1. Introduction

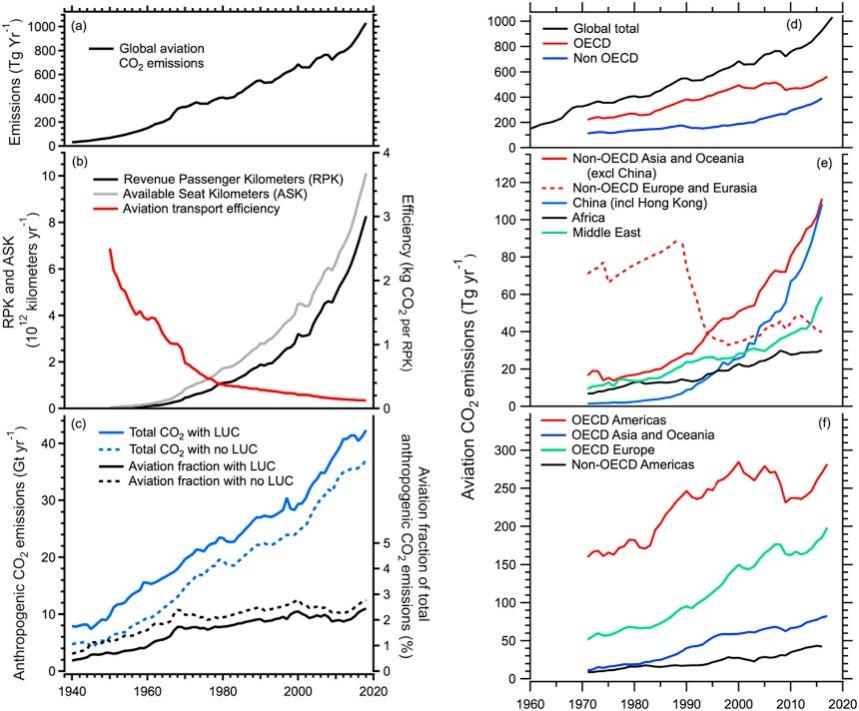

Air travel has realized human’s ‘flying’ dream and connects economies across continents, but it also exhibits strong climate impacts. Research shows that the aviation industry contributes roughly 2–3% of global carbon dioxide emissions, this number, as shown in Fig.1, has been growing for the past decades and will keep its trend if effective practices do not apply in time [1]. Therefore, it leads to a critical question: can we redesign the aviation wings to not only enhance performance but also lower fuel usage and emissions? In fact, we have seen many engineering progress made in the past: classical research on wingtip devices and non-planar lift systems demonstrates significant reductions in induced drag in both wind tunnel and analytical studies, and these gains translate into improved lift-to-drag ratios when structural trade-offs are effectively managed [2,3]. However, limitations remain. During transonic cruise, shock waves and flow separation increase drag and can cause buffet; maintaining stability at high angles of air attack or in adverse weather conditions becomes more challenging—issues critical to both efficiency and safety [4,5].

New methodologies introduce more promising solutions for addressing these problems. The use of high-fidelity Computational Fluid Dynamics (CFD) within Multidisciplinary Design Optimization (MDO) loops enables designers to balance aerodynamics with structural weight and other constraints, moving beyond an isolated pursuit of lift-to-drag ratios [6,7]. Recent research also shows that machine learning tools, including deep reinforcement learning, can explore shapes beyond traditional parameterizations and improve aerodynamic metrics; related reinforcement learning work in active flow control also reduces flow separation [8,9]. At the same time, morphing and bioengineering concepts offer additional drag reduction and adaptability for various flight conditions [10]. In all, this paper follows the following logic. First, it reviews CFD-MDO practices that link geometric changes to system-level benefits. Second, it examines AI-driven and bio-inspired strategies that expand the design space. Third, it discusses how these concepts perform under real operational conditions, such as transonic buffet and stability margins. The fundamental argument of this paper is clear: rethinking airfoil design is not merely about achieving better numerical results in a solver; it is a path toward cleaner and more reliable flight.

