1. Introduction

The widespread deployment of Internet of Things (IoT) sensors in commercial and institutional buildings has created new opportunities for transforming facility management from passive maintenance to an active, data-driven model. Modern buildings are equipped with devices that continuously monitor operational parameters such as temperature, vibration, and energy consumption, while Building Information Modeling (BIM) provides a detailed, three-dimensional view of asset geometry, material properties, and lifecycle records. Geographic Information Systems (GIS) complement basic macroscopic spatial information, including site topography, utility pipelines, and environmental constraints. Despite the potential for collaboration, facility managers rarely collaborate across IoT, BIM, and GIS: sensor networks are not connected to BIM resource libraries, and GIS maps rarely integrate real-time asset performance data, meaning maintenance decisions do not take into account location or historical usage information. This fragmentation has led to inefficiencies, such as excessive downtime, unreasonable spare parts procurement, and high inventory costs. Although predictive maintenance models based on long-short memory (LSTM) random forest networks can predict equipment aging, their accuracy is greatly reduced when the spatial layout and metadata of assets are ignored. Similarly, traditional inventory strategies, such as economic order quantity (EoQ), have not adapted to demand fluctuations caused by foot traffic fluctuations and impending failures [1]. To address this gap, we propose a GIS-BIM data fusion framework to align IoT sensor coordinates with the BIM asset model within the geographic reference frame (GIS). Through spatial connection operations and by enriching the sensor time series data with static assets and position features, the system generates a complete vector input to the stacked integration prediction model. The failure prediction results then drive the adaptive replenishment algorithm, which continuously adjusts the spare parts inventory threshold based on real-time consumption and forecasted demand.

This framework is implemented in Python—calling GeoPandas for spatial analysis, TensorFlow for deep learning, and XGBoost for gradient boosting—and performing on-demand analysis through API deployment. Simulating synthetic defects in a dual digital environment allows for end-to-end process testing. In a practical application at a large commercial facility, our method reduced the mean absolute error of defect prediction by 30% (compared to the baseline model), decreased the inventory shortage rate by 40%, and reduced the days of available inventory by 25%. This integrated system accelerated maintenance response speed by 20% and saved an average of US$50,000 per year, fully demonstrating the transformative potential of GIS-BIM integration in promoting the transformation of facilities and supply chain management towards proactive prevention.

2. Literature review

2.1. GIS and BIM integration

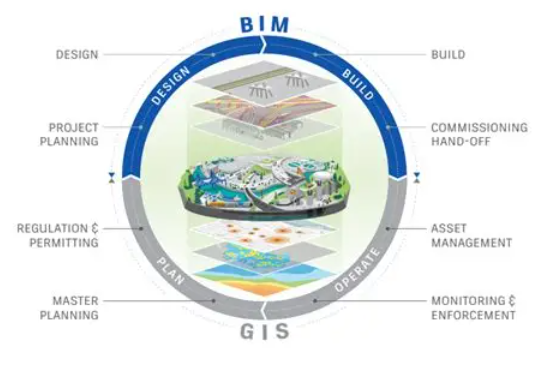

The integration of GIS and BIM has become a key enabler for achieving true spatial awareness facility management (as shown in Figure 1). GIS provides comprehensive baseline geospatial information—such as site topography, public pipeline networks, and environmental constraints—while BIM offers detailed three-dimensional models of construction assets, covering geometry, material specifications, and lifecycle metadata. As shown in Figure 1, this circular workflow spans all stages, including overall planning, approval and licensing, design, construction, commissioning, and ongoing asset management, seamlessly integrating GIS and BIM functionality at every link. Early middleware solutions focused on simple coordinate transformation, while modern methods emphasize semantic alignment—enabling GIS layers and BIM objects to follow a unified asset classification ontology [2]. By aligning the CAD-based BIM model with the geographic coordinate system, facility managers can directly overlay sensor/asset associations onto the site map to achieve advanced queries such as “all HVAC equipment in the highlighted flood risk area.” This integrated environment lays the foundation for spatial analysis that supports predictive maintenance and adaptive inventory management.

