuzor simulation technology in construction projects. Intelligent Building and Smart City, 2016, (11): 73-75.