2. CFD–MDO practices

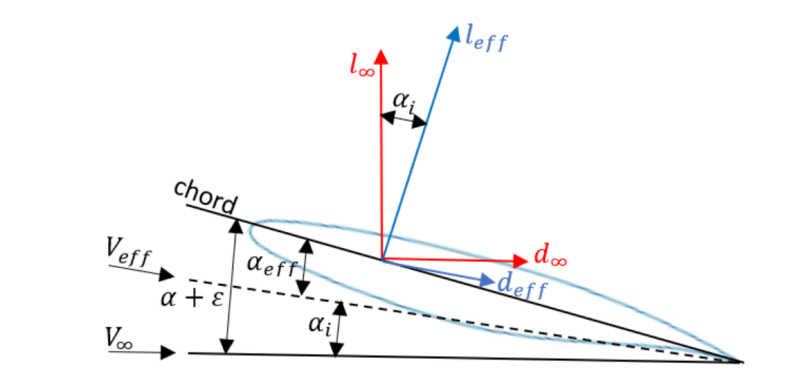

In the aviation industry, the lift-to-drag (LTD) ratio is a critical parameter that measures the lift an airplane experience compares to the drag (Fig.2), which could indicate the aerodynamic efficiency. It is straightforward to only focus on LTD. Real aircraft, however, require more. In real operation, they need to carry payload, remain lightweight, and be practical to manufacture. Therefore, many teams pair CFD with MDO to balance drag, structural requirements, and weight within a single loop [6]. In these workflows, designers adjust diverse shape control parameters, such as thickness, camber and twist, to run CFD and engineering analysis. This allows the designer to find the shape that satisfies most constraints and avoid stress failure rather than exploiting a single metric [6]. When using laminar flow tools, a similar loop could include boundary layer suction (Hybrid Laminar Flow Control, HLFC) and transition criteria, which enables the concurrent treatment of friction drag and shock wave losses, rather than in separate studies [7]. This design method connects computer simulations’ results directly to aircraft physical outcomes, such as lower fuel use and longer range, instead of only giving a nicer graph of lift and drag.

On the other hand, transonic cruise is particularly challenging. Shock waves can cause flow separation and buffet; drag increases and margins shrink. In this case, multi-fidelity setups help by running the search rapidly on simpler models first, and then using the more detailed models only for the final designs. This maintains accuracy at where matters most while reducing costs [4]. In practice, this "optimization in context" philosophy is simple: model the wing as it actually flies, and then ensure the design remains outperforming in all flight conditions, not just at a single design point [7,4]. This approach also aligns with the long history of induced drag reduction. Wingtip devices proved effective in wind tunnels when structural penalties were managed, and modern MDO extends this logic to full airframe trade-offs using superior tools and data [2,3,6]. The conclusion is evident: CFD-MDO links geometric modifications to system-level benefits, which is precisely what sustainable aviation requires.

