1. Introduction

Vehicle structural optimization is a key competitive advantage in the automotive sector, and it directly affects energy efficiency, emission reduction, collision safety, and cost control. Lightweighting increases energy efficiency and extends range. Material and topology optimization create high-strength safety structures. Today, with the lightweight requirements of new energy vehicles and autonomous driving, the industry is moving forward with a new round of technological innovation.

For instance, in the context of new energy vehicle propulsion systems, integrated die-casting and battery integration technologies use large-scale, integral die-cast components to replace the stamping and assembling of multiple steel plates. The result is a much greater reduction in manufacturing cost and also environmental sustainability.

Looking ahead, the integration of vehicle body structure will be further advanced, with four key integrated die-cast assemblies planned: front compartment assembly, rear compartment assembly, passenger compartment assembly, and 'Cell to Chassis (CTC)' assembly, which deeply integrates the battery and the chassis. CTC technology directly integrates the battery cells into a high-strength, monolithic floor pan. This close integration of the battery system with the chassis structure significantly cuts down on the number of components, optimizes the spatial layout, enhances structural efficiency, and effectively reduces the vehicle's weight.

The synergistic optimization of lightweight and safety in vehicle structures is the central challenge in automobile design. In particular, through innovative structure design and advanced application of materials, it can not only enhance weight reduction but also improve the performance of crash protection, thereby achieving dual breakthroughs in lightweighting and safety. This research work provides critical technical support for developing high-safety, lightweight vehicle bodies and is of great value in improving passive safety levels.

The paper starts off by reviewing the methods of vehicle structural optimisation. Then it proceeds to discuss important technologies and their latest developments in applications. The paper will also address challenges and issues pertinent to this field: high computational cost and low efficiency of computing, multi-objective trade-off dilemmas, bottlenecks in standardisation, and industrialization processes. Finally, this paper will propose future research trends in the area concerned.

2. Main methods of vehicle structure optimization

Vehicle structure optimization is a systematic engineering activity whose main objective involves the realization of lightweight vehicles with a minimum manufacturing cost and improvement of operational efficiency, satisfying various performance requirements that include the structural stiffness of the vehicle, mechanical strength, safety performance, and NVH characteristics. The three most important modern methodologies applied to vehicle structural optimization generally involve the following:

2.1. \tTopology optimisation

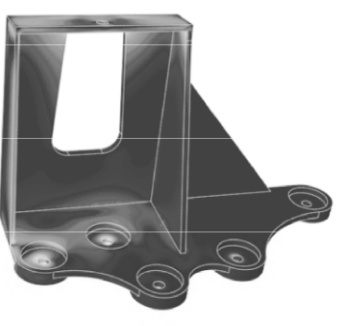

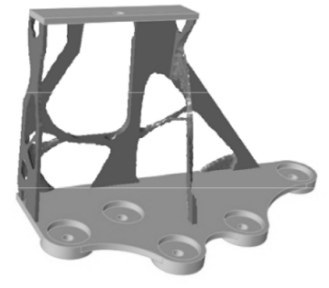

Topology optimisation is a core methodology in structural design. It aims to find the optimal material distribution within the design domain of the component in the conceptual design phase. It applies finite element analysis, uses material density as the design variable, and pursues the minimization of flexibility or the maximization of natural frequency under performance constraints to obtain an innovative layout with efficient force-flow paths, thus providing a theoretical basis and design prototype for weight reduction and performance improvement. For example, during topology optimisation of an automobile engine mount, the structure was divided into a design domain and a nondesign domain based on an analysis of the mechanical behavior of the original model in four typical working conditions and according to the actual installation requirements. Based on this, the topology optimisation of material distribution within the design domain was carried out to solve the problem of its load-carrying capacity under representative vertical and longitudinal conditions. In the process, it fully inherits the boundary constraints and load conditions of the original model, with maximization of the stiffness of the structure as the objective function. Eventually, it gives the optimized topological morphology for this component depending on the path through which load transmission is effected (according to Figures 1 and 2) [2].

2.2. Size and shape optimisation

Detailed parameters of the design are further refined after the dimensional and shape optimisation. Dimensional optimisation mainly gives the optimal value of parameters like plate thickness and beam section dimensions for structural parts; based on dimensional optimisation, shape optimisation adjusts the geometries on the boundary, such as transition radii and convex or concave profiles, to avoid all kinds of stress concentrations in order to improve the load-bearing capacity. The methodology can better liberate more weight-reduction potential with a reduced price within the defined design framework. Taking the sectional optimisation of electric vehicle sill beams as an example, in order to improve the ability of load transmission during side-pillar impacts and enhance protection for the battery pack, this study extracted characteristics of structural response and deformation from side-pillar collision simulations. The result of which gives a good definition of the design domain and boundary conditions for topology optimisation. In addition, driven by the new MMC method for topology optimisation, an innovative configuration of an extruded aluminium monocoque sill beam was obtained. Based on this, further thickness optimisation of the sill beam cross-section results in a weight reduction of 0.86 kg, accounting for 7.4% in the primary design. Validation of simulation results indicates that the optimised sill beam effectively reduces intrusion between the sill beam outer panel and the outer panel of the battery pack [3], while protecting the power battery pack effectively.

