1. Introduction

Modern cities are increasingly expanding vertically due to population growth and limited land availability. Skyscrapers, which are typically over 100 meters high or with 12 to 40 floors, have become central to urban development [1]. Unlike low-rise structures, high-rise buildings require distinct structural behavior, design practices, and construction management systems.

Constructing tall buildings involves integrating structural and mechanical systems with fire safety, vertical transportation, and environmental strategies. These projects pose challenges such as wind resistance, seismic stability, and foundation reliability, especially in dense urban areas.

Effective coordination throughout the entire project lifecycle, from excavation to final fit-outs, necessitates the utilization of advanced digital tools to guarantee both safety and efficiency [2].

For years, the construction industry has historically lagged in technological adoption, relying on traditional drafting and fragmented workflows. However, the emergence of Building Information Modeling (BIM) has initiated a major transformation. BIM provides a centralized platform for visualizing facility design and planning, enabling real-time collaboration among engineers, architects, contractors, and facility managers [3].

BIM enhances the entire building lifecycle—from conceptual planning through construction to operation and maintenance. Its multi-dimensional methodology enhances coordination, facilitates data-driven decision-making, and enables the detection of clashes between systems, thereby minimizing costly rework [4]. These features are especially critical in high-rise projects, where even small errors can lead to significant financial and safety risks.

Furthermore, BIM integrates with technologies such as the Internet of Things (IoT), Geographic Information Systems (GIS), and cloud computing to support smart construction systems. These integrations enhance real-time monitoring, improve safety management, and optimize equipment logistics [5]. As urban projects grow in complexity, such digital ecosystems offer essential competitive advantages.

This paper investigates how Building Information Modeling (BIM) optimizes deep foundation design, monitors excavation progress, enhances slipform construction operations, and strengthens site safety management. Additionally, it addresses existing limitations and outlines future research directions in this domain.

2. High-rise building construction overview

High-rise buildings require structurally robust systems to resist gravitational and lateral loads. Common structural solutions include rigid frames, which rely on beam-column interaction, shear walls composed of reinforced concrete for lateral resistance, and tube systems that use interconnected hollow frameworks to distribute loads efficiently. Beyond structural integrity, high-rises incorporate architectural detailing and centralized MEP (mechanical, electrical, and plumbing) cores to support essential utilities such as power, water, sewage, and HVAC systems [6]. Construction begins with feasibility studies and detailed planning, followed by site preparation, excavation, and foundation works using piles and caissons. Superstructure erection proceeds with floor-by-floor construction, MEP installation, and interior fit-outs. The final stages encompass finishes, system commissioning, and client handover [7]. However, high-rise construction faces recurring challenges, including complex trade coordination, elevated worksite hazards, schedule conflicts among teams, and frequent budget overruns due to design modifications during execution.

3. The use of Building Information Modelling (BIM) in deep foundation works

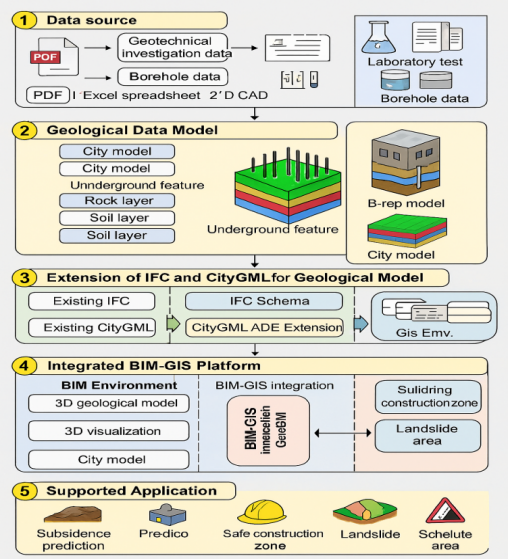

BIM-based tools integrate geotechnical data like soil profiles, borehole logs, and groundwater conditions into the design process, enabling engineers to visualize subsurface conditions, assess potential risks and optimize foundation design more effectively [8].

As illustrated in Figure 1, a comprehensive BIM model integrates geotechnical data to visualize subsurface conditions in 3D. Soil layers are color-coded by type and properties, while borehole data appears as vertical lines indicating depth and composition. Such integration is essential for designing deep foundations, piles, and retaining walls, with annotations and metadata enhancing analytical accuracy and decision-making.

This uniform visualization enables engineers and stakeholders to develop a shared understanding of site conditions, improving the precision of foundation and structural designs. Early identification of potential geotechnical risks in the design phase helps prevent costly issues during construction.