3. RL strategies

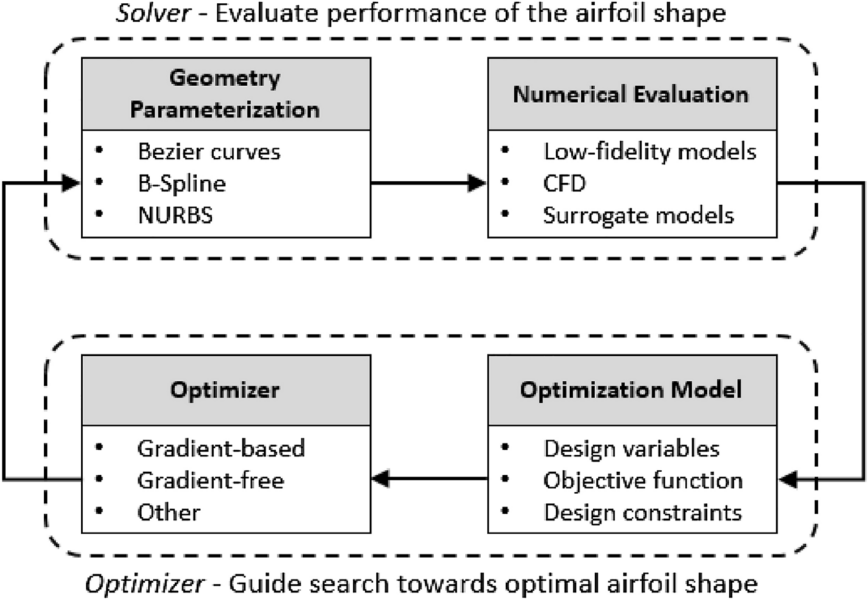

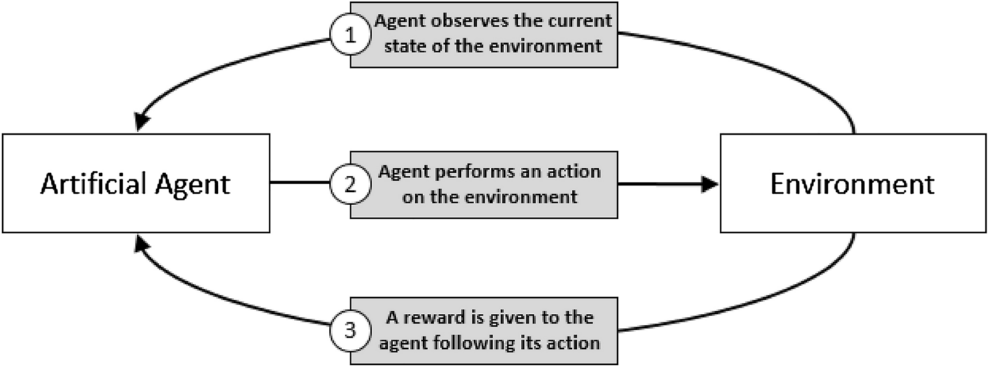

Reinforcement Learning (RL) treats design as a learning process. Change the shape slightly, check the result, then update the next action. A study framed airfoil design as a Markov Decision Process and trained an agent to modify thickness and camber; it improved the lift-to-drag ratio and rediscovered patterns from well-known airfoils, suggesting it learned useful aerodynamic rules rather than just tracking a specific target [8]. Later studies employs deep reinforcement learning with surrogate models to explore a wider range of designs, without very high computing costs, which still show aerodynamic improvements in airfoil tests [8]. These approaches are particularly valuable when marginal drag reductions accumulate over thousands of hours of service. RL is able to go beyond the usual ways of defining shapes and avoid getting stuck in narrow solutions that limit traditional methods. This makes it useful for finding innovative airfoil shapes that conventional design rules might ignore (Fig.3, Fig.4) [8].

Active flow control also plays an important role in RL strategies. Instead of altering the external shape only once, the goal is to control the flow in real-time. A recent AIAA paper demonstrated a reinforcement learning controller that uses surface blowing or suction to suppress laminar separation on an airfoil; the method reduced separation and improved efficiency in the test setup, pointing towards a path where controllers can learn strategies that classical open-loop schedules might miss [9]. In addition, hardware can also be adaptive. Morphing wings adjust camber or twist in flight, keeping the wing closer to its optimal point during climb, cruise, or turns. A recent survey reviews the mechanisms, control strategies, and performance benefits across various operating conditions, reporting lower off-design penalties compared to fixed shapes [10]. Simply put: if RL learns how the shape or flow should change, and morphing provides the means to execute that change, you create a feedback loop that maintains efficiency over a greater portion of the mission.