2.3. \tMaterial optimisation

Material optimisation is a multiscale systems design methodology oriented toward performance improvement and weight reduction. It seeks the optimal integration of structural efficiency with functional requirements through scientific selection of material types, collaborative design of distribution layouts, and adoption of advanced fabrication techniques. Its core idea lies in surmounting the traditional paradigm of homogeneous materials but adopting performance-driven gradient or composite configurations in the multimaterial system, according to the real mechanical condition and service environment of the structure. For instance, advanced high-strength steel, aluminum alloys, and carbon fibre-reinforced composites are lightweight with high strength and can be used to achieve a high-strength lightweight design of the whole vehicle while keeping the vehicle's overall mass consistent [4]. Hybrid and multi-material composites are at the frontline of lightweight material technology for automobiles. Advanced materials of this class integrate different classes of fibres, matrices, or even completely different material classes in order to achieve optimized performance characteristics [5].

3. Key technologies and application advances

The current technological developments in vehicle structural optimization have been centered on three pivotal issues: weight reduction, safety, and manufacturability. This has necessitated a deep level of integration and convergence in multidisciplinary technology development: there has been major progress in three key technological areas.

3.1. Lightweight design

The key points derived from both the vehicle structural optimisation methodologies and case studies discussed above reinforce that lightweight design has secured a critical position in today's automotive structure engineering. The concept of lightweight design has advanced from a simplistic, narrow pursuit of 'reduction in weight’ to a sophisticated engineering methodology for the best system efficiency while retaining performance. Beyond topology, dimension, shape, and material optimisation, modern lightweight design has adopted deeper and more systematic approaches. These approaches are often combined with the traditional methods for weight reduction from broader dimensionality or other angles. For example, integrated design and component consolidation achieve lightweighting and enhanced performance on account of fewer parts. The basic philosophy is redesigning and combining several functionally singular components into a single part with a complex geometry. More specifically, integrated design and manufacturing techniques for new energy vehicle battery systems, like CTC and CTB (Cell-to-Body) technologies, bring battery cells or modules directly into the chassis or body structure. Their obvious advantages are remarkably improved space utilization, enhanced overall rigidity, and a potential driver for the next generation of vehicle design and manufacturing paradigm shift. In fact, concept vehicles based on CTC technology have been introduced. However, its disadvantage lies in the critical challenges of battery safety, structural stability, and serviceability. Further examination is required to identify the optimal design strategies for various use cases, trading off the range, cost, and safety [6].

3.2. Optimisation of collision safety

Vehicle collision safety optimisation encompasses multiple disciplines and techniques to enhance the protection of occupants in impacts by optimising structure, materials, and simulation techniques. Its core competencies are found in optimizing the stiffness of both the energy absorption zones and the passenger compartment, coordinating restraint systems, and finding a balance between lightweight construction and high strength by making use of materials such as advanced high-strength steel and aluminum alloys. Meanwhile, new challenges have been thrown up by battery safety and repair economics in a quest to achieve optimum protective performance across many collision scenarios. Lei Zhengbao and Yi Xiaojian propose a multi-objective topology optimisation method which integrates crash safety with NVH performance in their research on the forward-concept design of a pure electric vehicle body. In this work, a weighted multi-objective optimisation model is developed for the passenger compartment by including bending and torsion (NVH conditions) and side impact and roof crush (crashworthiness conditions), adopting a variable density method for topology optimisation. The crashworthiness of the optimized configuration is strong under both a 50 km/h full-width collision and a 64 km/h offset collision; the peak acceleration value meets the requirements of safety regulations. Its minimum vibration frequency is 17.9 Hz, which avoids resonance because it is far away from the frequency of road excitation. Results confirm that this method effectively resolves the trade-off between crash safety and comfort, providing a promising pathway for multi-performance integrated design in electric vehicle bodies [7].