BIM further supports the visualization of ground improvement techniques, including soil stabilization and grouting, with features for clash detection and optimized sequencing based on established guidelines [9].

Additionally, the integration of sensor-based monitoring systems enables real-time tracking of excavation depth and progress, ensuring compliance with design specifications and facilitating early detection of anomalies, as outlined in Table 1 [10].

|

Aspect |

Traditional Monitoring |

BIM-Based Monitoring |

|

Data Collection |

Manual |

Automated |

|

Visualization |

2D Drawings |

3D Models |

|

Real-Time Updates |

Limited |

Available |

|

Risk Detection |

Reactive |

Proactive |

4. Improved deep foundation pit support systems result from BIM implementation

The accurate 3D models of foundation pit support systems generated by BIM enable the correct modeling of structural members and simulation of the construction sequence. The application of identification methods facilitates the detection of inefficiencies in design more easily.

4.1. Clash detection and structural coordination

Integrated BIM modelling enables the early detection of potential clashes between structural framework components, architectural elements, and MEP (Mechanical, Electrical, and Plumbing) systems. This proactive approach eliminates costly rework and construction delays.

4.2. Simulation of support system performance

BIM empowers engineers to simulate the responses of support systems under diverse load conditions, thereby enhancing structural stability assessments and facilitating the development of contingency plans [11]..In foundation pit construction, BIM supports realistic load simulations for optimizing support configurations, reducing design errors, and improving efficiency [12]. Early detection of potential issues minimizes construction waste and labor demands, leading to significant cost and time savings. Overall, BIM enhances both the planning and execution phases of foundation construction.

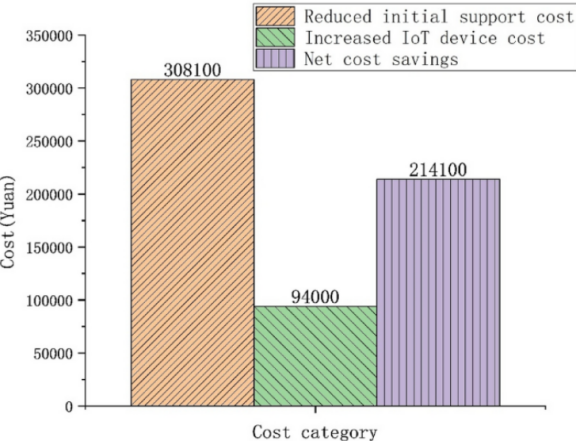

Figure 2 presents a bar graph comparing construction costs with and without BIM integration in foundation pit support projects. Traditional methods result in higher costs, while BIM-assisted approaches demonstrate significant reductions.

5. BIM serves as an ancillary function in association with slipform construction operations simultaneously with quality control measurements

Slipform construction enables rapid vertical structure formation through continuous concrete pouring into mobile formwork. BIM enhances slipform planning by optimizing construction sequencing and resource allocation. When integrated with structural health monitoring systems, BIM can help predict delays and detect anomalies at early stages [13]. Combined with IoT and sensor technologies, BIM allows real-time monitoring of concrete curing, alignment, and verticality, while supporting predictive maintenance and continuous process improvement [14].

6. High-rise building construction is made easier by BIM-based safety management features

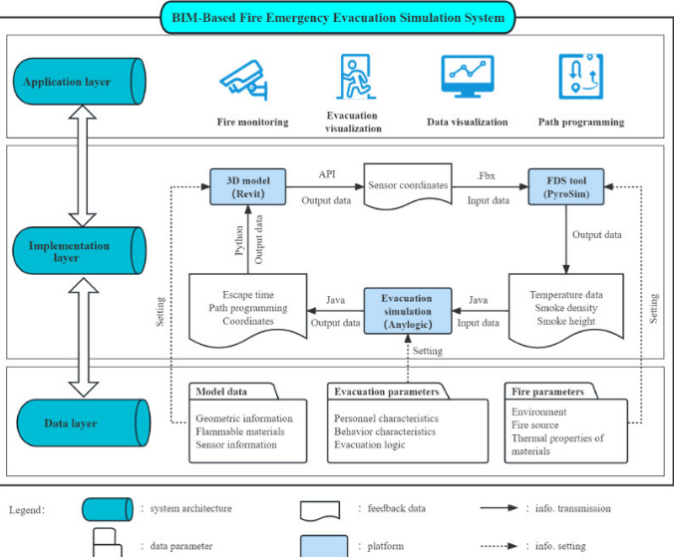

BIM technology facilitates early identification of safety risks through construction activity simulations, enabling engineers to develop and evaluate prevention strategies before construction begins. Its modeling capabilities support architectural design, including floor planning and occupant distribution tracking. BIM also aids in creating efficient evacuation routes, emergency response plans, and conducting virtual rehearsals, enhancing overall site safety management.BIM visualizations serve as effective tools for training and communication, providing visual safety procedure demonstrations, interactive staff simulations, and enhanced stakeholder engagement [15].