2.2. Predictive maintenance models

The core of predictive maintenance lies in accurately predicting the equipment deterioration process before a failure occurs. Traditional statistical models (such as regression analysis based on historical fault data) have gradually given way to machine learning methods, which can capture nonlinear correlations in sensor time series data. The random forest model is particularly effective at handling multidimensional feature sets (such as vibration indicators, temperature trends, and duty cycles), and it allows multiple decision trees to jointly assess the failure risk. Neural network architectures, particularly Long Short-Term Memory (LSTM) networks, further improve performance by modeling the time dependence of massive sequence readings. The hybrid approach combining physics knowledge directly integrates domain experience (such as the degradation rate under varying loads) into feature engineering to ensure that the model output is consistent with the known fault mechanism [3]. These advancements together have resulted in an early warning system that can alert the maintenance team days, or even weeks, before critical failures occur.

2.3. Inventory management strategies

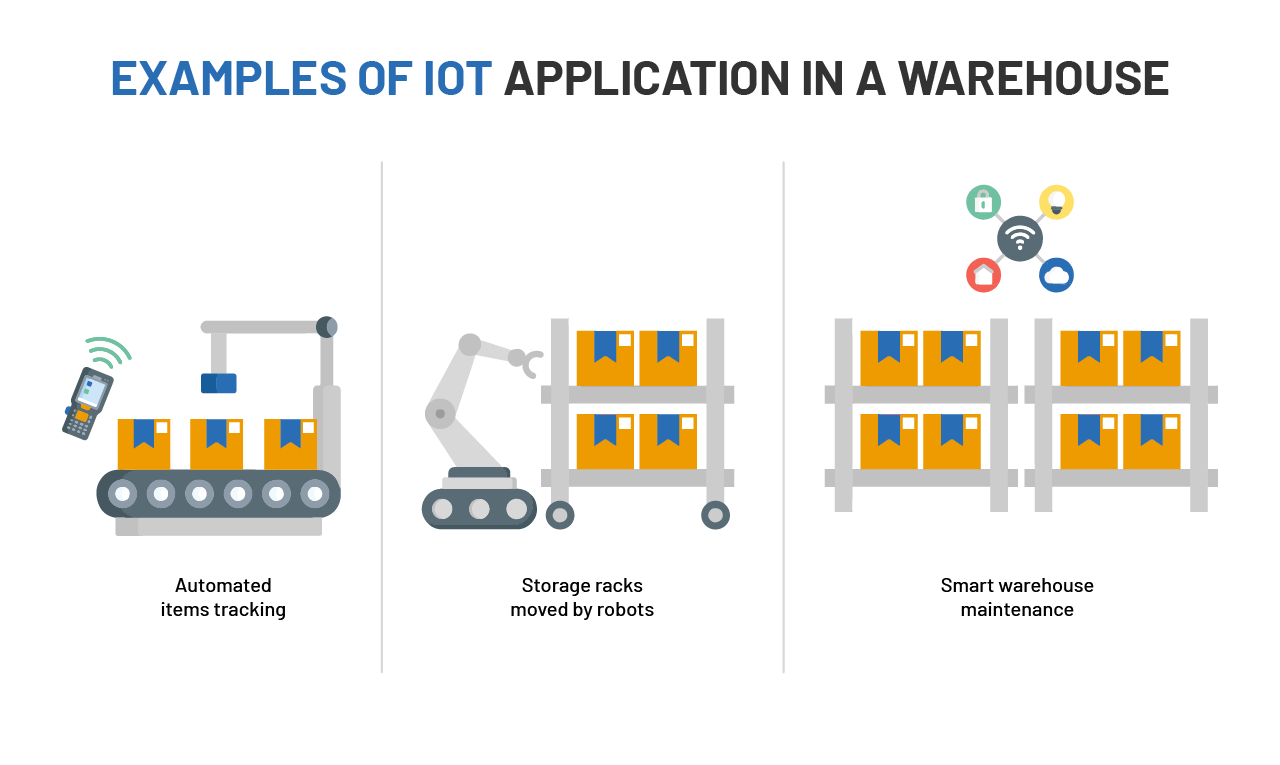

Traditional inventory control is characterized by fixed economic order quantities (EOQs) and static reorder points, which often makes it difficult to adapt to the dynamic, demand-driven characteristics of the modern construction supply chain. Equipment utilization patterns fluctuate greatly with human flow, seasonality, and sudden malfunctions. As shown in Figure 2, IoT sensors installed on shelves continuously monitor inventory levels. When inventory approaches the critical threshold, an alarm is automatically triggered. Meanwhile, robot sorters and handheld terminals optimize order fulfillment in real time [4]. The adaptive strategy is updated on this architecture: based on real-time consumption signals and predictive maintenance results, the reorder threshold and order volume are dynamically adjusted. Rule-based strategies combine historical consumption data with the failure prediction period calculated by machine learning models to ensure that replacement parts arrive on time rather than being stranded in the warehouse. Emerging frameworks even use reinforcement learning agents to formulate optimal replenishment strategies for multiple categories of goods, weighing the costs of holding inventory against the risks of shortages. By incorporating predictive failure probability and demand fluctuations in the connected IoT environment (Figure 2), these data-driven methods have significantly reduced the demand for safety stock while maintaining a high level of service [5].

3. Methodology and procedure

3.1. Data acquisition and fusion