4. Operating conditions and robustness

A design only matters if it performs effectively in the air. Transonic buffet serves as a key test case. Experiments show that porous trailing edges can reduce the unsteady shock motion that causes buffet. This not only widens the safe cruise range and lowers pressure fluctuations, but also offers an advantage that it is a small change instead of a complete wing redesign [5]. This is a practical victory: a relatively modest add-on that delivers both improved efficiency—more time spent near optimal cruise conditions—and enhanced stability in actual operating conditions [5]. When such retrofits are combined with the CFD-MDO and RL ideas mentioned above, the result is a toolkit that improves the shape, the flow, and the operational envelope, rather than betting everything on a single change.Search efficiency also improves by reducing the number of control parameters before optimization. Teams often start with many geometric parameters, but only a few directions significantly influence drag or lift. Methods that focus the search on these critical directions make CFD-MDO or RL more efficient without significant loss of accuracy, which is particularly helpful for small teams with limited computational resources [7,4]. The workflow then becomes: identify the important influential parameters (directions), run the optimization on this reduced set, and verify the final candidates with higher-fidelity checks [7,4]. This is how solver gains are transformed into real flight performance gains. It is also how small teams can rapidly prototype ideas and retain those that prove effective.

5. Conclusion

The message is straightforward. Examine the entire system, employ new search tools where beneficial, and ensure improvements hold up under real flight conditions. CFD combined with MDO ensures design reliability by balancing aerodynamics with structural and practical constraints [6,7,4]. RL and morphing open pathways to shapes that can adapt and maintain efficiency across a wider range of conditions [8,9,10]. Practical additions like porous trailing edges help the aircraft operate closer to its optimum point, not just in simulation but in actual service [5]. If the goal is to reduce fuel use and emissions, these steps all point in the same direction: wings and airfoils that are better not only on paper but also in the sky.

References

[1]. D. S. Lee, “The Contribution of Global Aviation to Anthropogenic Climate Forcing for 2000 to 2018, ” Atmospheric Environment, vol. 244, p. 117834, Sep. 2020, doi: https: //doi.org/10.1016/j.atmosenv.2020.117834.

[2]. R. Wbitcomb, “NASA Technical Note - A Design Approach and Selected Wind-tunnel Results at High Subsonic Speeds for Wing-tip Mounted Winglets, ” Jul. 1976. Available: https: //ntrs.nasa.gov/api/citations/19760019075/downloads/19760019075.pdf

[3]. Ilan Kroo, “DRAG DUE TO LIFT: Concepts for Prediction and Reduction, ” Annual Review of Fluid Mechanics, vol. 33, no. 1, pp. 587–617, Jan. 2001, doi: https: //doi.org/10.1146/annurev.fluid.33.1.587.

[4]. A. Sudhi, R. Radespiel, and C. Badrya, “Design Exploration of Transonic Airfoils for Natural and Hybrid Laminar Flow Control Applications, ” AIAA | Journal of Aircraft, vol. 60, no. 3, Mar. 2023, doi: https: //doi.org/10.2514/ja.2023.60.issue-3; article: article: 10.2514/1.C036968; website: website: aiaa-site; wgroup: string: AIAA.

[5]. E. Lagemann, S. L. Brunton, Wolfgang Schröder, and C. Lagemann, “Towards Extending the Aircraft Flight Envelope by Mitigating Transonic Airfoil Buffet, ” Nature Communications, vol. 15, no. 1, Jun. 2024, doi: https: //doi.org/10.1038/s41467-024-49361-3.

[6]. A. Benaouali and S. Kachel, “Multidisciplinary Design Optimization of Aircraft Wing Using Commercial Software Integration, ” Aerospace Science and Technology, vol. 92, pp. 766–776, Sep. 2019, doi: https: //doi.org/10.1016/j.ast.2019.06.040.

[7]. V. Mosca, A. Sudhi, C. Badrya, and A. Elham, “Multidisciplinary Design Optimization of Transonic Wings with Boundary Layer Suction, ” AIAA, Oct. 2023. Available: https: //eprints.soton.ac.uk/485647/1/2023_MDO_with_BLS.pdf

[8]. T. P. Dussauge, W. J. Sung, O. J. Pinon Fischer, and D. N. Mavris, “A Reinforcement Learning Approach to Airfoil Shape Optimization, ” Scientific Reports, vol. 13, no. 1, p. 9753, Jun. 2023, doi: https: //doi.org/10.1038/s41598-023-36560-z.