Figure 3 illustrates a BIM-based Fire Emergency Evacuation Simulation System structured in three layers: data, implementation, and application. The data layer integrates BIM model data with evacuation and fire parameters. The implementation layer employs Revit for 3D modeling, PyroSim for fire dynamics, and AnyLogic for evacuation simulation to analyze escape times, smoke density, and evacuation paths. Data transfer between systems is enabled via APIs and file exchanges, allowing real-time feedback and simulation optimization. The application layer provides users with visual fire monitoring, evacuation planning algorithms, and analytical results. This integrated simulation system enhances building safety by optimizing evacuation routes and supporting proactive decision-making during emergencies in high-rise buildings.

7. Efficient equipment layout by BIM includes tower cranes as one application example

Effective equipment positioning, especially for tower cranes, reduces material handling time, minimizes site congestion, and improves construction efficiency. BIM software facilitates this by visually mapping crane operational ranges, identifying obstructions, and optimizing placement through coverage analysis. Additionally, BIM enables simulation of material flow and site logistics in 3D, helping detect bottlenecks and streamline delivery schedules. These capabilities enhance site logistics management and safety by improving trade coordination and planning. Subsequent sections illustrate BIM-driven equipment optimization through case studies that demonstrate better coordination, planning, and increased site safety.

8. Technological and application constraints are encountered by the application of BIM in building high-rise structures

Despite BIM’s advantages, its adoption in construction faces several barriers. High software costs strain tight infrastructure budgets, while complex features and lack of interoperability among BIM platforms hinder usability. Successful implementation requires clear communication, standardized data formats, and robust data management to support collaboration. Additionally, employee resistance, insufficient training resources, and a shortage of experienced BIM professionals limit broader adoption [16]. Strengthening training programs and providing adequate support are essential to overcoming these challenges.

9. Conclusion

This paper reviewed the application of BIM in high-rise building construction, focusing on optimizing deep foundation design, slipform control, and site safety. The findings demonstrate that BIM enhances accuracy and efficiency in these processes. Integrating geotechnical data into 3D models improves foundation and excavation planning, while BIM enables real-time monitoring of slip form construction sequences and quality.

BIM also facilitates risk simulation and emergency planning, contributing to timely project completion, reduced material costs, fewer reworks, and improved stakeholder communication. Furthermore, BIM optimizes tower crane positioning and site logistics, lowering overall costs. Overall, BIM ensures precision, safety, and efficiency in high-rise construction projects.

However, this study primarily relies on existing literature without original case studies, limiting its depth. Future research should include empirical data from surveys and interviews to validate BIM’s effectiveness. Additionally, exploring BIM integration with AI, digital twins, and sustainability practices presents promising directions for further study.

Acknowledgment

Many thanks are extended to the tutors and academic advisors for their support and guidance while writing this document. Insights and motivation from them helped refine the topic of the research and raised the standard of my work.

References

[1]. M. Ali and K. Moon, “Advances in Structural Systems for Tall Buildings: Emerging Developments for Contemporary Urban Giants, ” Buildings, vol. 8, no. 8, p. 104, Aug. 2018, doi: https: //doi.org/10.3390/buildings8080104.

[2]. U. M. Eze, “Sponsors Milestone Payment Effect on Sustainable Construction, ” Theseus.fi, vol. 23, no. 9, 2023, doi: http: //www.theseus.fi/handle/10024/806724.

[3]. J. Patacas, N. Dawood, and M. Kassem, “BIM for facilities management: A framework and a common data environment using open standards, ” Automation in Construction, vol. 120, no. 6, Dec. 2020, doi: https: //doi.org/10.1016/j.autcon.2020.103366.

[4]. A. O. Akponeware and Z. A. Adamu, “Clash Detection or Clash Avoidance? An Investigation into Coordination Problems in 3D BIM, ” Buildings, vol. 7, no. 4, p. 75, Aug. 2017, doi: https: //doi.org/10.3390/buildings7030075.