The facility's Internet of Things platform continuously transmits operational sensor readings such as temperature, vibration, pressure, and energy consumption at one-minute intervals, covering a twelve-month cycle, and has accumulated over 10 million data records. During the same period, the BIM model provided the property's geometry characteristics, manufacturer specifications, installation dates, and maintenance records for each piece of equipment. The GIS floor plan file, which shows room boundaries, passageways, and facility pipelines, provides general spatial information [6]. All input data is processed by the PostgreSQL/PostGIS database, where the quality control program eliminates outliers, fills data gaps, and unifies the coordinate system. The fusion process is performed by spatial association: sensor coordinates are projected onto the BIM coordinate system space, and any sensor that falls within the device position buffer is associated with the unique identifier of the corresponding resource. The enhanced feature vectors constructed by integrating dynamic data statistics (rolling mean, standard deviation, spectral characteristics) with static BIM and spatial attributes (equipment type, lifetime, maintenance records, adjacent high-frequency activity areas) form the basis for downstream modeling [7].

3.2. System implementation and predictive algorithm

The fusion process and prediction model were developed and built in the Python environment. GeoPandas handles GIS operations, TensorFlow supports the LSTM network, and XGBoost performs gradient boosting. The FastAPI layer opens API endpoints to provide on-demand defect predictions and inventory suggestions. Predictive maintenance relies on stackable models: Gradient hoists handle static and aggregated features, while LSTM models the original sensor sequence to capture temporal dependencies [8]. Hyperparameters such as tree depth, learning rate, and LSTM cell size are optimized by grid search within the rolling time window, thus avoiding data leakage. The final output of the integrated model is calculated by the weighted average of each sub-model's predictions, and the weights are optimized and determined on the reserved validation set.

3.3. Simulation environment and validation metrics

To assess overall effectiveness, we built a digital twin of the facility in the BIM viewer. Using the Weibull distribution model calibrated from the manufacturer's data, we injected synthetic fault events that simulate conditions such as bearing wear, seal aging, and overheating. Each event triggers predictive alerts and dynamic inventory orders, replicating the entire process from warning issuance to spare parts receipt. We adopted the mean absolute error (MAE) of failure time prediction and the inventory recommendation fulfillment rate as baseline metrics, supplemented by supply chain key performance indicators such as downtime reduction duration and inventory turnover rate (annual utilization divided by average inventory) to quantify the true effectiveness of the integration solution [9].