3.3. Optimisation subject to manufacturing process constraints

The optimization of modern vehicle technology has become closely coupled with manufacturing process constraints, and the core trend has turned from "design-first" to design for additive manufacturing. Lightweighting pursues complex biomimetic structures created by topology optimization, which is realized by metal additive manufacturing (3D printing) and avoids process issues such as support structures and overheating deformation. Integrated die-casting technology represents a great breakthrough. Using large-scale die-casting machines, companies like Tesla integrate hundreds of components of the rear floor into one, which greatly enhances production efficiency and the rigidity of body structure. However, optimization should consider material flow, thermal stresses, and mold durability. In traditional manufacturing, stamping simulation remains essential. AI-driven algorithms predict defects related to sheet cracking and wrinkling during the design stage by optimizing part geometry and material nesting. This allows the effective and low-cost manufacture of ultra-high strength steel. Secondly, process limitations in multi-material joining-for example, steel-aluminum dissimilar bonding-manufacturing drive structural optimization, designing to avoid electrochemical corrosion and carefully choose compatible riveting or adhesive bonding methods. In summary, modern vehicle optimization has transformed into a systemic engineering discipline balancing performance objectives against manufacturability and cost. Each phase requires careful consideration of production process constraints.

4. Current challenges and limitations

The concurrent optimisation of vehicle lightweighting and safety currently encounters several challenges and limitations. First, computational cost and efficiency remain major bottlenecks. High-fidelity simulations—such as crash analysis and multiphysics topology optimisation—require extensive computational resources. Particularly for composite materials or complex multiscale models, long iteration cycles struggle to meet rapid product development demands. Second, multi-objective trade-offs pose significant difficulties. For example, material reduction may compromise crash energy absorption or stiffness, while reinforcing safety structures often adds weight. Optimisation algorithms must balance objectives such as crashworthiness, NVH performance, and fatigue life, yet weighting assignments rely on empirical judgement rather than objective criteria, often resulting in local optima. Third, experimental validation is insufficient. Despite advanced simulation techniques, full-cycle crash testing is prohibitively costly and non-repeatable, limiting data collection and model calibration. The scarcity of experimental evidence regarding critical mechanisms—including the mechanical behavior of multi-material joints and failure modes of heterogeneous materials—gives rise to inaccuracies in numerical simulations. Finally, standardisation and industrialisation bottlenecks restrict adoption. Process standards and joining specifications for emerging materials (e.g., CFRP and magnesium alloys) remain incomplete, requiring heavy investment in production line upgrades. Disconnects between traditional supply chains and novel design–manufacturing paradigms persist, while interdisciplinary collaboration across materials, structures, and processes proves challenging. Collectively, these factors hinder the large-scale implementation of advanced optimisation solutions.

5. Outlook

In the future, lightweight vehicle structure development and safety will further rely on systematic integration with intelligent and digital technologies. The next generation of multidisciplinary design processes will be characterized by intelligent optimization algorithms. These enable machine learning and evolutionary computation to independently search for Pareto optimal solutions efficiently under the support of complex constraints such as weight reduction targets, crash safety, and NVH performance-remarkably enhancing engineering efficiency while reducing resource consumption caused by iterative methods. New paradigms for material and structure innovation will be brought about by bio-inspired design theories. These methodologies will be capable of developing biomimetic composite and energy-absorbing structures with multi-level topological configuration and functional gradients by mimicking the superior mechanical principles in biological systems, consequently contributing to lightweight design while improving crashworthiness and structural durability. The concept of 'digital twins' will play a critical role in vehicle safety through real-time monitoring and predictive simulation with respect to hazard anticipation and mitigation, which is an essential link to make sure the structural integrity of an autonomous vehicle [8]. The synergistic development of these directions means that vehicle engineering is transforming from an experience-driven paradigm to the dual drive model driven by data and modeling, eventually realizing the deep integration of lightweighting, safety, and full-lifecycle sustainability.

6. Conclusion

This paper systematically reviews the progress of research and methodological frameworks on the co-optimization of lightweighting and safety in vehicle structural design. By analyzing core methodologies, including topological optimization, dimensional optimization, shape optimization, and material optimization, it has been shown that the modern vehicle structural design gradually moves from single-performance objective optimization to multi-objective co-optimization. Under the background of new energy vehicles and intelligent driving, lightweighting and safety are becoming an inseparable dual goal. The key advances in lightweight design, collision safety optimisation, and optimisation under manufacturing constraints are reviewed. The paper shows that with multidisciplinary integration and advanced simulation techniques, reducing weight can be realized simultaneously with improving structural safety and general performance. However, several issues still exist in current studies, such as high computational cost, imbalance of objectives, limited experimental validation, and bottlenecks in standardisation and industrialization. These problems limit the adoption of optimization methods in practical engineering on a large scale.

This research also has certain limitations. First, being a review-type study, it did not conduct empirical analysis or case simulation verification, and the conclusions were mainly drawn from induction and synthesis of existing literature. Second, only a limited number of publications could be covered, which could not comprehensively encompass all relevant research outcomes in recent years, especially when the latest advancements within international frontier areas are considered. Thirdly, the discussion over some of the emerging technologies, such as digital twins and AI-driven optimization, is preliminary and lacks in-depth technical pathway analysis.