[5]. Y. Jiang, S. Yin, and O. Kaynak, “Data-Driven Monitoring and Safety Control of Industrial Cyber-Physical Systems: Basics and Beyond, ” IEEE Access, vol. 6, no. 6, pp. 47374–47384, 2018, doi: https: //doi.org/10.1109/access.2018.2866403.

[6]. J. S. Gallego, I. Ortiz-Marcos, and J. Romero Ruiz, “Main challenges during project planning when working with virtual teams, ” Technological Forecasting and Social Change, vol. 162, no. 1, p. 120353, Jan. 2021, doi: https: //doi.org/10.1016/j.techfore.2020.120353.

[7]. H. Shanavaz et al., “Covalent organic frameworks as promising materials: Review on synthetic strategies, topology and application towards supercapacitors, ” Journal of Energy Storage, vol. 71, no. 8, p. 108006, Jun. 2023, doi: https: //doi.org/10.1016/j.est.2023.108006.

[8]. Y. Zhou, W. Su, L. Ding, H. Luo, and P. E. D. Love, “Predicting Safety Risks in Deep Foundation Pits in Subway Infrastructure Projects: Support Vector Machine Approach, ” Journal of Computing in Civil Engineering, vol. 31, no. 5, Sep. 2017, doi: https: //doi.org/10.1061/(asce)cp.1943-5487.0000700.

[9]. X. Wang, “BIM Handbook: A guide to Building Information Modeling for owners, managers, designers, engineers and contractors, ” Construction Economics and Building, vol. 12, no. 3, pp. 101–102, Sep. 2012, doi: https: //doi.org/10.5130/ajceb.v12i3.2749.

[10]. A. Ghaffarianhoseini et al., “Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges, ” Renewable and Sustainable Energy Reviews, vol. 75, no. 75, pp. 1046–1053, Aug. 2017.

[11]. A. Pavlov, D. Ivanov, D. Pavlov, and A. Slinko, “Optimization of network redundancy and contingency planning in sustainable and resilient supply chain resource management under conditions of structural dynamics, ” Annals of Operations Research, vol. 20, no. 14, Mar. 2019, doi: https: //doi.org/10.1007/s10479-019-03182-6.

[12]. Y. Yu, J. Han, H. Gu, and Y. Yang, “Dynamic Optimization of Construction Time-Cost for Deep and Large Foundation Pit Based on BIM Technology and Genetic Algorithm, ” Applied Sciences, vol. 13, no. 19, pp. 10716–10716, Sep. 2023, doi: https: //doi.org/10.3390/app131910716.

[13]. N. Rane, “Integrating Building Information Modelling (BIM) and Artificial Intelligence (AI) for Smart Construction Schedule, Cost, Quality, and Safety Management: Challenges and Opportunities, ” Social Science Research Network, vol. 1, no. 1, Jan. 2023, doi: https: //doi.org/10.2139/ssrn.4616055.

[14]. Y. Chen, X. Wang, Z. Liu, J. Cui, M. Osmani, and P. Demian, “Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building, ” Buildings, vol. 13, no. 2, p. 288, Feb. 2023, doi: https: //doi.org/10.3390/buildings13020288.

[15]. S. Singh, E. Chinyio, and S. Suresh, “The key enablers, techniques and benefits of managing stakeholders within BIM supported projects, ” Journal of Engineering, Design and Technology, vol. ahead-of-print, no. ahead-of-print, Dec. 2021, doi: https: //doi.org/10.1108/jedt-04-2021-0203.

[16]. O. I. Olanrewaju, N. Chileshe, S. A. Babarinde, and M. Sandanayake, “Investigating the barriers to building information modeling (BIM) implementation within the Nigerian construction industry, ” Engineering, Construction and Architectural Management, vol. 27, no. 10, May 2020, doi: https: //doi.org/10.1108/ecam-01-2020-0042.

Cite this article

Xu,Z. (2025). Integrating BIM Technology in High-Rise Building Construction: Applications in Deep Foundation Optimization, Slipform Process Control, and Safety Management. Applied and Computational Engineering,167,116-122.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. M. Ali and K. Moon, “Advances in Structural Systems for Tall Buildings: Emerging Developments for Contemporary Urban Giants, ” Buildings, vol. 8, no. 8, p. 104, Aug. 2018, doi: https: //doi.org/10.3390/buildings8080104.

[2]. U. M. Eze, “Sponsors Milestone Payment Effect on Sustainable Construction, ” Theseus.fi, vol. 23, no. 9, 2023, doi: http: //www.theseus.fi/handle/10024/806724.