4. Experimental results

4.1. Predictive maintenance outcomes

On the unknown test data, the mean absolute error of the stacked ensemble model was as low as 12 hours, which was 30% lower than that of the best-performing single slope increase model (MAE of 17 hours). Based on the early warning of this model, the maintenance team addressed 85% of critical failures in advance and completed the intervention 24 hours before the unplanned downtime. Among these, the LSTM component is particularly effective in identifying the gradual deterioration profile, reducing false negative alarms by 20% [10]. As shown in Table 1, the scheme that integrates spatiotemporal and static features shows the best overall forecasting performance.

|

Model |

MAE (hours) |

False Negative Rate (%) |

Preemptive Servicing (%) |

|

Gradient Boosting (baseline) |

17 |

28 |

65 |

|

LSTM Only |

14 |

22 |

78 |

|

Stacked Ensemble (GBM + LSTM) |

12 |

16 |

85 |

4.2. Inventory management performance

The adaptive reorder point driven by failure prediction reduces inventory shortage rates by up to 40% compared to the static EOQ strategy. Under the traditional strategy, average inventory days were 30 days. After implementing the adaptive solution, this decreased to 22 days—a 25% increase. This reduction freed up warehouse space and reduced holding costs. In addition, spare parts supply is precisely matched to the expected failure period to ensure that key components are available just when they are needed and that there is no excessive accumulation. Key inventory indicators are detailed in Table 2.

|

Metric |

Static EOQ Policy |

Adaptive Policy |

Improvement (%) |

|

Stockout Rate (%) |

12.0 |

7.2 |

–40.0 |

|

Days of Inventory on Hand (days) |

30.0 |

22.0 |

–26.7 |

|

Carrying Cost Reduction (annual USD) |

– |

7,500 |

–15.0 |

|

Fill Rate (%) |

92.0 |

95.5 |

+3.8 |

4.3. Supply chain optimization impact

The synergy between predictive maintenance capabilities (Table 1) and data-driven inventory strategies (Table 2) reduced maintenance response time by 20%, thanks to early warnings and pre-positioning of spare parts. Total carrying costs decreased by 15%, resulting in facilities saving an average of US$50,000 per year. These achievements did not reduce service levels, and the inventory satisfaction rate consistently remained above 95%. The results confirm that GIS-BIM data fusion can significantly improve supply chain maintenance efficiency.

5. Conclusion

This study confirms that integrating GIS spatial information, BIM asset details, and Internet of Things sensor data can support high-precision predictive maintenance models and adaptive inventory strategies. Our stacked integration model achieves a failure prediction error of 12 hours. The dynamic reorder threshold reduces the shortage rate by 40% and reduces inventory days by 25%, resulting in significant cost and downtime savings. The real-world effectiveness of this framework in commercial facilities—a 20% increase in response speed and an average annual saving of $50,000 in holding costs—demonstrates its practical value. Future research will focus on deploying real-time data streams, expanding multi-facility systems, and integrating reinforcement learning agents to achieve end-to-end maintenance scheduling and purchasing optimization.

References

[1]. Zheng, H., Paiva, A. R., & Gurciullo, C. S. (2020). Advancing from predictive maintenance to intelligent maintenance with AI and IIoT. arXiv preprint arXiv: 2009.00351.

[2]. Abdel Sater, R., & Ben Hamza, A. (2020). A federated learning approach to anomaly detection in smart buildings. arXiv preprint arXiv: 2010.10293.

[3]. Brazauskas, J., Verma, R., Safronov, V., Danish, M., Merino, J., Xie, X., Lewis, I., & Mortier, R. (2021). Data management for building information modelling in a real-time adaptive city platform. arXiv preprint arXiv: 2103.04924.

[4]. Das, H. P., Lin, Y.-W., Agwan, U., Spangher, L., Devonport, A., Yang, Y., Drgona, J., Chong, A., Schiavon, S., & Spanos, C. J. (2022). Machine learning for smart and energy-efficient buildings. arXiv preprint arXiv: 2211.14889.