[9]. L. Corona, A. Gross, and Q. Liu, “Active Airfoil Flow Control Based on Reinforcement Learning, ” AIAA Aviation Forum and ASCEND 2024, Jul. 2024, doi: https: //doi.org/10.2514/6.2024-4529.

[10]. L. Chu, Q. Li, F. Gu, X. Du, Y. He, and Y. Deng, “Design, modeling, and Control of Morphing aircraft: a Review, ” Chinese Journal of Aeronautics, vol. 35, no. 5, Oct. 2021, doi: https: //doi.org/10.1016/j.cja.2021.09.013.

Cite this article

Xu,H. (2025). Beyond Efficiency: Rethinking Airfoil Design for Sustainable Aviation. Applied and Computational Engineering,201,18-22.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-FMCE 2025 Symposium: Semantic Communication for Media Compression and Transmission

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. D. S. Lee, “The Contribution of Global Aviation to Anthropogenic Climate Forcing for 2000 to 2018, ” Atmospheric Environment, vol. 244, p. 117834, Sep. 2020, doi: https: //doi.org/10.1016/j.atmosenv.2020.117834.

[2]. R. Wbitcomb, “NASA Technical Note - A Design Approach and Selected Wind-tunnel Results at High Subsonic Speeds for Wing-tip Mounted Winglets, ” Jul. 1976. Available: https: //ntrs.nasa.gov/api/citations/19760019075/downloads/19760019075.pdf

[3]. Ilan Kroo, “DRAG DUE TO LIFT: Concepts for Prediction and Reduction, ” Annual Review of Fluid Mechanics, vol. 33, no. 1, pp. 587–617, Jan. 2001, doi: https: //doi.org/10.1146/annurev.fluid.33.1.587.

[4]. A. Sudhi, R. Radespiel, and C. Badrya, “Design Exploration of Transonic Airfoils for Natural and Hybrid Laminar Flow Control Applications, ” AIAA | Journal of Aircraft, vol. 60, no. 3, Mar. 2023, doi: https: //doi.org/10.2514/ja.2023.60.issue-3; article: article: 10.2514/1.C036968; website: website: aiaa-site; wgroup: string: AIAA.

[5]. E. Lagemann, S. L. Brunton, Wolfgang Schröder, and C. Lagemann, “Towards Extending the Aircraft Flight Envelope by Mitigating Transonic Airfoil Buffet, ” Nature Communications, vol. 15, no. 1, Jun. 2024, doi: https: //doi.org/10.1038/s41467-024-49361-3.

[6]. A. Benaouali and S. Kachel, “Multidisciplinary Design Optimization of Aircraft Wing Using Commercial Software Integration, ” Aerospace Science and Technology, vol. 92, pp. 766–776, Sep. 2019, doi: https: //doi.org/10.1016/j.ast.2019.06.040.

[7]. V. Mosca, A. Sudhi, C. Badrya, and A. Elham, “Multidisciplinary Design Optimization of Transonic Wings with Boundary Layer Suction, ” AIAA, Oct. 2023. Available: https: //eprints.soton.ac.uk/485647/1/2023_MDO_with_BLS.pdf

[8]. T. P. Dussauge, W. J. Sung, O. J. Pinon Fischer, and D. N. Mavris, “A Reinforcement Learning Approach to Airfoil Shape Optimization, ” Scientific Reports, vol. 13, no. 1, p. 9753, Jun. 2023, doi: https: //doi.org/10.1038/s41598-023-36560-z.

[9]. L. Corona, A. Gross, and Q. Liu, “Active Airfoil Flow Control Based on Reinforcement Learning, ” AIAA Aviation Forum and ASCEND 2024, Jul. 2024, doi: https: //doi.org/10.2514/6.2024-4529.

[10]. L. Chu, Q. Li, F. Gu, X. Du, Y. He, and Y. Deng, “Design, modeling, and Control of Morphing aircraft: a Review, ” Chinese Journal of Aeronautics, vol. 35, no. 5, Oct. 2021, doi: https: //doi.org/10.1016/j.cja.2021.09.013.