[3]. J. Patacas, N. Dawood, and M. Kassem, “BIM for facilities management: A framework and a common data environment using open standards, ” Automation in Construction, vol. 120, no. 6, Dec. 2020, doi: https: //doi.org/10.1016/j.autcon.2020.103366.

[4]. A. O. Akponeware and Z. A. Adamu, “Clash Detection or Clash Avoidance? An Investigation into Coordination Problems in 3D BIM, ” Buildings, vol. 7, no. 4, p. 75, Aug. 2017, doi: https: //doi.org/10.3390/buildings7030075.

[5]. Y. Jiang, S. Yin, and O. Kaynak, “Data-Driven Monitoring and Safety Control of Industrial Cyber-Physical Systems: Basics and Beyond, ” IEEE Access, vol. 6, no. 6, pp. 47374–47384, 2018, doi: https: //doi.org/10.1109/access.2018.2866403.

[6]. J. S. Gallego, I. Ortiz-Marcos, and J. Romero Ruiz, “Main challenges during project planning when working with virtual teams, ” Technological Forecasting and Social Change, vol. 162, no. 1, p. 120353, Jan. 2021, doi: https: //doi.org/10.1016/j.techfore.2020.120353.

[7]. H. Shanavaz et al., “Covalent organic frameworks as promising materials: Review on synthetic strategies, topology and application towards supercapacitors, ” Journal of Energy Storage, vol. 71, no. 8, p. 108006, Jun. 2023, doi: https: //doi.org/10.1016/j.est.2023.108006.

[8]. Y. Zhou, W. Su, L. Ding, H. Luo, and P. E. D. Love, “Predicting Safety Risks in Deep Foundation Pits in Subway Infrastructure Projects: Support Vector Machine Approach, ” Journal of Computing in Civil Engineering, vol. 31, no. 5, Sep. 2017, doi: https: //doi.org/10.1061/(asce)cp.1943-5487.0000700.

[9]. X. Wang, “BIM Handbook: A guide to Building Information Modeling for owners, managers, designers, engineers and contractors, ” Construction Economics and Building, vol. 12, no. 3, pp. 101–102, Sep. 2012, doi: https: //doi.org/10.5130/ajceb.v12i3.2749.

[10]. A. Ghaffarianhoseini et al., “Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges, ” Renewable and Sustainable Energy Reviews, vol. 75, no. 75, pp. 1046–1053, Aug. 2017.

[11]. A. Pavlov, D. Ivanov, D. Pavlov, and A. Slinko, “Optimization of network redundancy and contingency planning in sustainable and resilient supply chain resource management under conditions of structural dynamics, ” Annals of Operations Research, vol. 20, no. 14, Mar. 2019, doi: https: //doi.org/10.1007/s10479-019-03182-6.

[12]. Y. Yu, J. Han, H. Gu, and Y. Yang, “Dynamic Optimization of Construction Time-Cost for Deep and Large Foundation Pit Based on BIM Technology and Genetic Algorithm, ” Applied Sciences, vol. 13, no. 19, pp. 10716–10716, Sep. 2023, doi: https: //doi.org/10.3390/app131910716.

[13]. N. Rane, “Integrating Building Information Modelling (BIM) and Artificial Intelligence (AI) for Smart Construction Schedule, Cost, Quality, and Safety Management: Challenges and Opportunities, ” Social Science Research Network, vol. 1, no. 1, Jan. 2023, doi: https: //doi.org/10.2139/ssrn.4616055.

[14]. Y. Chen, X. Wang, Z. Liu, J. Cui, M. Osmani, and P. Demian, “Exploring Building Information Modeling (BIM) and Internet of Things (IoT) Integration for Sustainable Building, ” Buildings, vol. 13, no. 2, p. 288, Feb. 2023, doi: https: //doi.org/10.3390/buildings13020288.

[15]. S. Singh, E. Chinyio, and S. Suresh, “The key enablers, techniques and benefits of managing stakeholders within BIM supported projects, ” Journal of Engineering, Design and Technology, vol. ahead-of-print, no. ahead-of-print, Dec. 2021, doi: https: //doi.org/10.1108/jedt-04-2021-0203.

[16]. O. I. Olanrewaju, N. Chileshe, S. A. Babarinde, and M. Sandanayake, “Investigating the barriers to building information modeling (BIM) implementation within the Nigerian construction industry, ” Engineering, Construction and Architectural Management, vol. 27, no. 10, May 2020, doi: https: //doi.org/10.1108/ecam-01-2020-0042.