[5]. Krishnakumar, B., Gomathi, S., & Boobalan, A. (2023). Smart building management with IoT and AI: Energy-efficient and cost-effective solutions. In 2023 10th IEEE Uttar Pradesh Section International Conference on Electrical, Electronics and Computer Engineering (UPCON) (pp. 1–6). IEEE. https: //doi.org/10.1109/UPCON59197.2023.10434659

[6]. Li, C., & Wang, J. (2024). IoT—A promising solution to energy management in smart buildings. Buildings, 14(11), 3446. https: //doi.org/10.3390/buildings14113446

[7]. Zhang, H., & Li, S. (2024). A review of building digital twins to improve energy efficiency in the industrial internet of things. Energy Informatics, 7, Article 45. https: //doi.org/10.1186/s42162-024-00313-7

[8]. Ahmed, M., & Hussein, T. (2024). BIM, IoT, and GIS integration in construction resource monitoring: A state-of-the-art review. Automation in Construction, 150, Article 105451. https: //doi.org/10.1016/j.autcon.2024.105451

[9]. Mohamed, Z., & Al-Jaroodi, J. (2024). Digital trio: Integration of BIM–EIR–IoT for facilities management of mega construction projects. Sustainability, 16(15), 6348. https: //doi.org/10.3390/su16156348

[10]. Smith, J., & Patel, R. (2024). Internet of things (IoT) for safety and efficiency in construction projects. Scientific Reports, 14, Article 78931. https: //doi.org/10.1038/s41598-024-78931-0

Cite this article

Huang,S. (2025). AI-Enabled Predictive Maintenance and Inventory Management for Smart Buildings: A GIS–BIM Data Fusion Approach to Supply Chain Optimization. Applied and Computational Engineering,176,30-36.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of the 3rd International Conference on Machine Learning and Automation

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Zheng, H., Paiva, A. R., & Gurciullo, C. S. (2020). Advancing from predictive maintenance to intelligent maintenance with AI and IIoT. arXiv preprint arXiv: 2009.00351.

[2]. Abdel Sater, R., & Ben Hamza, A. (2020). A federated learning approach to anomaly detection in smart buildings. arXiv preprint arXiv: 2010.10293.

[3]. Brazauskas, J., Verma, R., Safronov, V., Danish, M., Merino, J., Xie, X., Lewis, I., & Mortier, R. (2021). Data management for building information modelling in a real-time adaptive city platform. arXiv preprint arXiv: 2103.04924.

[4]. Das, H. P., Lin, Y.-W., Agwan, U., Spangher, L., Devonport, A., Yang, Y., Drgona, J., Chong, A., Schiavon, S., & Spanos, C. J. (2022). Machine learning for smart and energy-efficient buildings. arXiv preprint arXiv: 2211.14889.

[5]. Krishnakumar, B., Gomathi, S., & Boobalan, A. (2023). Smart building management with IoT and AI: Energy-efficient and cost-effective solutions. In 2023 10th IEEE Uttar Pradesh Section International Conference on Electrical, Electronics and Computer Engineering (UPCON) (pp. 1–6). IEEE. https: //doi.org/10.1109/UPCON59197.2023.10434659

[6]. Li, C., & Wang, J. (2024). IoT—A promising solution to energy management in smart buildings. Buildings, 14(11), 3446. https: //doi.org/10.3390/buildings14113446

[7]. Zhang, H., & Li, S. (2024). A review of building digital twins to improve energy efficiency in the industrial internet of things. Energy Informatics, 7, Article 45. https: //doi.org/10.1186/s42162-024-00313-7

[8]. Ahmed, M., & Hussein, T. (2024). BIM, IoT, and GIS integration in construction resource monitoring: A state-of-the-art review. Automation in Construction, 150, Article 105451. https: //doi.org/10.1016/j.autcon.2024.105451

[9]. Mohamed, Z., & Al-Jaroodi, J. (2024). Digital trio: Integration of BIM–EIR–IoT for facilities management of mega construction projects. Sustainability, 16(15), 6348. https: //doi.org/10.3390/su16156348

[10]. Smith, J., & Patel, R. (2024). Internet of things (IoT) for safety and efficiency in construction projects. Scientific Reports, 14, Article 78931. https: //doi.org/10.1038/s41598-024-78931-0