References

[1]. Li, X. (2025). Current status and outlook of lightweighting technologies for new energy vehicles. Automotive Digest, (3), 17-23. doi: 10.19822/j.cnki.1671-6329.20230273.

[2]. Shan, K. Z., Wang Kedong, Liu Chao, Hu Xuefang & Mo Yanbin. (2023). Lightweight design of automotive engine mounts based on topology optimisation. Automotive Practical Technology, 48(23), 68–73. doi: 10.16638/j.cnki.1671-7988.2023.023.013.

[3]. Jiang, Q., Wu, J. & Shi, G. (2024). Optimisation design of electric vehicle sill beam cross-section based on the movable deformation component method. Shanghai Automobile, (12), 19-26.

[4]. Zhou, W. L. (2025). Exploring optimised design and analysis of automotive body structures using lightweight materials. Times Automotive, (7) : 120-122.

[5]. Yan, L. & Xu, H. 2025. Lightweight composite materials in automotive engineering: State-of-the-art and future trends. Alexandria Engineering Journal, 118, pp. 1-10.

[6]. Shi, P., Shan, Z., Zhu, H., Hai, B., Wang, L., & Lu, F. (2025). Integrated design technology for new energy vehicle power battery systems. Chinese Journal of Mechanical Engineering, 36(7), 1611–1623.

[7]. Lei, Z. B. & Yi, X. J. (2016). Multi-objective topology optimisation for collision safety and NVH in electric vehicles. Journal of Highway and Transportation Engineering, 29(5), 144-150.

[8]. S. Almeaibed, S. Al-Rubaye, A. Tsourdos and N. P. Avdelidis, 'Digital Twin Analysis to Promote Safety and Security in Autonomous Vehicles, ’ in IEEE Communications Standards Magazine, vol. 5, no. 1, pp. 40-46, March 2021, doi: 10.1109/MCOMSTD.011.2100004.

Cite this article

Zhao,S. (2025). Collaborative Optimization of Lightweighting and Safety: A Review of the Research on Vehicle Structural Design. Applied and Computational Engineering,210,63-69.

Data availability

The datasets used and/or analyzed during the current study will be available from the authors upon reasonable request.

Disclaimer/Publisher's Note

The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of EWA Publishing and/or the editor(s). EWA Publishing and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content.

About volume

Volume title: Proceedings of CONF-MLA 2025 Symposium: Intelligent Systems and Automation: AI Models, IoT, and Robotic Algorithms

© 2024 by the author(s). Licensee EWA Publishing, Oxford, UK. This article is an open access article distributed under the terms and

conditions of the Creative Commons Attribution (CC BY) license. Authors who

publish this series agree to the following terms:

1. Authors retain copyright and grant the series right of first publication with the work simultaneously licensed under a Creative Commons

Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this

series.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the series's published

version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial

publication in this series.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and

during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See

Open access policy for details).

References

[1]. Li, X. (2025). Current status and outlook of lightweighting technologies for new energy vehicles. Automotive Digest, (3), 17-23. doi: 10.19822/j.cnki.1671-6329.20230273.

[2]. Shan, K. Z., Wang Kedong, Liu Chao, Hu Xuefang & Mo Yanbin. (2023). Lightweight design of automotive engine mounts based on topology optimisation. Automotive Practical Technology, 48(23), 68–73. doi: 10.16638/j.cnki.1671-7988.2023.023.013.

[3]. Jiang, Q., Wu, J. & Shi, G. (2024). Optimisation design of electric vehicle sill beam cross-section based on the movable deformation component method. Shanghai Automobile, (12), 19-26.

[4]. Zhou, W. L. (2025). Exploring optimised design and analysis of automotive body structures using lightweight materials. Times Automotive, (7) : 120-122.

[5]. Yan, L. & Xu, H. 2025. Lightweight composite materials in automotive engineering: State-of-the-art and future trends. Alexandria Engineering Journal, 118, pp. 1-10.

[6]. Shi, P., Shan, Z., Zhu, H., Hai, B., Wang, L., & Lu, F. (2025). Integrated design technology for new energy vehicle power battery systems. Chinese Journal of Mechanical Engineering, 36(7), 1611–1623.

[7]. Lei, Z. B. & Yi, X. J. (2016). Multi-objective topology optimisation for collision safety and NVH in electric vehicles. Journal of Highway and Transportation Engineering, 29(5), 144-150.

[8]. S. Almeaibed, S. Al-Rubaye, A. Tsourdos and N. P. Avdelidis, 'Digital Twin Analysis to Promote Safety and Security in Autonomous Vehicles, ’ in IEEE Communications Standards Magazine, vol. 5, no. 1, pp. 40-46, March 2021, doi: 10.1109/MCOMSTD.011.2100004.